High-polarity polypropylene material and application thereof as inner and outer decorative parts of automobile

A technology of polypropylene material and high polarity, applied in upper structure sub-assembly, upper structure, bumper, etc., can solve problems such as complex production process, achieve excellent performance, energy saving, and good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

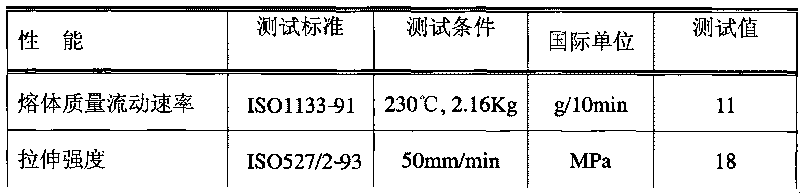

[0029] Table 1 Embodiment 1 formula content

[0030] components

Manufacturer

weight percentage

PP EPC30R

Sinopec Maoming Petrochemical Branch

manage

64%

POE 8137

dow chemical co., ltd.

20%

talcum powder

10%

epoxy resin

Yueyang Baling Huaxing Petrochemical Co., Ltd.

company

5%

Antioxidant: Irganox1010,

Ciba Fine Chemical Industry Co., Ltd.

company

0.25%

Antioxidant: Irganox168

Ciba Fine Chemical Industry Co., Ltd.

company

0.25%

Carbon black: 50L

Degussa Specialty Chemicals

0.5%

[0031] Put the above-mentioned raw materials into a high-speed mixer with a rotation speed of about 1000rpm and mix them for 3 minutes according to the polarity of the weight percentage, and then put them into a twin-screw extruder. It can be extruded and granulated under the condition of 10 minutes. T...

Embodiment 2

[0037] Table 3 embodiment 2 formula content

[0038] components

Manufacturer

weight percentage

PP CB5290

KOPC

65%

POE 5171

ExxonMobil Chemical Company

10%

talcum powder

20%

Vinyl Acrylate Elvaloy2112

AC

dow chemical co., ltd.

4%

Antioxidant: Irganox1010,

Ciba Fine Chemical Industry Co., Ltd.

company

0.25%

Antioxidant: Irganox168

Ciba Fine Chemical Industry Co., Ltd.

company

0.25%

Carbon black: 50L

Degussa Specialty Chemicals

0.5%

[0039] Put the above raw materials into a high-speed mixer with a rotation speed of about 1000rpm and mix for 3 minutes. See Example 1 for the extrusion granulation process. The properties of the prepared samples are shown in Table 4:

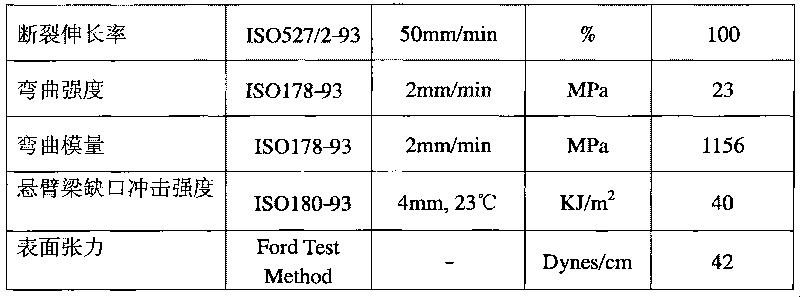

[0040] Table 4 performance table

[0041] performance

Embodiment 3

[0043] Table 5 embodiment 3 formula content

[0044] components

Manufacturer

weight percentage

PPAW191

Singapore Polyolefins Pte Ltd

company

66%

POE 8842

dow chemical co., ltd.

18%

talcum powder

10%

EVA

ExxonMobil Chemical Company

5%

Antioxidant: Irganox1010

Ciba Fine Chemical Industry Co., Ltd.

company

0.25%

Antioxidant: Irganox168

Ciba Fine Chemical Industry Co., Ltd.

company

0.25%

Carbon black: 50L

Degussa Specialty Chemicals

0.5%

[0045] Put the above raw materials into a high-speed mixer with a rotation speed of about 1000rpm and mix for 3 minutes. See Example 1 for the extrusion granulation process. The properties of the prepared samples are shown in Table 6:

[0046] Table 6 Performance table

[0047] performance

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com