Process for preparing dibasic acid ester

A technology of dibasic acid esters and dibasic carboxylic acids, which is applied in the field of preparing dibasic acid esters, and can solve problems such as unfavorable continuous industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

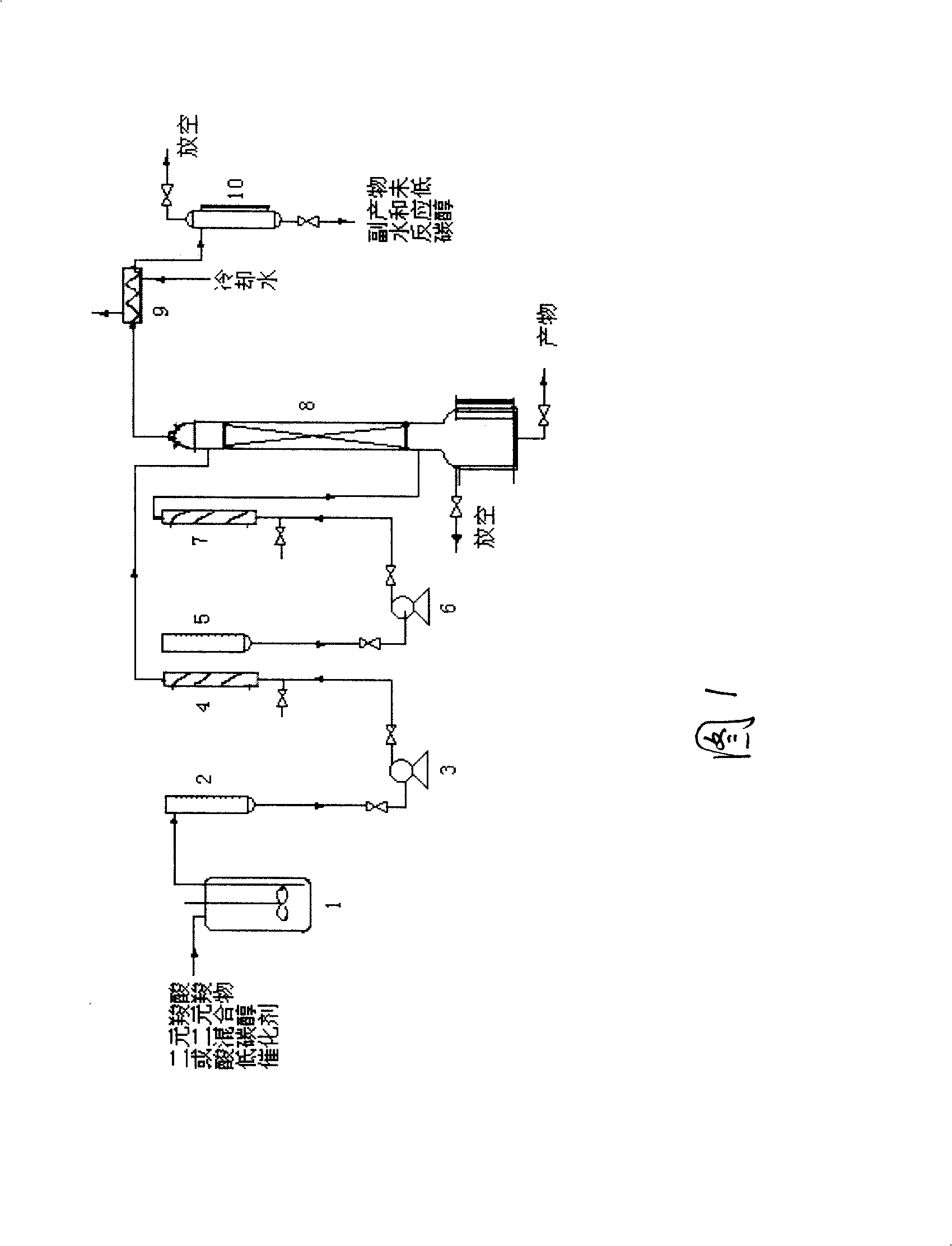

Method used

Image

Examples

Embodiment 1

[0022] (1). In the pre-esterification kettle 1, a solid acid catalyst is first added from the feed port, and the dicarboxylic acid or dicarboxylic acid mixture is added into the pre-esterification kettle 1 from the feed port of the pre-esterification kettle; Alcohol is fed into the pre-esterification kettle 1 from the low-carbon alcohol intermediate storage tank with an intermittent feed pump. In normal operation, the solid acid catalyst is stored in the kettle for repeated use. Based on the quality of dicarboxylic acid or dicarboxylic acid mixture, the amount of solid acid catalyst added is 1% to 10% of dicarboxylic acid or dicarboxylic acid mixture, and the preferred amount is 3% to 7%. ; The alkyd-acid molar ratio is 1-10, and the preferred alkyd-acid molar ratio is 2-5.

[0023] (2). Heating the pre-esterification tank, the low-carbon alcohol vapor discharged from the pre-esterification tank during the reaction is condensed and then returned to the pre-esterification reac...

Embodiment 2

[0031] Add solid acid catalyst, adipic acid and methanol in the esterification kettle, heat and stir at normal pressure, and carry out pre-esterification reaction. The amount of catalyst added is based on the quality of adipic acid. The specific results are as follows:

[0032] Table 1 Adipic acid and methanol pre-esterification experimental results

[0033] Catalyst added

Embodiment 3

[0035] Add solid acid catalyst, glutaric acid and methanol in the esterification kettle, under normal pressure, heat and stir, and carry out pre-esterification reaction. The amount of catalyst added is based on the quality of glutaric acid. The specific results are as follows:

[0036] Table 2 Glutaric acid and methanol pre-esterification experimental results

[0037] Catalyst added

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com