Multi-pattern space dyeing equipment for fabric

A multi-pattern and fabric technology, applied in the processing of textile material equipment configuration, textiles and papermaking, textile processing machine accessories, etc., can solve the problems of splashing, wasting dyeing, complicated processes, etc., and achieve great competitiveness and economic benefits. , the effect of enhancing adsorption capacity and reducing the amount of residues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

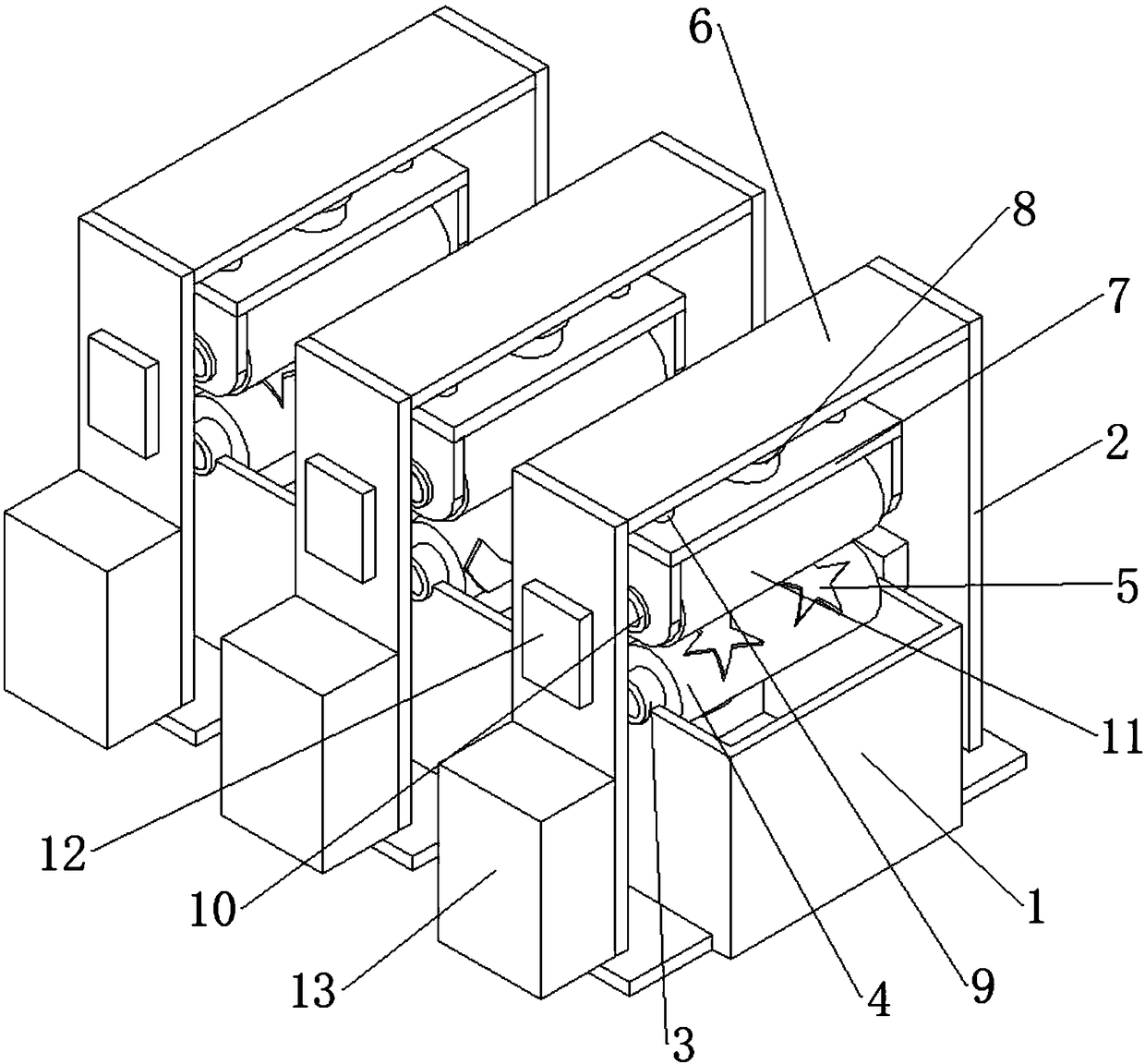

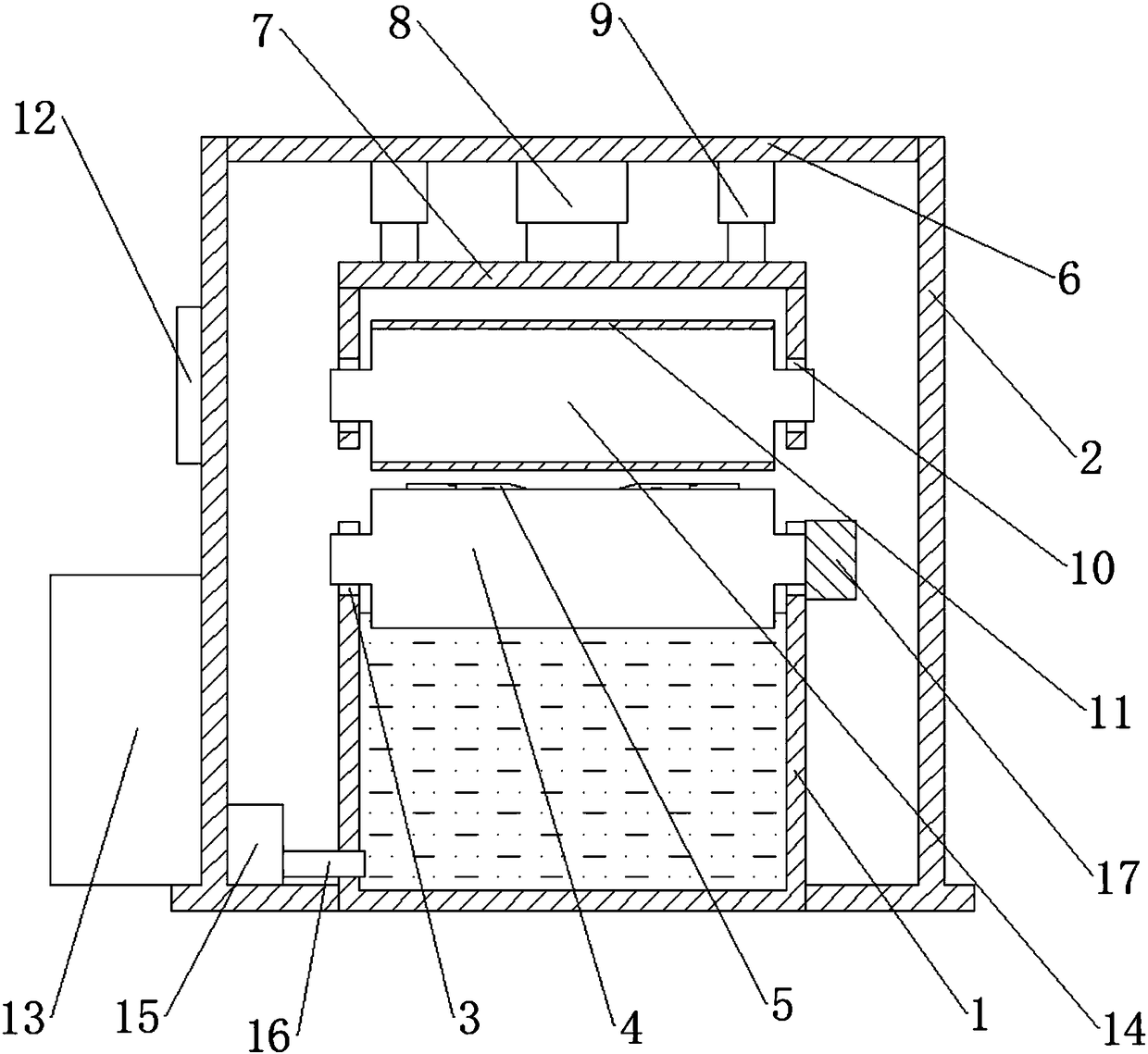

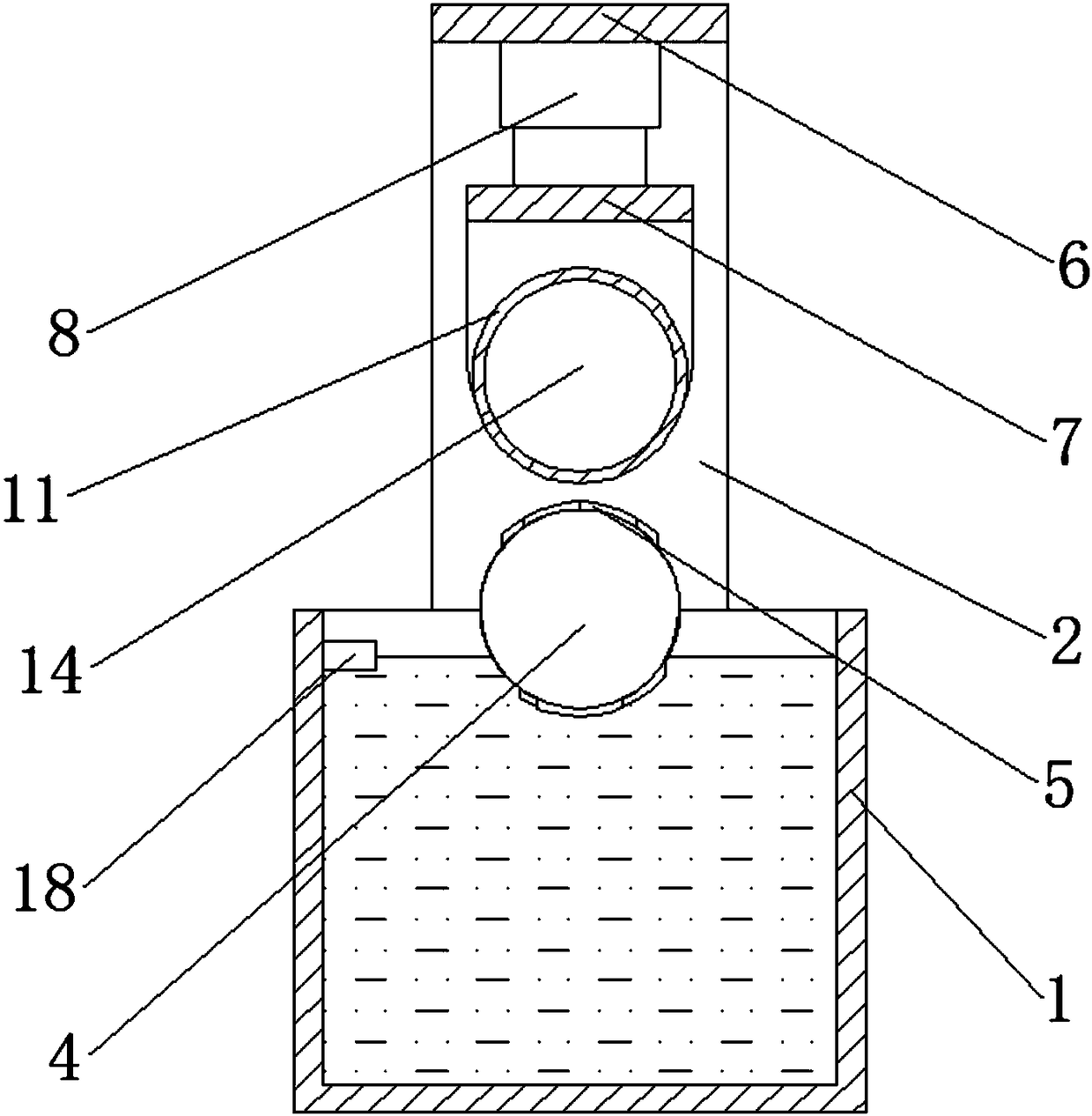

[0040] See Figure 1-4 , A fabric multi-pattern section dyeing equipment, including a dye slurry configuration barrel 1, both sides of the dye slurry configuration barrel 1 are fixedly connected with brackets 2, the upper end of the dye slurry configuration barrel 1 is fixedly connected with a pair of lower bearings 3, two lower The lower pressure roller 4 is fixedly connected between the inner rings of the bearing 3, and a motor 17 is fixedly connected to one side wall of the dyeing and slurry disposing barrel 1. The model of the motor 17 is Y80M1-4 three-phase asynchronous motor, which has good performance and can meet the needs , The rotating end of the motor 17 is fixedly connected with one end of the lower press roller 4, the dye slurry is filled in the dye slurry configuration barrel 1, and a support plate 6 is fixedly connected between the two brackets 2, and the support plate 6 is located in the dye slurry configuration An upper pressure roller stand 7 is provided direc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com