Silicon Wafer Slicing Mechanism

A silicon chip and body technology, applied in the field of auxiliary equipment for the preparation of solar cells, can solve the problems of low slicing efficiency and discontinuity, and achieve high slicing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

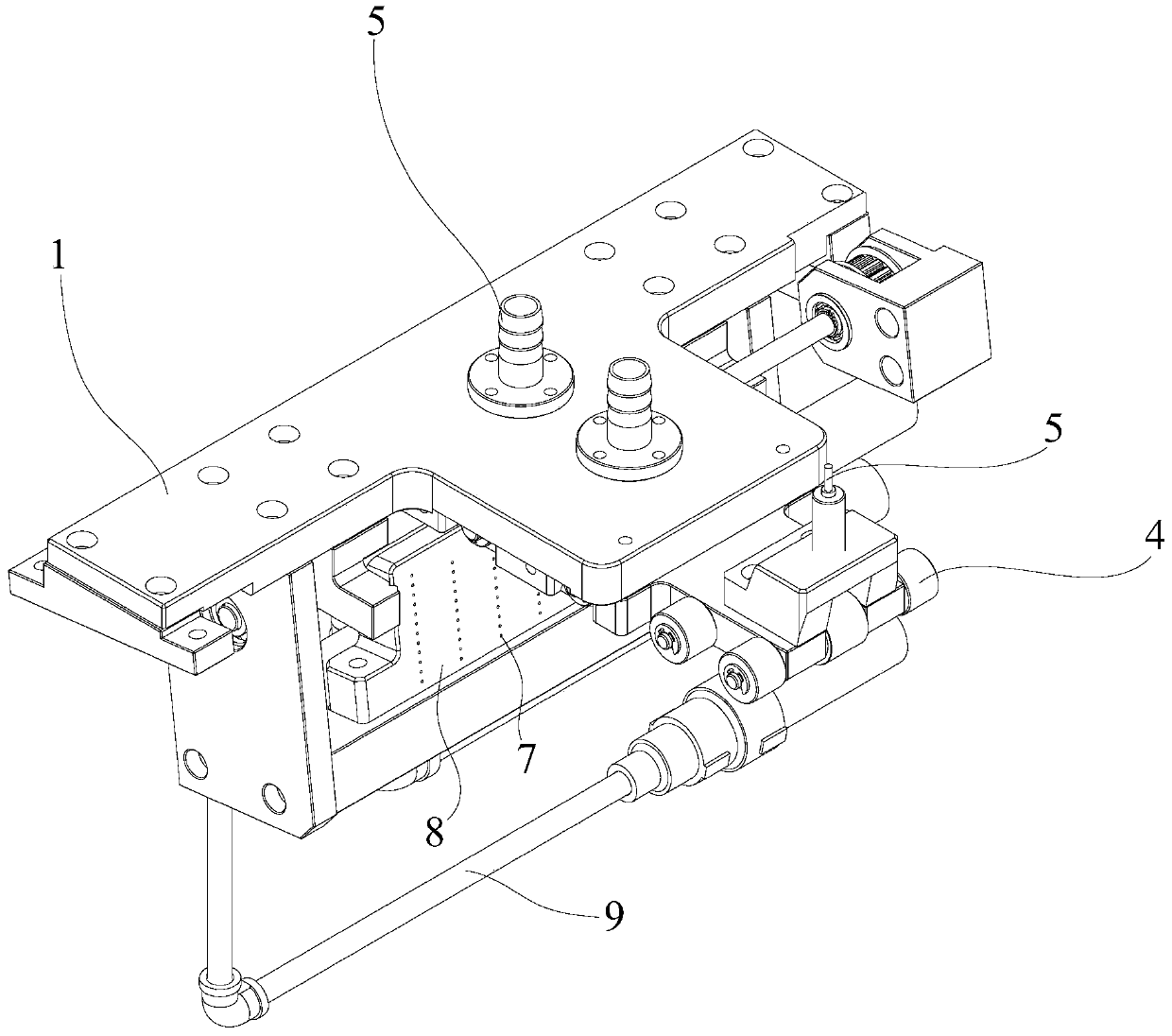

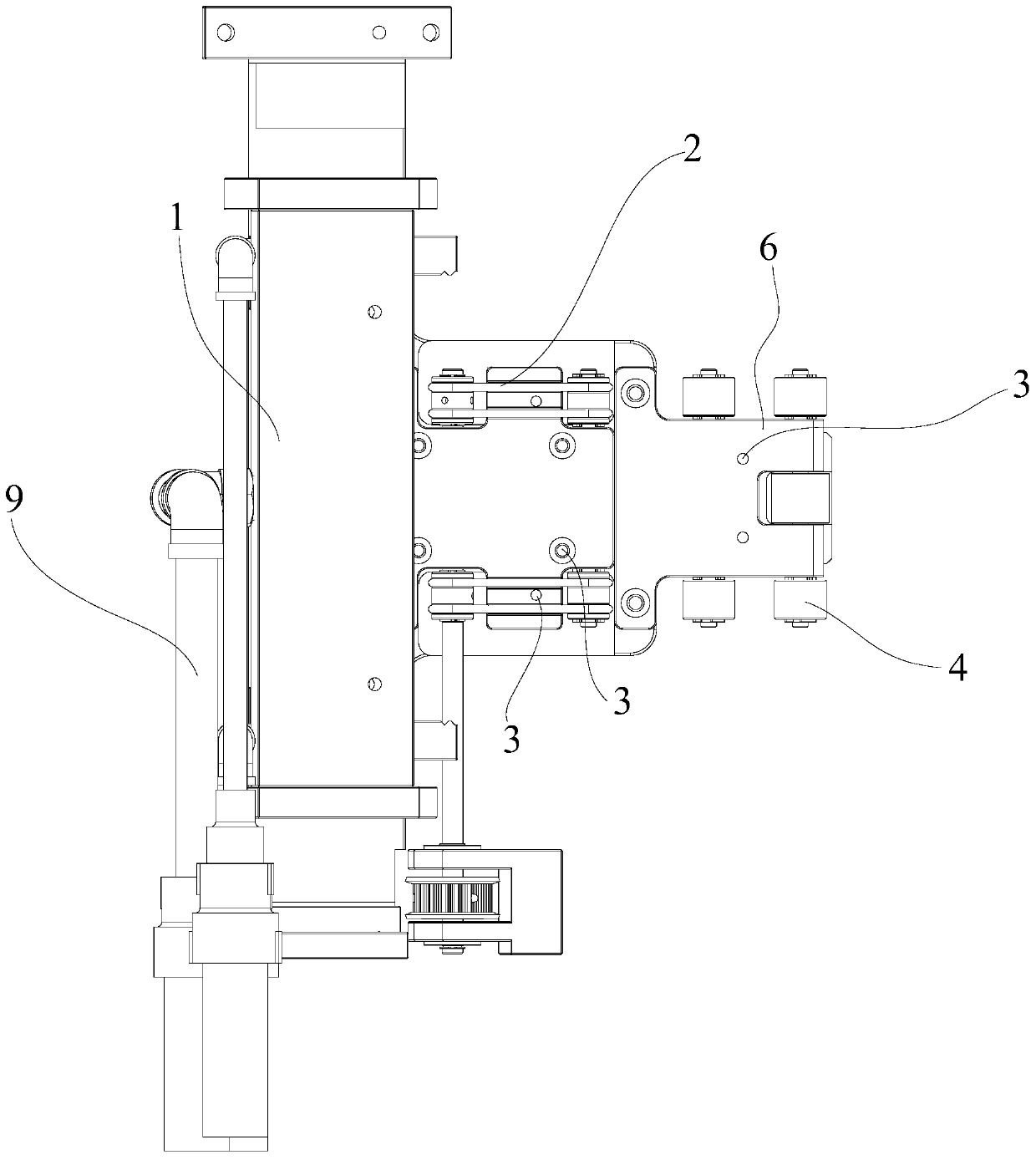

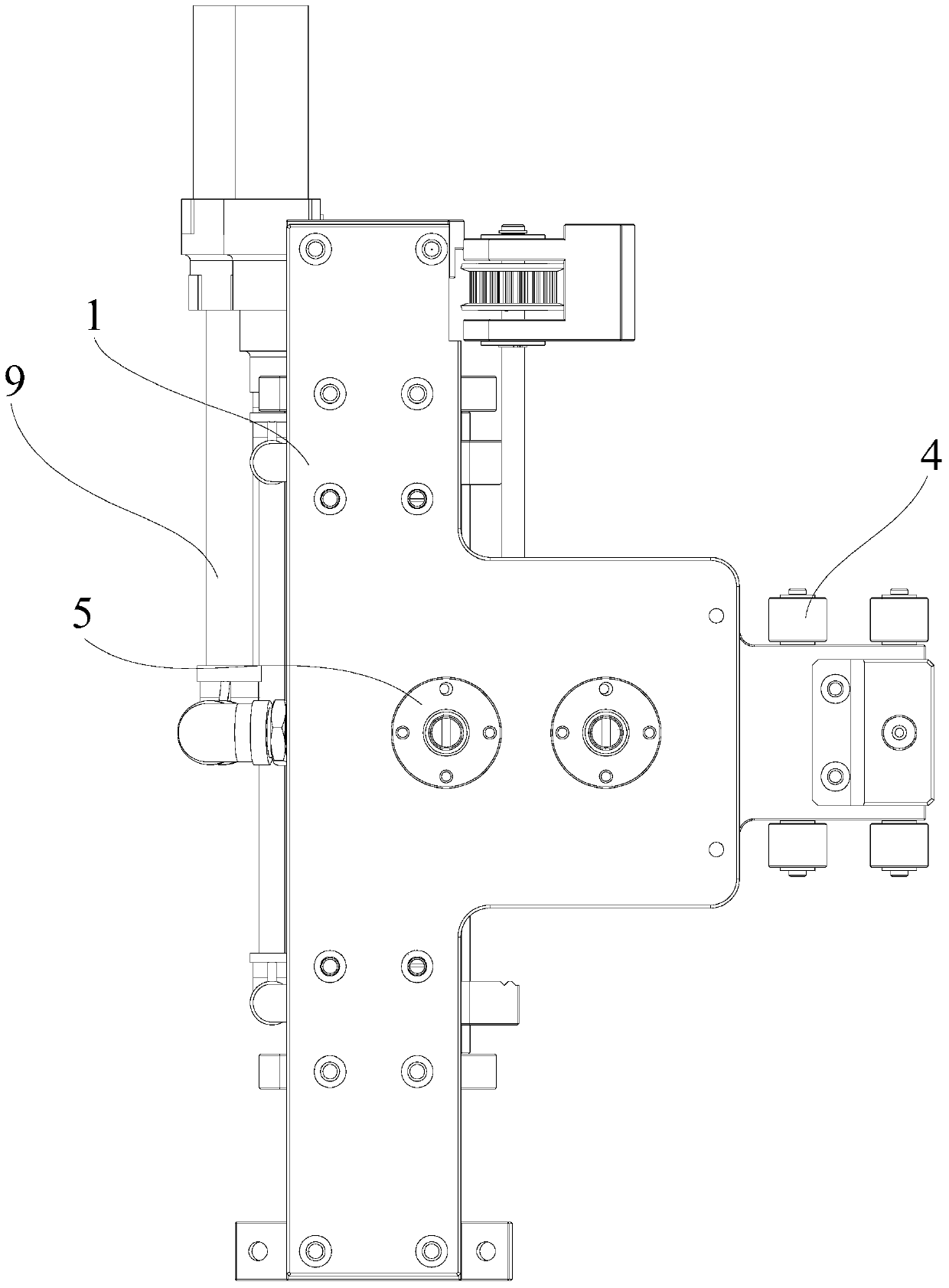

[0024] Embodiment: silicon wafer slicing mechanism

[0025] See attached Figure 1-5 As shown, the silicon chip slicing mechanism includes a silicon chip slicing mechanism body 1, and the silicon chip slicing mechanism body 1 is provided with two parallel and spaced conveyor belts 2 downwards. The silicon chip slicing mechanism body 1 A suction hole 3 is provided toward the conveyor belt 2, and the suction hole 3 communicates with a suction device (not shown in the figure) through a pipeline, and the suction device may be a vacuum suction device. The front end of the silicon chip splitting mechanism body 1 corresponding to the conveying direction of the conveyor belt 2 is provided with a roller 4; The air blowing hole 7 communicates with a blowing device (not shown in the figure) through a pipeline 9 . The blowing device can be, for example, a blower.

[0026] A preferred embodiment is: the conveyor belt is a synchronous belt.

[0027] A preferred embodiment is: the synchr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com