Midair piece breaking-off mechanism and corresponding piece separation material-collecting station

A technology of breaking pieces and breaking boards, which can be used in conveyors, conveyor objects, sustainable manufacturing/processing, etc., and can solve problems such as low board breaking efficiency and inability to meet modern production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

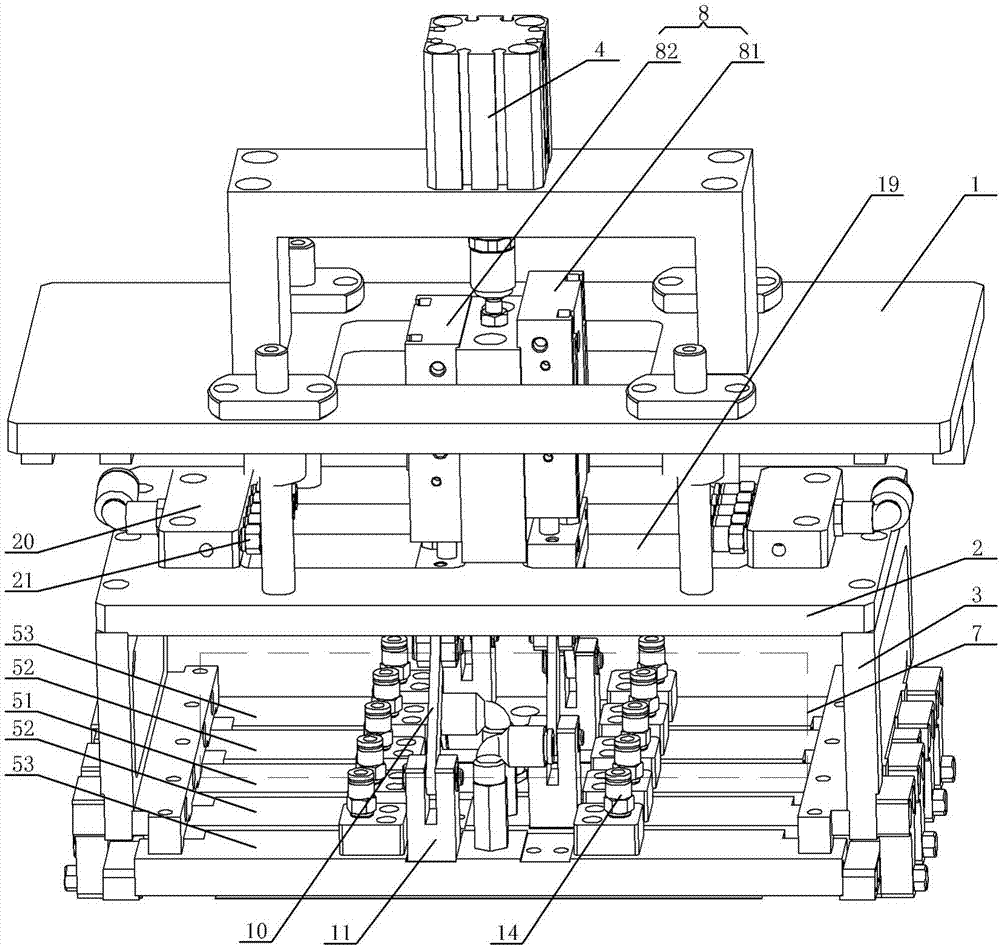

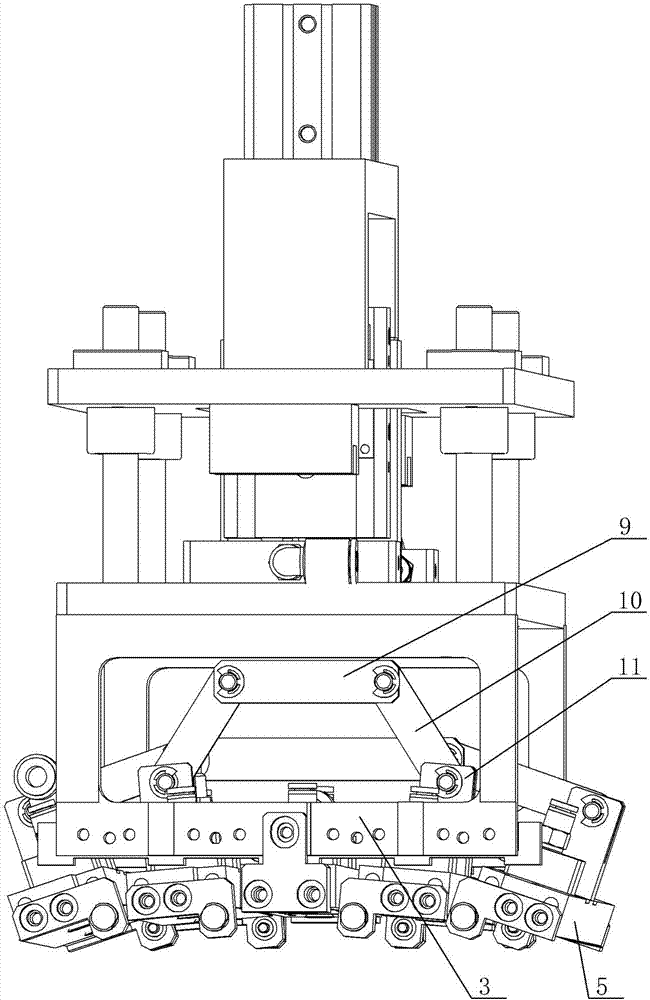

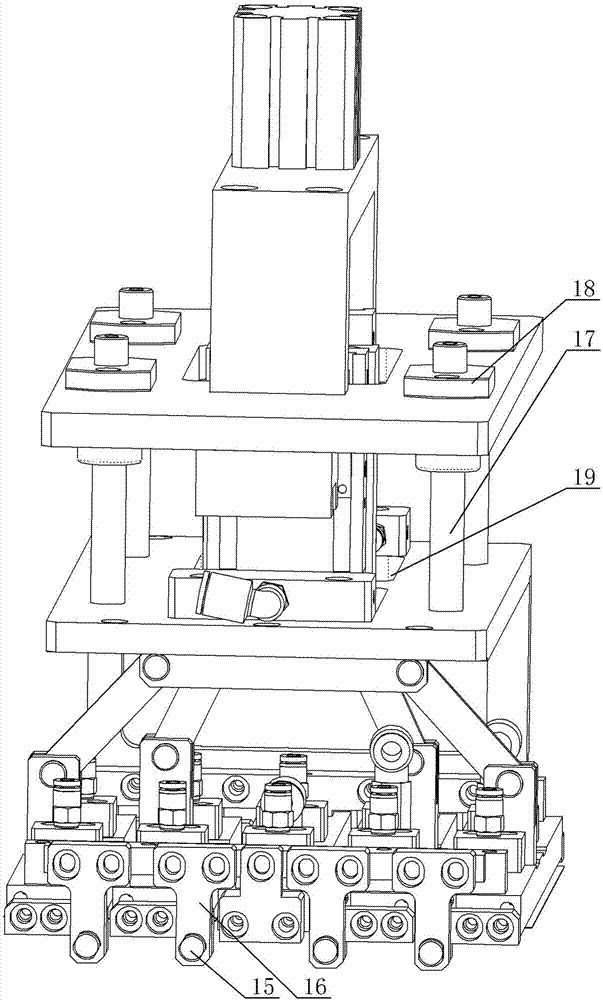

[0025] A kind of breaking mechanism in the air, see Figure 1-Figure 5 : It includes the breaking plate upper plate 1, the breaking plate upper plate 1 is directly lowered to be provided with a breaking plate frame 2, the breaking plate frame 2 includes two side plates 3, the lifting cylinder 4 is fixed on the breaking plate upper plate 1, and the lower piston rod of the lifting cylinder 4 The breaker frame 2 is fixed, and N pieces of breaker plates 5 are arranged between the lower ends of the two side plates 3 of the breaker frame 2, where N is a natural number greater than 1, the number of breaker plates 5 and the number of battery pieces 6 that need to be sliced The number is the same, a combined plane formed by the N pieces of breaking boards 5 in the non-working state. They are respectively connected to the corresponding positions of the side plates 3 through the rotating shaft mechanism. M pieces of piece cylinders 8 are fixedly installed on the piece piece frame 2, wher...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com