Apparatus and method for depositing synthetic fibers to form a non-woven web

A technology of synthetic fibers and textile webs, applied in textiles and papermaking, melt spinning, fiber processing, etc., can solve problems such as loss of effectiveness, and achieve the effect of increasing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

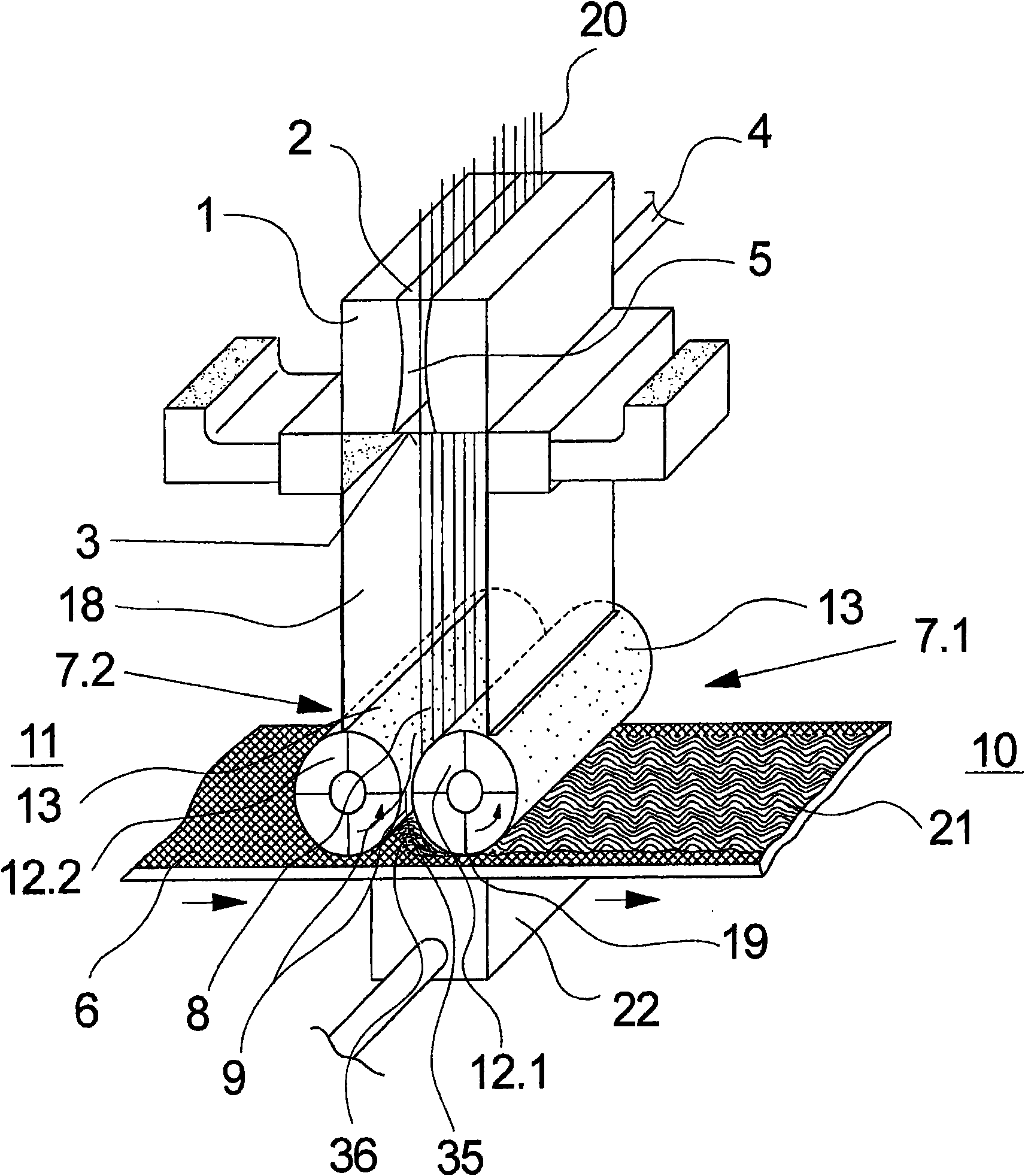

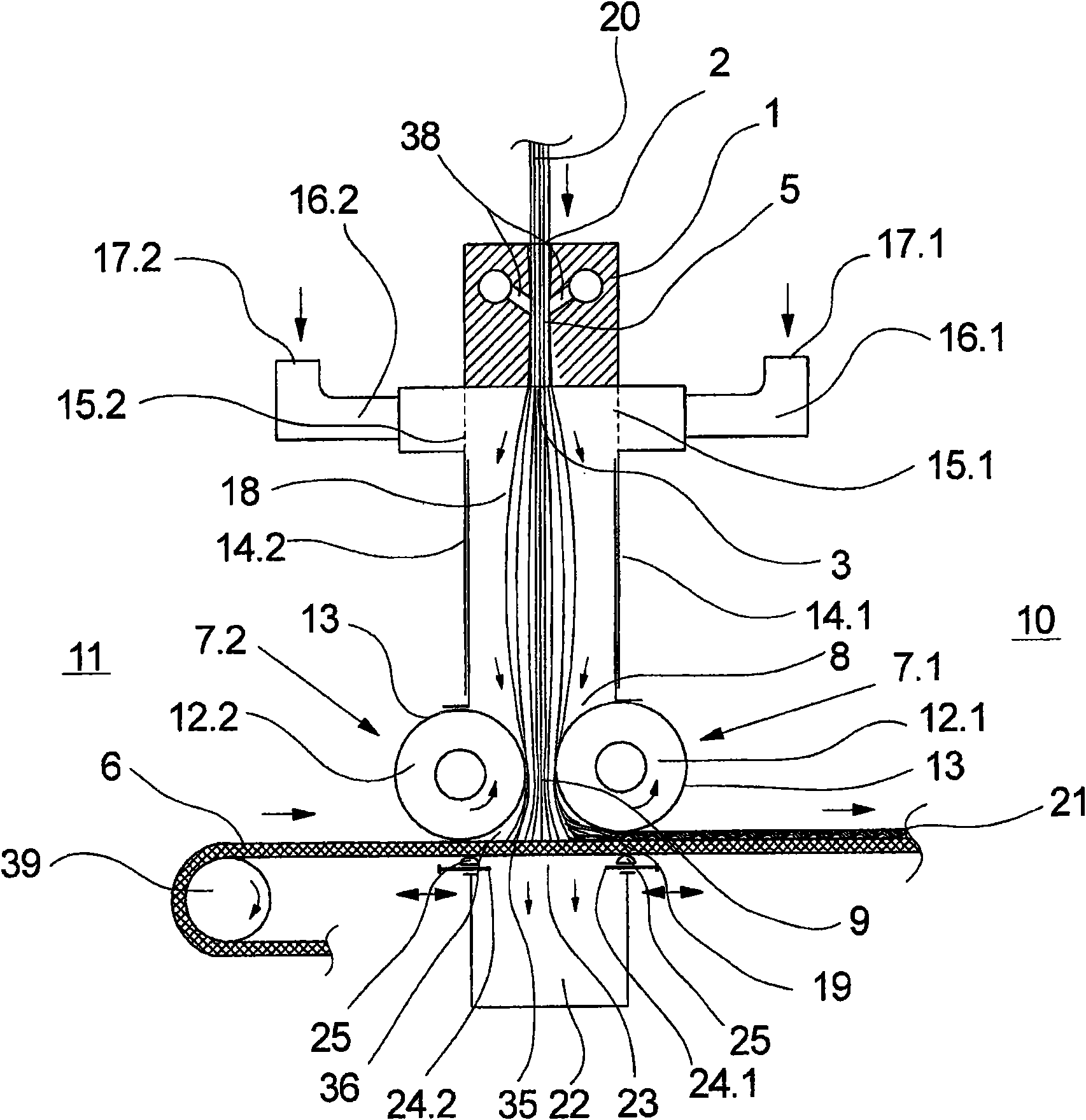

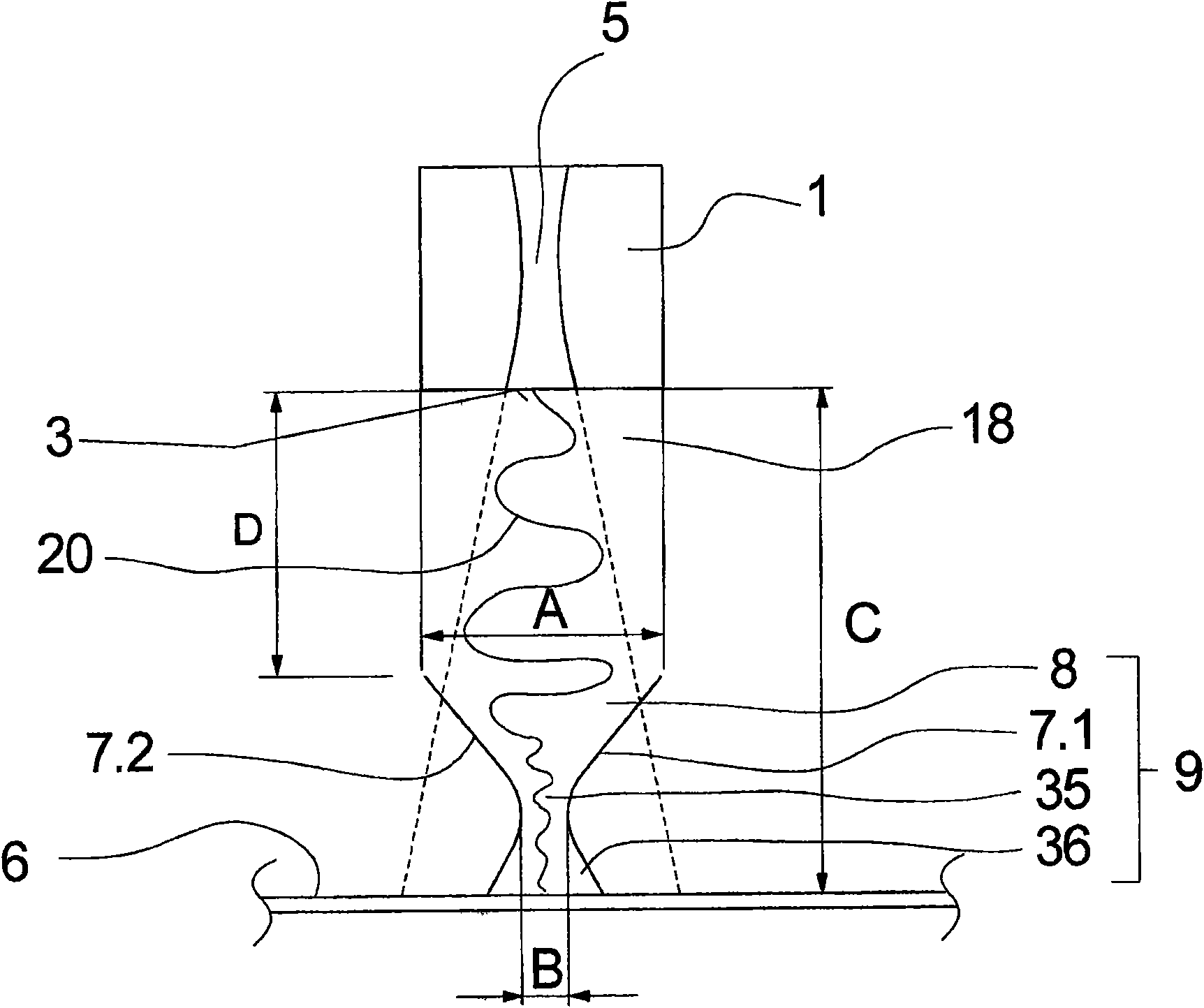

[0037] figure 1 and figure 2 A first exemplary embodiment of the device according to the invention for carrying out the method according to the invention for laying down synthetic fibers to form a nonwoven web is shown schematically. figure 1 shows a side view of the exemplary embodiment while figure 2 A cross-sectional view thereof is schematically shown. The following description applies to both figures unless reference is made to a certain figure.

[0038] figure 1 and figure 2 The exemplary embodiment shown shows a parallelepiped drawing unit 1 which is generally arranged below the spinning arrangement. Pulling units of this type are generally known and described in detail in US patent documents US 6,183,684 B1 or US 7,172,398 B2. In this respect reference is made to the aforementioned publications, only the main parts of which are included below.

[0039] The drawing unit 1 comprises a central conveying channel 5 which is delimited on the upper side of the drawi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com