Knitting open-width wet processing unit with oscillating meshed washing cloth guide roller

A technology of wet processing and cloth guide roller, which is applied in the processing of textile materials, liquid/gas/steam textile material processing, textile processing machine accessories, etc. It can solve the problems of affecting the quality of fabrics, stretching and deformation of fabrics, and unusability. , to improve washing efficiency, prevent stretching and deformation, and ensure fabric quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

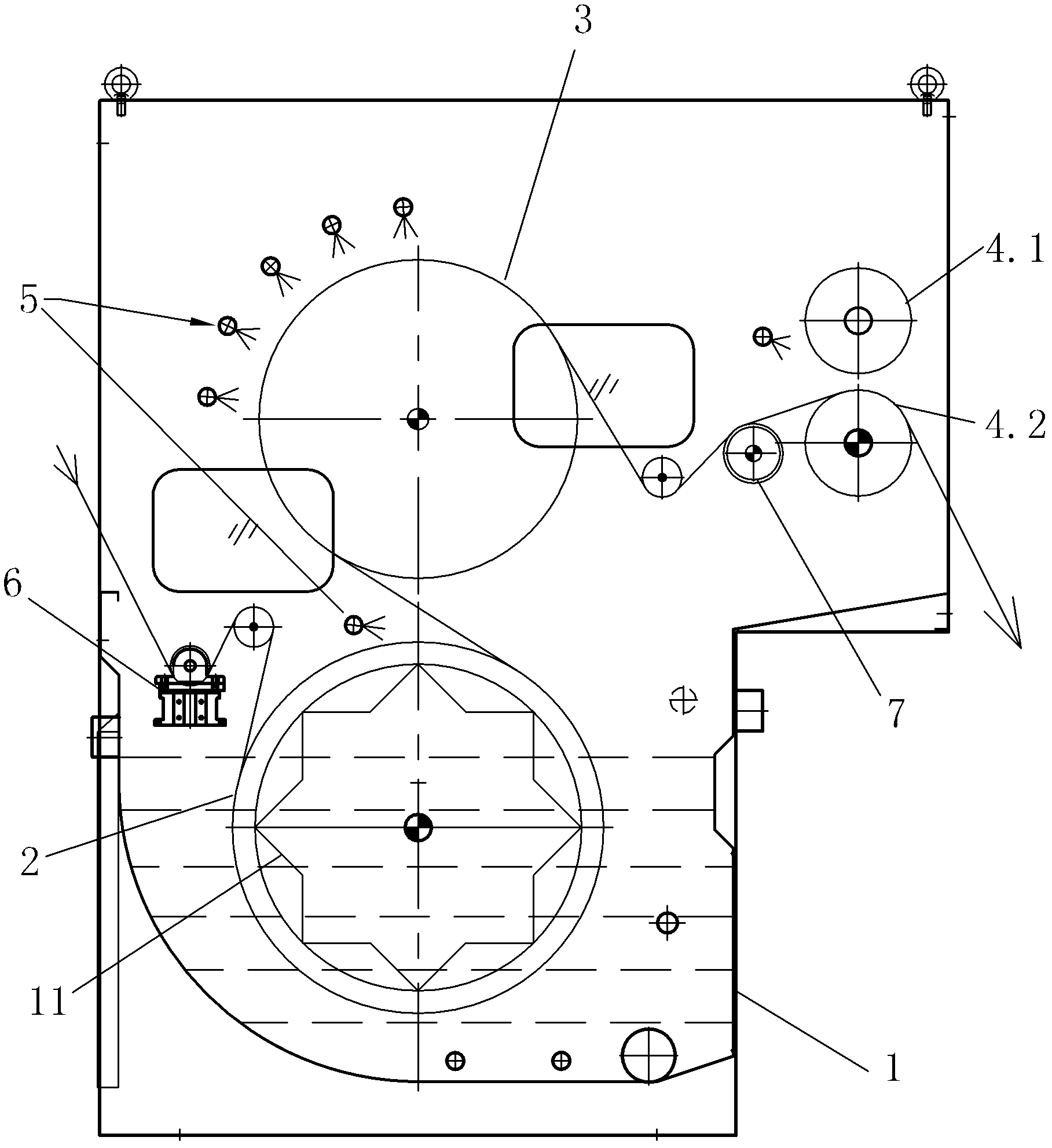

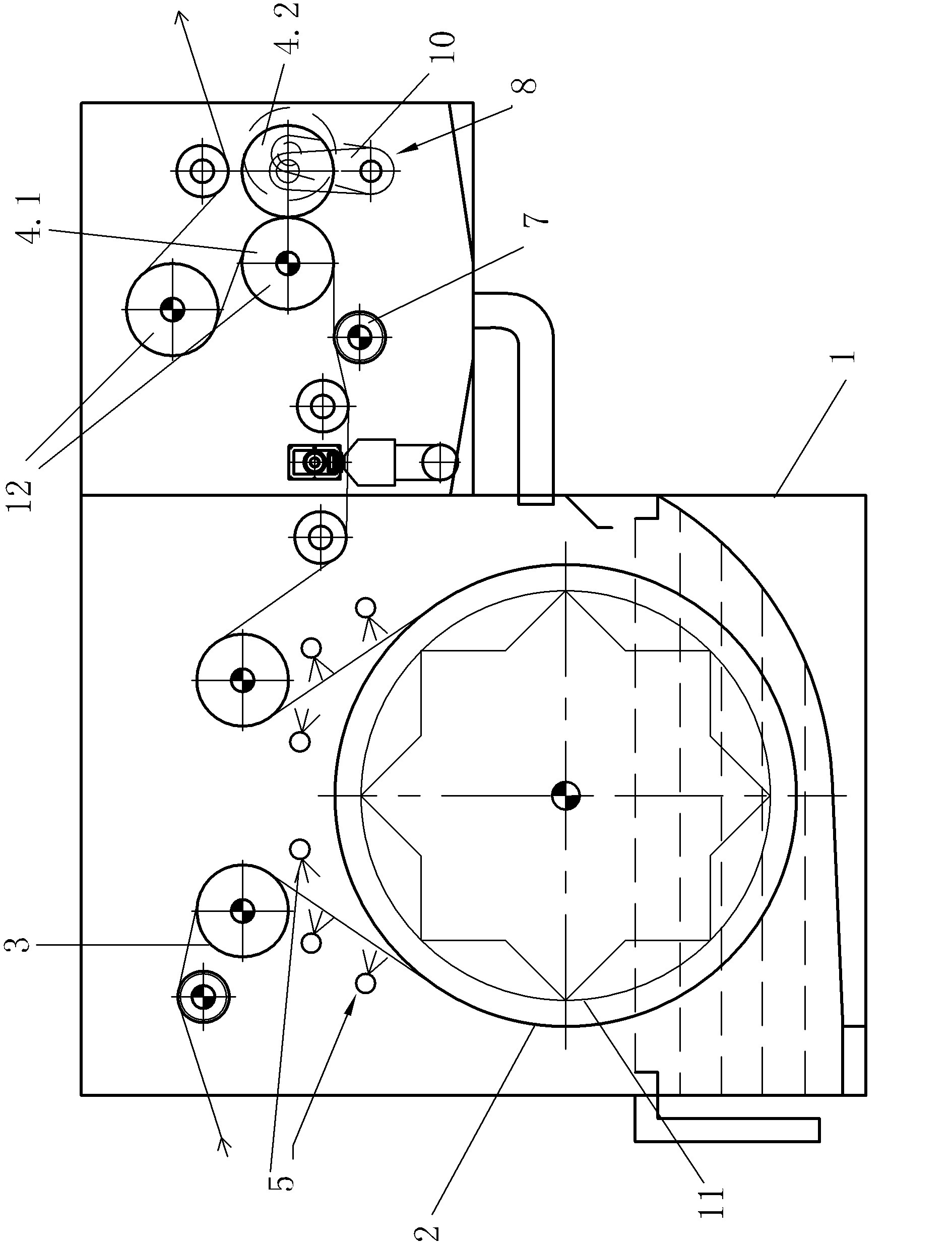

[0023] Example: Knitting open-width wet processing units with oscillating mesh wash guides, e.g. figure 1 , figure 2 As shown, it includes a wet processing unit machine, and a drum set (including a lower drum 2, an upper drum 3, and a cloth guide roller 12) is provided in the cabinet 1 of the wet processing unit machine, and the drum set is matched with the drum set The roll set, the drum set includes a lower drum 2 and an upper drum 3 that cooperate with each other. The drum surface of the lower drum 2 is a net-shaped drum surface, and the inner cavity of the lower drum 2 is also provided with an oscillation roller 11 arranged in the same direction as the lower drum 2 and having a polygonal cross section. The drum set is the main transmission component, and the roll set includes active rolls 4.1 and passive rolls 4.2 that cooperate with each other.

[0024] Such as Figure 3-Figure 6 As shown, the meshed drumhead is a meshed drumhead formed by round welding of stainless...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com