Conductive film separating device

A technology of conductive film and mounting board, which is applied in the field of conductive film slicing device, can solve the problem of low slicing efficiency of conductive film, and achieve the effect of improving slicing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, so that those skilled in the art can better understand the present invention and implement it, but the examples given are not intended to limit the present invention.

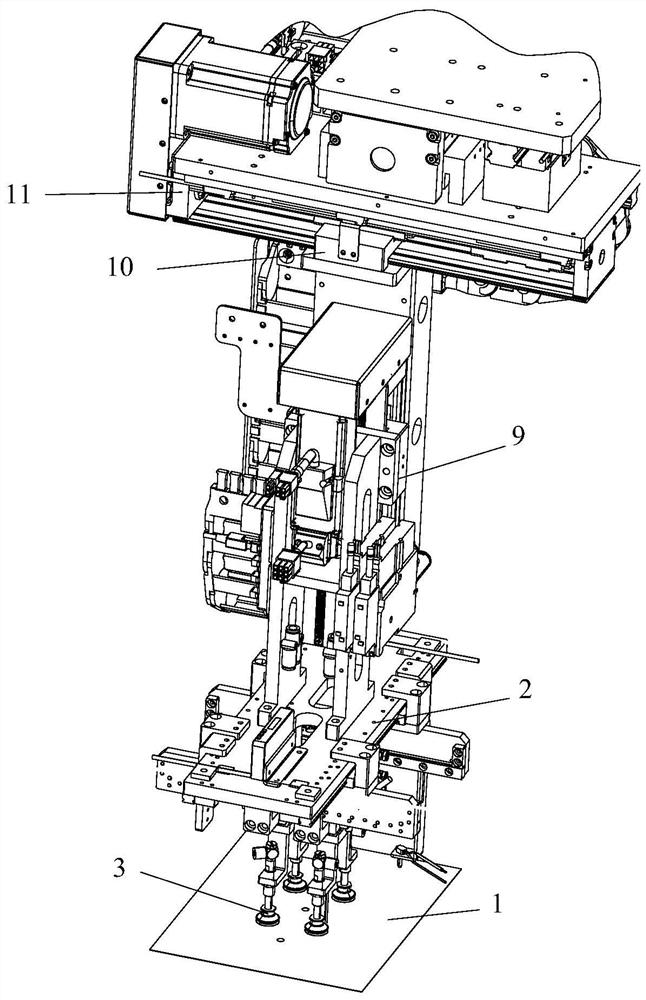

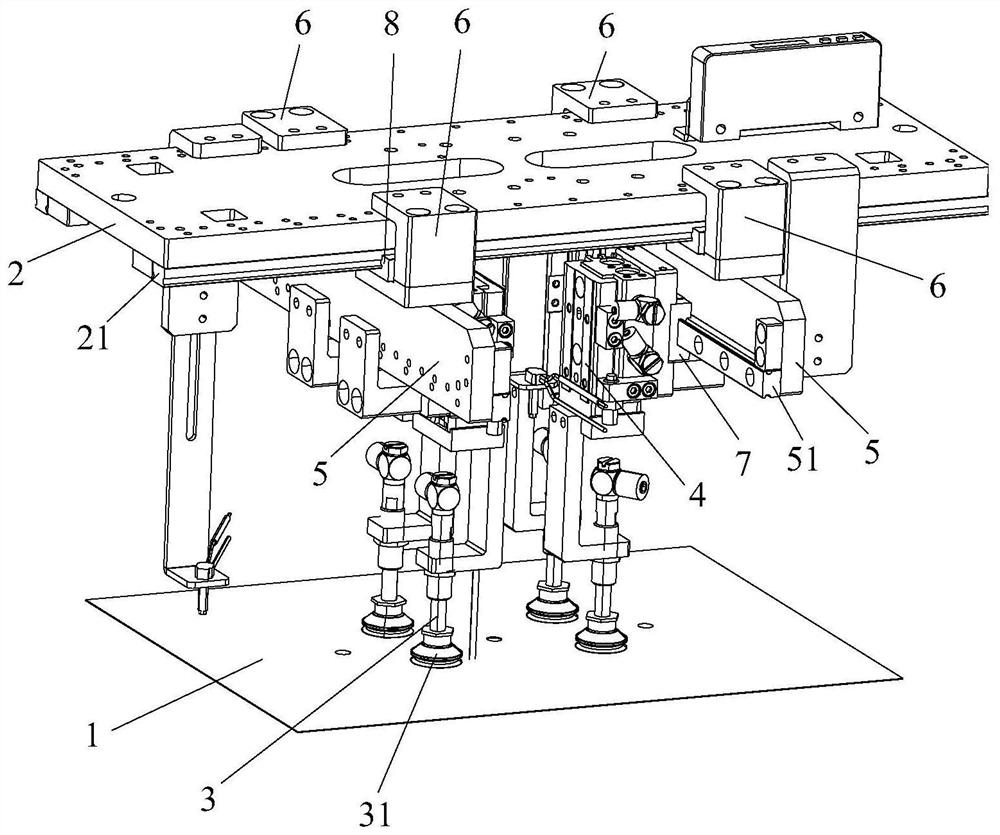

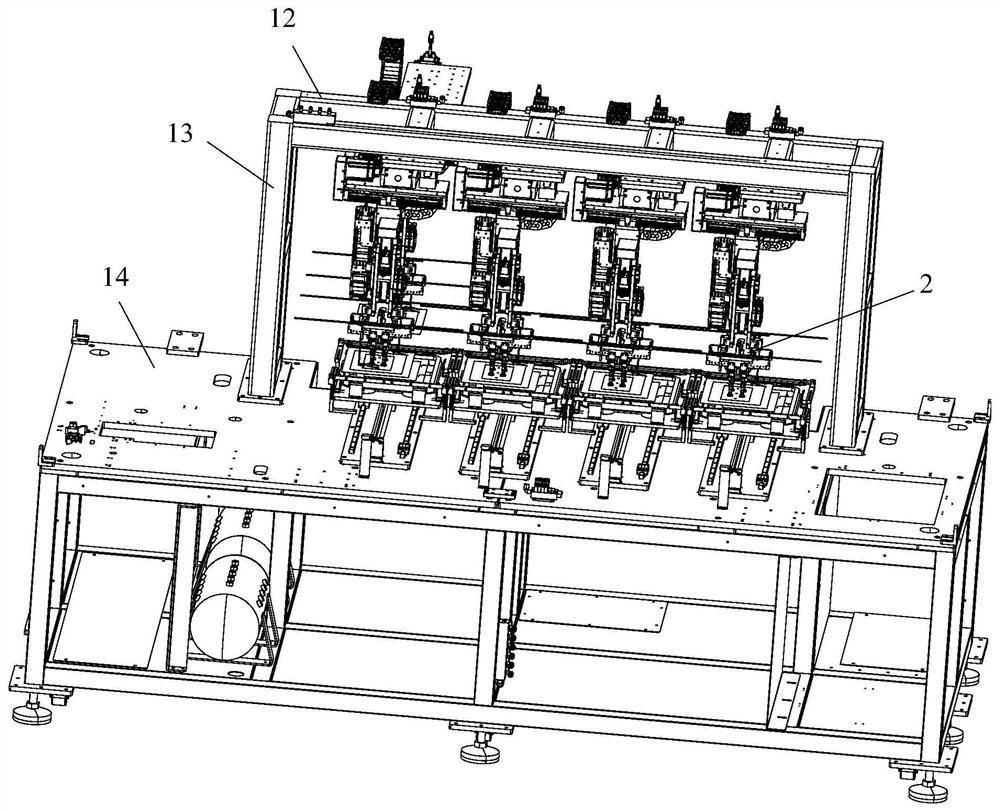

[0022] refer to Figure 1-Figure 2 As shown, the present invention discloses a conductive film slicing device, comprising a nozzle frame 2 and a plurality of suction nozzles 3, a plurality of first lifting drive devices 4 are connected to the nozzle frame 2, the first lifting drive device 4 and The suction nozzles 3 are in one-to-one correspondence, and each suction nozzle 3 is driven up and down by the corresponding first lifting drive device 4, so that each suction nozzle 3 can be lifted and lowered independently, and a plurality of suction nozzles 3 are surrounded by a quadrilateral frame for easy suction. The nozzle 3 can absorb the four corners of the conductive film 1, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com