Intelligent temperature-adjusting viscose fibre and its production

A technology of intelligent temperature regulation and viscose fiber, which is applied in the direction of fiber chemical characteristics, artificial filament made of viscose, single-component cellulose artificial filament, etc., can solve the problem of products that have not yet been industrialized and marketed Variable materials are in the laboratory stage and other issues

Inactive Publication Date: 2007-09-05

HEBEI JIGAO CHEM FIBER +1

View PDF1 Cites 32 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Most domestic research and application of phase change materials in textile products are still in the laboratory stage, and there are no large-scale industrial production and market promotion products.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Dry breaking strength | aaaaa | aaaaa |

| Phase transition temperature | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Login to View More

Abstract

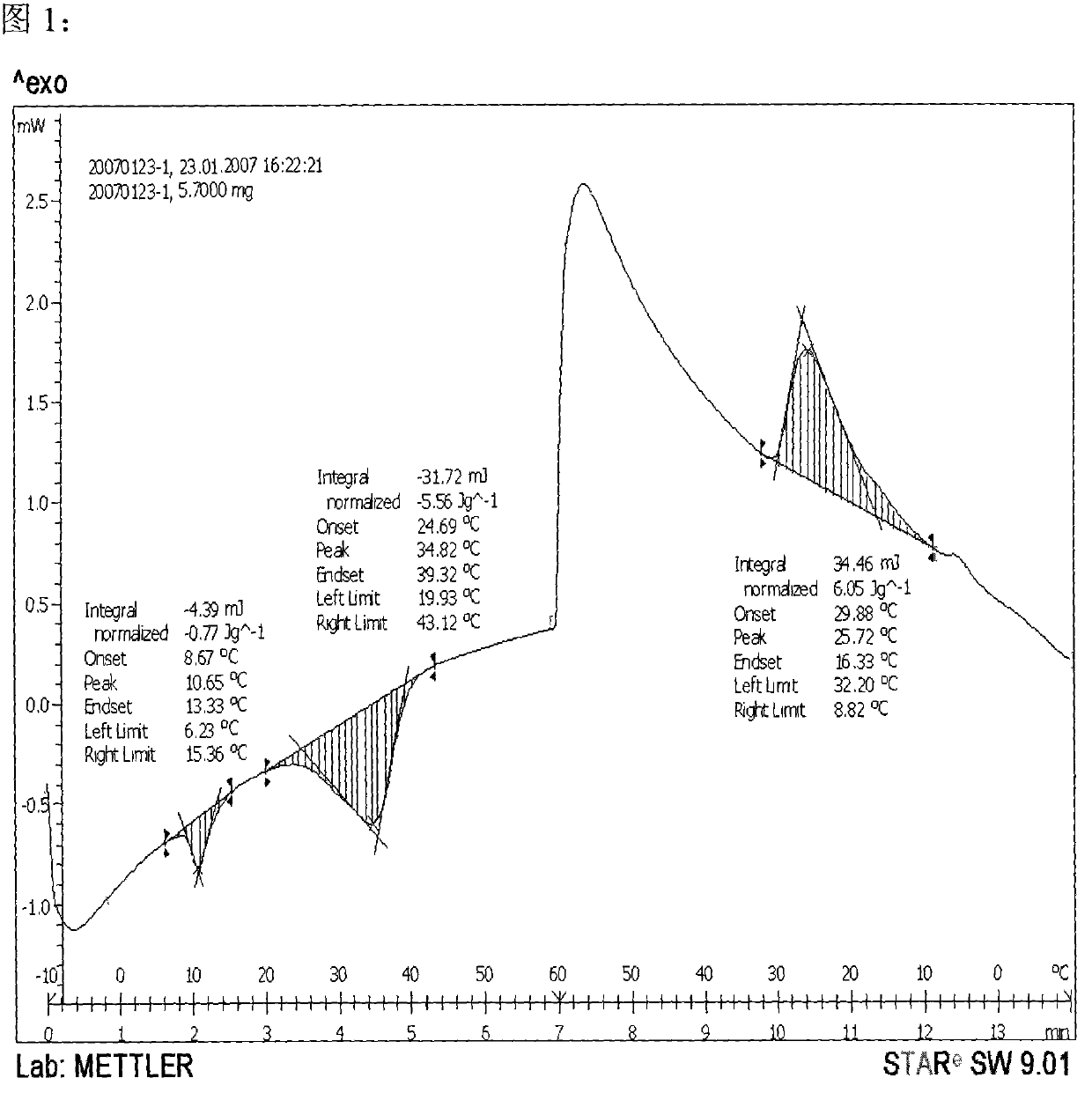

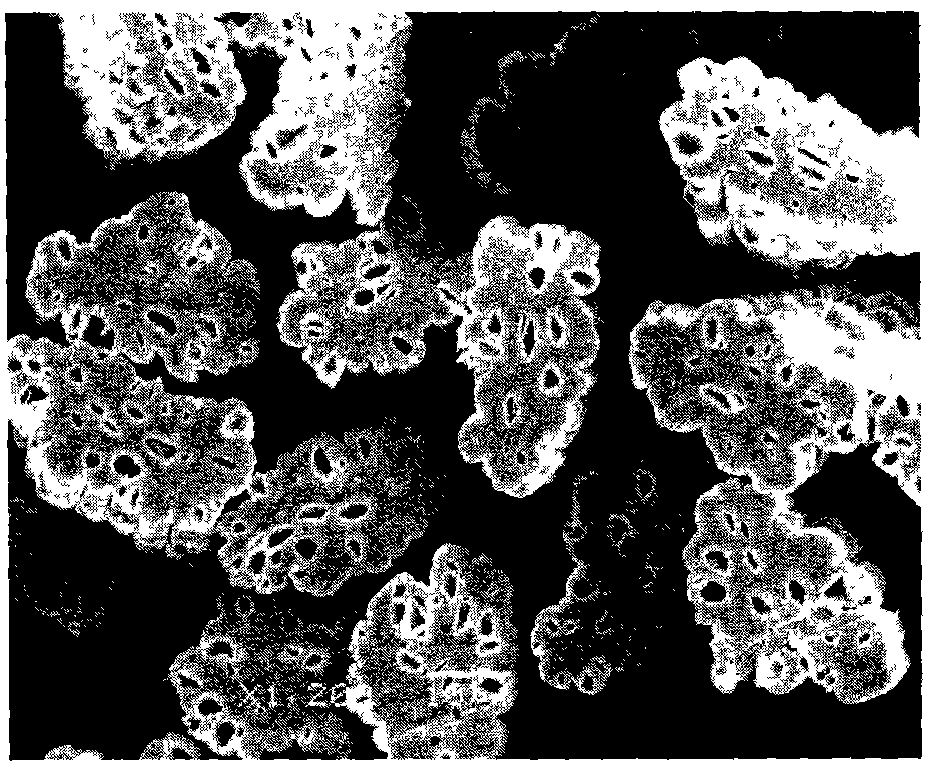

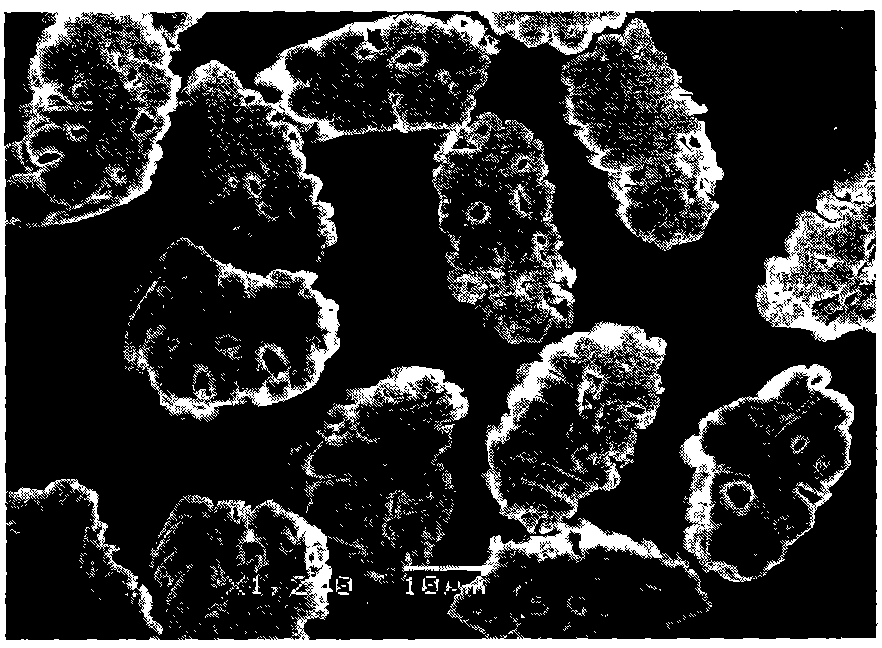

A phase-variable material micro-capsule as temperature-adjusting functional material, an intelligent temperature-adjusting viscose fiber and its production are disclosed. Dry breakdown strength is >=1.42CN / dtex, wet breakdown strength is>=0.64CN / dtex; It consists of cellulose 84.7-92.75wt%, micro-capsule 5-30wt% and water-content 7-15wt% and oil solution 0.15-0.30wt%. The fiber coagulation heat-liberation enthalpy valueDeltaH>=1.0J / g, melt heat-adsorption enthalpy value DeltaH>=1.0J / g. It is non-toxic, has better adaptability and no harm.

Description

technical field The invention relates to the production of intelligent temperature-regulating viscose fiber and its method by using phase-change material microcapsules as additives. The raw materials are obtained through a certain production process for industrial production of intelligent temperature-adjusting viscose fiber. technical background At present, with the rapid development of science and technology, people's living standards are gradually improving, and the requirements for the comfort of textiles are getting higher and higher. Intelligent temperature-adjusting viscose fiber follows this development trend and provides people with a kind of fabric that can release heat when it is cold and absorb heat when it is hot. Thermal smart textiles that eliminate the feeling of hot and cold due to temperature changes. Enhance the wearability of textiles. American Outlast Company and Japanese Yamato Company have also successively developed phase-change temperature-regula...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): D01F2/10D01F2/08

Inventor 宋德武孙国林岳福升韩晋民郑书华李振峰孙同会范小永耿建强常书利吕彦松朱焕有顾宇鹭

Owner HEBEI JIGAO CHEM FIBER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com