Cashmere protein cellulose fiber and preparation method thereof

A cellulose fiber and cellulose technology, applied in the field of cashmere protein cellulose fiber and its preparation, can solve the problems of weak bonding, poor spinning spinnability, easy to fall off after washing, etc., and achieve the effect of soft hand feeling and related characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

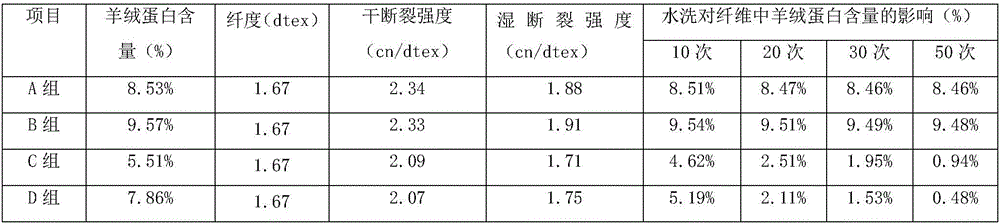

Image

Examples

Embodiment 1

[0020] Perform the following steps:

[0021] (1) Preparation of cashmere protein pretreatment solution: pump 50L of water into the glass-lined reactor, start stirring, add 10Kg of cashmere protein, drop dilute sodium hydroxide solution to adjust the pH of the system to 11-12, and fully dissolve the cashmere Protein and filtered to obtain an alkaline aqueous solution, then the cashmere protein alkaline aqueous solution was heated to 55-65°C, and the system temperature was maintained at 55-65°C, and 3.5L γ-(2,3- Glycidoxy)propyltrimethoxysilane, after the dropwise addition, raise the system temperature to 100-110°C, maintain the system temperature at 100-110°C for 2 hours to obtain the cashmere protein pretreatment solution, and then lower it to room temperature for later use;

[0022] (2) Viscose grafting treatment: Before the viscose enters the aging intermediate barrel, add the cashmere protein pretreatment liquid prepared in step (1) according to the ratio of cashmere protei...

Embodiment 2

[0027] (1) Preparation of cashmere protein pretreatment solution: pump 50L of water into the glass-lined reactor, start stirring, add 10Kg of cashmere protein, drop dilute sodium hydroxide solution to adjust the pH of the system to 11-12, and fully dissolve the cashmere Protein and filter to obtain alkaline aqueous solution, then heat the cashmere protein alkaline aqueous solution to 55-65°C, maintain the system temperature at 55-65°C, add 3.5L γ-glycidyl ether oxypropylene dropwise to the system within 20-30min under stirring conditions Trimethoxysilane, after the dropwise addition, raise the system temperature to 100-110°C, maintain the system temperature at 100-110°C for 2 hours to obtain the cashmere protein pretreatment solution, and then lower it to room temperature for later use;

[0028] (2) Viscose grafting treatment: Before the viscose enters the aging intermediate barrel, add the cashmere protein pretreatment liquid prepared in step (1) according to the ratio of cash...

Embodiment 3

[0031] Perform the following steps:

[0032] (1) Preparation of cashmere protein pretreatment solution: pump 50L of water into the glass-lined reactor, start stirring, and add 10Kg of cashmere protein, then add 0.12Kg of dissolving aid PEG400, drop dilute sodium hydroxide solution to lower the pH of the system After adjusting to 11-12, fully dissolve the cashmere protein and filter to obtain an alkaline aqueous solution, then heat the cashmere protein alkaline aqueous solution to 55-65°C, maintain the system temperature at 55-65°C, and drop it in the system within 20-30min under stirring conditions Add 3.5L of γ-(2,3-glycidyloxy)propyltrimethoxysilane, raise the temperature of the system to 100-110°C after the dropwise addition, and keep the temperature of the system at 100-110°C for 2 hours to obtain the cashmere protein preform Treatment solution, then lowered to room temperature for standby;

[0033] (2) Viscose grafting treatment: Before the viscose enters the aging inter...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of grafting | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com