Photo gripping device and gripping method

A grasping device and grasping unit technology, applied in the directions of manipulators, chucks, manufacturing tools, etc., can solve the problems of inability to supply power, narrow space, and inability to apply devices to implement work, and achieve simplified design, reduced size, and actuators. and the effect of a simple operating mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

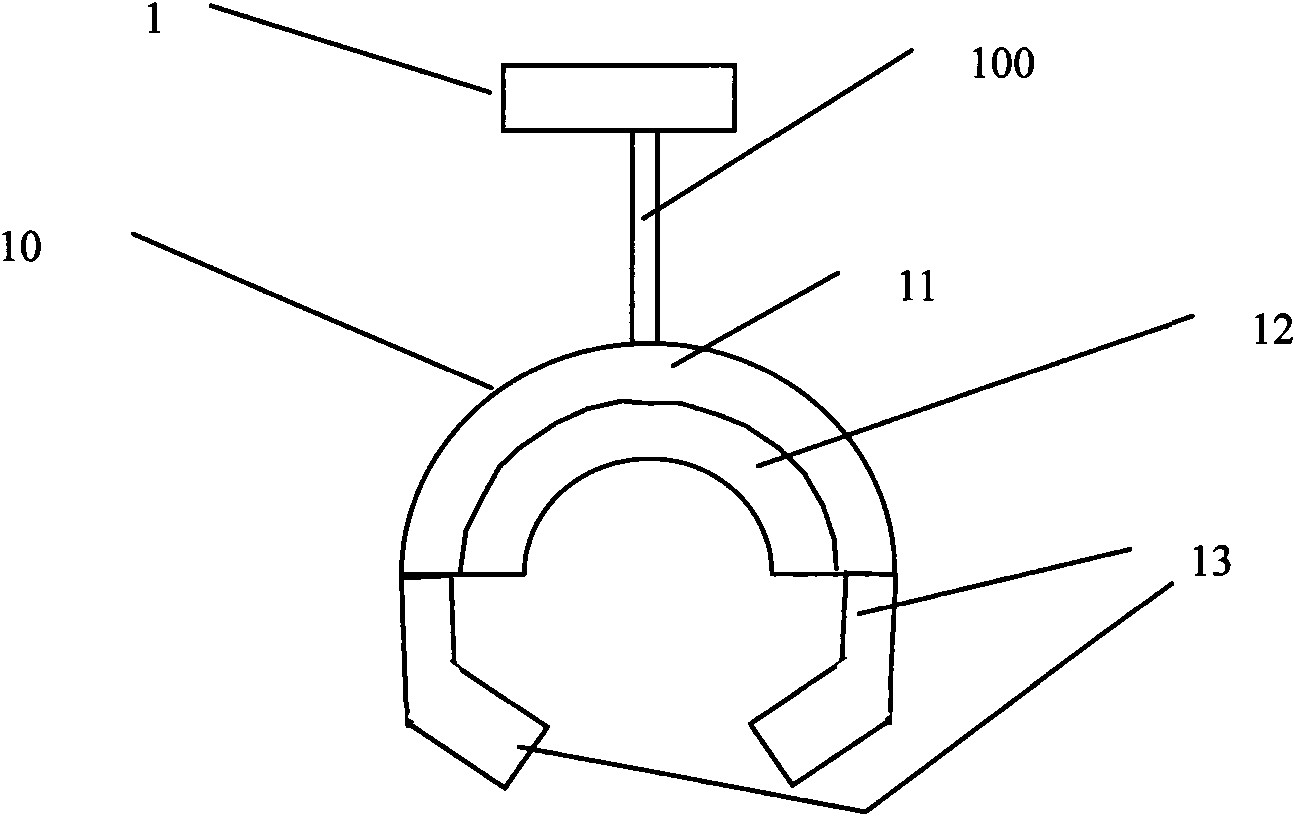

[0025] see figure 1 As shown, a light control grabbing device at least includes a base 1, the base 1 is provided with an arm 100, the tail end of the arm 100 is fixed on the base 1, and the arm 100 is provided with a grabbing unit 10, so The arm 100 is connected with the grasping unit 10 through an adhesive, and the arm 100 is made of a flexible polymer material, here, a uniaxially stretched low-density polyethylene film is selected. The grasping unit 10 is composed of two layers. The upper layer 11 is made of photodeformable material, and its shape is semicircular. Specifically, the material prepared by the specific implementation method in the patent CN101225137A is selected, and the lower layer 12 is made of a flexible polymer material. , the shape is a semicircle, and what is selected here is a uniaxially stretched low-density polyethylene film, and the layers are bonded by an adhesive. The two ends of the upper layer 11 are respectively provided with hook-shaped grasping ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com