Impregnating compound for basalt fibers

A basalt fiber and sizing technology, which is applied in the field of reinforced fiber sizing and its preparation, can solve the problems of poor resin binding force, flying silk and hairiness, poor film-forming performance, etc., and achieve increased fiber strength and good protection , Good film-forming performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

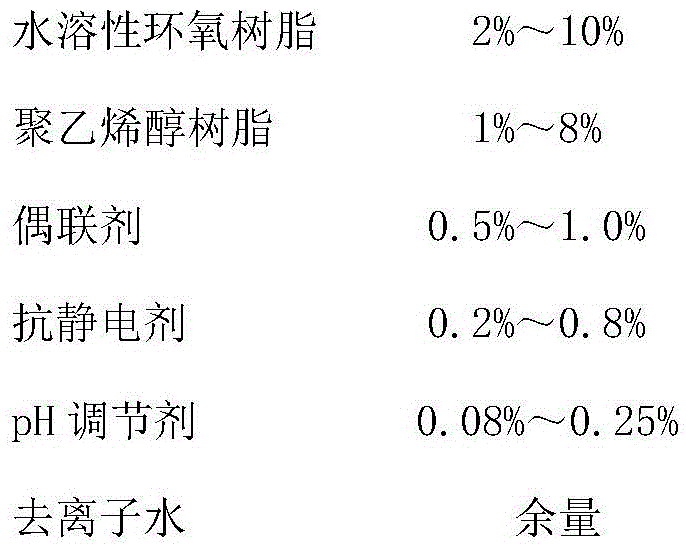

[0026] A basalt fiber epoxy type sizing agent consists of the following components by weight percentage:

[0027]

[0028] Preparation steps:

[0029] a. Slowly add polyvinyl alcohol in cold water at about 20 degrees Celsius to make it fully swell, disperse and escape volatile substances in cold water. When the temperature reaches about 95 degrees Celsius, it will accelerate the dissolution, and keep it warm for 2 to 2.5 hours for later use.

[0030] b. Add the water-soluble epoxy resin into the water and stir evenly, the water temperature is 50-70 degrees; the amount of water is 5-10 times the weight of the water-soluble epoxy resin for later use;

[0031] c. Add a pH regulator in deionized water to adjust the pH value to 4-6, add aminosilane coupling agent under stirring, and continue stirring for 25-35 minutes until the aqueous solution is clear and transparent; the amount of water accounts for 10% of the total weight of the wetting agent 1 / 20;

[0032] d. Dissolving t...

Embodiment 2

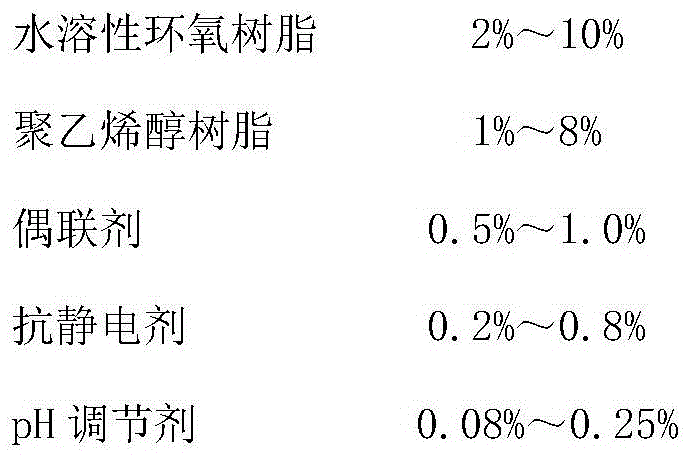

[0035] A basalt fiber epoxy type sizing agent consists of the following components by weight percentage:

[0036]

[0037] Preparation steps:

[0038] a. Slowly add polyvinyl alcohol in cold water at about 20 degrees Celsius to make it fully swell, disperse and escape volatile substances in cold water. When the temperature reaches about 95 degrees Celsius, it will accelerate the dissolution, and keep it warm for 2 to 2.5 hours for later use.

[0039] b. Add the water-soluble epoxy resin into the water and stir evenly, the water temperature is 50-70 degrees; the amount of water is 5-10 times the weight of the water-soluble epoxy resin for later use;

[0040] c. Add a pH regulator in deionized water to adjust the pH value to 4-6, add aminosilane coupling agent under stirring, and continue stirring for 25-35 minutes until the aqueous solution is clear and transparent; the amount of water accounts for 10% of the total weight of the wetting agent 1 / 20;

[0041] d. Dissolving t...

Embodiment 3

[0044] A basalt fiber epoxy type sizing agent consists of the following components by weight percentage:

[0045]

[0046] Preparation steps:

[0047] a. Slowly add polyvinyl alcohol in cold water at about 20 degrees Celsius to make it fully swell, disperse and escape volatile substances in cold water. When the temperature reaches about 95 degrees Celsius, it will accelerate the dissolution, and keep it warm for 2 to 2.5 hours for later use.

[0048] b. Add the water-soluble epoxy resin into the water and stir evenly, the water temperature is 50-70 degrees; the amount of water is 5-10 times the weight of the water-soluble epoxy resin for later use;

[0049] c. Add a pH regulator in deionized water to adjust the pH value to 4-6, add aminosilane coupling agent under stirring, and continue stirring for 25-35 minutes until the aqueous solution is clear and transparent; the amount of water accounts for 10% of the total weight of the wetting agent 1 / 20;

[0050] d. Dissolving t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com