Wetting agent used for pretreated enhancement type filter cloth

A sizing and reinforcement technology, applied in the field of continuous medium-alkali glass fiber yarn, can solve the problems of power consumption and damage to the strength of the cloth surface, and achieve good social and economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

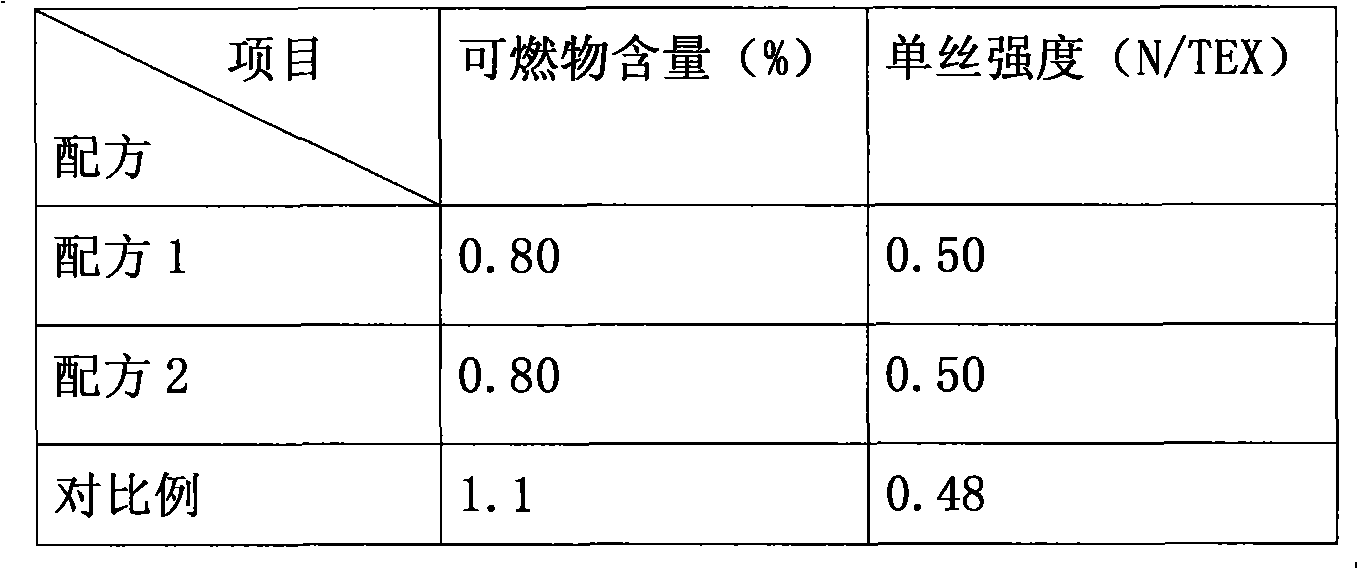

Examples

Embodiment 1

[0022] Fixing agent: 2.0%

[0023] Epoxy: 2.5

[0024] Water-soluble unsaturated polyester resin: 3%

[0025] A151: 0.5%

[0026] Alcohol: 0.5%

[0027] Tween-80: 0.2%

[0028] Demineralized water: 91.3%

[0029] Prepare according to the method described in the present invention, and its pH is adjusted to 5.0 with glacial acetic acid.

Embodiment 2

[0031] Fixing agent: 2.5%

[0032] Epoxy resin: 2.0%

[0033] Water-soluble unsaturated polyester resin: 3%

[0034] A151: 0.5%

[0035] Alcohol: 0.5%

[0036] Tween-80: 0.2%

[0037] Demineralized water: balance

[0038] Prepare according to the method described in the present invention, and its pH is adjusted to 5.0 with glacial acetic acid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com