Rotary drum type dyeing machine

A dyeing machine, drum type technology, applied in the field of dyeing machines, can solve the problems of long dyeing time, high energy consumption, large labor workload of workers, etc., and achieve the effect of reducing processing time, reducing labor amount, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

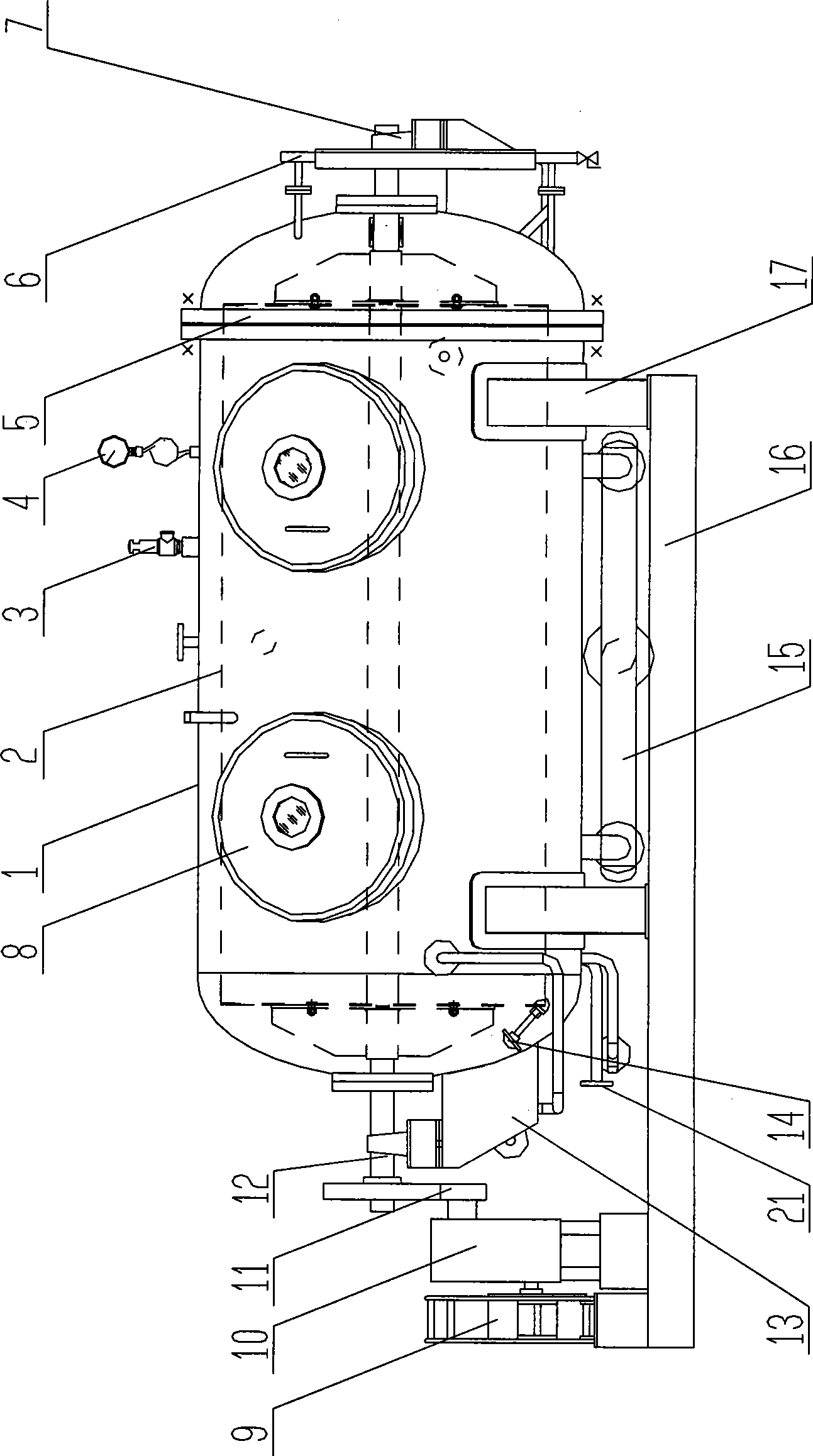

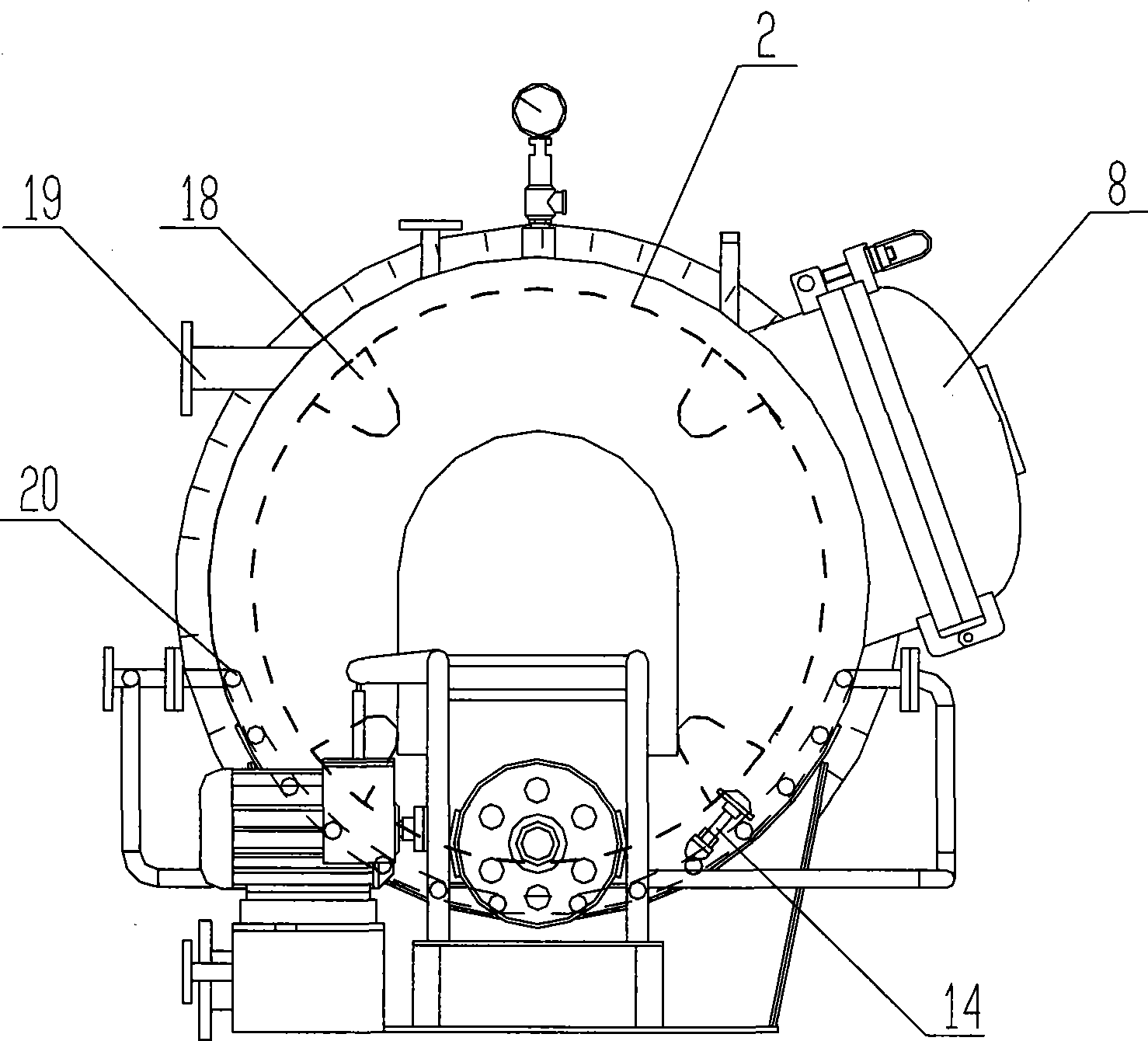

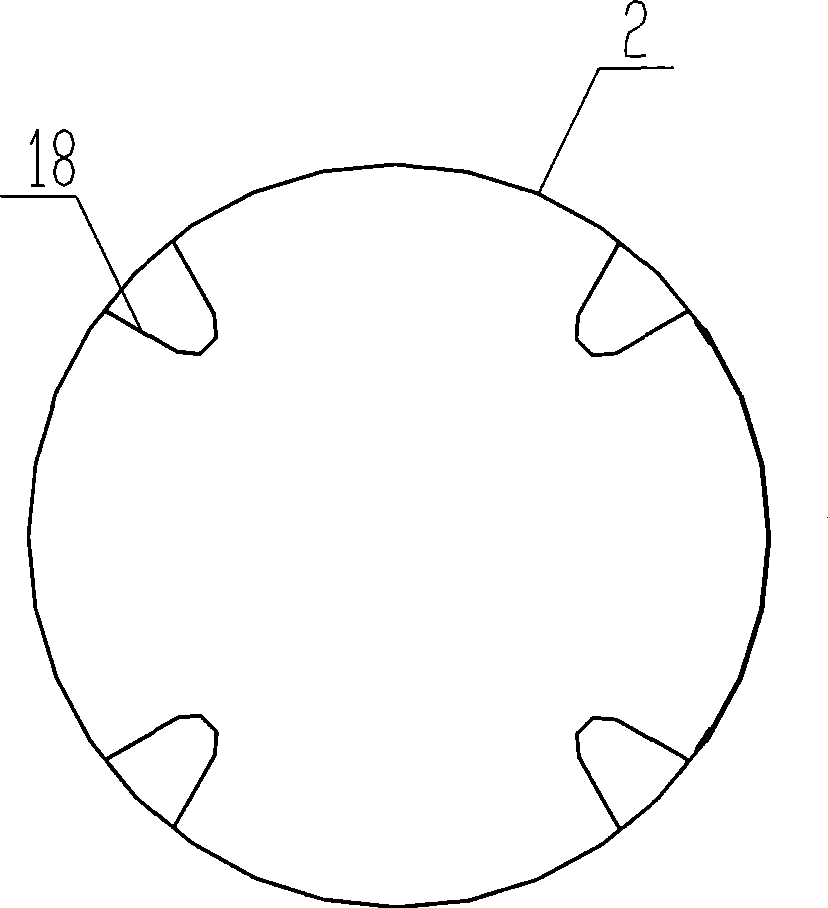

[0019] Such as Figures 1 to 2 As shown, in the drum dyeing machine of the present invention, the two ends of the pressure-bearing cylinder 1 are heads, and the middle is a cylindrical cylinder, and the head at one end is movably connected to the cylinder through the container flange 5, which is convenient Maintenance inside the container; the transmission shaft 12 passes through the two heads, and is connected with the pressure-bearing cylinder 1 through a mechanical seal, and the inner drum 2 coaxial with the cylindrical cylinder and the transmission shaft 12 is fixedly installed on the transmission shaft 12, There are material holes for the fabric to enter and exit. The outer surface of the inner drum 2 is uniformly distributed with small holes, and the inner surface is evenly distributed with several ridge-like protrusions 18. The body 1 rotates inside; the bracket 13 installed on the head at both ends supports the transmission shaft 12 through the bearing seat 7, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com