Anti-icing fluid capable of realizing thickening through at least one oligomeric cationic surfactant and preparation method of anti-icing fluid

A technology of surfactants and polycations, applied in chemical instruments and methods, other chemical processes, etc., can solve problems such as drastic changes in performance, potential safety hazards, hydration gels, etc., and achieve excellent viscosity stability and excellent low temperature stability performance, excellent compatibility of corrosion-inhibiting materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

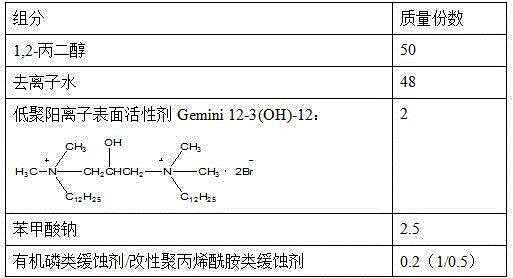

[0037] An anti-icing fluid thickened by an oligomeric cationic surfactant, characterized in that it comprises the following components in parts by mass:

[0038] 0.5 to 15 parts of at least one oligomeric cationic surfactant;

[0039] 0.5-15 parts of at least one anionic inorganic salt or organic salt;

[0040] 30-90 parts of at least one polyol;

[0041] 0.01~2 parts of at least one corrosion inhibitor;

[0042] 20-90 parts of deionized water.

Embodiment 2

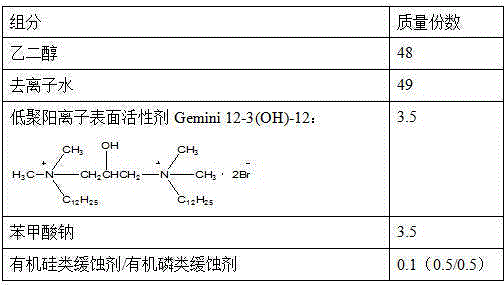

[0044] An anti-icing fluid thickened by an oligomeric cationic surfactant, characterized in that it comprises the following components in parts by mass:

[0045] 1-10 parts of at least one oligomeric cationic surfactant;

[0046] 1-10 parts of at least one anionic inorganic salt or organic salt;

[0047] 40-70 parts of at least one polyol;

[0048] 0.1~1 part of at least one corrosion inhibitor;

[0049] And 40-70 parts of deionized water.

Embodiment 3

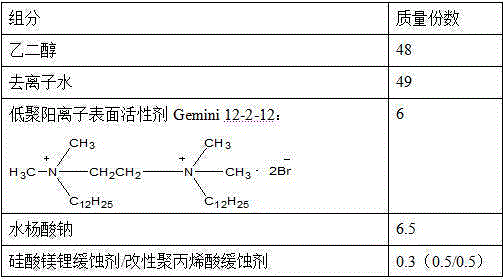

[0051] An anti-icing fluid thickened by an oligomeric cationic surfactant, characterized in that it comprises the following components in parts by mass:

[0052] 0.5 to 15 parts of at least one oligomeric cationic surfactant;

[0053] 0.5-15 parts of at least one anionic inorganic salt or organic salt;

[0054] 30-90 parts of at least one polyol;

[0055] 0.01~2 parts of at least one corrosion inhibitor;

[0056] 20-90 parts of deionized water;

[0057] The molar concentration ratio of oligomeric cationic surfactant to anionic inorganic salt or organic salt is 1 / 0.1~1 / 5.

[0058] The oligomeric cationic surfactant includes at least one of gemini cationic surfactants, trimerized cationic surfactants, and tetramerized or higher cationic surfactants.

[0059]The anionic organic salts include sodium or potassium salts containing a benzene ring structure, specifically: at least one of sodium salicylate and its derivatives, sodium benzoate and sodium acetate.

[0060] The anion...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com