Silicon Wafer Slicing Device

A technology of silicon wafers and driving devices, applied in the directions of transportation and packaging, conveyor objects, sustainable manufacturing/processing, etc., can solve the problems of discontinuity and low slicing efficiency, and achieve the effect of small damage and high slicing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

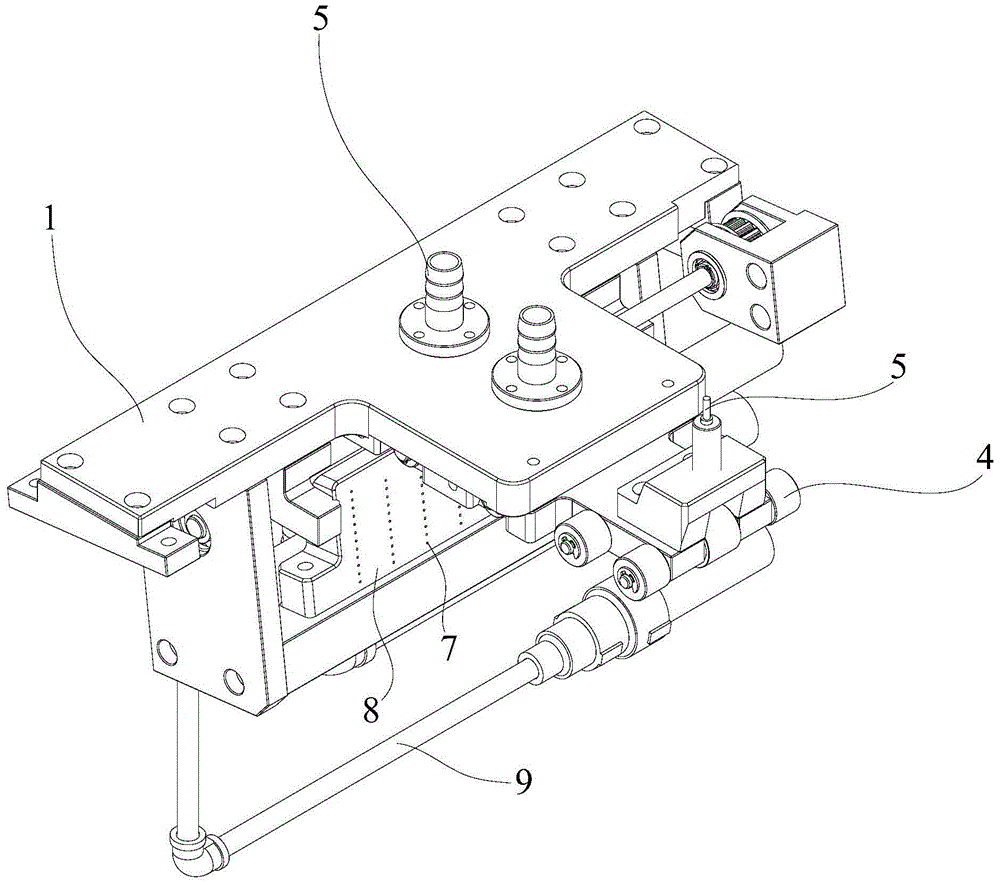

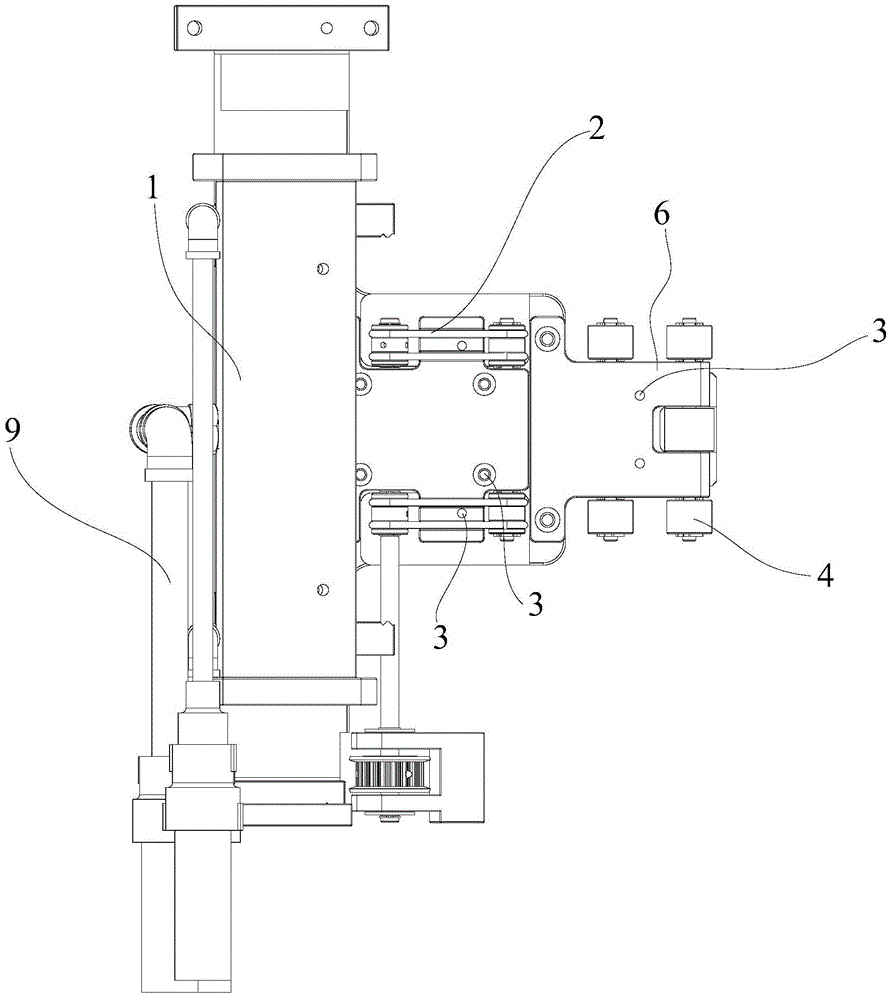

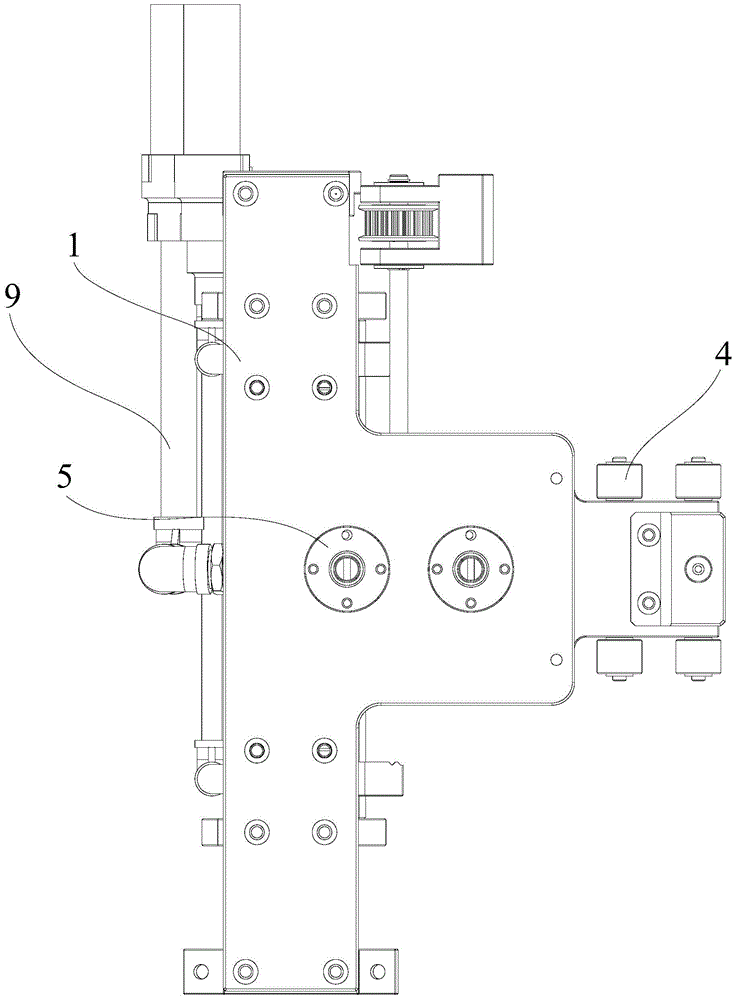

[0027] Embodiment: Silicon Wafer Slicing Device

[0028] See attached Figure 1~6 As shown, the silicon wafer slicing device includes a slicing mechanism 10 and a feed trough.

[0029] Slicing mechanism 10 comprises silicon chip slicing mechanism body 1, and this silicon chip slicing mechanism body 1 is provided with two parallel and spaced apart slicing conveyor belts 2 downwards, and described silicon chip slicing mechanism body 1 faces the The piece conveyor belt 2 is provided with an air extraction hole 3, which communicates with an air extraction device (not shown in the figure) through a pipeline, and the air extraction device may be a vacuum air extraction device. The front end of the silicon chip slicing mechanism body 1 corresponding to the conveying direction of the slicing conveyor belt 2 is provided with a roller 4; The air hole 7 is communicated with the blowing device (not shown in the figure) through the pipeline 9 . The blowing device can be, for example, a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com