Long glass fiber reinforced polypropylene material and preparation thereof

A long glass fiber, polypropylene material technology, applied in the direction of coating, can solve the problems of glass fiber exposure, unsatisfactory impregnation effect, unsatisfactory product performance, etc., to reduce the cost of raw materials, easy to control the production process, and solve the problem of exposure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

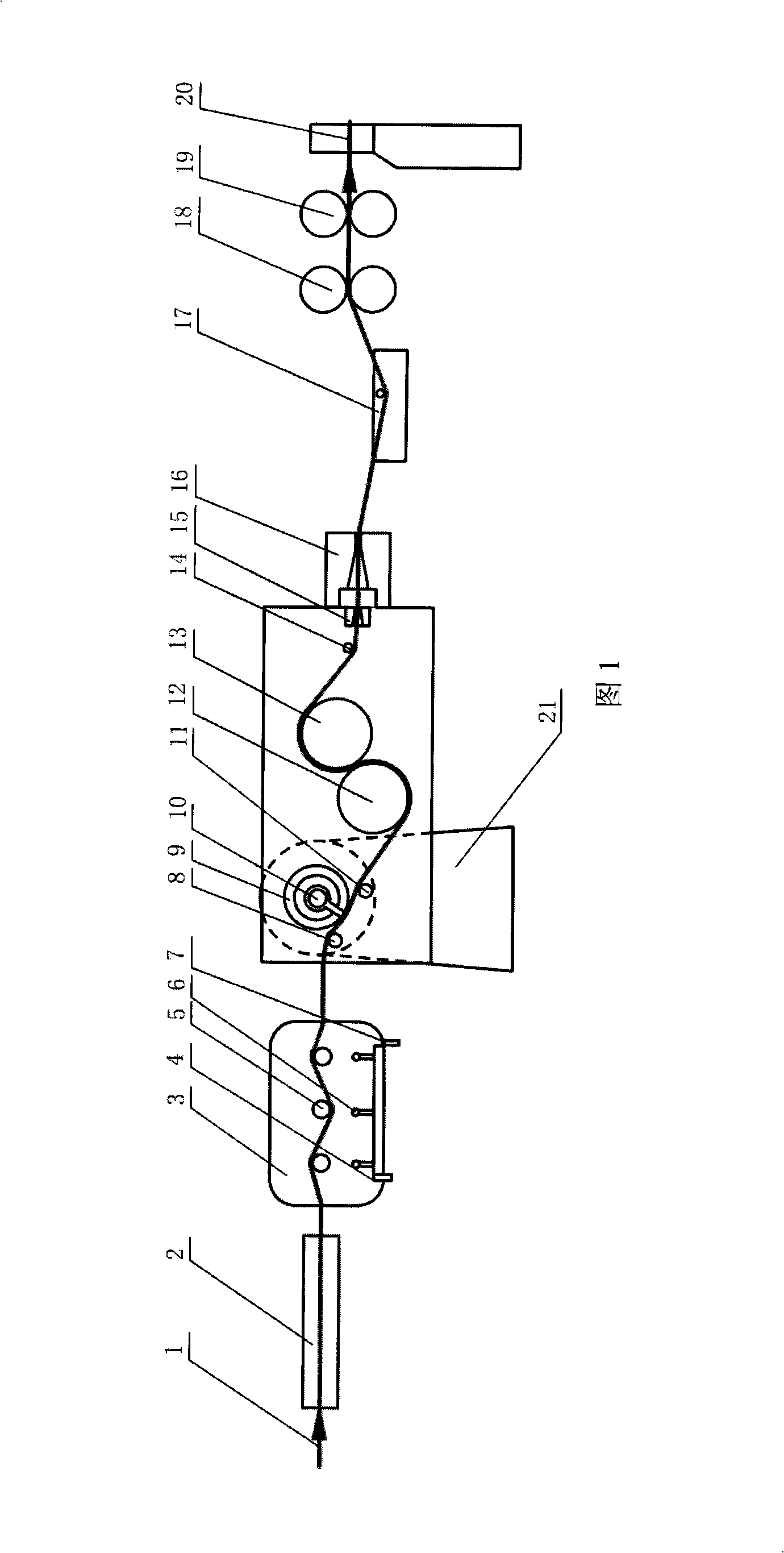

Image

Examples

Embodiment 1

[0027] 54.4 parts of medium-melt index homopolypropylene, 5 parts of maleic anhydride grafted polypropylene compatibilizer, 4 parts of PP cooling masterbatch, 0.1 part of antioxidant 1790 and 0.2 part of antioxidant DLTDP, 1 part of ethylene double hard Fatty amide is added into the mixer to make it fully mixed evenly. The mixture is fed into the twin-screw extruder through the feeding port. The processing temperature is 185-230°C. The temperature control of the twin-screw extruder is equipped with six sections. The extrusion temperature of several sections is 210-230°C; the residence time of the material in the twin-screw extruder is 8 minutes, and the speed of the main engine is 300-350r.min -1 ; Then extrude the melt through the die of the twin-screw extruder to form a molten pool. Preheat and dry 35 parts of continuous long glass fibers to make the surface temperature reach 65-80°C, then treat the surface of the long glass fibers with a glass fiber surface treatment devic...

Embodiment 2

[0029] 43.6 parts of medium melt finger copolymerized polypropylene, 10 parts of maleic anhydride grafted polypropylene compatibilizer, 3 parts of PP cooling masterbatch, 0.2 part of antioxidant 1098 and 0.4 part of antioxidant 168, 2 parts of high molecular weight polypropylene wax Add to the mixer to mix well. The mixture is fed into the twin-screw extruder through the feeding port. The processing temperature is 180-230°C. The temperature control of the twin-screw extruder has six sections. The extrusion temperature of the first and second sections is 180-200°C. Other The extrusion temperature of several sections is 200-230°C; the residence time of the material in the twin-screw extruder is 3 minutes, and the speed of the main engine is 250-350r.min -1 ; Then extrude the melt through the die of the twin-screw extruder to form a molten pool. Preheat and dry 40 parts of continuous long glass fibers to make the surface temperature reach 60-75°C; then use a glass fiber surface ...

Embodiment 3

[0031] 15 parts of medium-melt finger copolymerized polypropylene, 23 parts of medium-melt finger homopolypropylene, 6 parts of maleic anhydride grafted polypropylene compatibilizer, 4 parts of PP cooling masterbatch, 0.2 part of antioxidant 1010 and 0.3 part of antioxidant 168, 0.5 parts of high molecular weight polypropylene wax and 0.5 parts of ethylene bis stearamide are added to the mixer to make them fully mixed evenly. Put the mixture into the twin-screw extruder through the feeding port, the processing temperature is 190-230°C, the temperature control of the twin-screw extruder has six sections, the extrusion temperature of the first section and the second section is 190-200°C, other The extrusion temperature of several sections is 200-230°C; the residence time of the material in the twin-screw extruder is 5 minutes, and the speed of the main engine is 250-300r.min -1 ; Then extrude the melt through the die of the twin-screw extruder to form a molten pool. Preheat and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com