Method of constructing graphical magnetic micro-nano structure through laser beam direct writing

A micro-nano structure and laser beam technology, applied in the manufacture of micro-structure devices, micro-structure technology, micro-structure devices, etc., can solve the problems of easy damage, poor thermal and mechanical stability of chemically modified layers of organic substances, and super-hydrophobic metal surfaces. problems such as loss of properties, to achieve the effect of good material compatibility, precise and controllable fine structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0024] The method for constructing a patterned magnetic micro-nano structure by laser beam direct writing provided by the present invention comprises the following steps:

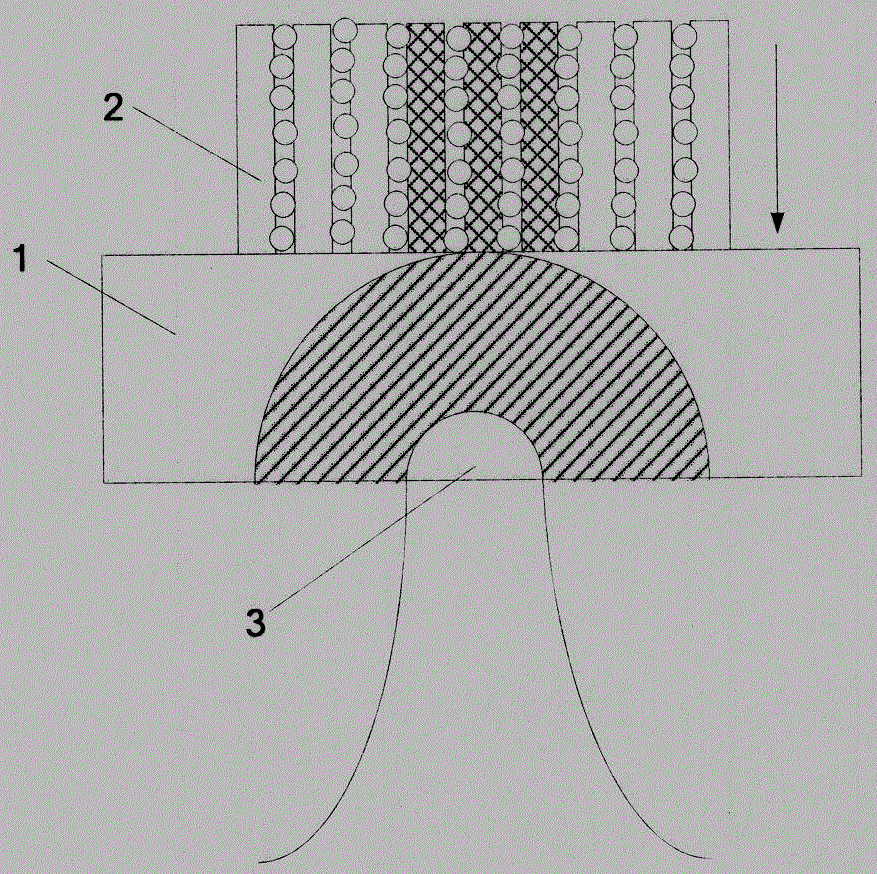

[0025] (1) if figure 1 As shown, a certain thickness of micro- and nanometer-sized magnetic material particles 2 are placed on the surface of the substrate 1. The size range of the magnetic material particles 2 is from 100 microns to 10 nanometers, and the thickness of the magnetic material particles 2 is greater than the average size of the magnetic material particles 2. , so that the surface of the substrate 1 is paved with at least one layer of magnetic material particles 2; then a controllable magnetic field ( figure 1 The middle arrow shows the direction of the magnetic field), so that the magnetic material particles 2 are arranged in an orderly manner on the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com