Chamfering processing equipment for full-automatic silicon wafer and processing technic thereof

A kind of processing equipment, fully automatic technology, applied in the direction of metal processing equipment, grinding/polishing equipment, manufacturing tools, etc., can solve the problems of time-consuming and labor-intensive, low work efficiency, etc., to save human resources, improve work efficiency, save self-adjustment The effect of the heart step

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

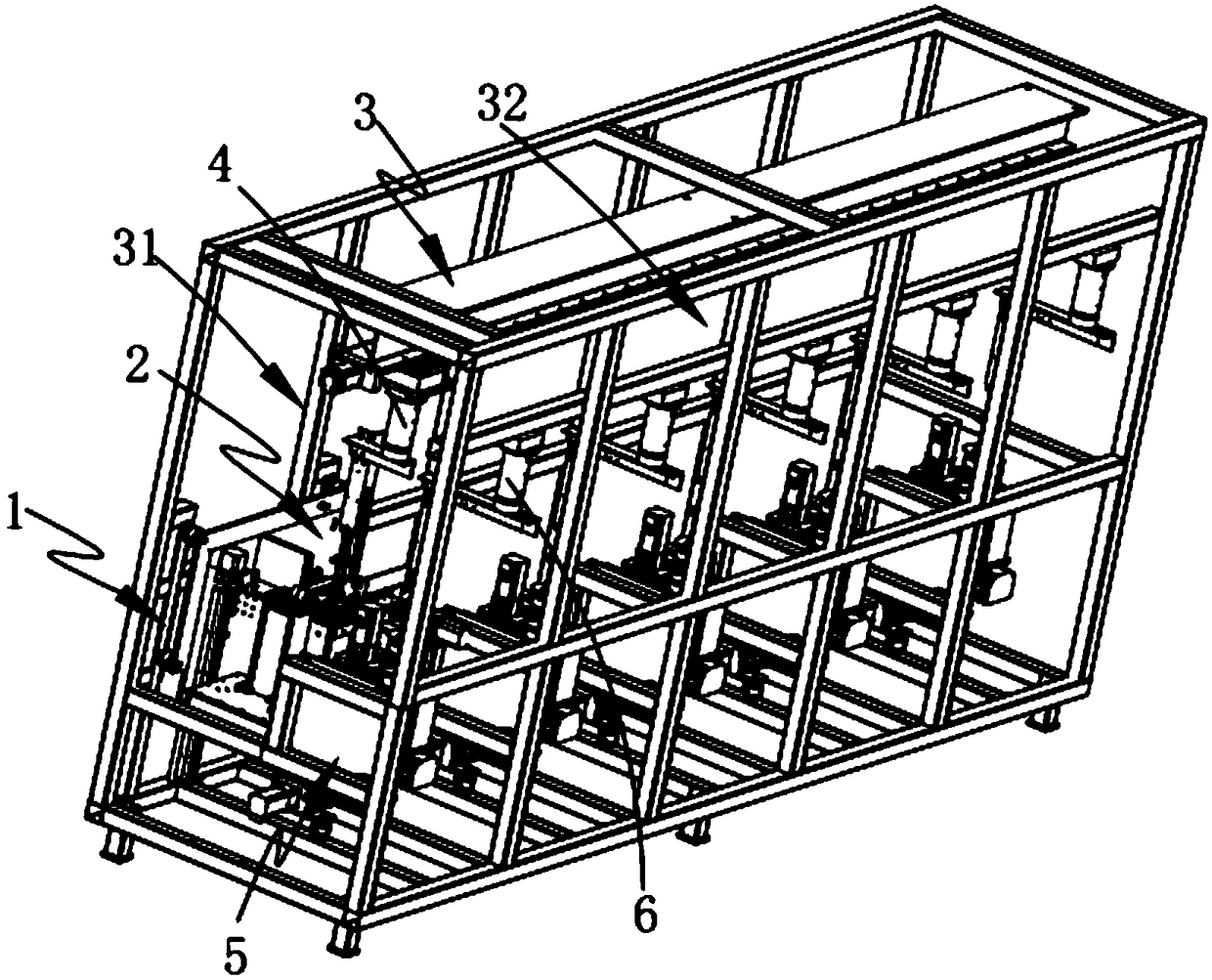

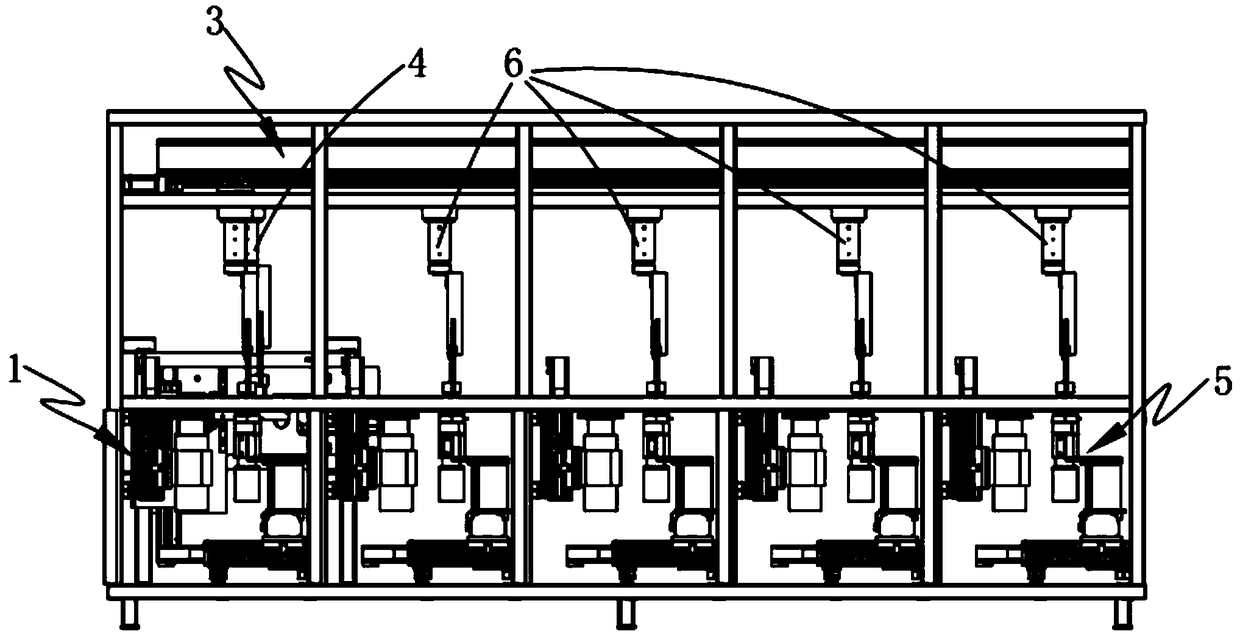

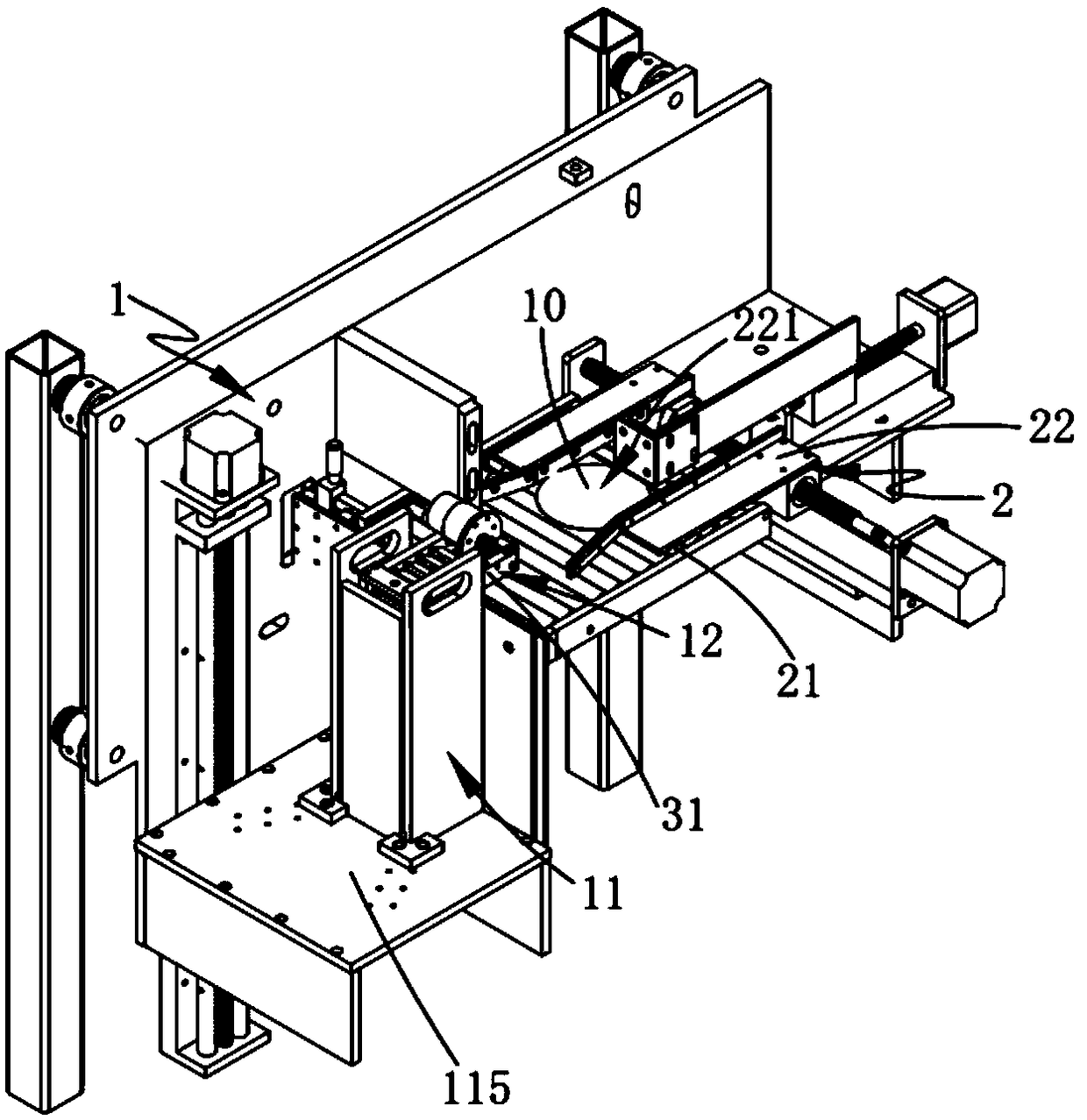

[0107] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, a fully automatic silicon wafer chamfering processing equipment includes:

[0108] frame;

[0109] Loading self-positioning unit I, the loading self-positioning unit I is installed at one end inside the frame, which includes:

[0110] Slice feeding device 1, which includes a feed lifting mechanism 11 for driving a cassette 118 with a number of silicon wafers 10 stacked inside to move upwards, and a slice loading mechanism 11 arranged on the rear side of the feed lifting mechanism 11. Institution 12; and

[0111] Transmission self-centering device 2, said transmission self-centering device 2 is arranged on the rear side of said piece-feeding device 1 and vertically arranged with said piece-feeding device 1, said transmission self-centering device 2 includes a transmission mechanism 21 And self-centering mechanism 22, the silicon chip 10 that is positioned at the top of sheet box 118 is automatically tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com