Substrate bonding device, substrate bonding method, and electronic device manufacturing method

A technology for laminating devices and substrates, which is applied in semiconductor/solid-state device manufacturing, electronic equipment, chemical instruments and methods, etc., can solve the problems of substrate handling deterioration and achieve the effect of reducing the number of residues and warping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

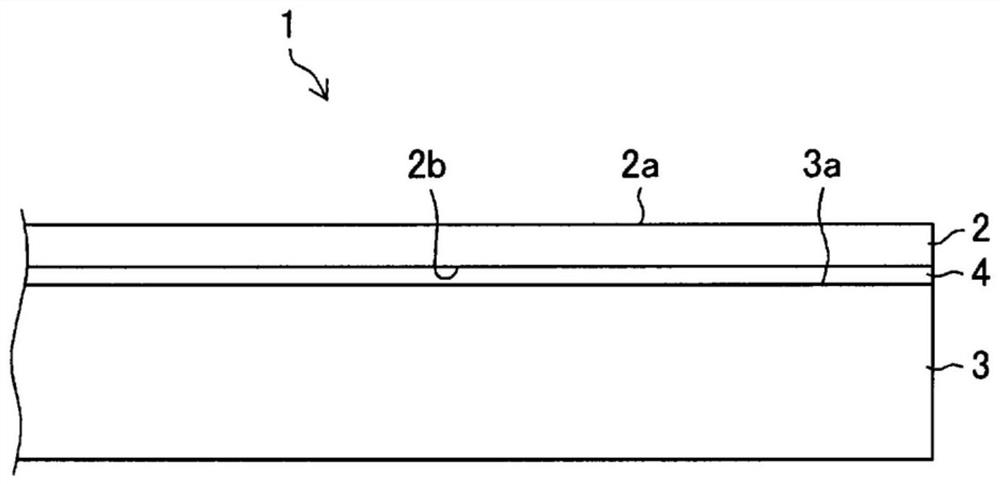

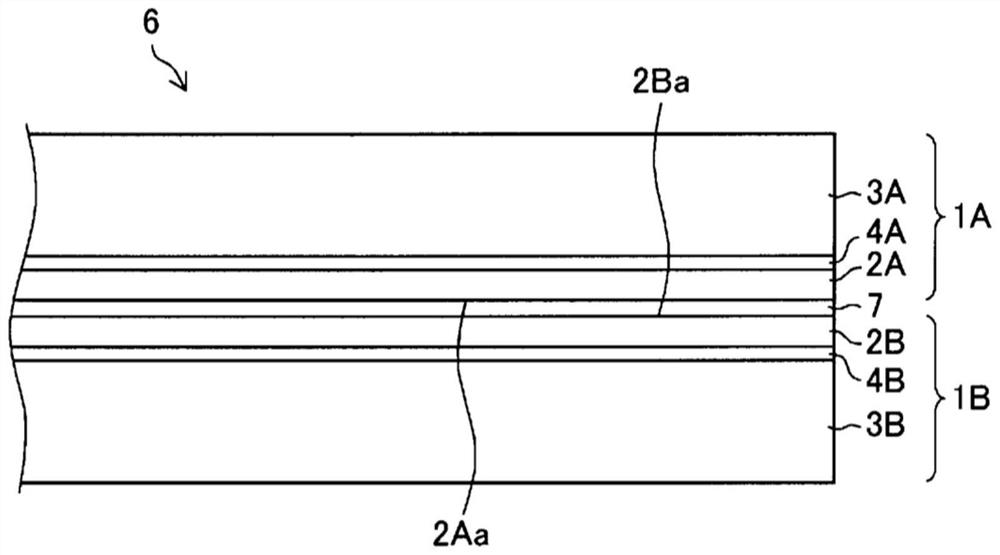

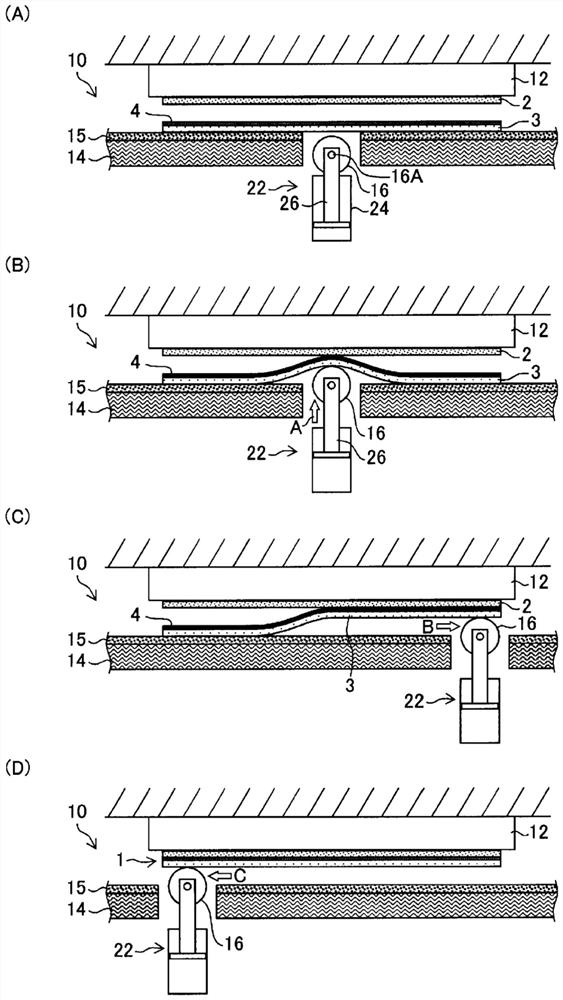

[0041] Embodiments of the present invention will be described below with reference to the drawings.

[0042] Hereinafter, the case where the bonding apparatus and bonding method of the board|substrate of this invention are used in the manufacturing process of an electronic device is demonstrated.

[0043] Electronic devices refer to electronic components such as display panels, solar cells, and thin-film secondary batteries. Examples of the display panel include a liquid crystal display panel (LCD: Liquid Crystal Display), a plasma display panel (PDP: Plasma Display Panel), and an organic EL display panel (OELD: Organic Electro Luminescence Display).

[0044] Manufacturing process of electronic devices

[0045] Electronic devices are produced by forming functional layers for electronic devices (thin-film transistors (TFTs) and color filters (CFs) in the case of LCDs) on surfaces of substrates made of glass, resin, or metal.

[0046] Before forming the functional layer, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com