Knitted fabric dyeing method with low living bath ratio

A dyeing method and technology for knitted fabrics are applied in the field of textile processing to achieve the effects of environment-friendly dyeing, long dyeing time, and improved dyeing water consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

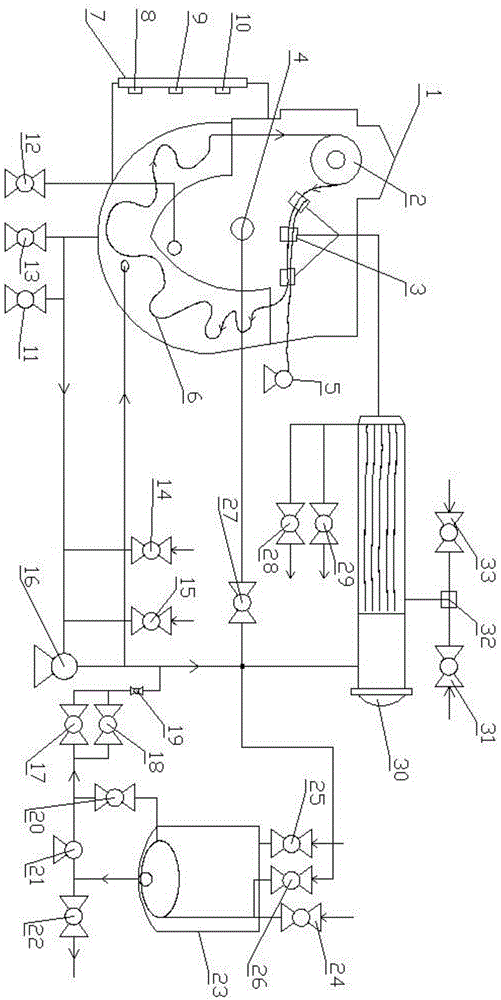

[0013] Embodiment 1: This embodiment is in figure 1 The overflow type ultra-low active bath ratio dyeing system shown in the device is completed, and its specific dyeing process includes the following steps:

[0014] (1) Pretreatment: immerse the knitted fabric in the dyeing vat 1 containing the pretreatment liquid determined as the lowest dyeing water level after measurement, and control and adjust the pretreatment at a temperature of 60-80°C for 20-30min; The material is all kinds of pure cotton knitted fabrics; the determination method of the minimum dyeing water level is: according to the capacity of the dyeing vat 1 in the dyeing system device, add the pretreatment liquid with the lowest running water level that can normally run, and then put it into the knitted fabric, and then When the knitted fabric is put in, the liquid in the dyeing vat 1 is gradually absorbed by the knitted fabric, and the dyeing system device will not be able to start. The auxiliary material cylin...

Embodiment 2-4

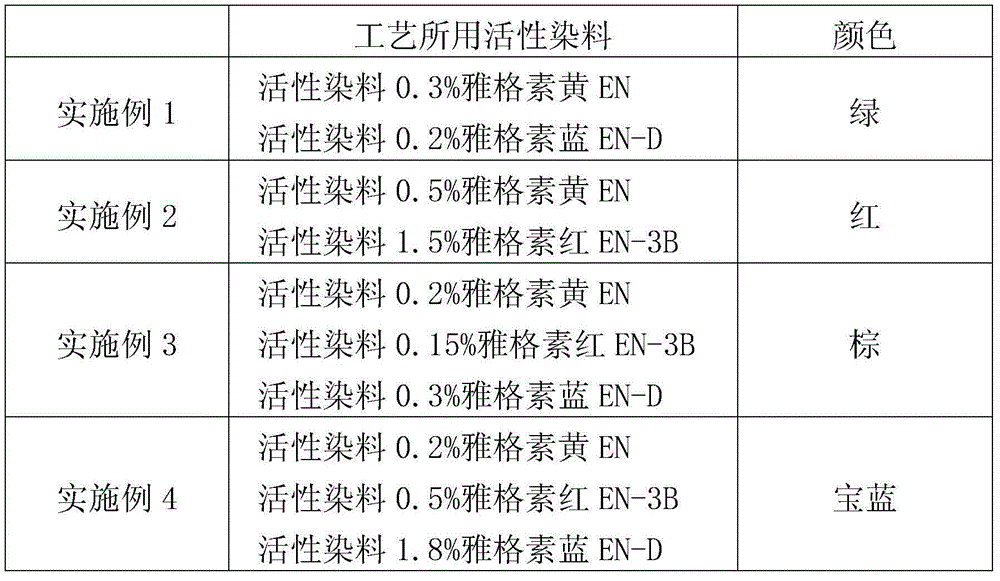

[0018] The dyeing process of the present embodiment 2-4 is basically the same as that of embodiment 1, and the reactive dye components and ratios used are different, specifically see the items listed in Table 1; the dyeing effect of each embodiment all reaches the requirements of the invention; its water saving rate reached more than 30%.

[0019] Table 1:

[0020]

Embodiment 5

[0022] In this embodiment, a dyeing vat 1 with a design capacity of 1500 kg and a low active-bath ratio overflow dyeing system device is selected. First, the dyeing active-bath ratio is determined to be 1:5-8, and then the actual water consumption of the dyeing vat 1 is measured, and Adjust the parameter values of each water consumption as follows:

[0023] lowest water level

Cloth weight per cylinder

water consumption

Simulation parameters

bath ratio

4400

640kg

4750

5000

1:7.4

4400

800kg

5150

5200

1:6.4

4400

960kg

5500

5500

1:5.7

4400

1120kg

5930

6000

1:5.2

4400

1280kg

6830

6960

1:5.3

4400

1440kg

7550

8050

1:5.2

[0024] In this embodiment, according to the selected low active bath ratio dyeing system device, input the weight of the knitted fabric with changing values, and then input the relevant simulation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com