Method for effectively improving strength and conductivity of alloy

A technology for alloy strength and electrical conductivity, applied in the field of alloys, can solve the problems of NiTi phase annealing twins, electrical conductivity improvement, strength reduction, etc., and achieve the effect of excellent comprehensive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

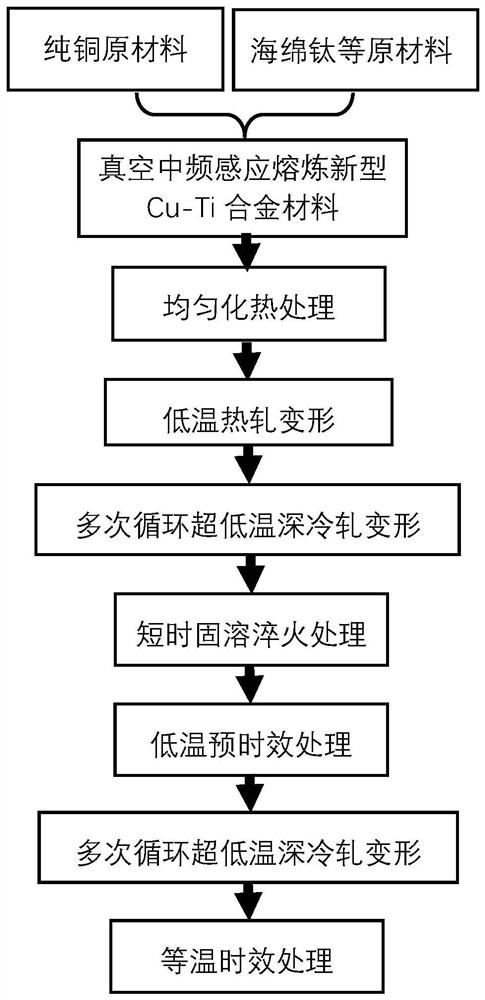

[0034] like figure 1 As shown, the preparation method of the present invention includes the following steps: preparing alloy ingots by vacuum smelting→homogenizing heat treatment→low temperature hot rolling→multiple cycles of ultra-low temperature deep cold rolling deformation→short-time solution quenching treatment→low temperature short-time pre-aging treatment→ Multiple cycles of ultra-low temperature deep cold rolling deformation → isothermal aging treatment can not only control the grain structure of copper alloy, but also significantly induce the number and density of precipitates in the peak aging state of the alloy, and finally make the copper alloy have both high strength and high electrical conductivity.

[0035] The raw materials are 99.9wt% electrolytic high-purity Cu, sponge Ti and other intermediate alloys and pure metals. First, the alloy is smelted in a vacuum intermediate frequency induction furnace. The specific chemical compositions of the alloys used in the...

Embodiment 1

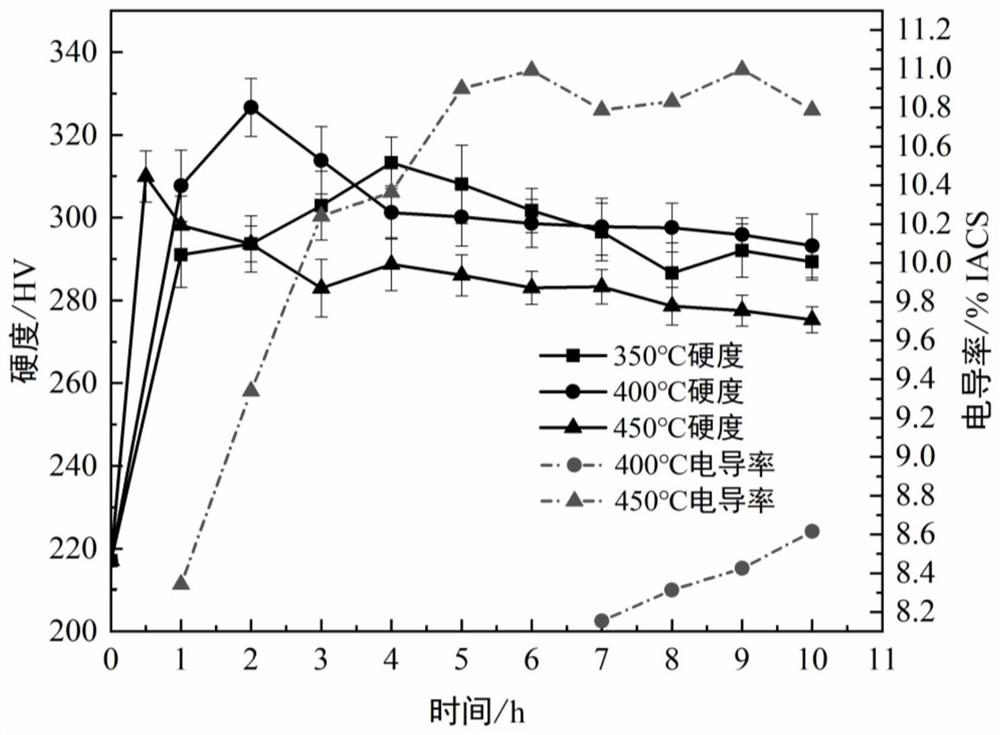

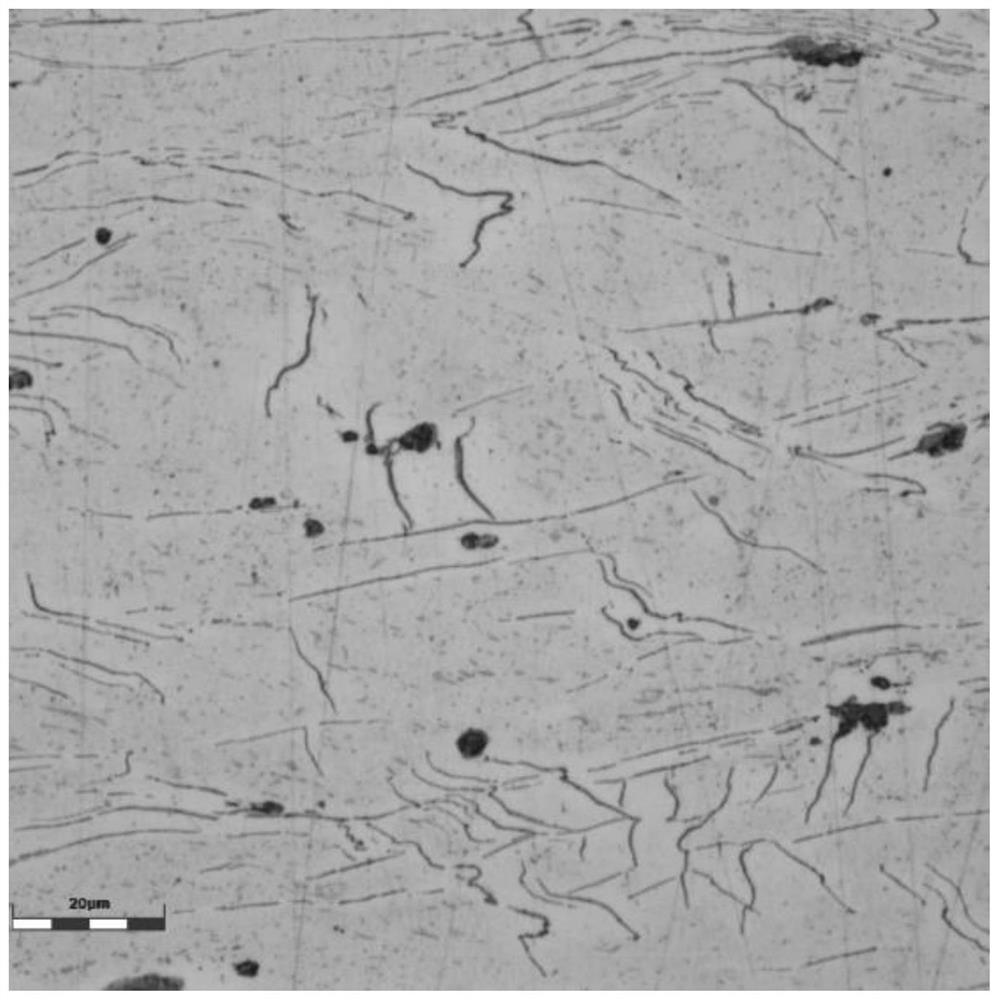

[0045] According to the design value of the composition of alloy 1#, the alloy is first smelted in a vacuum intermediate frequency induction furnace; then the ingot of the invented alloy is subjected to homogenization heat treatment (temperature: 750-850°C, time: 15-30h), and then multi-process thermal processing Coupling control, the specific treatment process is as follows: firstly, the homogenized ingot is subjected to low-temperature hot-rolling deformation, the rolling start temperature: 710-750°C, the holding time: 0.1-1h, the deformation amount: 45-80%, and the deformation method: Unidirectional rolling, pass reduction: 3-15%, final rolling temperature: greater than 500°C; and then carry out multiple cycles of ultra-low temperature deep cold rolling deformation treatment on the hot-rolled sheet, the number of low-temperature deformation cycles is greater than 10 times, first Place it in the liquid nitrogen tank for more than 30 minutes, and then carry out ultra-low tempe...

Embodiment 2

[0047] According to the composition design value of the inventive alloy 2#, the alloy is first smelted in a vacuum intermediate frequency induction furnace; then the ingot of the inventive alloy is subjected to a homogenization heat treatment (temperature: 750-850°C, time: 15-30h), and then heat processed for more Process coupling control, the specific treatment process is as follows: firstly, the ingot after homogenization treatment is subjected to low-temperature hot rolling deformation, rolling start temperature: 710-750°C, holding time: 0.1-1h, deformation amount: 45-80%, deformation method : Unidirectional rolling, pass reduction: 3-15%, final rolling temperature: greater than 500°C; then the hot-rolled sheet is subjected to multiple cycles of ultra-low temperature deep cold rolling deformation treatment, and the number of low-temperature deformation cycles is greater than 10 times. First place it in a liquid nitrogen tank for more than 30 minutes, and then carry out ultra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com