Knitting open-width wet processing unit with spray washing device

A water washing device and wet treatment technology, which is applied in the direction of spray/jet textile material treatment, textile material treatment, textile processing machine accessories, etc., can solve the problems of fabric stretching deformation, affecting fabric quality, producing defective products, etc., to prevent Stretch deformation, improve washing efficiency, and ensure the effect of fabric quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

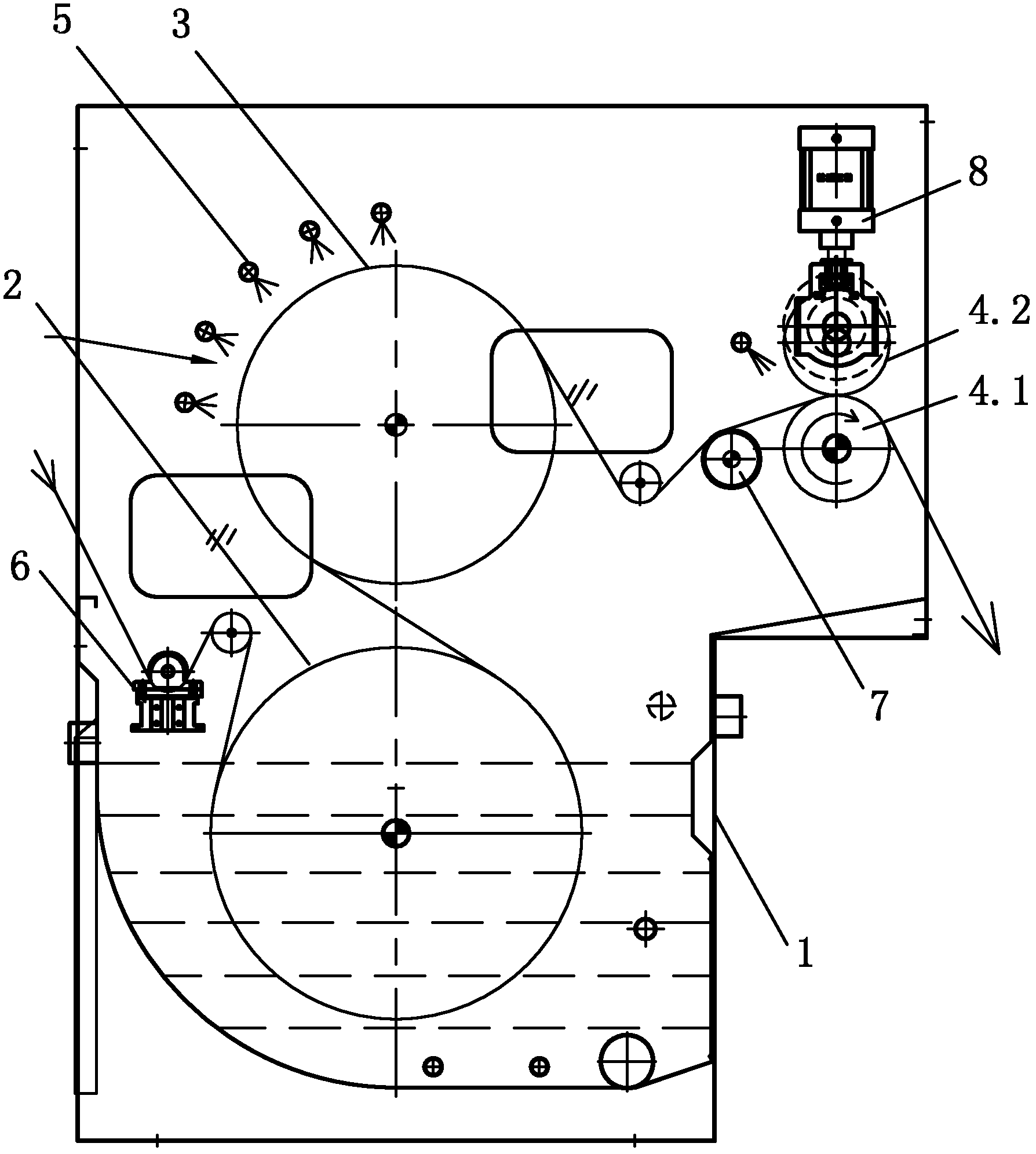

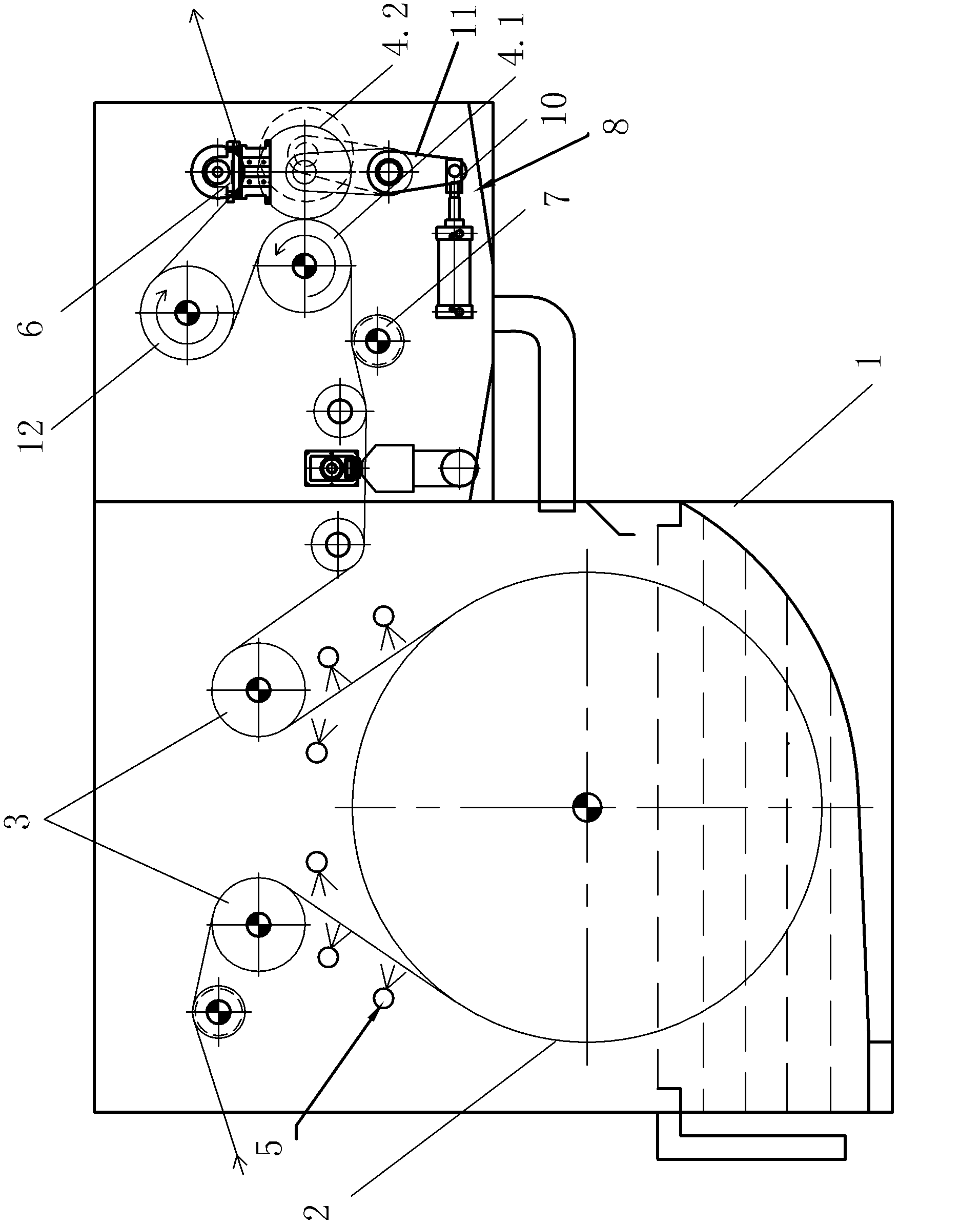

[0022] Example 1: Wet processing unit of knitted open width wet processing unit with spray water washing device, such as figure 1 As shown, the box body 1 is provided with a drum group (including a lower drum 2, an upper drum 3, a cloth guide roller 12), and a roller group matched with the drum group. The rotating drum group is the main transmission component, and the roll group includes a cooperating active roll 4.1 and a passive roll 4.2. The drum surface of the rotating drum 2 is a mesh drum surface. Or, at the same time, the drum surface of the upper drum 3 is also a mesh drum surface, such as Figure 3-5 As shown, the reticulated drum surface is an integral structure formed by rolling and welding stainless steel plates, and the mesh holes 9 on it are punched and evenly distributed on the roller surface; or the reticulated drum surface is constructed of stainless steel wire. Mesh drum head.

[0023] In order to achieve the purpose of automatic and precise tension cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com