Direct current power supply

A technology of DC power supply and DC power, applied in the field of electronics, can solve the problems of large ripple of DC power supply, power loss, large power consumption of regulating tube, etc., and achieve the effect of reducing dv/dt value, reducing harmonic content and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

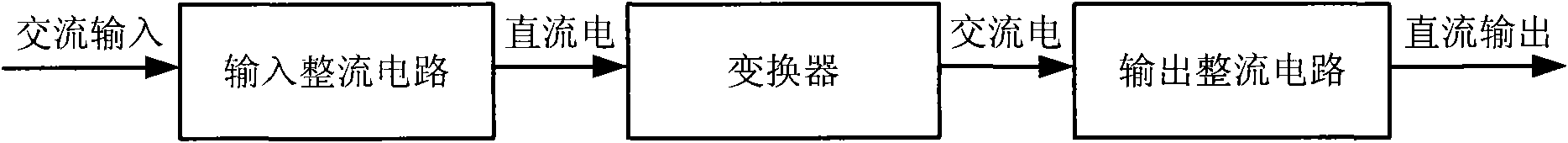

[0032] The key point of the present invention is to improve the switching power supply provided by the prior art, specifically,

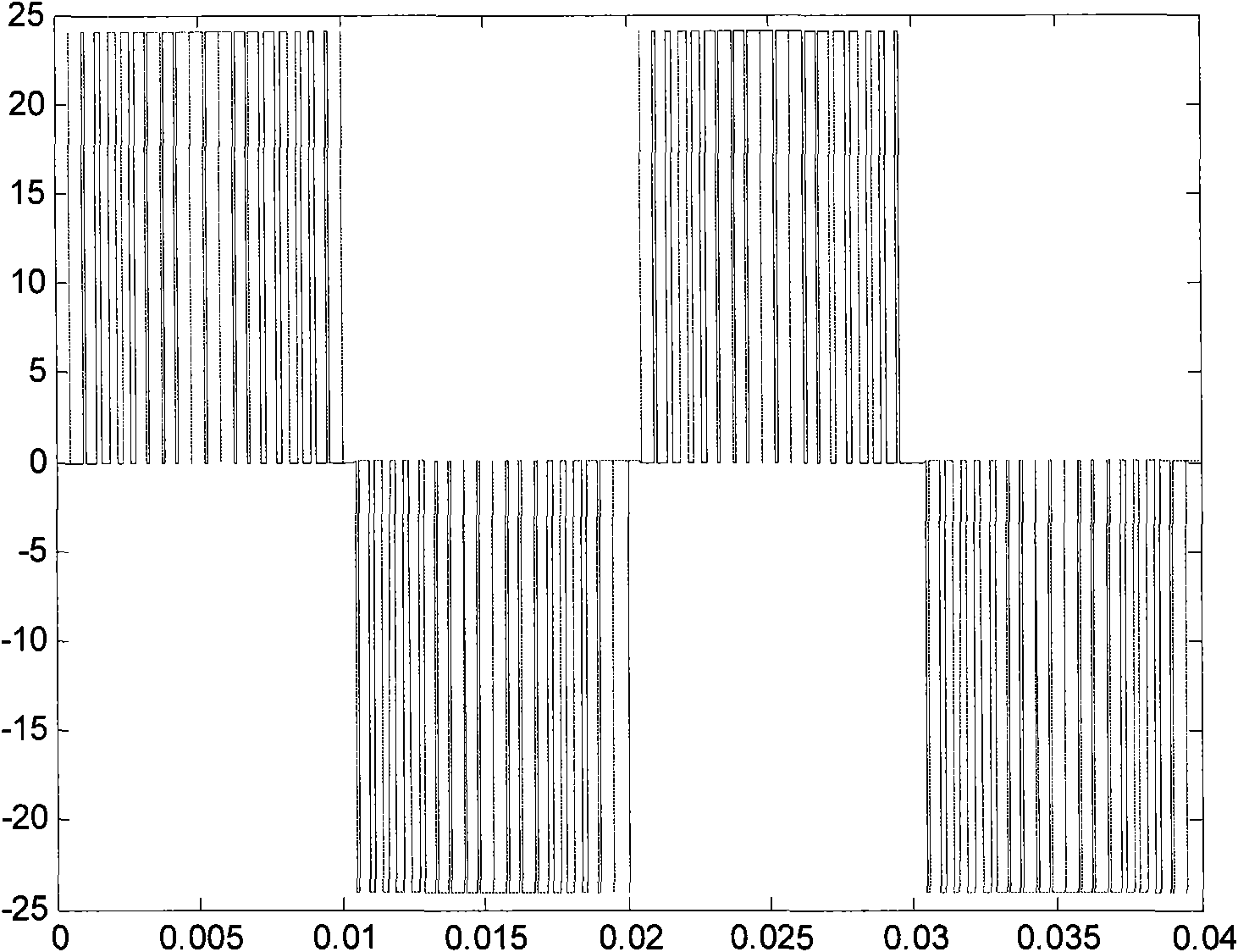

[0033] The invention adopts a closed-loop control strategy to control the output voltage of the DC power supply with small ripples and high precision, so as to improve the power supply quality of the power supply and reduce adverse effects such as interference to loads.

[0034] In order to enable those skilled in the art to better understand the technical solution of the present invention, the DC power supply provided by the present invention will be described in detail below with reference to the accompanying drawings.

[0035] see Figure 4 , the DC power supply 100 provided by the present invention mainly includes: an inverter unit 110 , an output filter unit 120 , a detection unit 130 and a DSP processor 140 .

[0036] Wherein, the inverter unit 110 performs inverse conversion on the rectified and voltage-divided commercial power, and transmit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com