Preparation method of dope-dyed cotton linter composite filament

A technology of dope dyeing and compound filament, applied in the direction of conjugated rayon, cellulose/protein conjugated rayon, wet spinning, etc. Low problems, to achieve excellent textile performance and wear performance, reduce environmental pressure, avoid dyeing and finishing wastewater effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

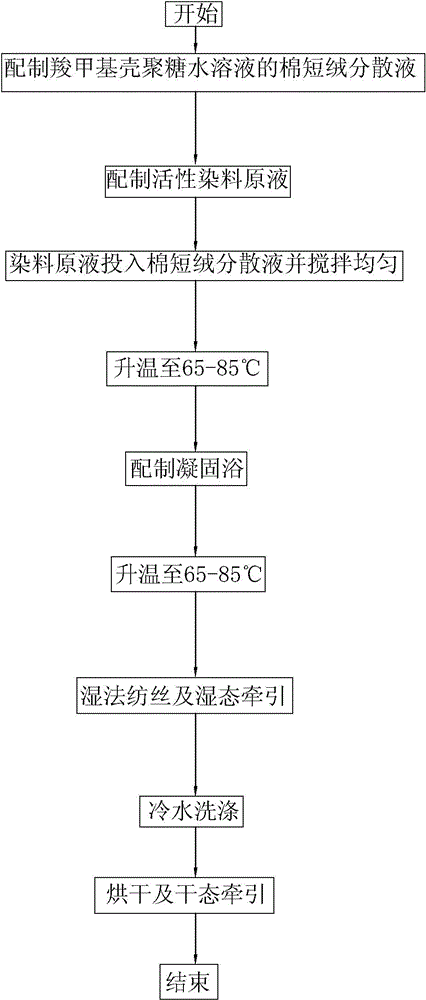

[0014] Such as figure 1 Shown, the preparation method of the cotton linter composite filament dyed by this stock solution comprises the following steps:

[0015] 1) Preparation of dye stock solution: dissolving the reactive dye in water to prepare a dye stock solution with a reactive dye concentration of 20-40 wt%. The reactive dye can be selected from any one of the prior art according to the required color.

[0016] 2) preparation of spinning solution: the dyestuff stock solution is added in the cotton linter dispersion liquid, and the cotton linter dispersion liquid is carboxymethyl chitosan aqueous solution, the add-on of described dyestuff stock solution is based on the weight of reactive dyestuff It is calculated as 1-3.5wt% of the cotton linters dispersion liquid; after stirring evenly, the temperature is raised to 70° C. to obtain a d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com