Method for slicing heavy leather blade paraffin

A paraffin section and leaf technology, which is used in sampling devices, preparation of samples for testing, etc., can solve the problems of difficult production process, broken materials, and prolonged soaking time of reagents.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Specific steps are as follows:

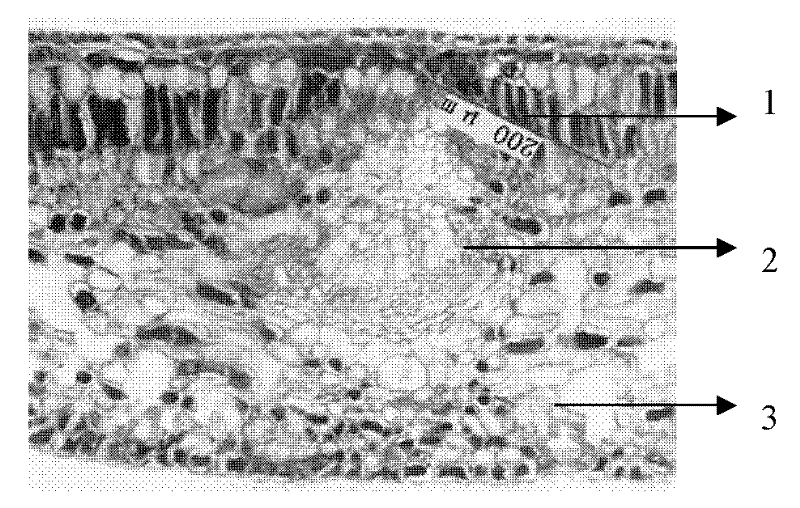

[0037] 1) Take fresh disease-free Cuban milk tree (Manilkara roxburghiana (Wight) Dubard) leaves (thickness 450~500μm, leathery), and cut 5~6mm on both sides of the main vein with a single-sided blade to cut the central veins And then cross-cut into small sections of 5-6mm.

[0038] 2) Fixation: The fixative adopts universal fixative (also known as FAA fixative, the formula is 70% ethanol 90ml, glacial acetic acid 5ml, formalin 5ml), fixed time 24h, and can be stored for a long time.

[0039] 3) Dehydration: dehydration using ethanol, starting with 60% ethanol, increasing by 5%, each level is 4h, specifically 60% ethanol 4h→65% ethanol 4h→70% ethanol 4h→75% ethanol 4h→80% ethanol Medium 4h→85% ethanol 4h→90% ethanol 4h→95% ethanol 4h→100% ethanol 4h (first time)→100% ethanol 4h (second time).

[0040] 4) Transparent: Take different ratios (volume ratio) of xylene and ethanol for transition, each level is 3 hours, the specific process is xylene:...

Embodiment 2

[0050] 1)~4) As described in Example 1.

[0051] 5) Use soft wax with a melting point of 52~54℃ for penetration wax, adopt a 1:1 (volume ratio) solution of xylene: paraffin wax to immerse the wax in a 37℃ thermostat for 72 hours, then change to pure paraffin wax in a 63℃ thermostat During the immersion of wax, it is necessary to change the pure paraffin one or two times, and then embed.

[0052] 6) As described in Example 1.

[0053] 7) Extend the film: first transition in 25% ethanol, and then extend the film in warm water at 55°C.

[0054] 8) As described in Example 1.

[0055] 9) Baked slices: Baked slices in a 35°C incubator for 36 hours.

[0056] 10) Dewaxing and rehydration: The specific procedure is 100% ethanol: xylene: 1:2 (volume ratio) solution for 1 min→100% ethanol: xylene: 1:1 (volume ratio) solution for 1 min→100% ethanol: Xylene is 2:1 (volume ratio) in a solution for 1 min→100% ethanol for 1 min (first time) → 100% ethanol for 1 min (second time) → 95% ethanol for 1 mi...

Embodiment 3

[0060] 1)~6) As described in Example 1.

[0061] 7) Extend the film: first transition in 35% ethanol, and then extend the film in warm water at a water temperature of 48°C.

[0062] 8) As described in Example 1.

[0063] 9) Baked slices: Baked slices in a 35°C incubator for 36 hours.

[0064] 10) Dewaxing and rehydration: The specific procedure is 100% ethanol: xylene for 1:2 (volume ratio) solution for 2 min → 100% ethanol: xylene for 1:1 (volume ratio) solution for 2 min → 100% ethanol: Xylene is 2:1 (volume ratio) in the solution for 2min→100% ethanol 2min (first time)→100% ethanol 2min (second time)→95% ethanol 2min→85% ethanol 2min→70% ethanol 2min→50 % Ethanol for 2min.

[0065] 11) Staining: the specific procedure is 1% safranin solution for 3h→95% ethanol for 2min→100% ethanol for 2min (first time)→100% ethanol for 2min (second time)→100% ethanol:xylene is 2:1 2min in the solution→100% ethanol:xylene for 2min in a 1:1 solution→100% ethanol:xylene for 2min in a 1:2 solution→xy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com