Patents

Literature

36results about How to "Extend dyeing time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

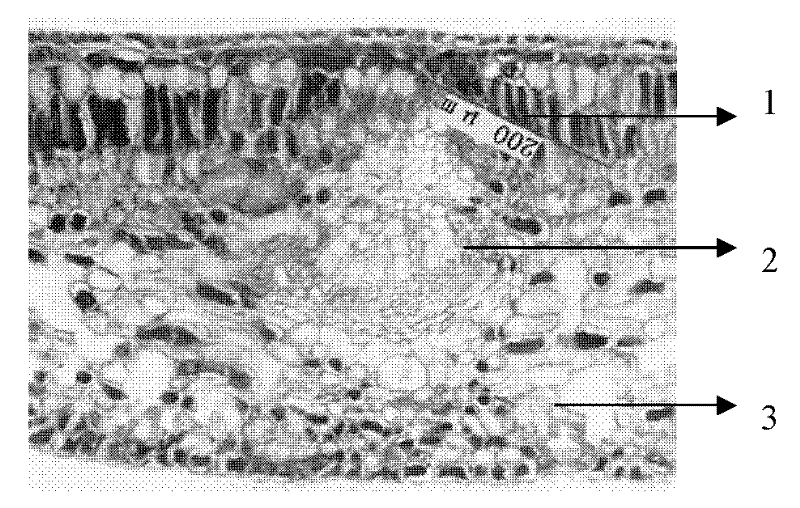

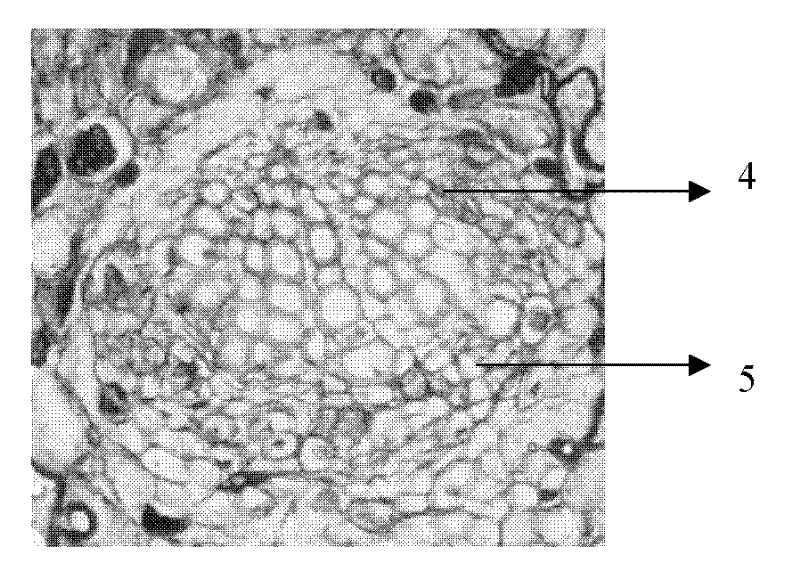

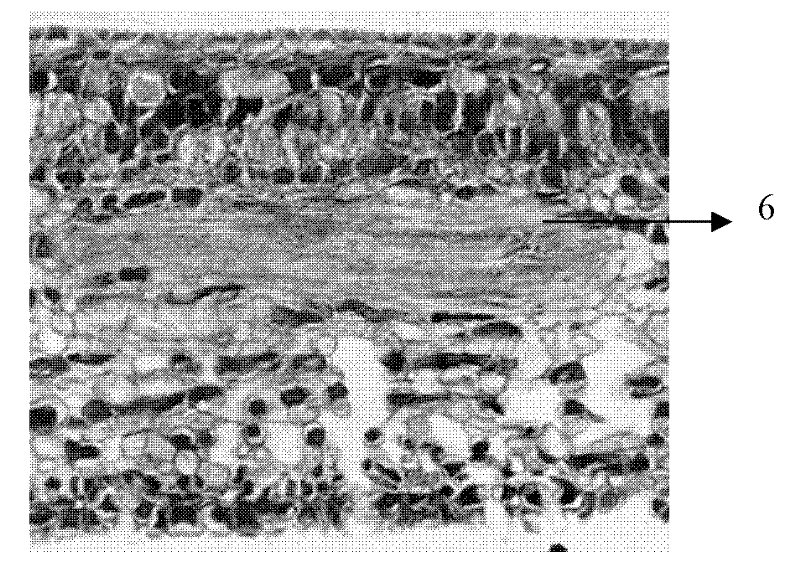

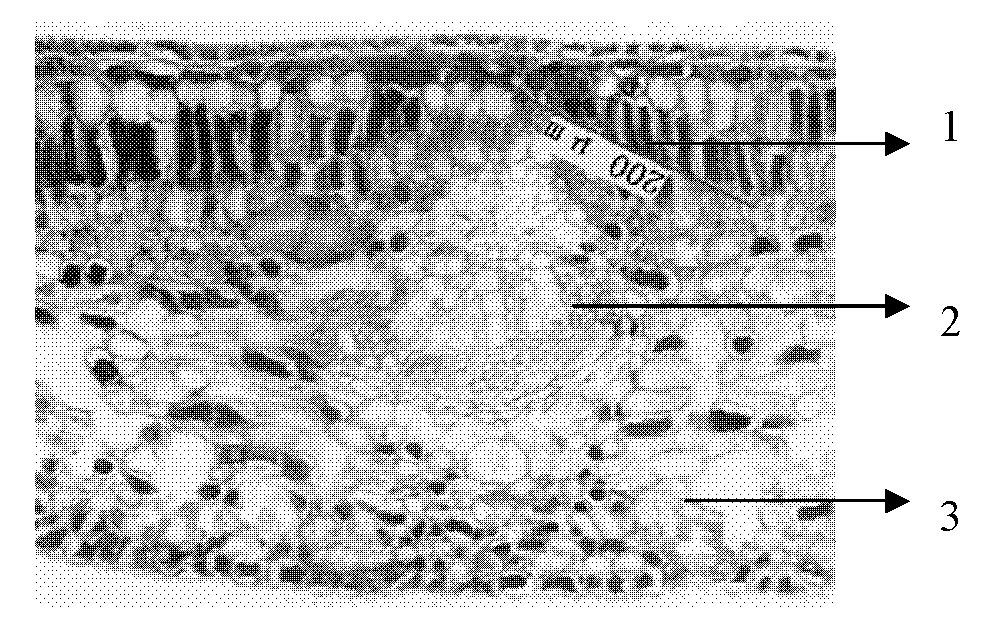

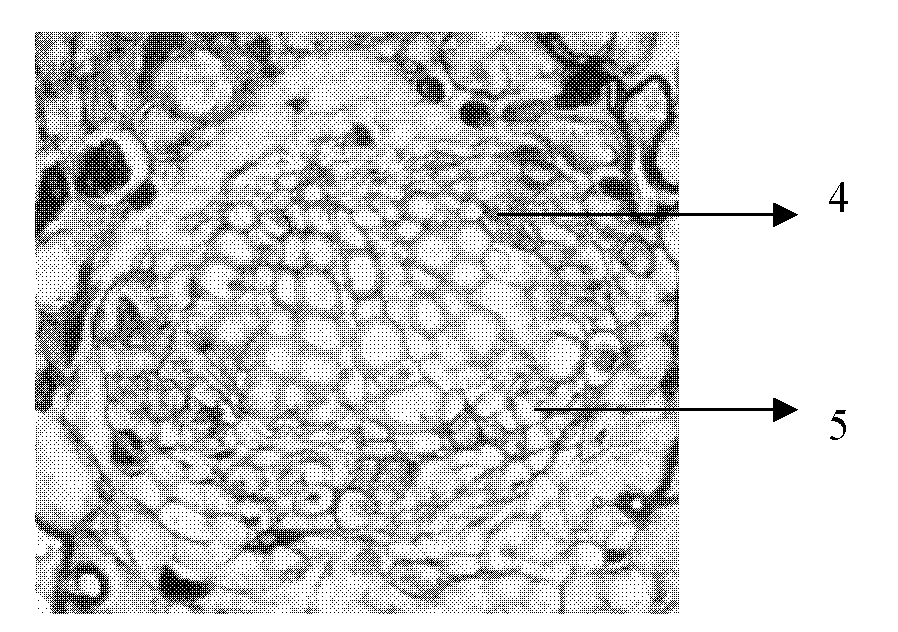

Method for slicing heavy leather blade paraffin

InactiveCN102175482AIncrease the number of levelsExtend dyeing timeWithdrawing sample devicesPreparing sample for investigationWaxParaffin oils

The invention discloses a method for slicing heavy leather blade paraffin and relates to a method for slicing plant paraffin. Operating procedures include fixing, dehydrating, transparentizing, paraffin infiltration, embedding, slicing, dewaxing, dyeing and mounting. In the splicing process of the heavy leather blade paraffin, a fixing agent, a dehydrating procedure, a transparentizing procedure, a paraffin infiltration method, a dyeing method and mounting are improved, i.e., selection of the fixing agent, determination of the dehydrating procedure, determination of the transparentizing procedure, determination of the dewaxing procedure, the dyeing method and the mounting method are improved. The method is also suitable for other blades with different thicknesses and properties. By adopting the method, slice manufacturing of blade paraffin with different thicknesses and properties can be realized practically, and a uniform and practical manufacturing method for theoretical manufacturing of paraffin is popularized.

Owner:XIAMEN UNIV

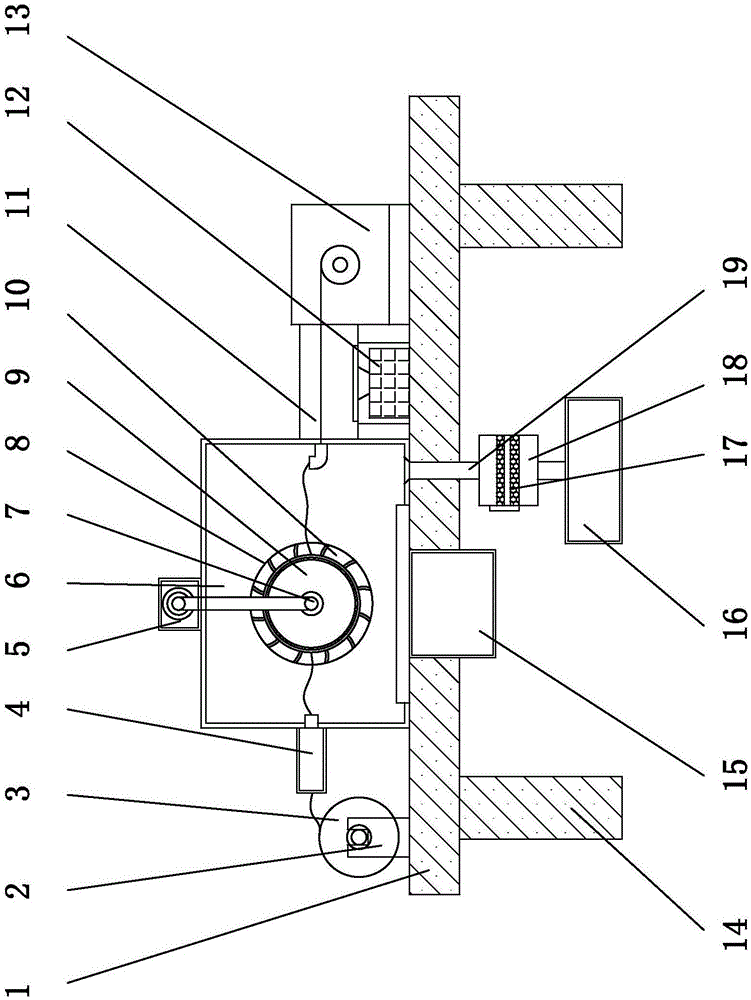

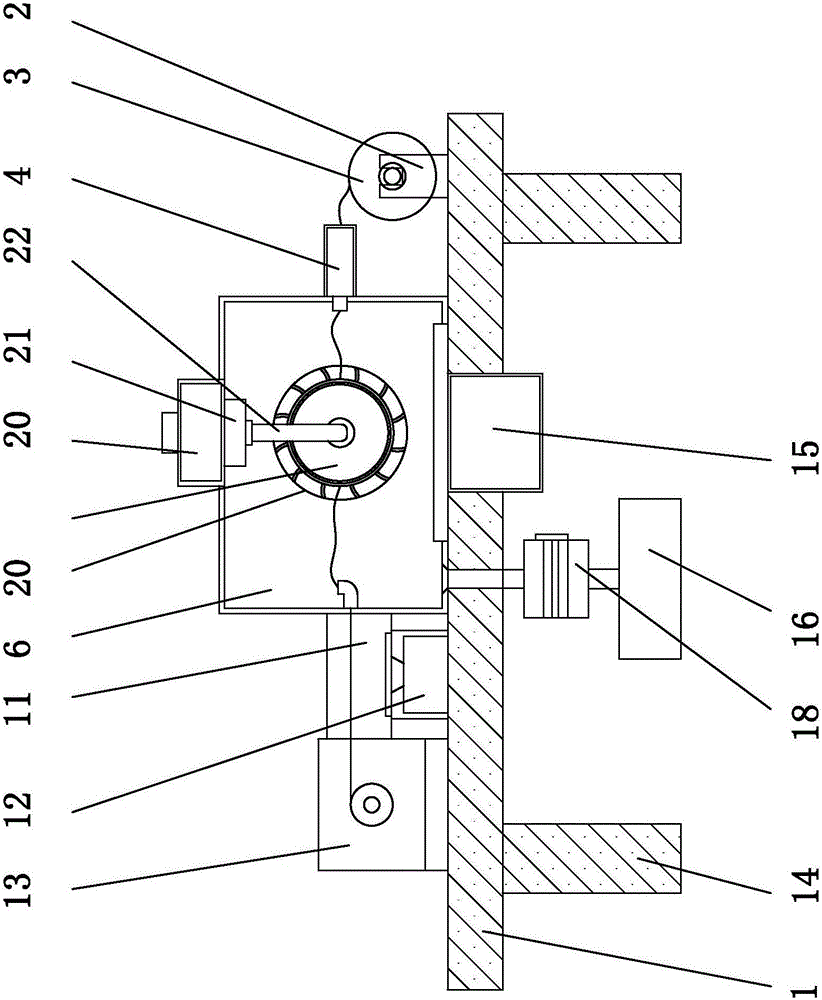

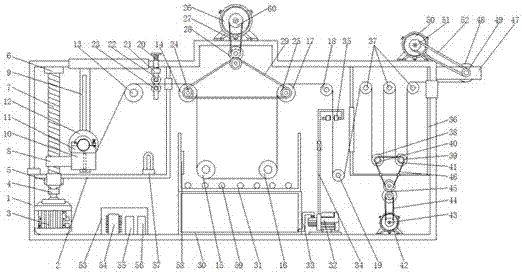

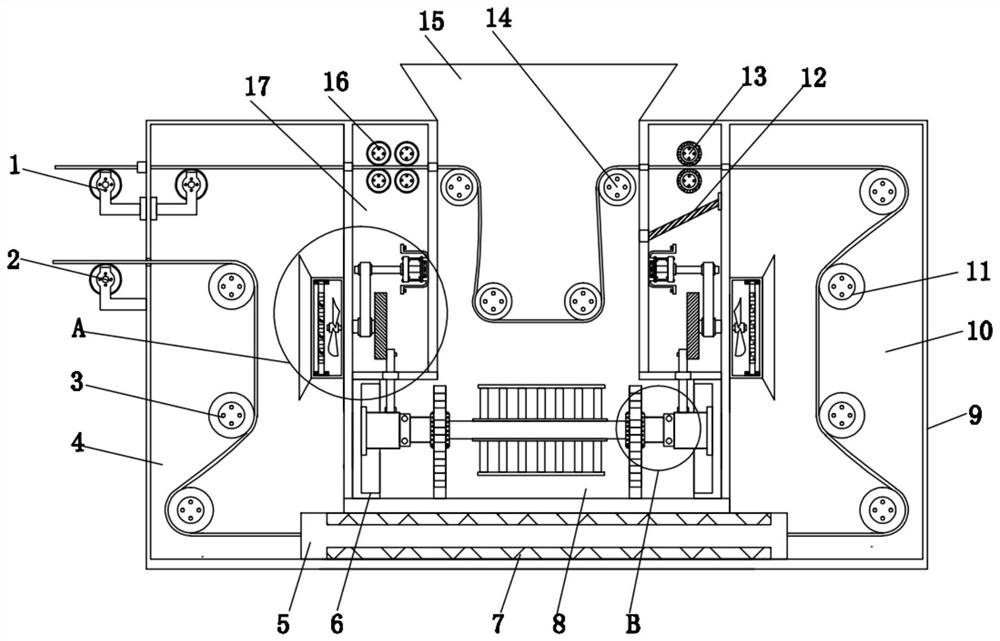

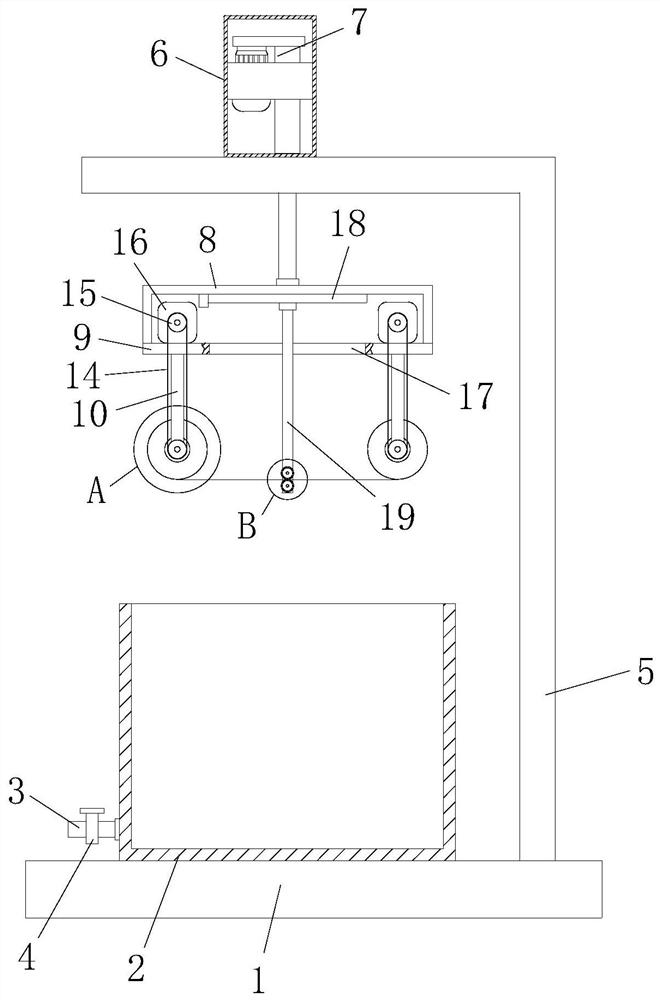

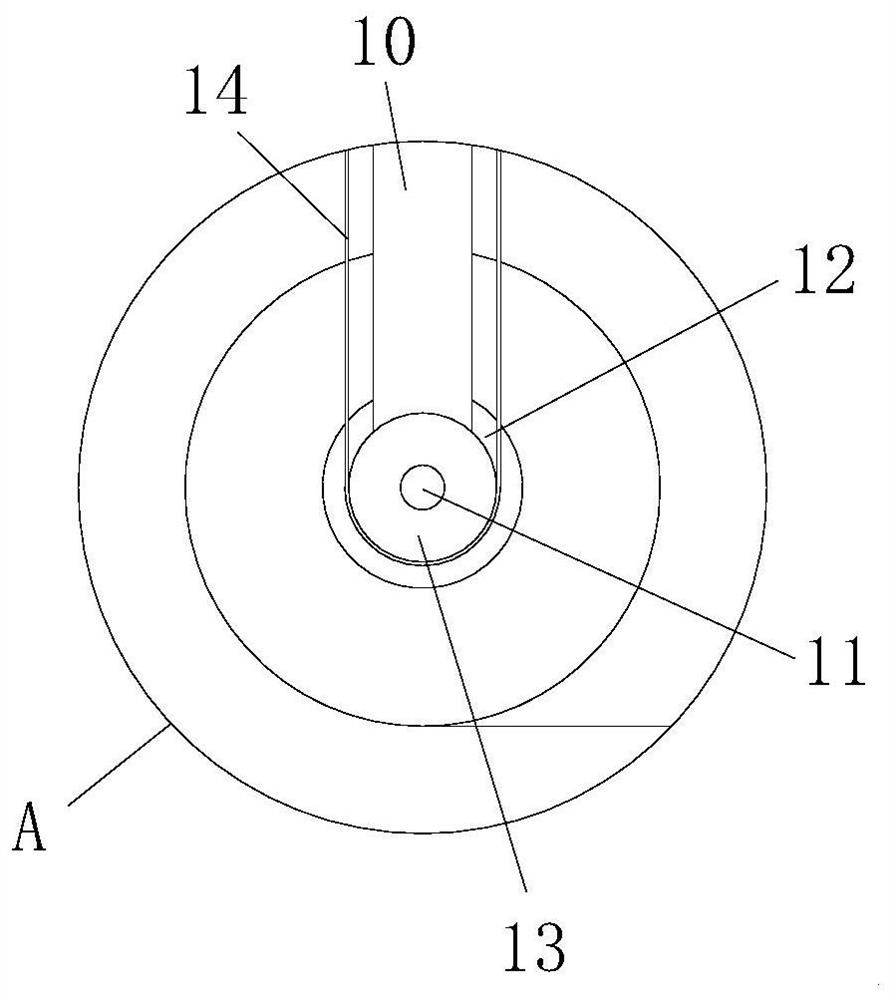

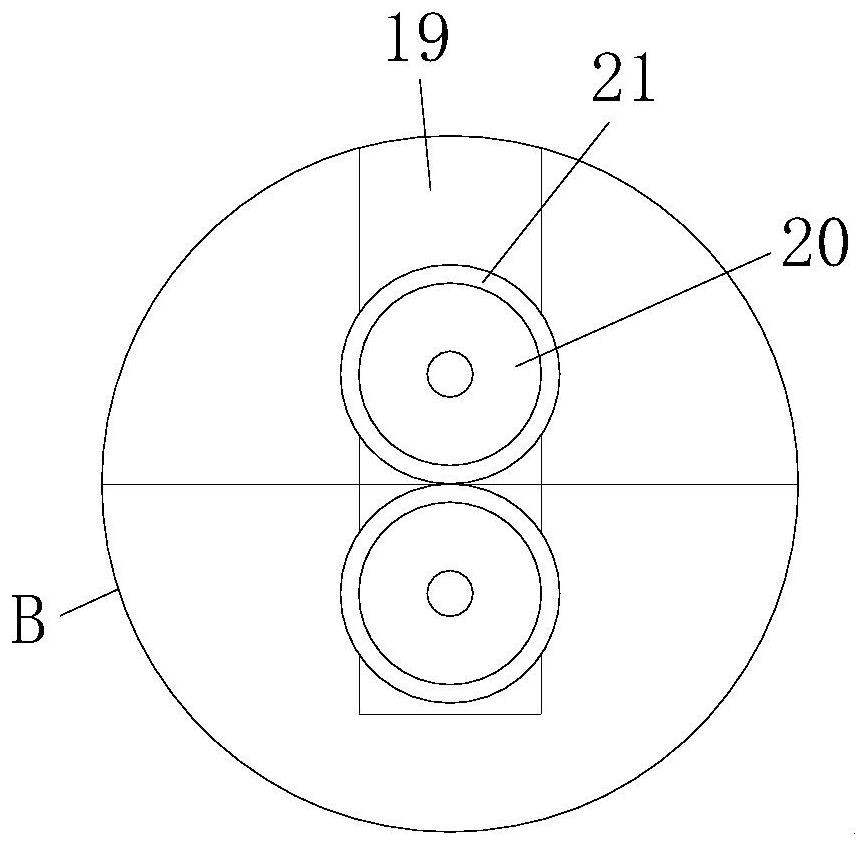

Spiral yarn printing and dyeing equipment

ActiveCN106702633AIncrease productivityExtend dyeing timeLiquid/gas/vapor removalTextile treatment machine arrangementsYarnEngineering

The invention discloses spiral yarn printing and dyeing equipment which comprises a base, a discharge roller, a dyeing and printing chamber, a drying chamber and a pigment tank. The two ends of the bottom of the base are each provided with a support column, a yarn discharge device is installed at a feed inlet formed in the side, close to a discharge base, of the dyeing and printing chamber, the output end of a booster pump is connected with a pigment ejection pipe through a pigment guide pipe, and a bearing structure is installed on the inner side wall of the portion, at the joint of the pigment guide pipe and the pigment ejection pipe, of the dyeing and printing chamber. According to the spiral yarn printing and dyeing equipment, yarn can be spirally wound on a dyeing and printing roller to be dyed through an arranged dyeing and printing roller with a spiral yarn groove, the dyeing time is prolonged, the dyeing uniformity is guaranteed, and the phenomenon that color segments and color points with different lengths and sizes are generated is avoided; meanwhile, pigments can be saved by means of the pigment ejection pipe arranged in the dyeing and printing roller on the premise that the yarn is fully dyed and are greatly saved by cooperating with usage of a pigment recycle tank, the dyeing and printing cost is reduced, and meanwhile the dyeing and printing quality and the yarn dyeing and printing production efficiency are improved.

Owner:海宁鑫港源纺织品有限公司

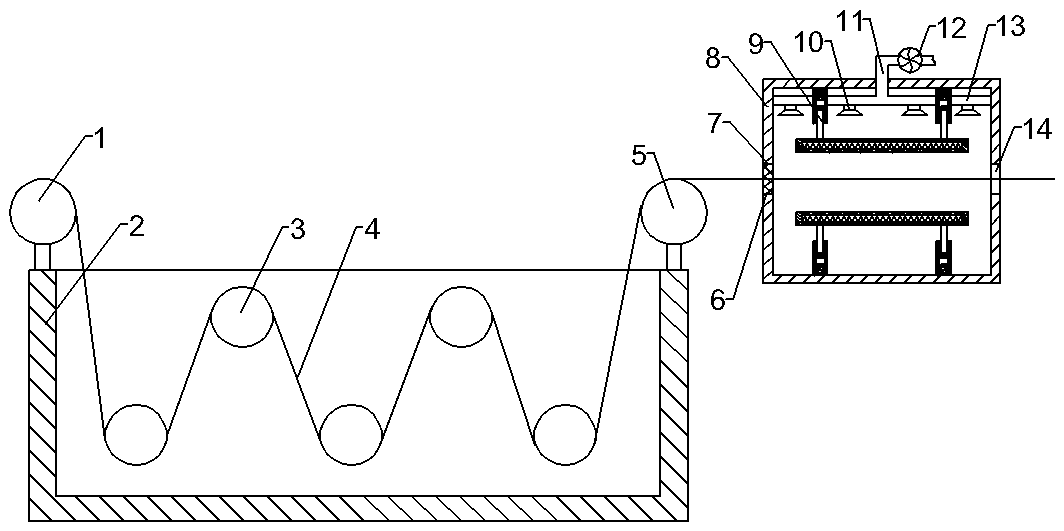

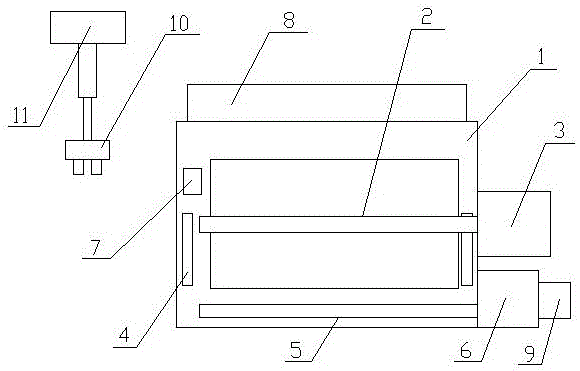

Textile fabric dyeing and drying device with drying distance adjustable function

InactiveCN108360183AExtended contact pathEasy to controlTextile treatment machine arrangementsLiquid/gas/vapor removal by squeezingEngineeringDyeing

A textile fabric dyeing and drying device with a drying distance adjustable function comprises a dyeing tank, a fabric unwinding roller, a fabric winding roller and a drying device. The fabric unwinding roller and the fabric winding roller are arranged on the upper sides of the two sides of the dyeing tank respectively. A plurality of guide rollers are arranged in the dyeing tank. A textile fabricsequentially penetrates through the fabric unwinding roller, the guide roller and the fabric winding roller. The drying device is arranged on the right side of the dyeing tank, and comprises a dryingbox. A fabric inlet and a fabric outlet are formed in the left side wall and the right side wall of the drying box respectively. The textile fabric penetrates through the fabric inlet and the fabricoutlet. A squeezing layer is arranged on the textile inlet. Two heating devices are symmetrically arranged at the upper portion and the lower portion of the drying box. A gas distributing pipe is arranged on the inner top of the drying box and communicated with a gas inlet pipe. The textile fabric dyeing and drying device has the advantages that the contact route of the textile fabric and a dryingagent is lengthened through the guide rollers, the dyeing time and dyeing effect are shortened and improved, then the textile fabric is dried, work efficiency is improved, and processing time is shortened.

Owner:严梓展

Warp-knitting dacron short pile fabric and weaving method thereof

InactiveCN107761242AShrinkage ControlNot easy to shrinkPattern makingWarp knittingFiberChemical treatment

The invention discloses a warp-knitting dacron short pile fabric and a weaving method thereof, and belongs to the technical field of warp-kitting fabric weaving. 50-75D of dacron FDY and dacron DTY composite filaments are adopted as pile yarn, 50D / 24F of polyester silk FDY or polyester silk DTY is adopted as bottom yarn, a two-comb or three-comb Tricot warp knitting machine conducts weaving to obtain gray fabric, then the procedures of pre-shaping, fuzzing process implementation, dyeing, drying, hot trimming and burnt-out are carried out, and after dehydration and drying for shaping are conducted, checking and packaging are carried out. By means of a chemical treatment method for dacron fibers, the effect of forming a three-dimensional pattern diversified in color and different in shape onthe fuzzing surface of the fabric is achieved, the gram weight of the fabric is low, and the fabric has better heat preservation performance and higher comfort degree.

Owner:JIANGSU ZHENYANG GROUP

Large-scale production method of plant indigo dye for garment dyeing

ActiveCN110158329ASolve the problem that it cannot be applied on a large scale to modern garment dyeing machinesImprove color fastness to dry and wet rubbingDyeing processNitrogenEngineering

The invention relates to a large-scale production method of a plant indigo dye for garment dyeing. The plant indigo dye is used in the large-scale production method of garments, nitrogen is filled into a garment dyeing device to remove the air, or the garment dyeing device is vacuumed to form minus 0.05-minus 0.07MPa negative pressure, the garments are then dyed with the plant indigo dye in the garment dyeing device, the dyeing temperature is 26-70DEG C, and the dyeing time is 50-150 minutes. By the arrangement, the problem that the plant indigo dye cannot be applied to a modern garment dyeingmachine on a large scale can be solved, and dyeing times are greatly reduced from traditional 6-18 times repeated dyeing to 1-3 times; the dyeing temperature can be raised so as to improve dye-uptake, level-dyeing property and dye permeability, and the color fastness of dry and wet friction and light resistance of the plant indigo dye are improved.

Owner:苏州麻朵纺织科技有限公司

Dyeing device for silk fabrics

PendingCN107354633ASolution refiningSolve the problem of separate dyeingLiquid/gas/vapor treatment machines driving mechanismsLiquid/gas/vapor removalProduction lineEngineering

The invention discloses a dyeing device for silk fabrics. The dyeing device comprises a box body. One side of the inner wall of the box body is fixedly connected with a heating box, and a heater is fixedly connected to the bottom of the inner wall of the heating box. A first motor, a control box, a fixing agent box, a liquid pump and a second motor are fixedly connected to the bottom of the inner wall of the box body. The first motor is connected with a sliding block through a screw rod, the top of the box body is fixedly connected with a third motor, an output shaft of the third motor is in transmission connection with a first belt pulley and a second belt through a first rotating device, the top of the fixing agent box is fixedly connected with a dye tank, the end of a liquid outlet of the liquid pump communicates with a spray head through an infusion tube, and a drying box is fixedly connected to one side of the inner wall of the box body. The invention relates to the technical field of silk fabric processing. According to the dyeing device for the silk fabrics, the problem that refining and dyeing are performed respectively is solved; after being dyed, the silk fabrics can enter the drying box quickly and efficiently to be dried, a production line space is effectively utilized, and the cost is reduced.

Owner:浙江德清华丝纺织有限公司

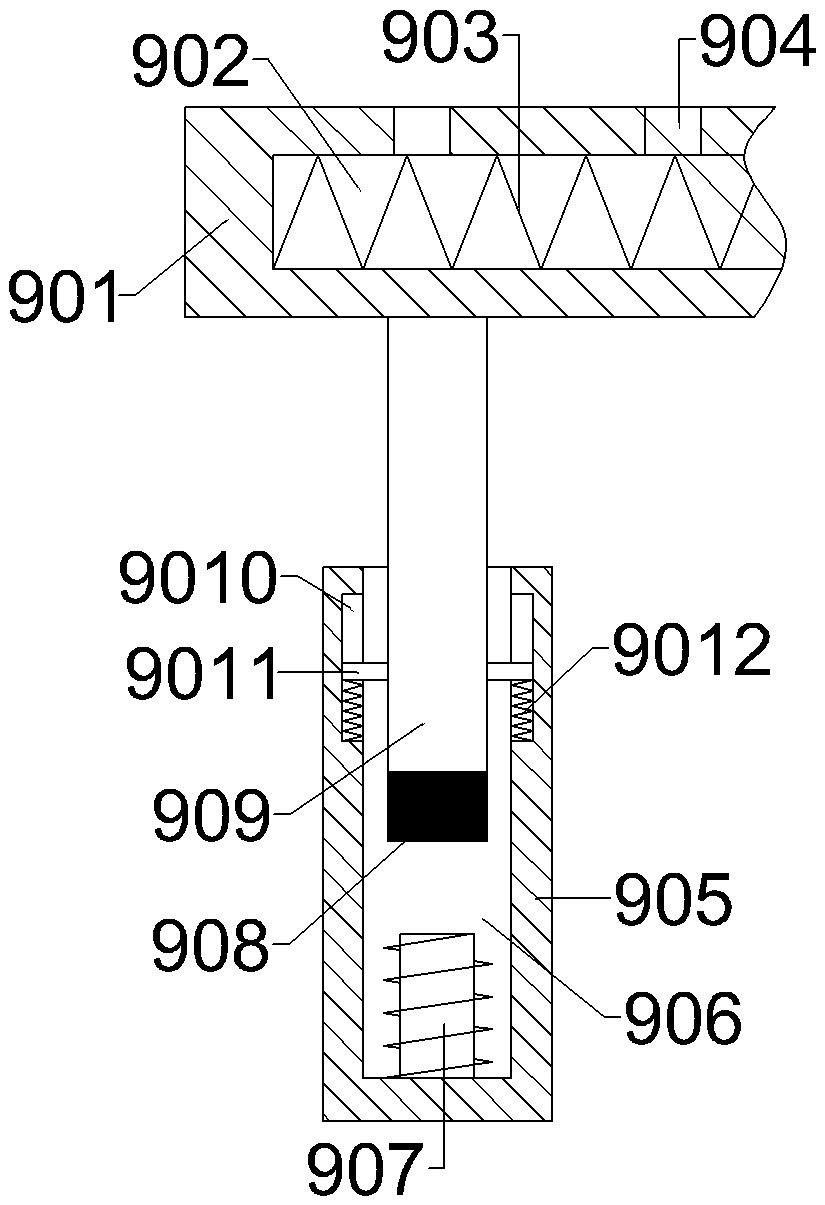

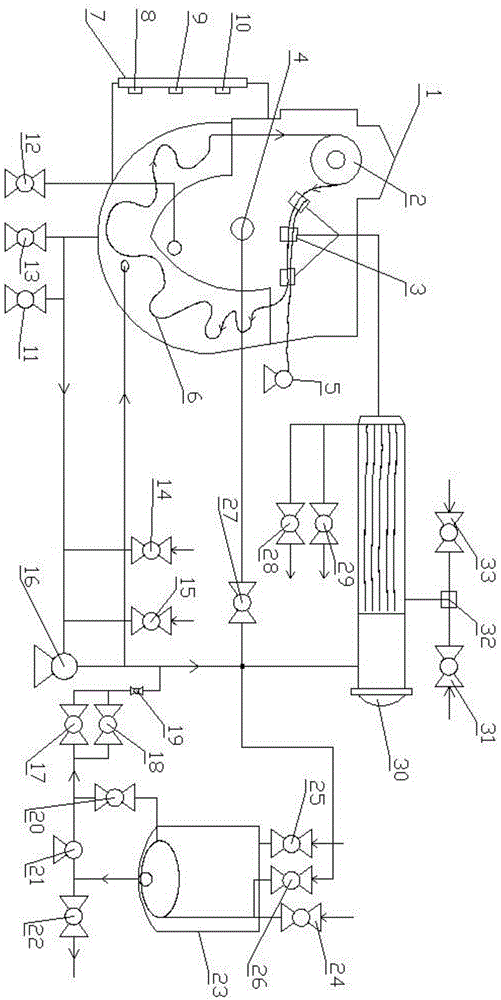

Device for quick dyeing of yarn

InactiveCN105970521AExtend dyeing timeImprove cutting efficiencyTextile treatment machine arrangementsLiquid/gas/vapor yarns/filaments treatmentYarnWater storage tank

The invention provides a device for quick dyeing of yarn. The device comprises a dyeing box, wherein a stirring device is arranged inside the dyeing box, a rotary device is arranged at the right end of the stirring device to drive the stirring device to rotate, and heating devices are arranged in the dyeing box and located on the four walls in the dyeing box; an overturning plate is arranged in the dyeing box and located at the bottom of the dyeing box, and the overturning plate is driven by overturning motors arranged on two sides to overturn. Dip dyeing of yarn is achieved through the dyeing box, yarn is overturned through the stirring device and the overturning plate, and dyeing liquid is heated through the heating devices so that dyeing time is shortened; a water temperature detection device and a cooling water storage tank are arranged to control the temperature of dyeing stuff, yarn is fed through a feeding hand and wound through a rotary motor, and feeding efficiency is improved.

Owner:WUHU FUCHUN DYEING & WEAVING

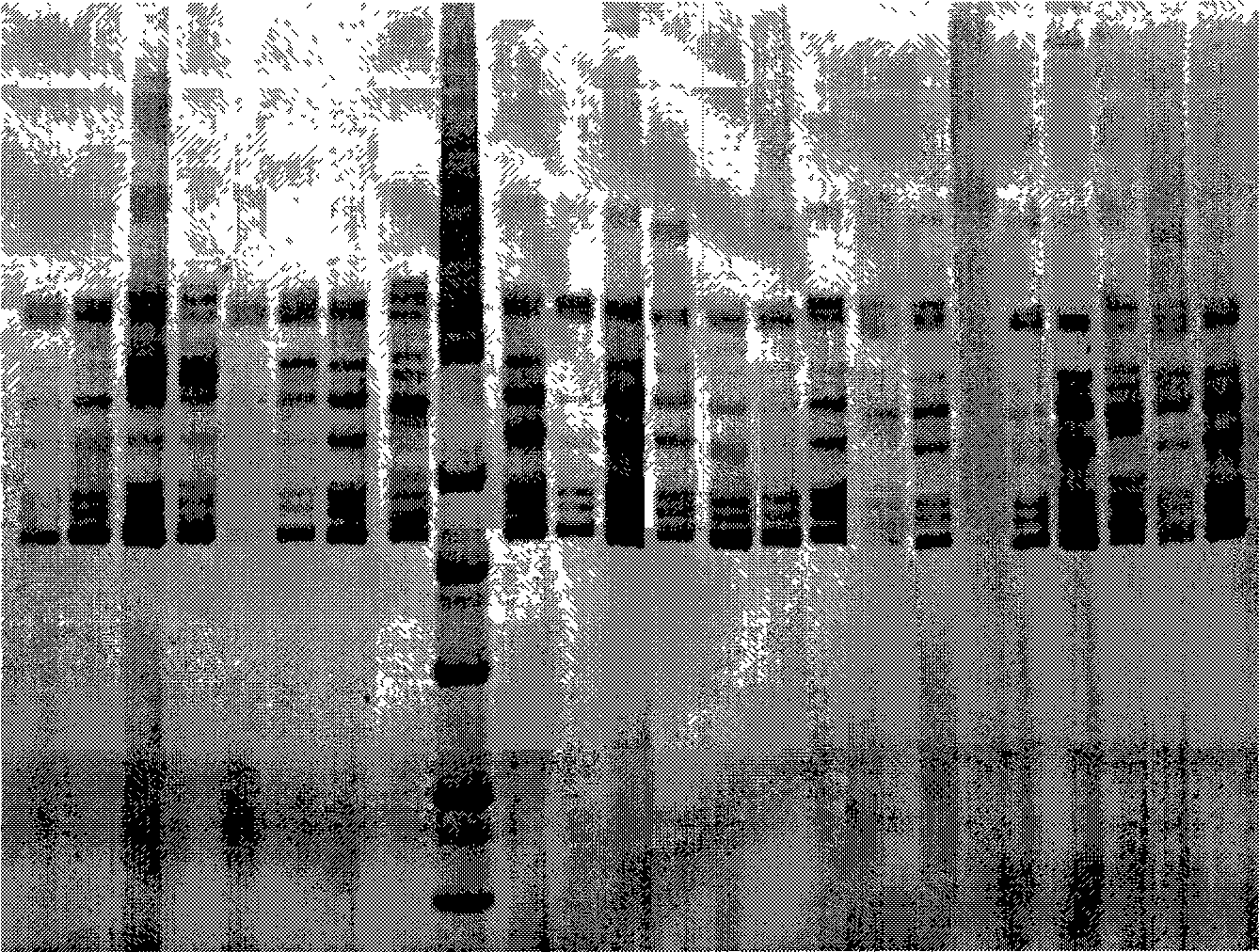

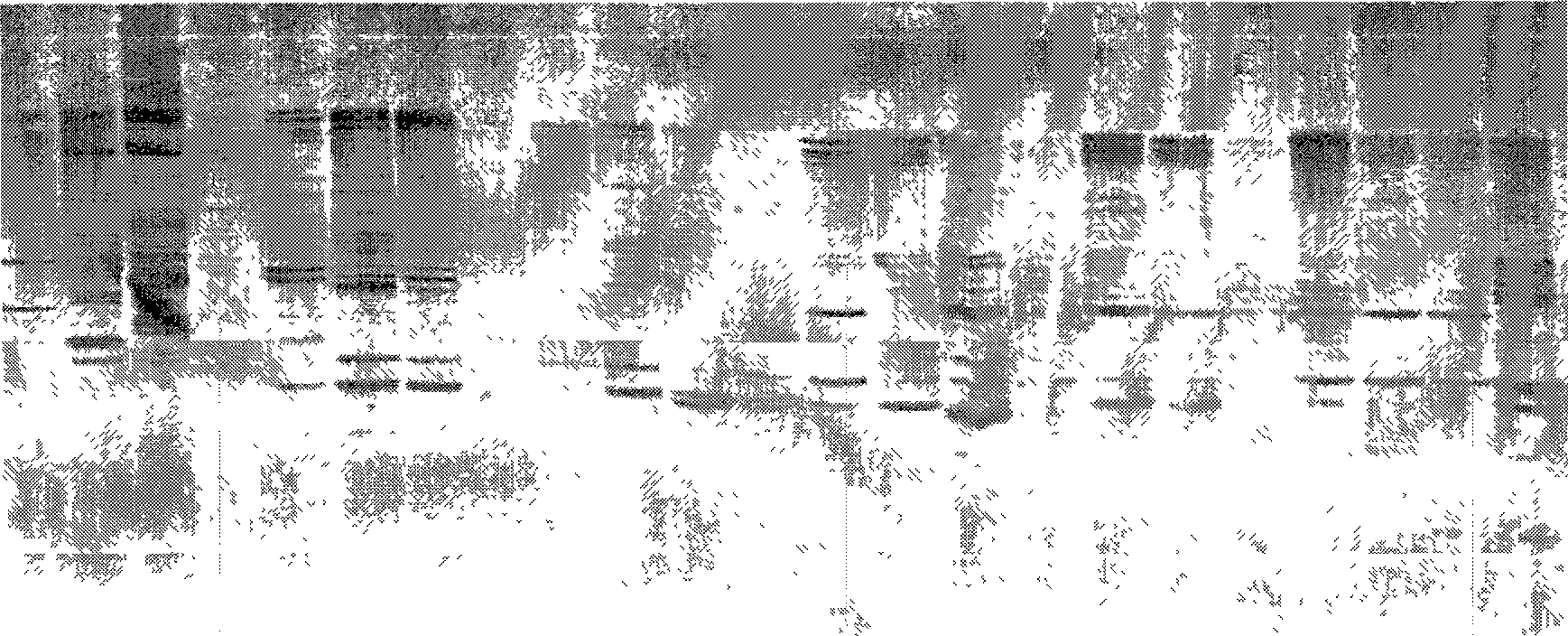

DNA silver staining method

InactiveCN101477001AImprove the development effectAvoid pungent odorsPreparing sample for investigationMaterial analysis by optical meansAcetic acidElectrophoresis

The invention discloses a DNA silver staining method. The method comprises the following steps: (1) cutting off power supply after finishing electrophoresis, pouring a buffer solution out from an electrophoresis tank, then taking off a gel plate, putting the rubber plate into a porcelain dish filled with distilled water, and rinsing the gel plate by the distilled water for 2 to 3 times; (2) carrying out silver staining: adding a staining agent to carry out silver staining, shaking ceaselessly, staining for 8 to 12 minutes, and then rinsing by the distilled water for 2 to 3 times; (3) carrying out developing: adding a developing agent to carry out color development, shaking ceaselessly, and developing for 8 to 12 min; (4) rinsing by the distilled water for 2 to 3 times; and (5) carrying out gel shooting: spreading gelatin onto a X-ray film viewer to take a photo. The method integrates the fixing step and the staining step, adopts ethanol to fix, and overcomes the defects that the belt color is lighter when acetic acid is used for fixing, and the acetic acid has penetrating odor, causticity and so on in the prior sliver staining method. Additionally, the method does not need use ethanol and / or acetic acid to stop developing color, omits the color development stopping step, and solves the problems of penetrating odor and causticity brought by the acetic acid and the like.

Owner:HENAN UNIV OF SCI & TECH

Knitted fabric dyeing method with low living bath ratio

ActiveCN104611952AImprove dyeing water consumptionExtend dyeing timeLiquid/gas/vapor treatment of propelled fabricsBiochemical fibre treatmentLiquid waterHigh energy

The invention belongs to the technical field of textile processing and relates to a knitted fabric dyeing method with a low living bath ratio. The knitted fabric is stained by carrying out steps such as knitted fabric pretreatment, dyeing, knitted fabric after-treatment and finishing in a dyeing system device with a low living bath ratio; a regulation and control process of an ultralow pretreatment liquid water level and dye liquor water level is adopted to achieve energy-saving dyeing; the defects of large water consumption, large dye additive dosage, long dyeing duration and the like of the traditional knitted fabric overflow dyeing method are overcome, and the problems of high pollution and high energy consumption in knitted fabric dyeing are solved; the integral process is simple, the design principle is scientific, the application and operation are safe and reliable, the energy saving and emission reduction effects are good, and the dyeing is environment-friendly.

Owner:QINGDAO FURUNDA TEXTILE

Congo red staining method

ActiveCN105018567ACongo red concentrationIncrease concentrationMicrobiological testing/measurementBiotechnologyColony morphology

The invention discloses a Congo red staining method comprising steps as follows: a sodium carboxymethyl cellulose agar plate medium is coated and inoculated with bacteria, the plate medium is placed in a constant-temperature incubator for culture, and single bacterial colonies with clear morphology grow; target bacterial colonies are marked out according to the morphology of the bacterial colonies; the plate medium where the colonies grow is soaked with a Congo red solution with the concentration of 2-5 mg / mL for 0.5-1 min, and then the Congo red solution is removed; the plate medium is washed with an added sodium chloride solution with the concentration of 1 mol / L for 1-3 times and then soaked with the sodium chloride solution with the concentration of 1 mol / L for 3-5 min, then the sodium chloride solution is poured out, and a yellowish transparent zone can appear around the colonies producing cellulase. Staining and soaking time is shortened, so that the dispersion of the colonies is reduced, the possibility of cross contamination is decreased, and time is saved.

Owner:SHANDONG ORIENTAL OCEAN SCI TECH

Method for performing normal-temperature rapid dip dyeing on seaweed non-woven fabric and enhancing ultraviolet resistance

ActiveCN106049101AImprove hydrophobicitySmall particle sizeLiquid/gas/vapor removalDyeing processUltraviolet lightsNonwoven fabric

The invention relates to a method for performing normal-temperature rapid dip dyeing on a seaweed non-woven fabric and enhancing ultraviolet resistance, in particular to a method for utilizing a copper phthalocyanine pigment to perform rapid dip dyeing on the seaweed non-woven fabric and enhance ultraviolet resistance, and belongs to the technical field of spinning dyeing and printing. According to the method, cationic surfactant cetyltrimethylammonium chloride is utilized to prepare the small copper phthalocyanine pigment stably dispersed in water, the normal-temperature rapid dip dyeing of the seaweed non-woven fabric is achieved, the ultraviolet light transmittance can be remarkably lowered, the ultraviolet protection factor (UPF) of the non-woven fabric is improved remarkably, and thus the ultraviolet resistance of the seaweed non-woven fabric can be enhanced obviously.

Owner:QINGDAO UNIV

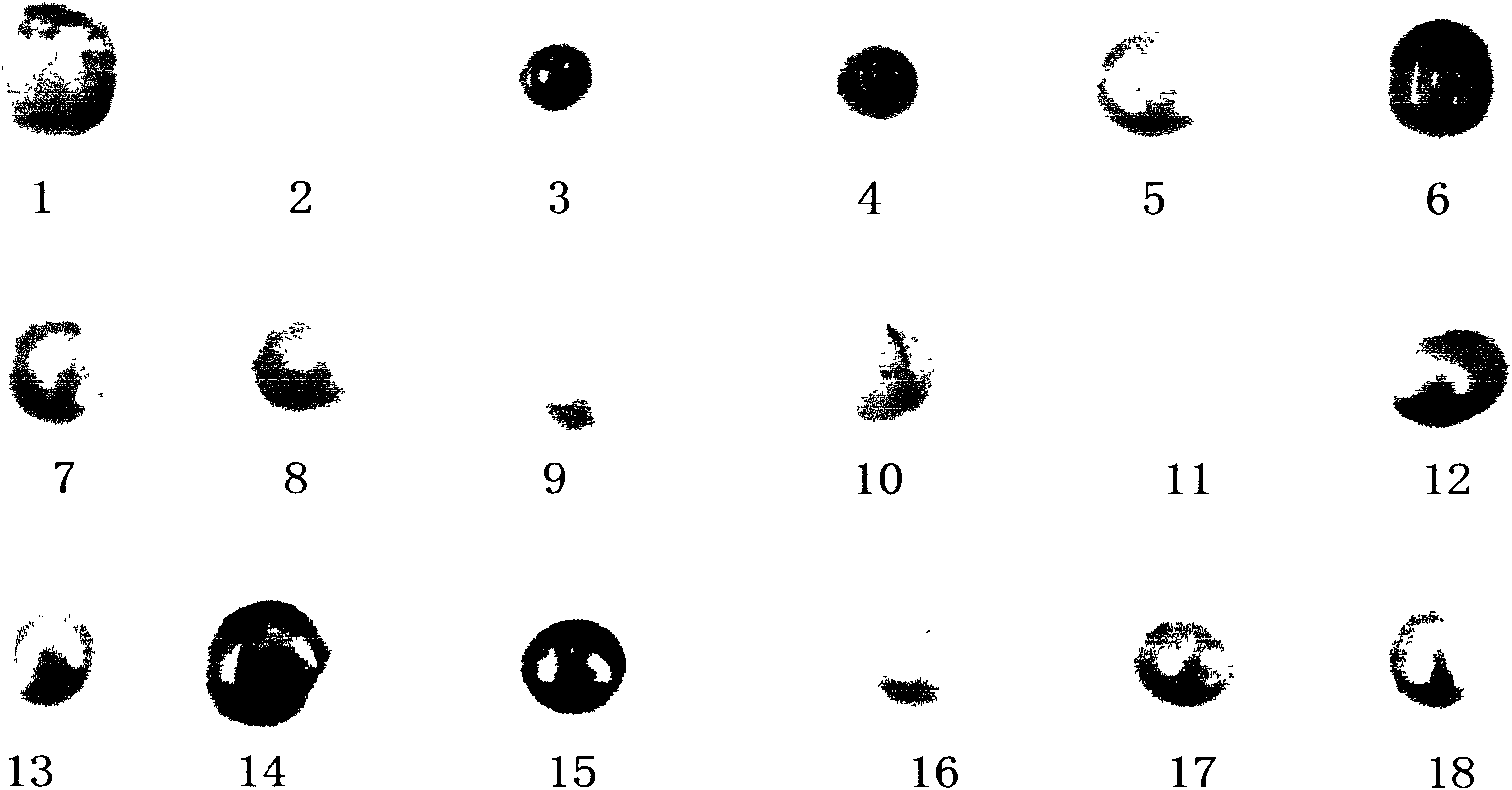

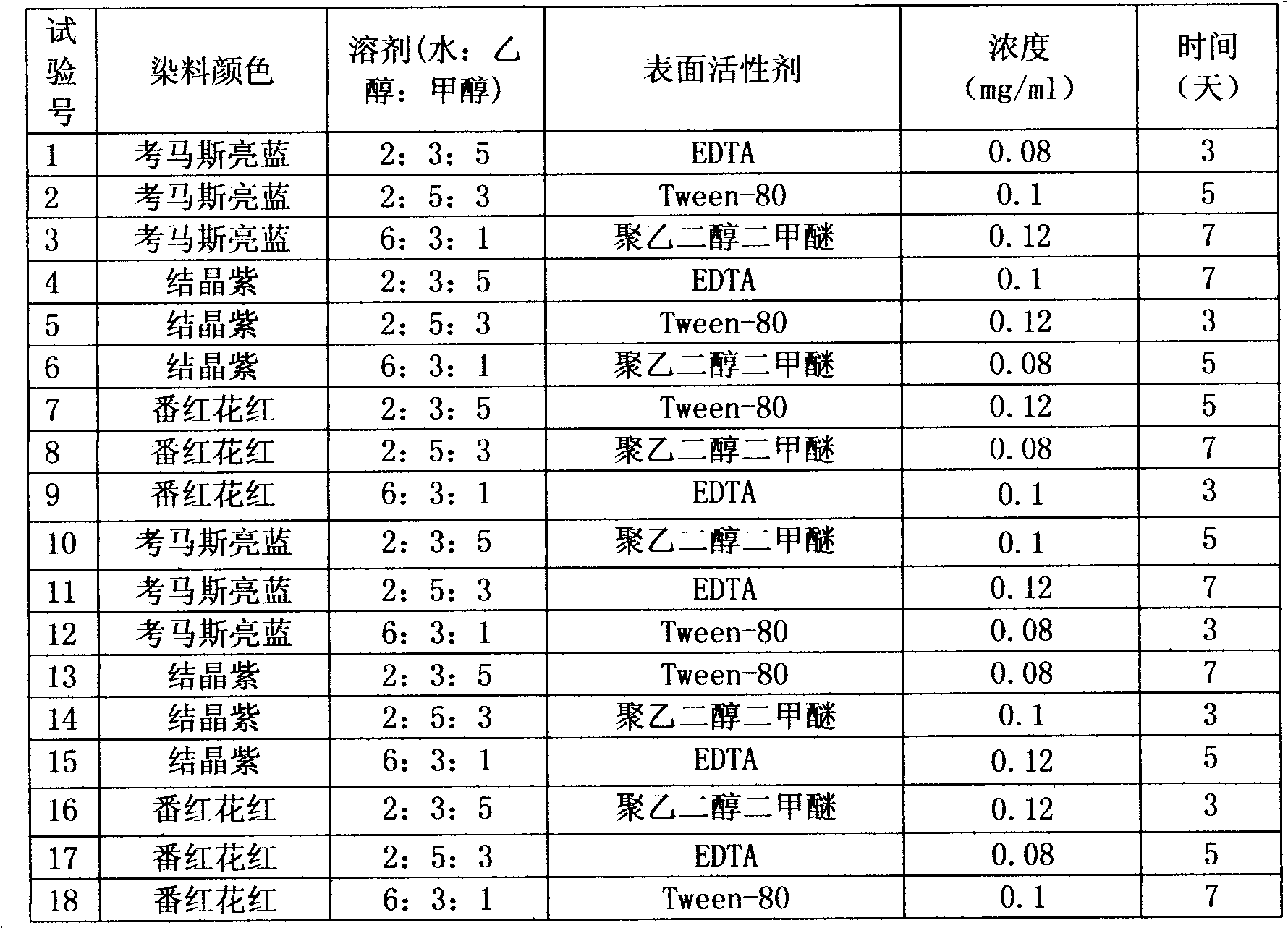

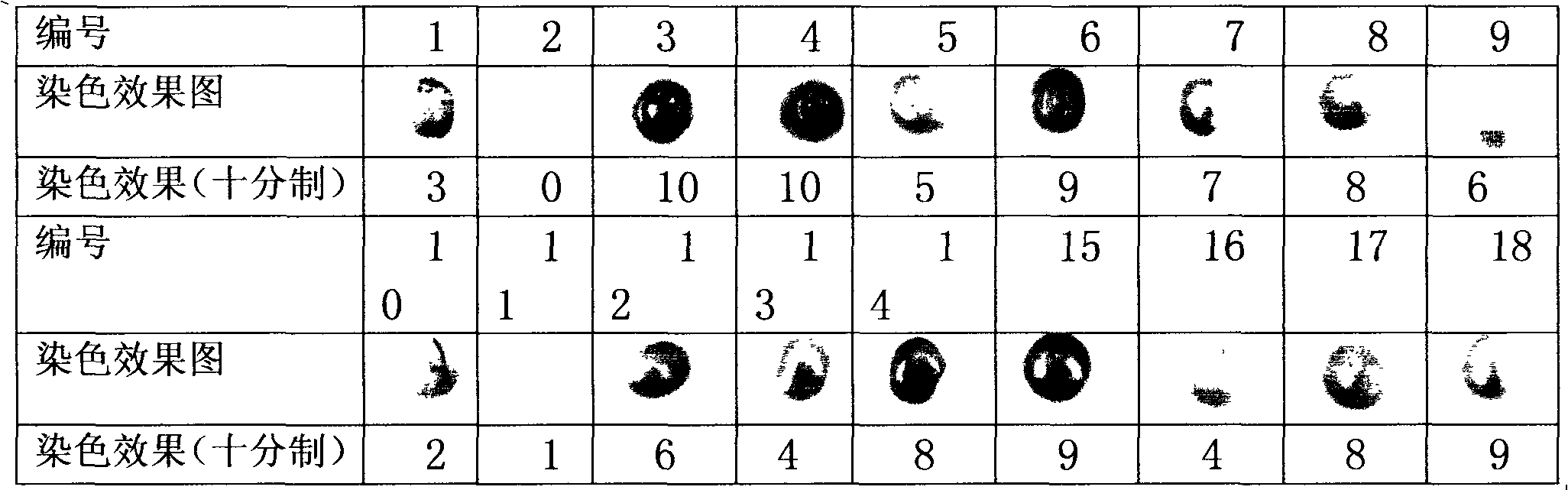

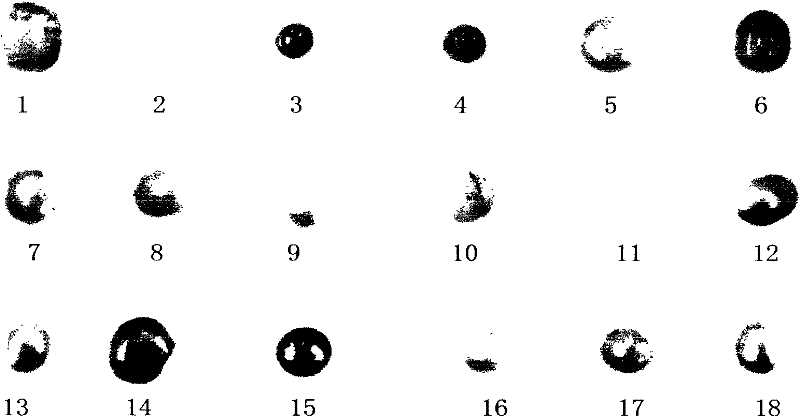

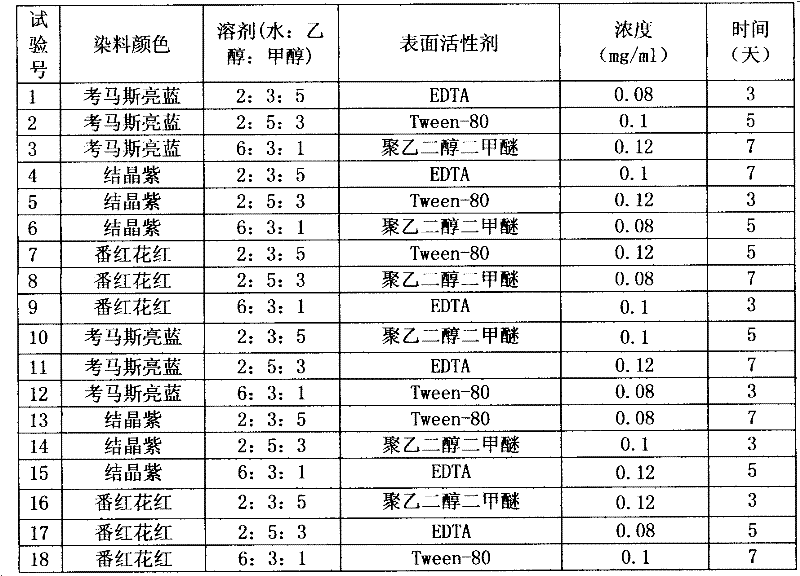

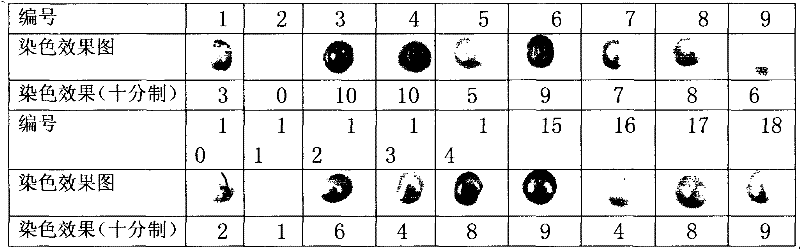

Pearl dyeing method

The invention discloses a pearl dyeing method belonging to the technical field of pearl dyeing. The method comprises the following steps: (1) preliminary treatment of a pearl: soaking a cleaned pearl in oxydol for 12-24 hours, transferring into anhydrous alcohol to carry out first dehydration, and then replacing the anhydrous alcohol once; (2) preparation of a dyeing liquid: preparing water, anhydrous alcohol and anhydrous methanol into a solvent according to a volume ratio of 2-6:3-5:1-5, and adding dye, potassium iodide and surfactant to the solvent; and (3) dyeing of the pearl: impregnating the pretreated pearl in the prepared dyeing liquid, dyeing at a constant temperature of 45 DEG C for 3-7 days, and airing after cleaning to obtain a finished product. The invention has the advantages of uniform dyeing and delicate and bright color.

Owner:SHAOXING UNIVERSITY

One-bath dyeing process for cotton and linen blended fabric by using natural vegetable dye

The invention discloses a one-bath dyeing process for a cotton and linen blended fabric by using natural vegetable dye. The one-bath dyeing process comprises the following steps: firstly, carrying out low-temperature treatment on the cotton and linen blended fabric; secondly, finishing boiling off, bleaching and dyeing at a time by adopting a one-bath treatment process. According to the one-bath dyeing process, a process flow is shortened, the discharge amount of wastewater is reduced, energy consumption is reduced, and the national requirements of energy conservation, consumption reduction, and reduction of discharge amount of the wastewater and waste gases on a textile industry are met; no organic solvent is used in the whole dyeing process, so that the harm to a human body and environment is little; a one-bath treatment solution can be repeatedly used, so that the discharge mount of the wastewater can be reduced; the dyeing color difference can be remarkably reduced by prolonging the one-bath treatment time; after the solution is treated by adopting a one-bath method and is subjected to color fixing by a sodium silicate solution, so a color fixing effect is excellent, the dyeing rate can reach 95 percent or above, and the color fixing rate also can reach 90 percent or above.

Owner:长兴锦桥纺织有限公司

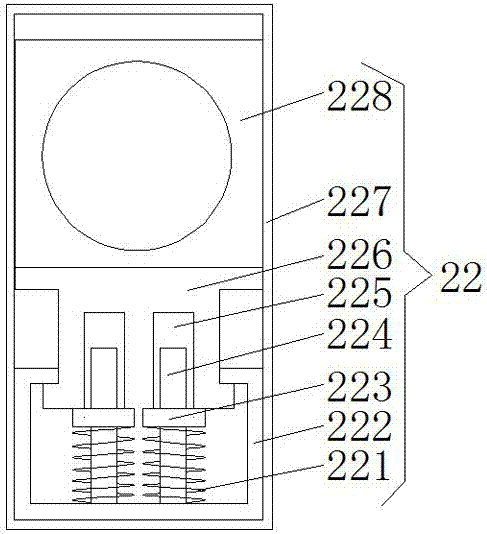

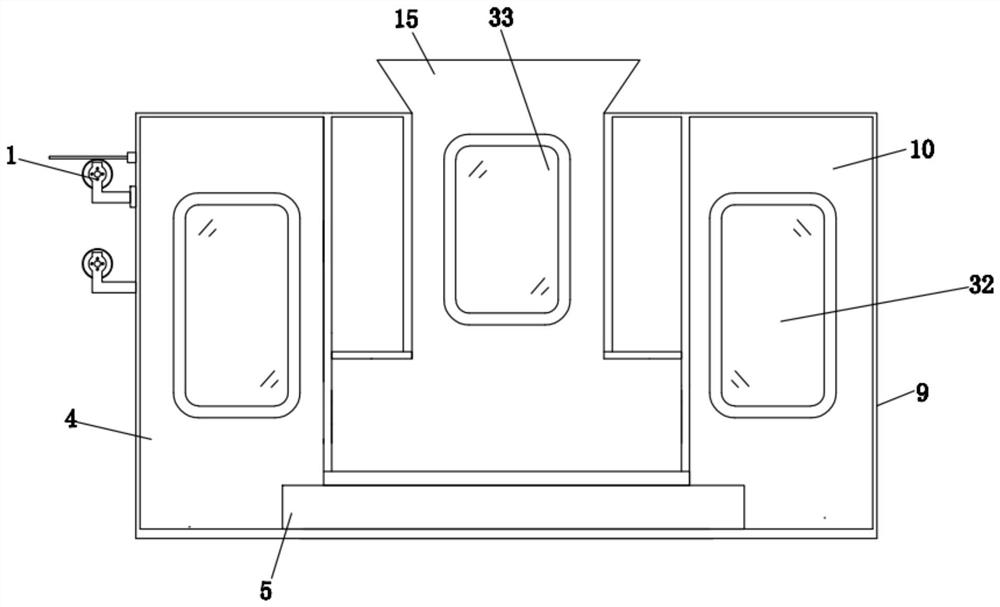

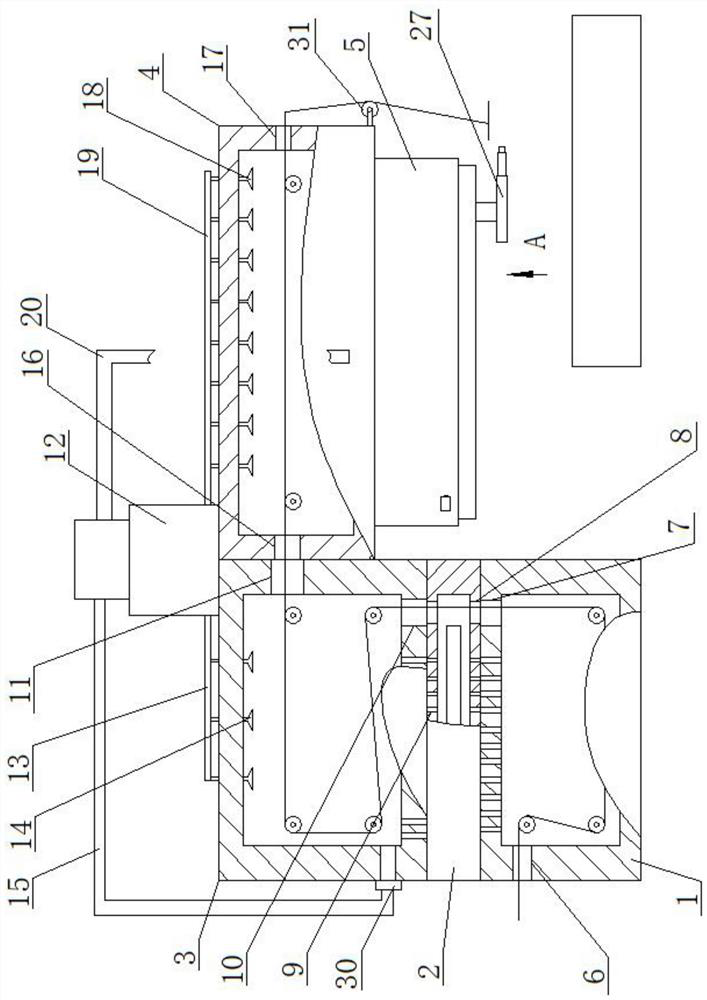

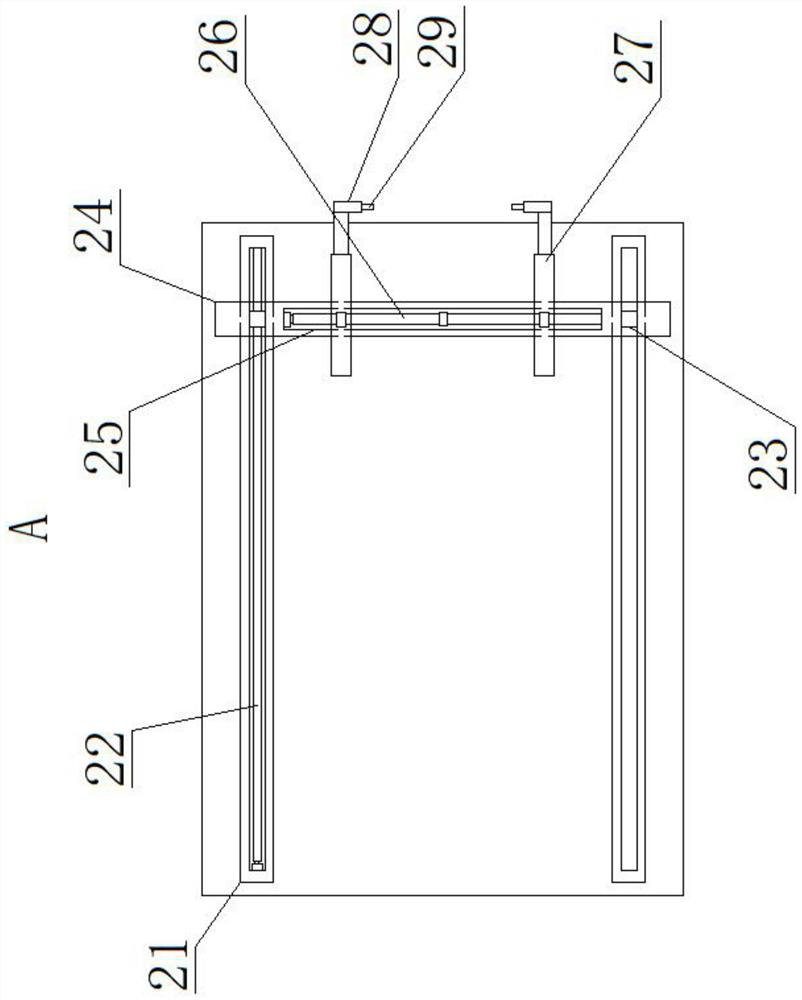

Novel cloth dyeing device for textile

InactiveCN111910362AExtend dyeing timeExtend heating timeLiquid/gas/vapor removal by squeezing rollersTextile treatment machine arrangementsMechanical engineeringDyeing

The invention discloses a novel cloth dyeing device for a textile. The device comprises a first drying chamber, a dyeing chamber, a body and a second drying chamber, a supporting plate is arranged inthe middle of the bottom in the body, the dyeing chamber is arranged at the top of the supporting plate, and mounting grooves are oppositely formed at the upper end of the inner wall of the dyeing chamber. One end of a rotating shaft extends into a gas hood and is provided with a fan, a driving mechanism used for enabling the fan to rotate is arranged in the mounting groove, a limiting roller is arranged in the middle of the interior of the dyeing chamber, a first conveying roller is arranged in the first drying chamber, the second drying chamber is arranged at the portion, at the other side of the dyeing chamber, in the body, and a second conveying roller is arranged in the second drying chamber. Through ingenious design of the structure, the dyeing quality and the drying effect are improved, and meanwhile the device is small in occupied size and convenient to carry and move.

Owner:岑田淼

Efficient cloth dyeing device for garment processing

ActiveCN112048860AImprove dyeing effectTo achieve the purpose of recyclingLiquid/gas/vapor removal by squeezing rollersTextile treatment machine arrangementsProcess engineeringMechanical engineering

The invention discloses an efficient cloth dyeing device for garment processing. The efficient cloth dyeing device comprises a dyeing box, a filter box, a first box body, a second box body and a collecting box, wherein the filter box is installed at the top of the dyeing box, the first box body is installed at the top of the filter box, the second box body is installed on one side of the first boxbody, the collecting box is installed at the bottom end of the second box body, a feeding port is formed in the left side of the dyeing box, a plurality of first rollers are movably installed insidethe dyeing box, a discharging port is formed at the right side of the top of the dyeing box, and through grooves are formed in the right side of the bottom of the filter box and the right side of thetop of the filter box. According to the efficient cloth dyeing device, the dyeing time can be prolonged in the dyeing process, and namely, redundant dye moves upwards along with cloth and then flows back into the dyeing box under the action of gravity; in the preheating process, the dyeing effect can be enhanced, and the temperature of the cloth can be increased; and in the subsequent drying process, the efficiency is improved, and the extruded dye enters the filter box through through holes above firstly, is filtered by a filter plate and enters the dyeing box, so that the waste of the dye isavoided.

Owner:WENZHOU POLYTECHNIC

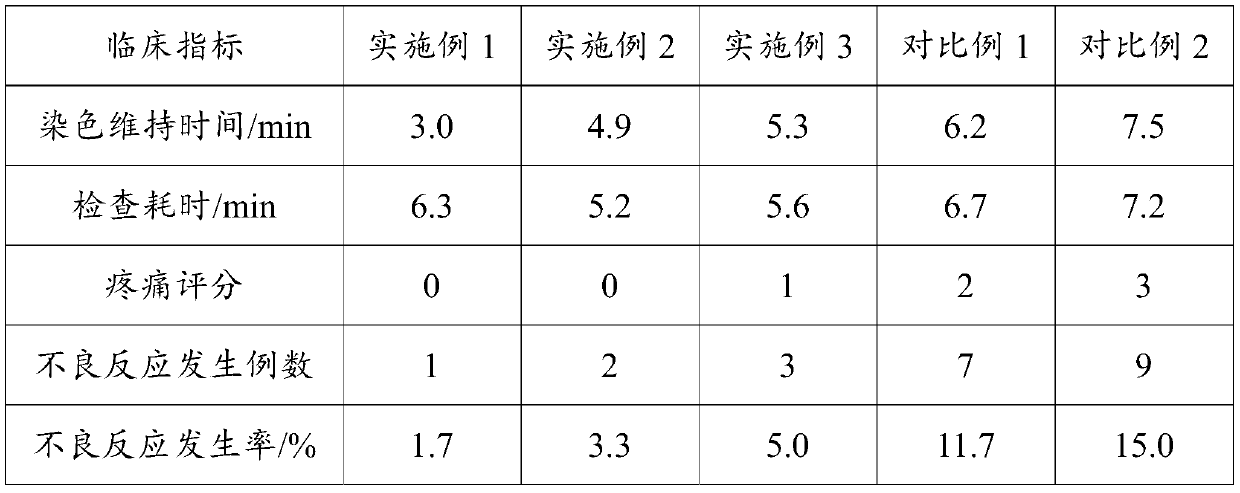

Staining agent for early diagnosis of esophageal cancer and preparation method of staining agent

ActiveCN110201190ALess irritatingReduce drug riskLuminescence/biological staining preparationPharmaceutical non-active ingredientsSocial benefitsMedicine

The invention discloses a staining agent for early diagnosis of esophageal cancer, a preparation method of the staining agent, and application of xanthan gum in an iodine staining agent for living body staining. The staining agent comprises the following components in percentages by weight: 0.05-0.1% of xanthan gum, 0.5-1% of iodine, 1.25-1.5 times of iodine weight of potassium iodide, and the balance of water. A certain proportion of xanthan gum is compounded with the iodine and the potassium iodide, the content of the iodine and the potassium iodide is reduced, meanwhile, enough dyeing timecan be provided, the influence on patients is small, the staining agent is safe to us, examination time can be effectively saved, the dosage of anesthetic drugs is reduced, the examination indicationis expanded, the preparation cost is low, and good economic and social benefits are achieved.

Owner:施瑞华

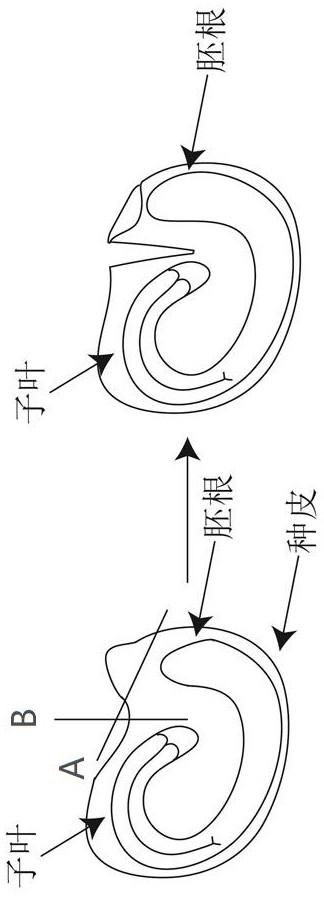

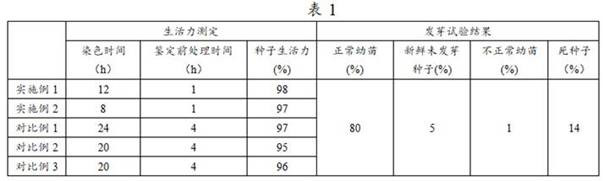

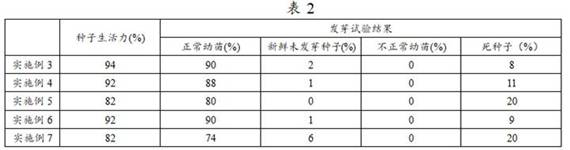

Tetrazole determination method for viability of sweet pepper seeds

The invention discloses a tetrazole determination method for viability of sweet pepper seeds, and belongs to the technical field of quality inspection of crop seeds. The tetrazole determination method for viability of the sweet pepper seeds comprises the following steps that clean sweet pepper seeds are soaked in clear water for 12-18 hours, and then taken out; one third of the seeds are longitudinally cut in the direction of radicles and cotyledon tips along a flat plane, meanwhile, seed coats close to base parts of the seeds are cut off, the radicles are not damaged, and therefore embryo cavities of the seeds are opened; the treated seeds are put into a tetrazole solution which is prepared from a phosphate buffer solution and has a mass concentration of 1.0%, and dyed for 6-12 hours in a dark place at a constant temperature of 30-35 DEG C; and after dyeing is finished, the seeds are washed with tap water for 2-3 times, and the flat surfaces of the seeds are extruded with tweezers, so that the radicles are extruded from the embryo cavities along notches of the base parts, and whether the seeds have viability or not is judged according to the coloring condition of the radicles. The invention provides a simple and feasible method for inspecting the quality of the sweet pepper seeds, the identification standard is visual, the result is reliable, and the seed quality identification in the production and circulation of the sweet pepper seeds is convenient.

Owner:LANZHOU UNIVERSITY

Method for slicing heavy leather blade paraffin

InactiveCN102175482BIncrease the number of levelsExtend dyeing timeWithdrawing sample devicesPreparing sample for investigationWaxParaffin oils

The invention discloses a method for slicing heavy leather blade paraffin and relates to a method for slicing plant paraffin. Operating procedures include fixing, dehydrating, transparentizing, paraffin infiltration, embedding, slicing, dewaxing, dyeing and mounting. In the splicing process of the heavy leather blade paraffin, a fixing agent, a dehydrating procedure, a transparentizing procedure,a paraffin infiltration method, a dyeing method and mounting are improved, i.e., selection of the fixing agent, determination of the dehydrating procedure, determination of the transparentizing procedure, determination of the dewaxing procedure, the dyeing method and the mounting method are improved. The method is also suitable for other blades with different thicknesses and properties. By adopting the method, slice manufacturing of blade paraffin with different thicknesses and properties can be realized practically, and a uniform and practical manufacturing method for theoretical manufacturing of paraffin is popularized.

Owner:XIAMEN UNIV

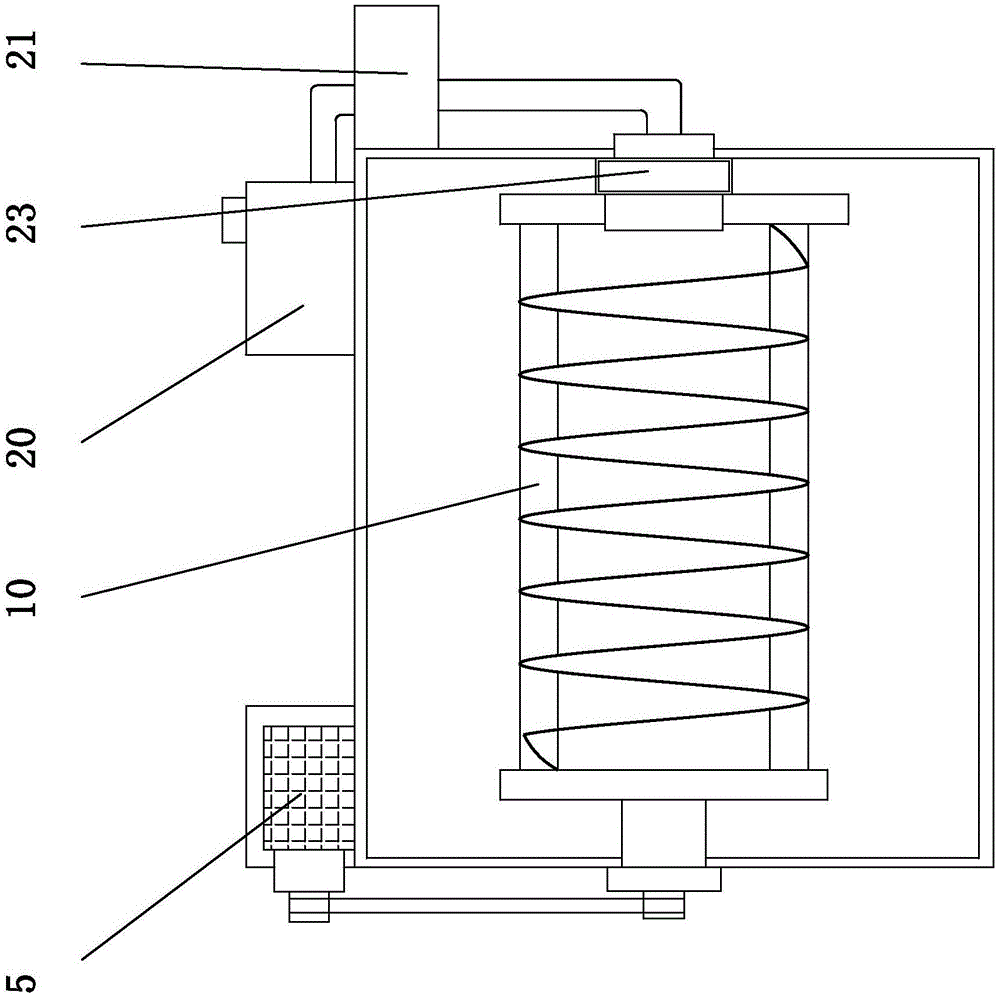

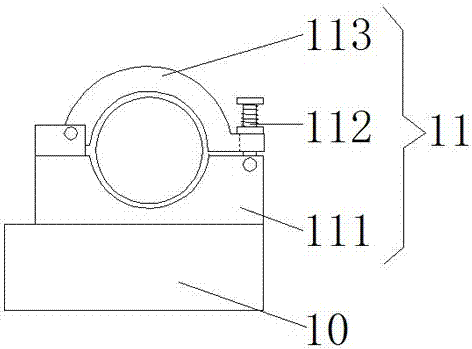

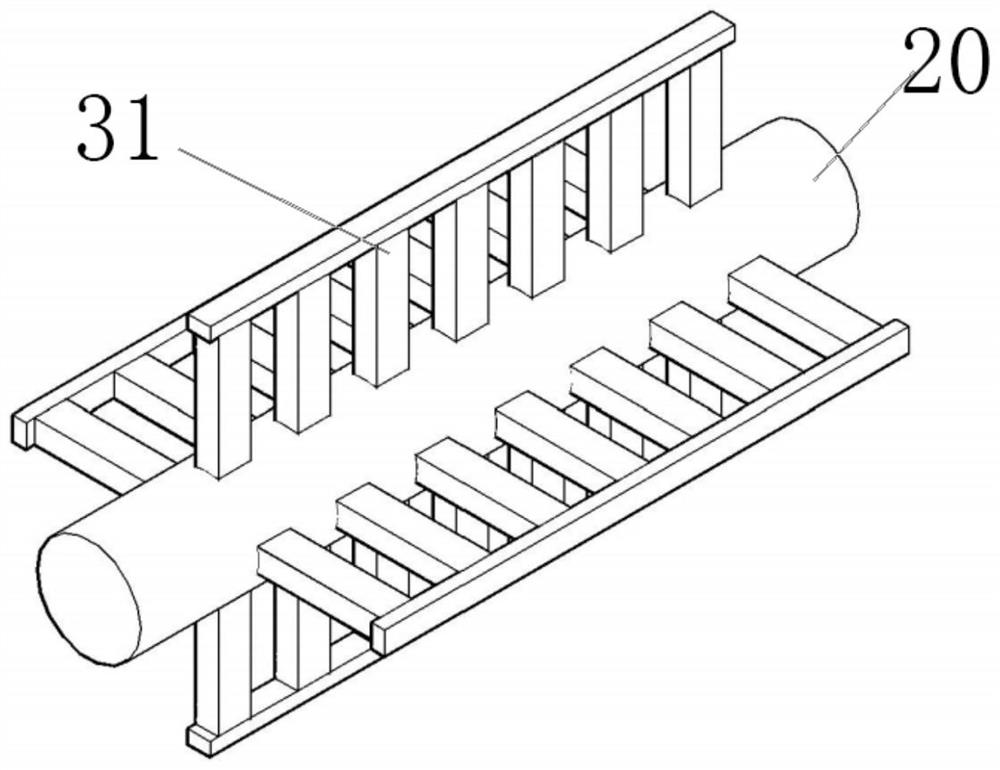

Dyeing device for non-woven fabric production

InactiveCN112080879AExtend dyeing timeUniform dyeingLiquid/gas/vapor treatment machines driving mechanismsLiquid/gas/vapor removal by squeezing rollersElectric machineryWoven fabric

The invention discloses a dyeing device for non-woven fabric production. The dyeing device comprises a base, a support, a machine box, an electric push rod and a top frame, wherein the support is fixedly connected to one side of the top of the base, the machine box is fixedly connected to the top of the support, the electric push rod is fixedly connected to the interior of the machine box, and anoutput shaft of the electric push rod movably penetrates through the bottom of the machine box and the top of the support and is arranged below the top of the support. According to the dyeing device,non-woven fabric can be immersed into dye through the electric push rod, and two rotating rollers can be kept rotating continuously under the driving of two stepping motors, so that the non-woven fabric is dyed more uniformly, and the problem that an existing dyeing device cannot be used for dyeing uniformly during dyeing is solved; and two extrusion rollers are driven by a linear module to move,and dye in the non-woven fabric can be extruded out, so that the situation that the drying time is prolonged due to excessive moisture in the non-woven fabric in the later drying process is avoided.

Owner:邓才芳

Pearl dyeing method

The invention discloses a pearl dyeing method belonging to the technical field of pearl dyeing. The method comprises the following steps: (1) preliminary treatment of a pearl: soaking a cleaned pearl in oxydol for 12-24 hours, transferring into anhydrous alcohol to carry out first dehydration, and then replacing the anhydrous alcohol once; (2) preparation of a dyeing liquid: preparing water, anhydrous alcohol and anhydrous methanol into a solvent according to a volume ratio of 2-6:3-5:1-5, and adding dye, potassium iodide and surfactant to the solvent; and (3) dyeing of the pearl: impregnating the pretreated pearl in the prepared dyeing liquid, dyeing at a constant temperature of 45 DEG C for 3-7 days, and airing after cleaning to obtain a finished product. The invention has the advantages of uniform dyeing and delicate and bright color.

Owner:SHAOXING UNIVERSITY

A kind of plant blue indigo dye is used for the large-scale production method of garment dyeing

ActiveCN110158329BPrevent oxidationSolved the problem that the vegetable indigo dye could not be usedDyeing processEngineeringIndigo dye

Owner:苏州麻朵纺织科技有限公司

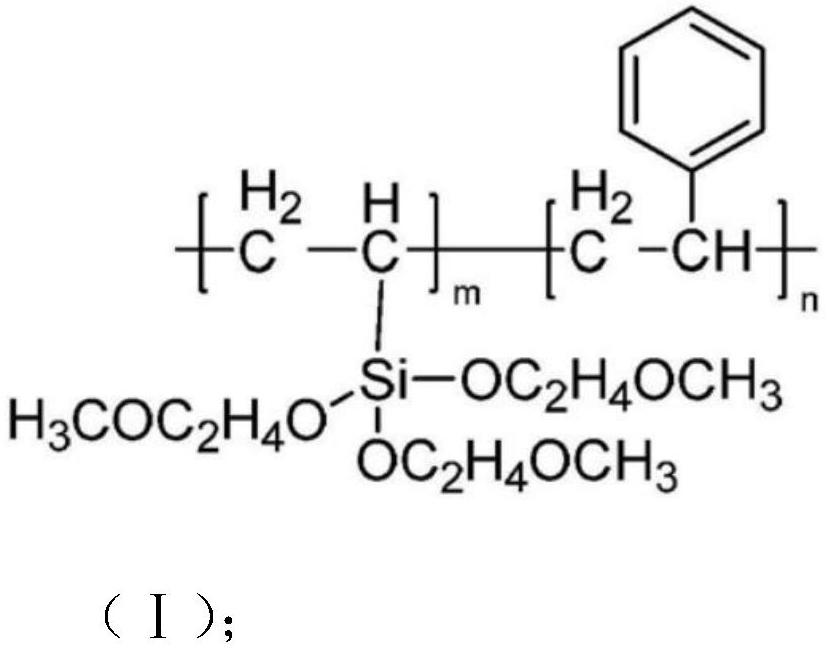

A functional compound dyeing acid

The invention discloses a functional compound dyeing acid, which comprises the following components: glacial acetic acid, formic acid, EDTA, penetrant, modified graphene oxide, dispersant and deionized water. The acid component of the compound dyeing acid is mainly provided by glacial acetic acid and formic acid. In order to reduce the influence of the dye on the dyeing acid, a complexing agent EDTA is added, and the addition of a penetrating agent can improve the penetration effect of the dyeing acid and shorten the dyeing time; and this The silicon-containing modified graphene oxide and silicon-containing hyperdispersant used in the invention can not only significantly improve the dispersion effect of dyeing acid, shorten the dyeing time, reduce the amount of dyeing auxiliaries, but also reduce the yellowing of fabrics caused by formic acid Effect, thereby enhancing the vividness of fabric dyeing.

Owner:华维新材料科技(杭州)有限公司

A method for fast dip-dyeing of seaweed non-woven fabric at room temperature and enhancing anti-ultraviolet performance

ActiveCN106049101BImprove hydrophobicitySmall particle sizeLiquid/gas/vapor removalDyeing processUltraviolet lightsNonwoven fabric

The invention relates to a method for performing normal-temperature rapid dip dyeing on a seaweed non-woven fabric and enhancing ultraviolet resistance, in particular to a method for utilizing a copper phthalocyanine pigment to perform rapid dip dyeing on the seaweed non-woven fabric and enhance ultraviolet resistance, and belongs to the technical field of spinning dyeing and printing. According to the method, cationic surfactant cetyltrimethylammonium chloride is utilized to prepare the small copper phthalocyanine pigment stably dispersed in water, the normal-temperature rapid dip dyeing of the seaweed non-woven fabric is achieved, the ultraviolet light transmittance can be remarkably lowered, the ultraviolet protection factor (UPF) of the non-woven fabric is improved remarkably, and thus the ultraviolet resistance of the seaweed non-woven fabric can be enhanced obviously.

Owner:QINGDAO UNIV

Lace bi-color thick plied yarn of nylon-wrapped cotton-core thread and dyeing method of lace bi-color thick plied yarn

ActiveCN108086024AExtend dyeing timeHigh energy consumptionDry-cleaning apparatus for textilesDyeing processCotton threadYarn

The invention provides a lace bi-color thick plied yarn of a nylon-wrapped cotton-core thread and a dyeing method of the lace bi-color thick plied yarn. The dyeing method comprises first-section dyeing, first-section dyeing aftertreatment, second-section dyeing and second-section dyeing aftertreatment. According to the technical scheme, sufficient dyeing of a cotton thread in a plied yarn core isrealized mainly by changing a dyeing process and adding sequences of both of a dyeing dye and an additive. Sufficient permeation of the plied yarn is realized on the precise of neither prolonging thedyeing time nor increasing energy consumption. Stable colors are obtained, mutual color crossing is less and follow-up physical performance is favorable.

Owner:FUZHOU DESHENG KNITTING & DYEING CO LTD

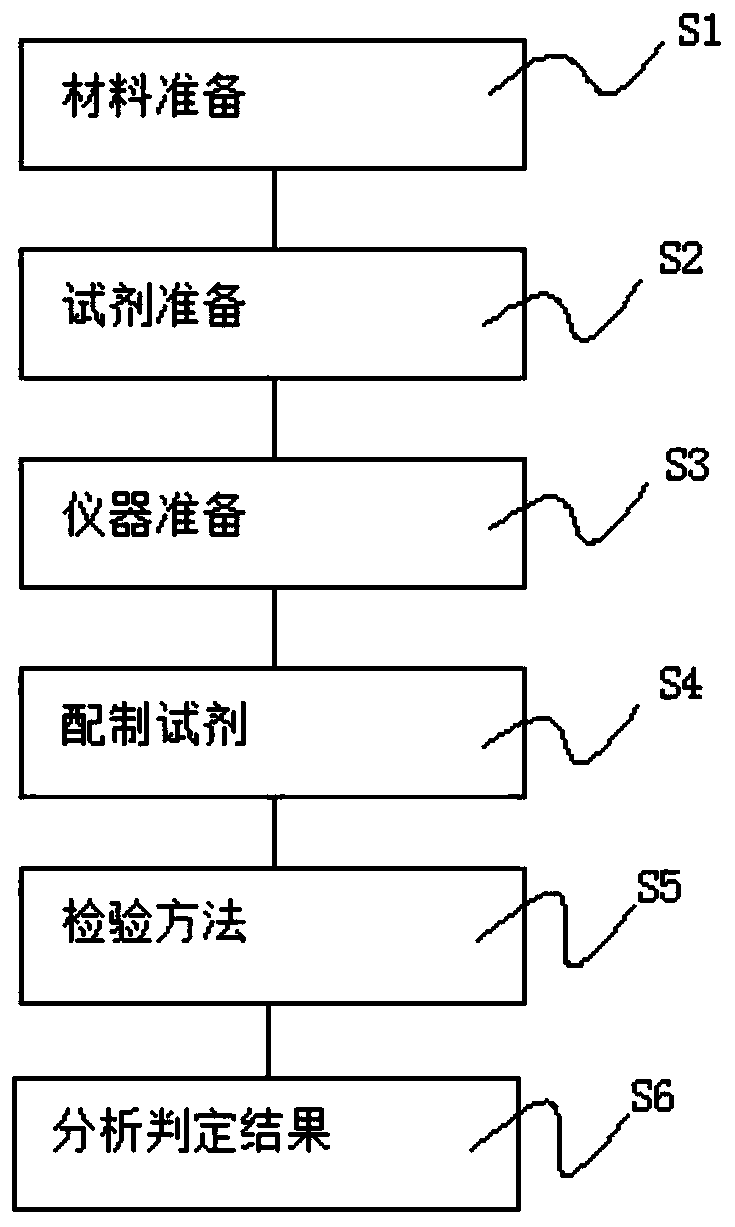

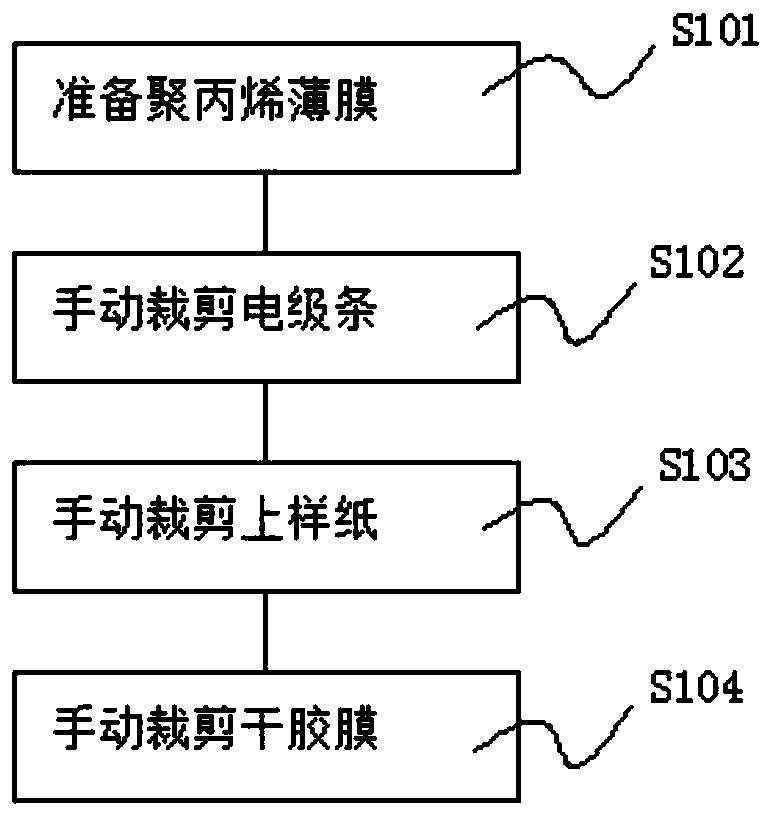

Isoelectric focusing electrophoresis isoelectric point detection method of recombinant protein

InactiveCN110554081AThe result is scientific and reasonableHave pursuasive powerMaterial analysis by electric/magnetic meansMaterials preparationElectrophoresis

The invention discloses an isoelectric focusing electrophoresis isoelectric point detection method for recombinant protein. The isoelectric focusing electrophoresis isoelectric point detection methodcomprises the following steps: s1, material preparation, various materials used in the experiment are prepared properly so as to ensure that the experiment is carried out smoothly; s2, reagent preparation; reagents, to-be-detected samples and reference substances required by the experiment are required to be prepared in time for the experiment; s3, instrument preparation; experimental instrumentsare cleaned in advance and well reserved; s4, reagent preparation; reagents which cannot be directly used in an experiment are manually prepared for use, so that the experiment can be smoothly carriedout; s5, an inspection method; electrophoresis is mainly used as a method for inspection; s6, judgment result analysis, a result is analyzed and judged through a comparison reference substance; The method covers preparation of materials, reagents and instruments, reasonable preparation of the reagents, a scientific inspection method and rigorous analysis and judgment, isoelectric focusing electrophoresis isoelectric point detection is carried out on the recombinant protein, the result is scientific and reasonable, and the method is persuasive.

Owner:DONGGUAN TAILI BIOTECH

Fabric Dyeing Method with Good Dyeing Stability

The invention discloses a fabric dyeing method with good dyeing stability. The method comprises steps as follows: fabric is firstly soaked in a dyeing auxiliary, is subjected to stirring and ultrasonic oscillation treatment simultaneously and then is subjected to roll compacting and dry blowing treatment, a dye solution is evaporated into dye steam, the dye steam is introduced to the fabric for dyeing, furthermore, repeated circulating pressurization and negative pressure application are performed during dyeing, dyes are pressed to the fabric for dyeing through pressurization, the dyeing efficiency is improved, part of dyes with poorer dyeing stability are separated out through the negative pressure application, then the fabric is dyed again through pressurization, and the dyeing stability is improved; a color fixing agent is added for fumigation treatment, and steam formed through evaporation of the color fixing agent is used for fumigating the fabric; finally, the fabric is washed and dried, and a finished product is obtained. The fabric dyeing method has the advantages as follows: the dyeing time can be shortened, the dyeing efficiency is improved, and the dyeing stability is good.

Owner:ZHEJIANG CADY IND

Surface optical grafted modification treatment process for nylon fishing net

InactiveCN108589290AImprove adsorption capacityImprove permeabilityFibre treatmentNylon materialGraft reaction

The invention discloses a surface optical grafted modification treatment process for a nylon fishing net. According to the invention, a grafting solution is added in a reaction vessel, and then is kept under constant temperature, nitrogen is introduced in grafting liquid to eliminate oxygen in the grafting solution, a monofunctional compound modified nylon fishing net is employed, and is then is immersed in the grafting solution, ultraviolet light uniform irradiation is carried out to generate a grafting reaction, after the reaction, the material is taken out, then is added to a sodium carbonate solution for immersion, and is taken out, the material is immersed by employing a citric acid solution, then is taken out, is flushed by employing deionized water, and is naturally drained to obtain the product. Through the surface optical grafted modification treatment process, and the adsorption performance of the nylon surface on dyed molecules through a grafting method.

Owner:安徽省义顺渔网渔具有限公司

Method for producing organic mulch from landscaping waste

ActiveCN105557406BEasy to disinfectFully disinfectedPlant protective coveringsDecompositionPhosphoric acid

The invention relates to a method for producing organic mulch from landscaping waste. According to the method, the landscaping waste in maintaining and planting processes is taken as a raw material, the raw material is mechanically ground, the size of fragments is not larger than 5 cm, lignin and bark in the fragments after mechanical grinding are subjected to enzymolysis, after a phosphate flame retardant solution is sprayed, a wood dyer is sprayed uniformly to dye the landscaping waste fragments, and finally, the fragments are subjected to vacuum packaging after insect killing, bacteria killing and drying. The method is simple, the steps are easy to operate, the organic mulch is prepared from the landscaping waste as the raw material, so that not only is the pressure for municipal refuse disposal relieved, but also resources are used more sufficiently, and the organic mulch prepared after grinding, enzymolysis, drying, flame retardant treatment, dying, bacteria killing and insect killing is sufficiently sterilized, not prone to decomposition, packaged more sanitarily and easy to store.

Owner:WUXI MISHO ECOLOGY LANDSCAPE

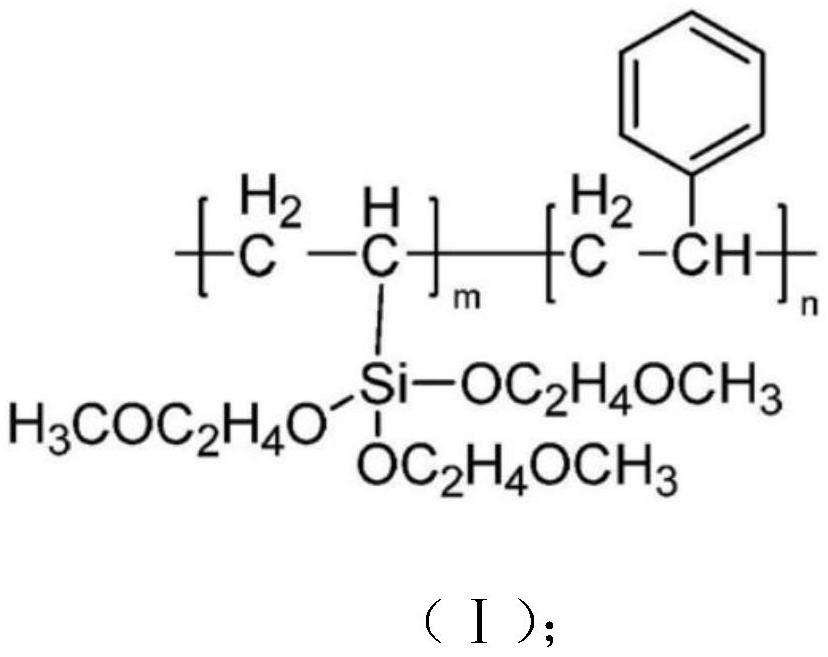

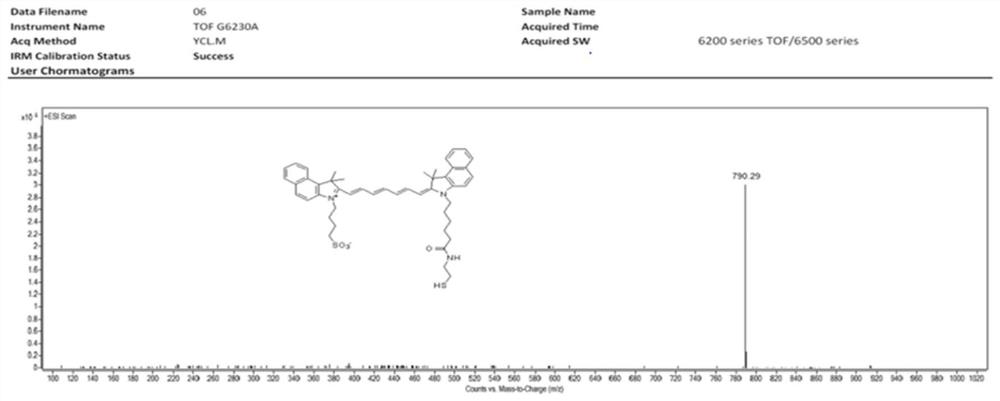

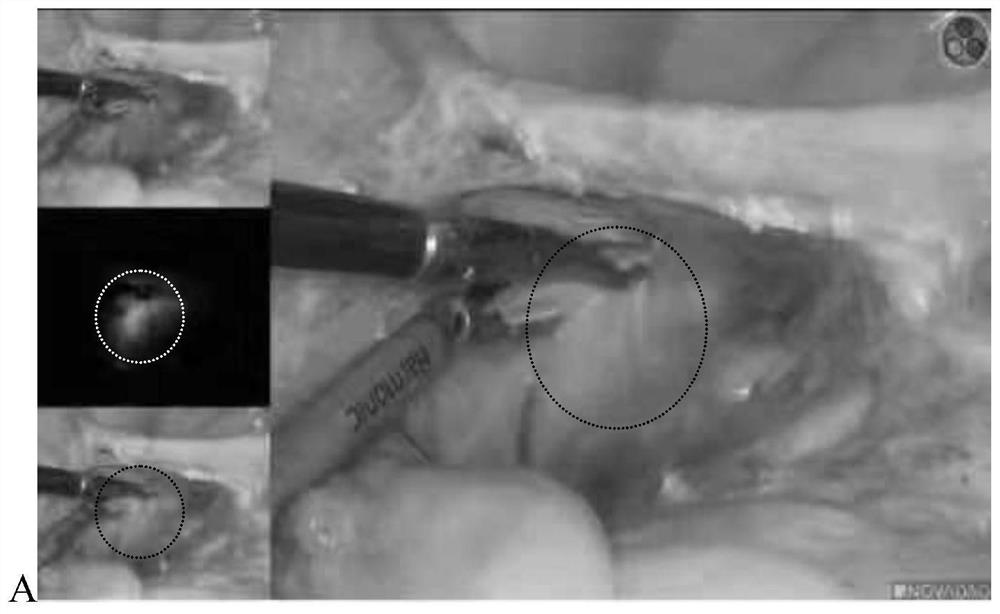

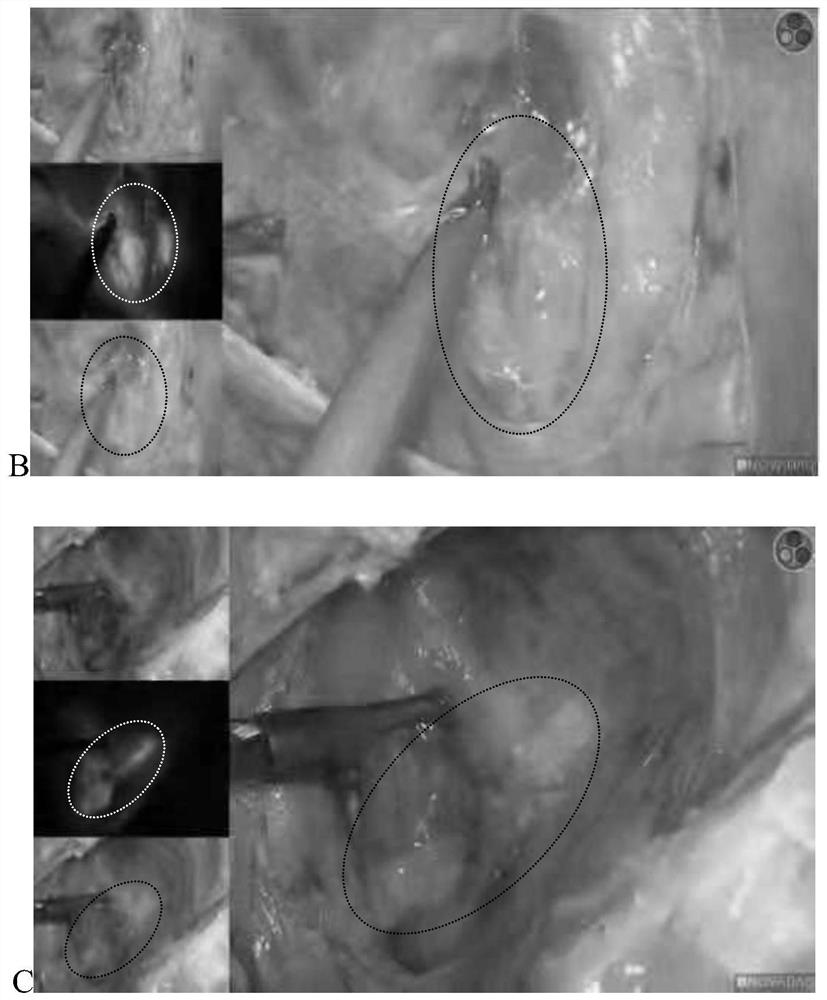

A kind of near-infrared fluorescent dye and its preparation method and application

ActiveCN111218127BImprove stabilityNot easy to spreadMethine/polymethine dyesOrganic chemistryPhotochemistryAnalytical chemistry

The invention provides a near-infrared fluorescent dye and its preparation method and application. The near-infrared fluorescent dye is called ICG-SH, and its structure is as shown in formula (I). The compound ICG-SH retains the indocyanine green The luminescent group has stable properties and stronger stability.

Owner:SHANDONG UNIV QILU HOSPITAL

A rapid silk dyeing process with low liquid feeding rate

ActiveCN104372545BIncrease the outer circulationReduce consumptionTextile treatment containersTextile treatment by spraying/projectingEngineeringLiquid content

The invention discloses a low-liquor-feeding-rate rapid silk dyeing technology. According to the low-liquor-feeding-rate rapid silk dyeing technology, dyeing is achieved by conducting dip dyeing and jet dyeing on shell fabric, external circulation of dye liquor in a cylinder body is added, in this way, the liquor feeding rate is lowered greatly, dyeing time is shortened, energy consumption is reduced, and the quality of products is improved.

Owner:ZHEJIANG QIANJIANG TEXTILE PRINTING & DYING CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com