Patents

Literature

58results about How to "Timely detection of hidden troubles" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Power distribution network line fault on-line monitoring and alarming system

InactiveCN105093061AReduce line patrol workloadAchieve positioningTransmission systemsFault locationFault indicatorSoftware system

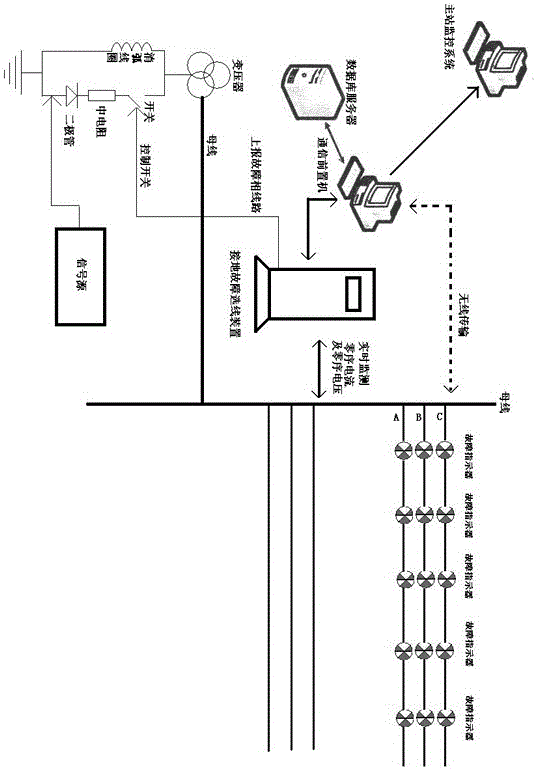

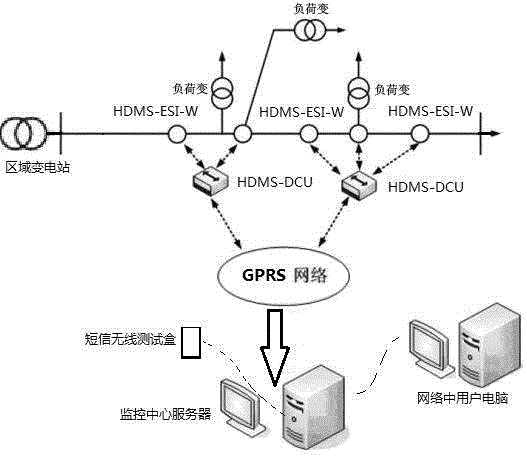

The invention discloses a power distribution network line fault on-line monitoring and alarming system. The system includes a fault positioning software system and a power distribution line fault indicator. The fault positioning software system and the power distribution line fault indicator cooperate. The fault positioning software system includes an intrastation grounding line selection apparatus, a communication front-end processor, an injection signal source and an aerial conductor line fault positioning main station monitoring system. The grounding line selection apparatus and the injection signal source serve to perform single phase grounding fault positioning. The power distribution line fault indicator and a data acquisition concentrator are outrastation apparatuses. The data acquisition concentrator and the power distribution fault indicator form a subnetwork. Among the subnetworks, a monitoring system for a line via the intrastation communication front-end processor is constituted. The fault positioning software system and the power distribution line fault indicator communicate by using cascade via radio frequency. According to the invention, with the cooperation between the fault position software system on a fault line selection host computer and the power distribution fault indicator which has communication function on the line, information which indicates the position and time of the fault can be displayed within minutes of the occurrence of the fault on a geographic information system map of a monitoring center, which facilitates maintenance personnel to head to the site of the fault, eliminate the fault and increase reliability of power supply.

Owner:JIANGSU ANFANG ELECTRIC POWER TECH

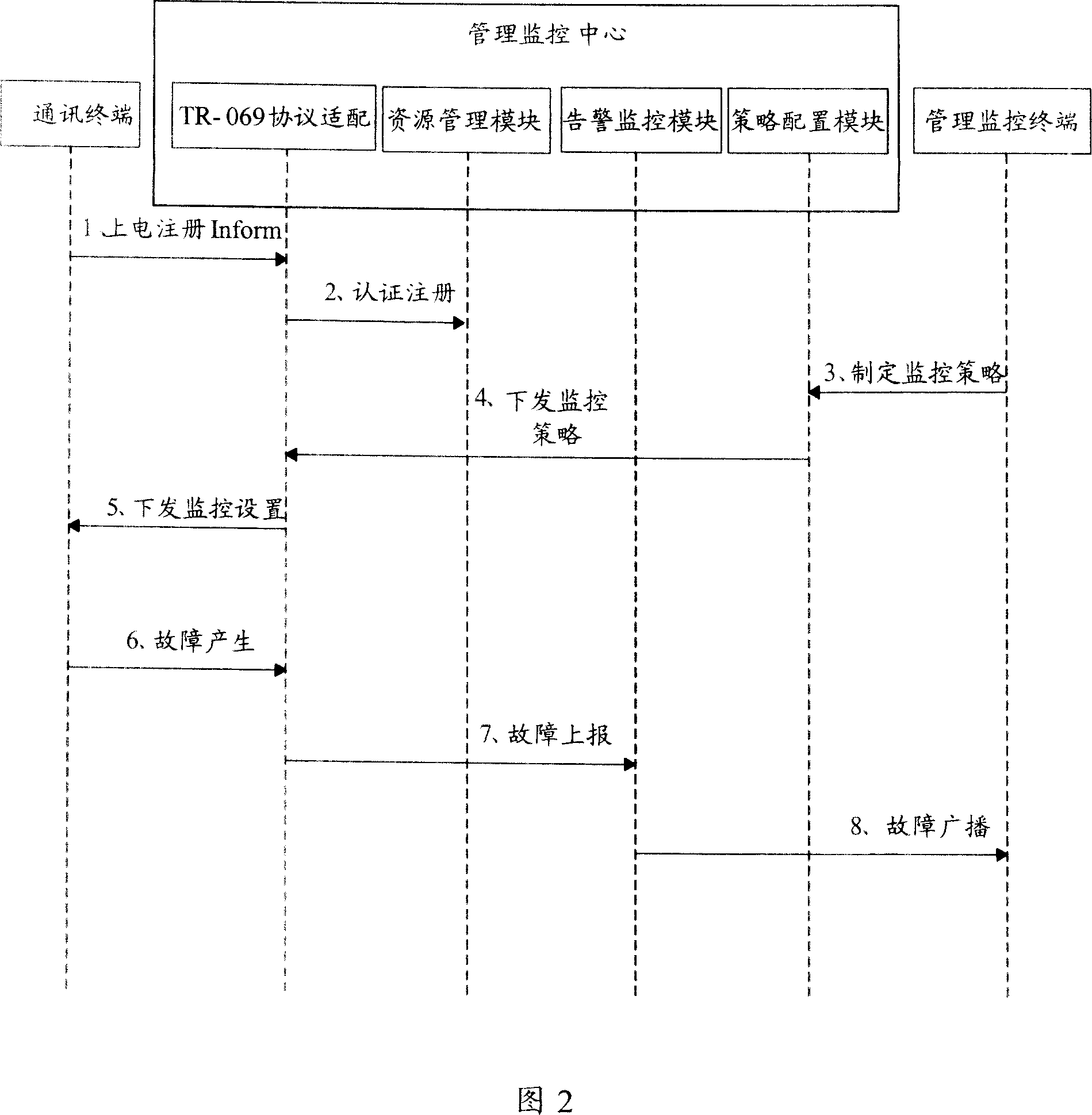

Communication terminal failure monitoring system and implementing method thereof

InactiveCN101115264AGuaranteed uptimeTimely detection of hidden troublesRadio/inductive link selection arrangementsData switching networksTR-069Monitoring system

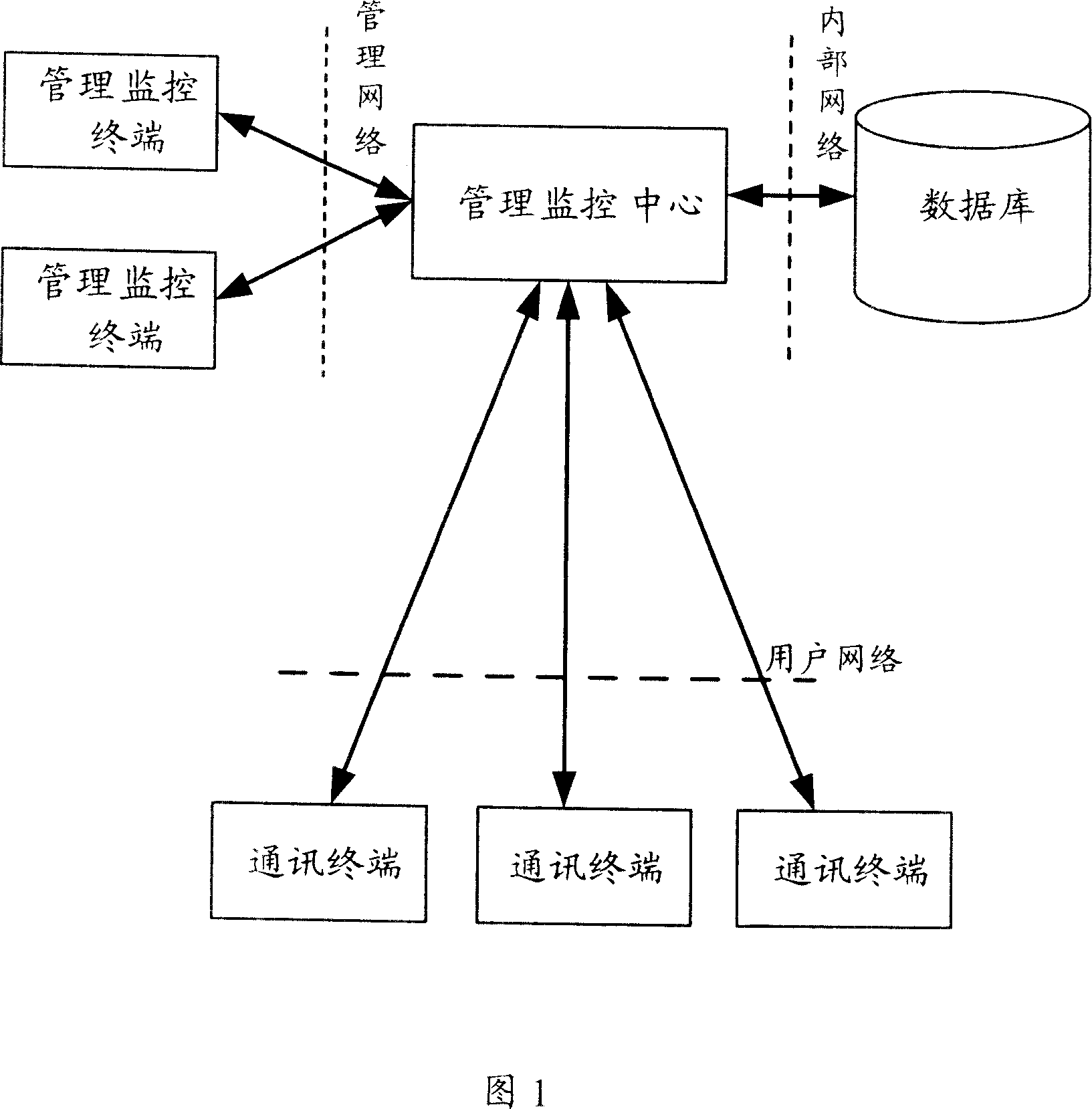

The invention discloses a monitoring system for a communication terminal error, which includes a communication terminal which is used for reporting the warning information to a management and monitoring center or writing the error information into an error diary of the communication terminal itself when the warnings are produced in the motion; a management and monitoring center which registers the legal communication terminal, refuses to register the illegal communication terminal, group the registered communication terminal, set the warning to report classes of different groups of communication terminals; while receiving the error information of the communication terminal, the management and monitoring center broadcasts the error information to the management and monitoring terminal; a management and monitoring terminal which receives the error information that is reported by the management and monitoring center; the error information is monitored through the management and monitoring center that is controlled by the management and monitoring terminal. The management and monitoring center adopts the TR-069 Agreement. The invention also discloses a realizing method to monitor the error of the communication terminal.

Owner:STATE GRID BEIJING ELECTRIC POWER +1

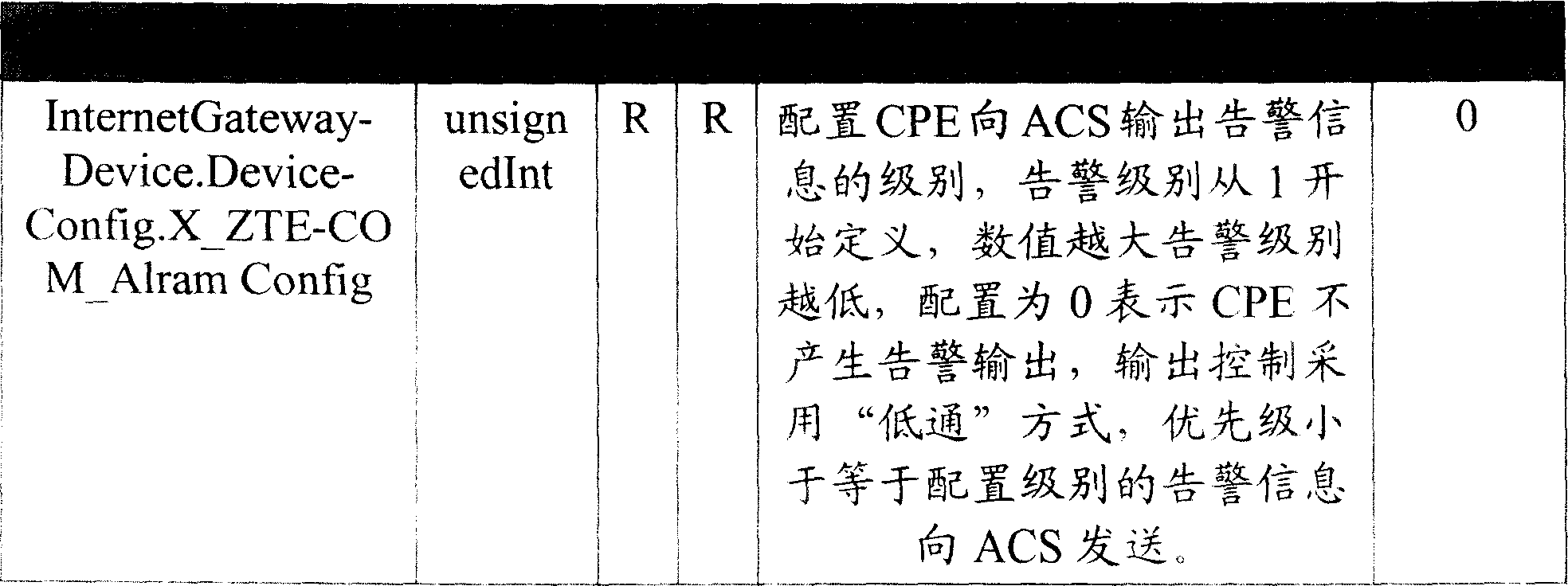

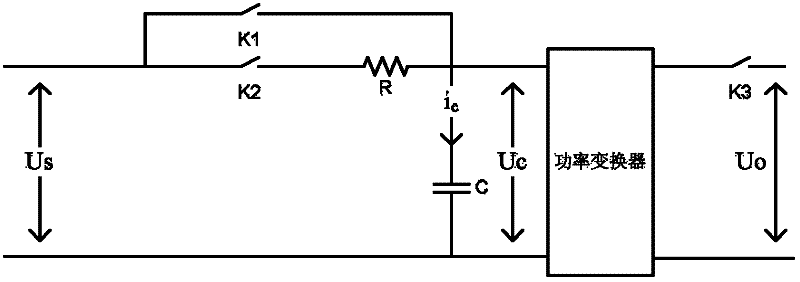

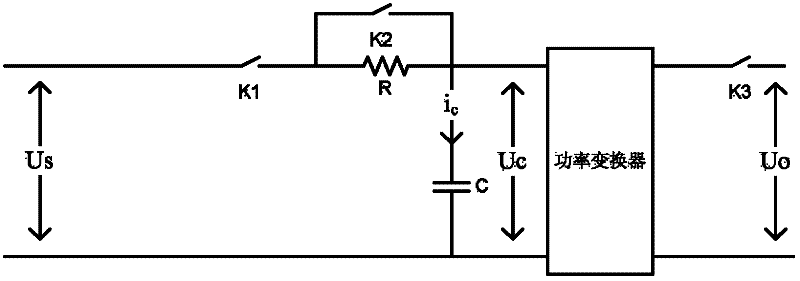

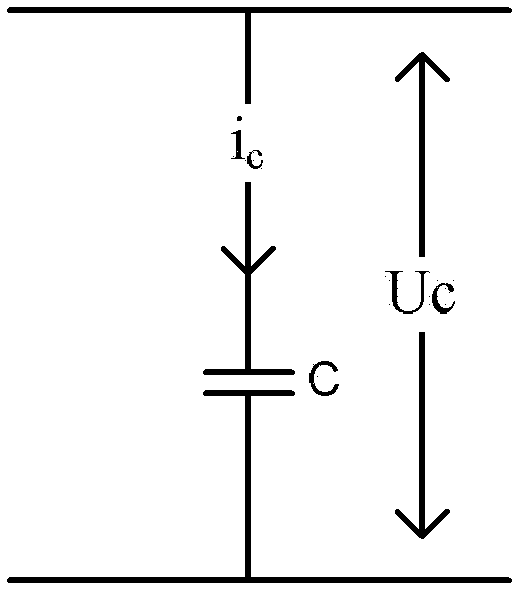

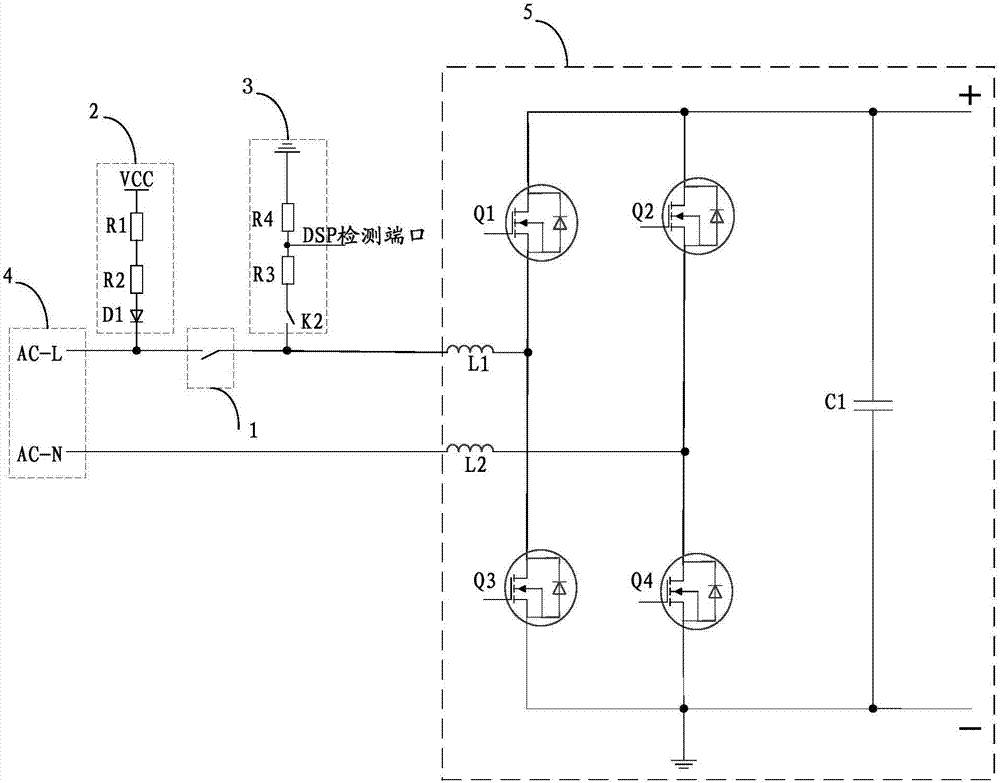

Method and circuit for online monitoring capacity state of bus capacitor

ActiveCN102495292ATimely detection of hidden troublesReduce maintenance costsResistance/reactance/impedenceCapacitanceCapacitor voltage

The invention discloses a method for online monitoring the capacity state of a bus capacitor. According to the method, a capacitor current real-time value ic and a capacitor voltage real-time value Uc of the bus capacitor in the charge / discharge process are detected in real time; as the bus capacitor C is a function of the capacitor current ic, the capacitor voltage Uc and time t, the capacitor capacity is estimated according to the functional relationship; and the capacity state of the bus capacitor is monitored online by judging whether the estimated value of the capacitor capacity is normal. The method can discover the performance drop of the capacitor and possible failure caused by the performance drop in time and does not require forced regular replacement of the bus capacitor, thereby reducing the maintenance cost; and moreover, as the method does not have low requirement on the maintenance personnel, the maintenance cost and the technical difficulty in maintenance are reduced.

Owner:BEIJING DINGHAN TECH GRP CO LTD

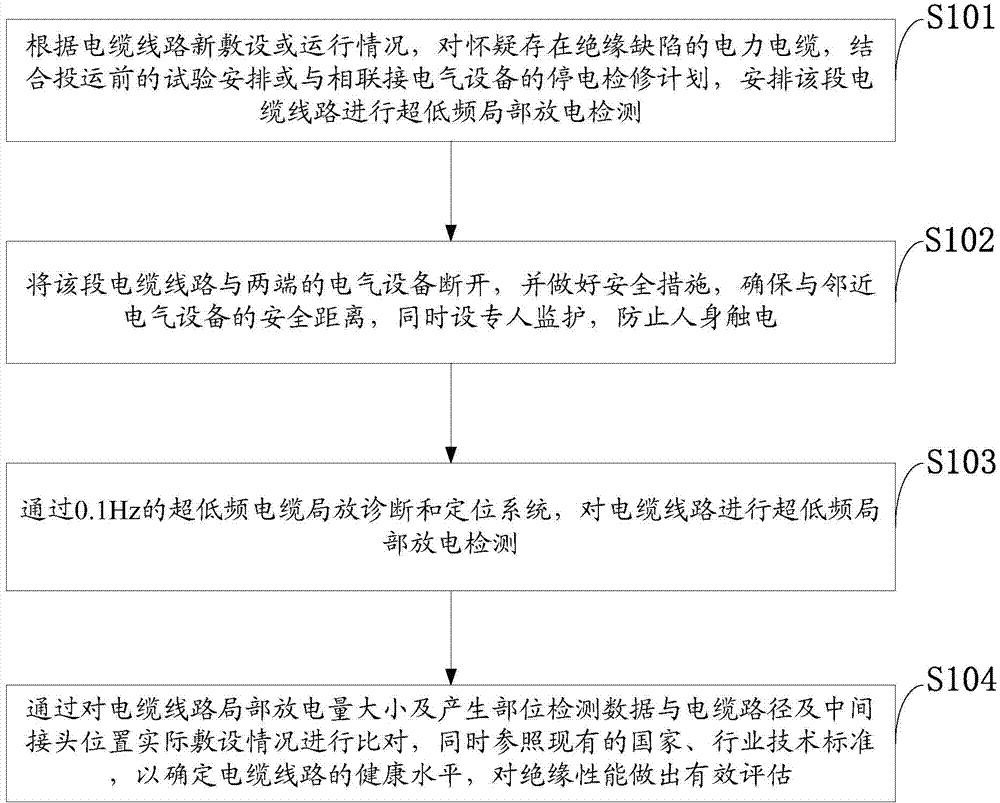

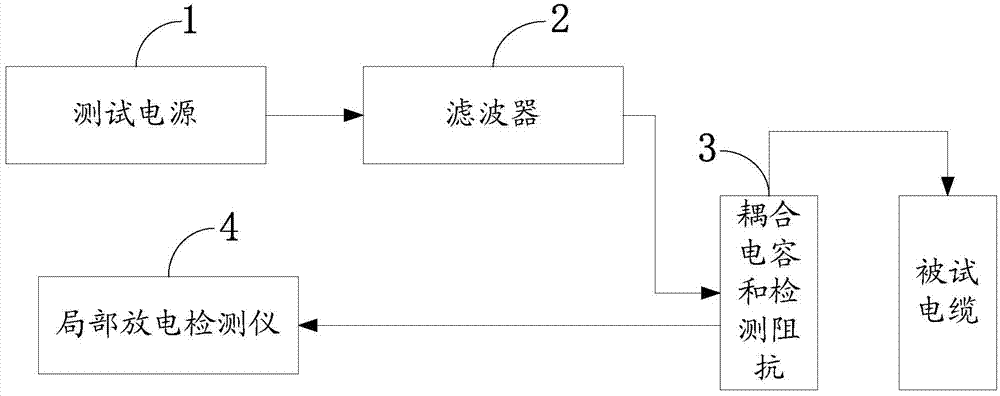

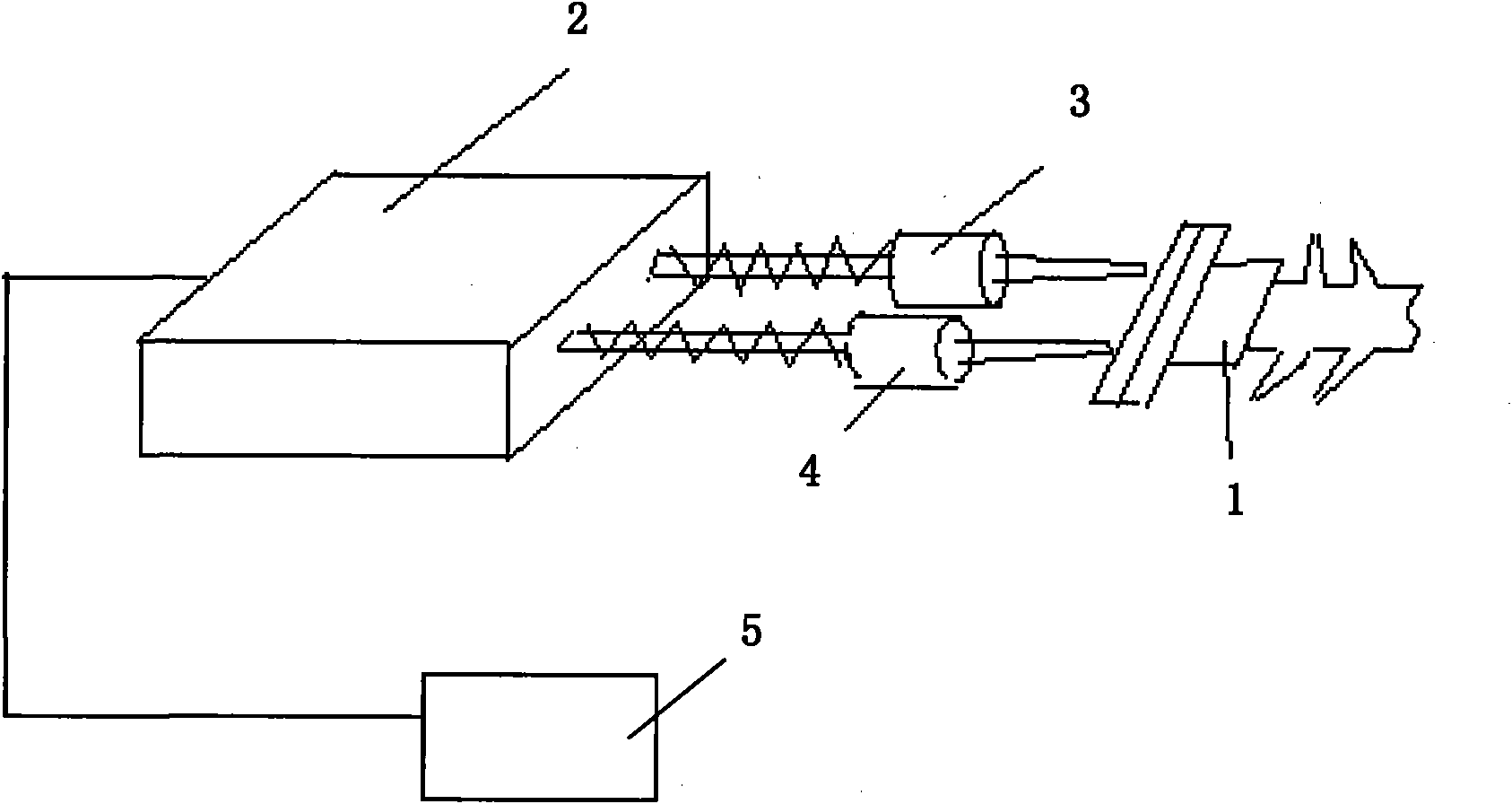

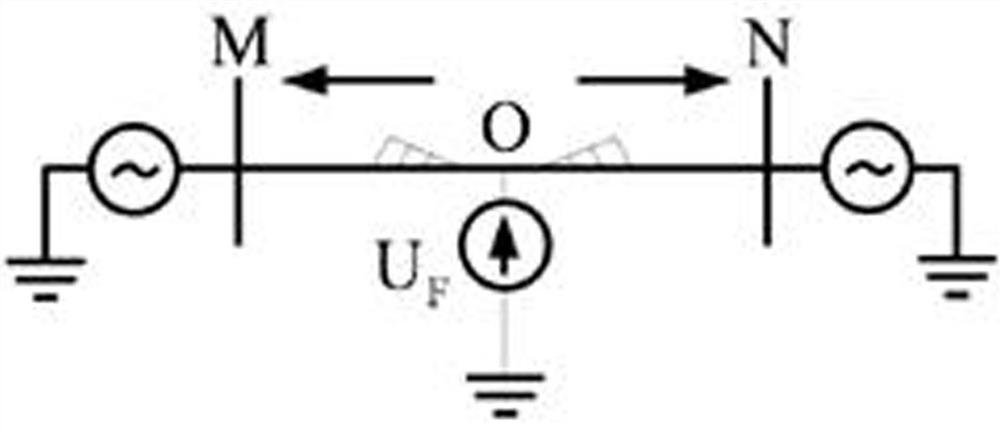

Ultralow frequency partial discharge detection-based evaluation method and system

ActiveCN103499777ADiscover the quality of the installationUnderstanding Insulation ConditionsTesting dielectric strengthFault locationCapacitanceEngineering

The invention discloses an ultralow frequency partial discharge detection-based evaluation method and an ultralow frequency partial discharge detection-based evaluation system. The method comprises the following steps: determining a power cable on which insulation performance evaluation is required to be performed according to the new laying or operation condition of a cable line; disconnecting the section of cable line with electric equipment at the two ends and taking a safety measure; performing ultralow frequency partial discharge detection on the cable line through an ultralow frequency cable partial discharge diagnosis and positioning system; performing symmetrical analysis on a partial discharge detection result by comparing the laying conditions at a cable path and a middle joint position so as to make effective evaluation on the insulation performance of the cable line. The system comprises a testing power supply, a filter, a coupling capacitor, an impedance detector and a partial discharge detector. According to the method and the system, by performing ultralow frequency partial discharge actual measurement on the cable, the mounting quality of the cable is effectively discovered, and the insulation situation of the cable is learnt, the faults of the cable are reduced, the hidden faults of the cable line can be timely discovered, and the method and system have great significance to safe and reliable operation of a power grid.

Owner:STATE GRID CORP OF CHINA +1

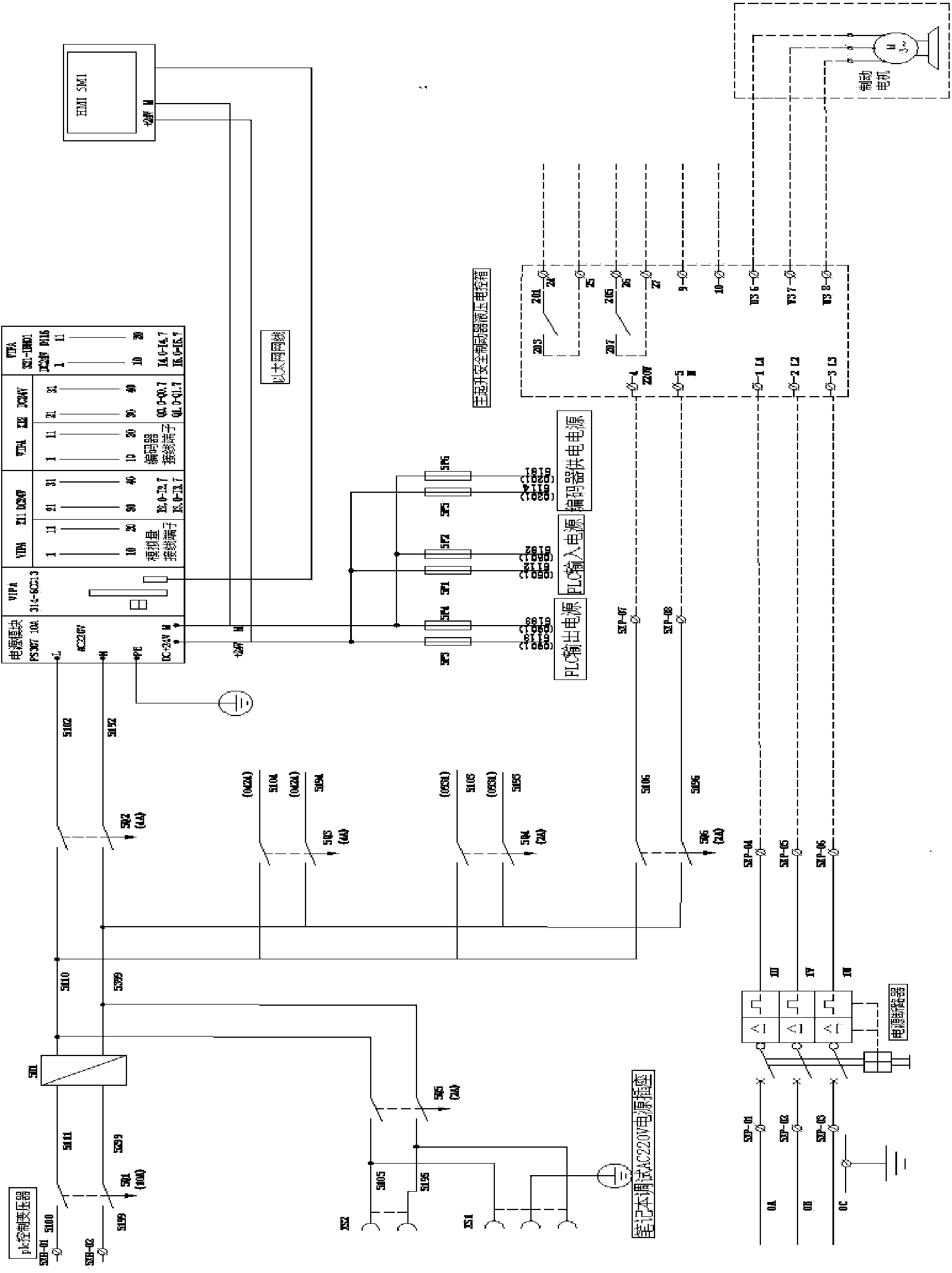

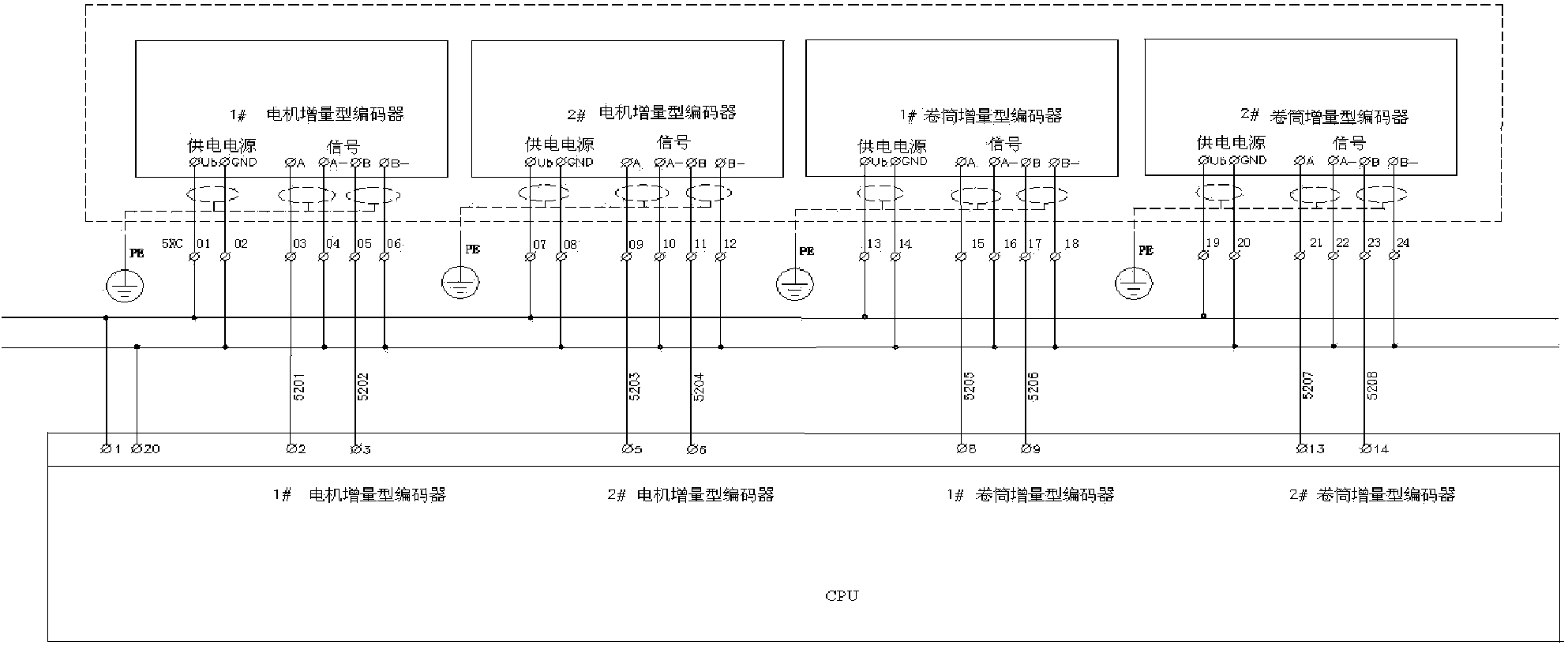

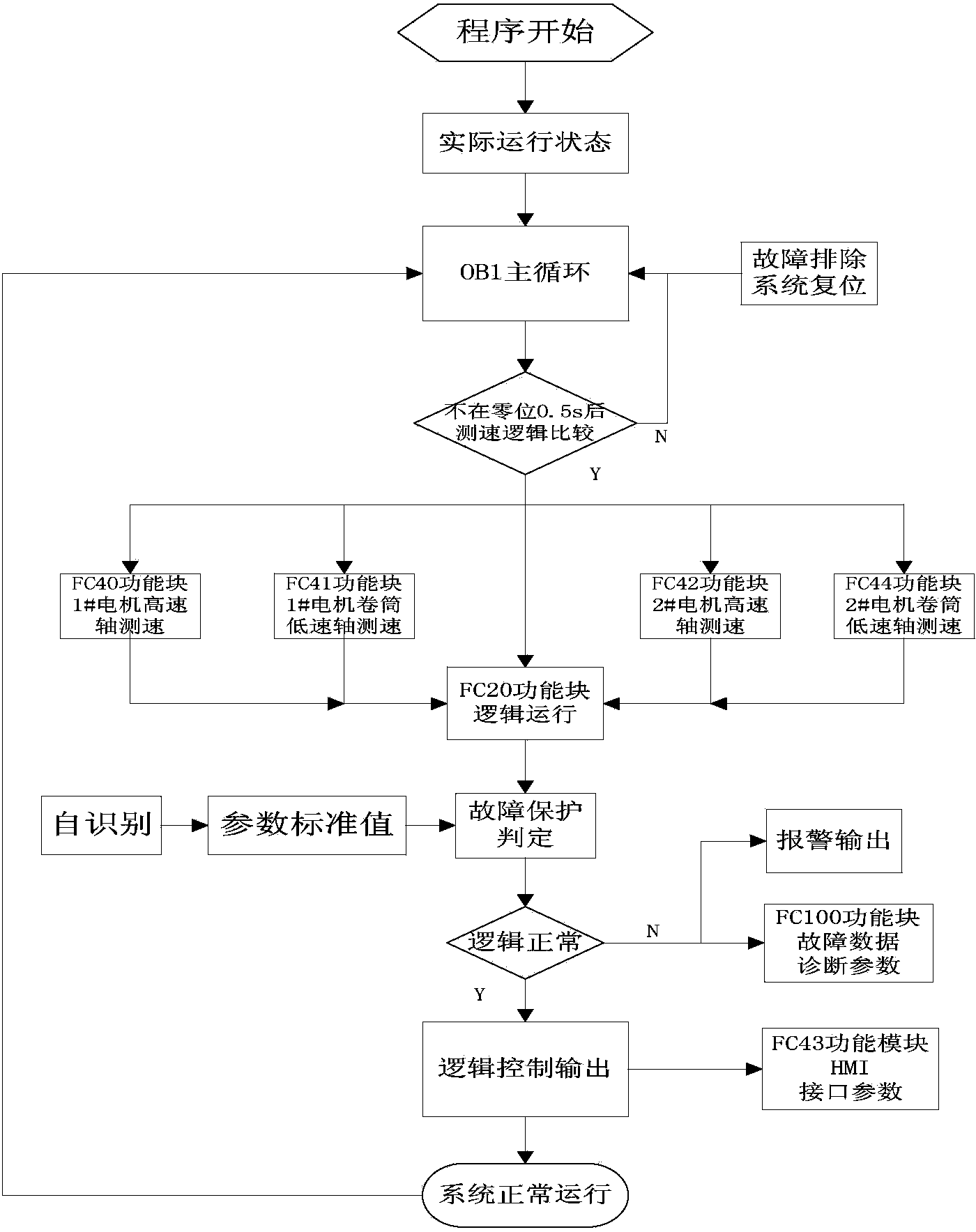

Safety-brake PLC (Programmable Logic Controller) control system with self recognition and control method thereof

ActiveCN103910288AReduce malfunctionReduce the possibility of malfunctionSafety gearLow speedCommand and control

The invention discloses a safety-brake PLC (Programmable Logic Controller) control system with self recognition and a control method of the safety-brake PLC control system. The system comprises an incremental type encoder, a safety brake control unit and an operation unit, wherein the incremental type encoder is used for acquiring rotating-speed signals of a high-speed shaft and a low-speed shaft; the safety brake control unit comprises a PLC, a control output module and a voltage-stabilizing power supply; the PLC is used for carrying out logic operation analysis on the acquired rotating-speed signals and outputting corresponding logic control commands to the control output module according to a logic operation analysis result; and the control output module acts according to the received logic control commands and controls a working brake or a safety brake to act. The safety-brake PLC control system and the control method disclosed by the invention have the advantages that the potential hazards of faults can be found in time, the possibility of false operation of the safety brake is reduced, the damage of protective action to a mechanical structure is greatly reduced, the debugging is simple and convenient and the use efficiency of the safety brake is improved.

Owner:大连美恒电气有限公司

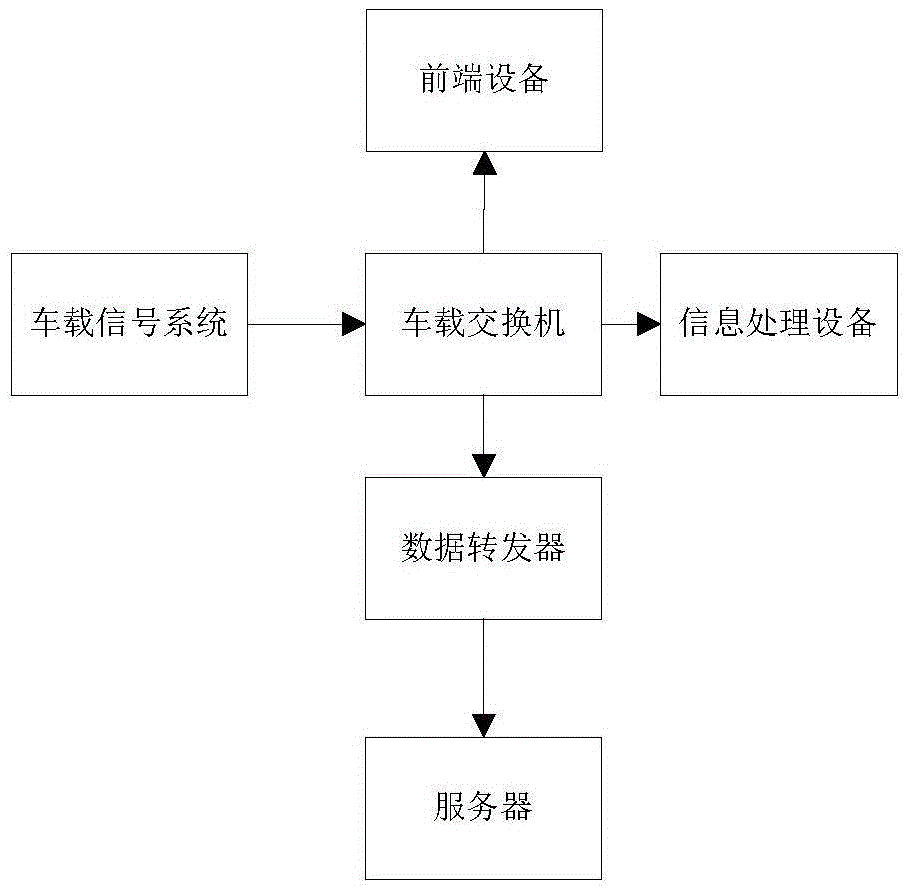

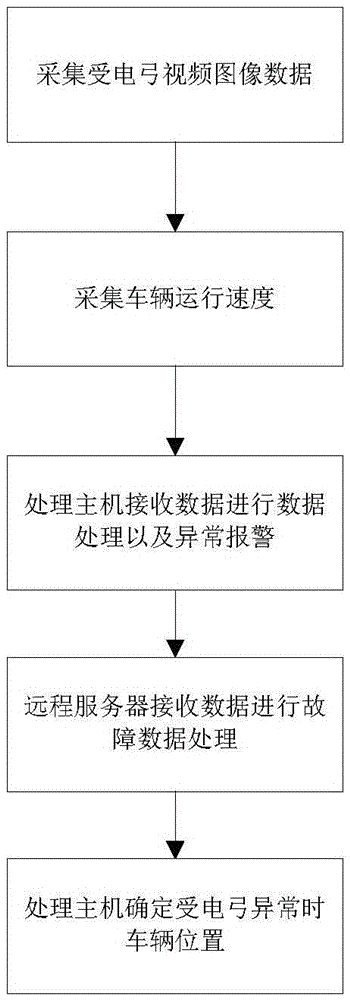

Pantograph monitoring system

InactiveCN105539512AWith automationIntelligentPhotogrammetry/videogrammetrySignalling indicators on vehicleInformation processingElectricity

The invention provides a pantograph monitoring system. The pantograph monitoring system comprises front end equipment used for obtaining pantograph image information, information processing equipment used for providing a power source, storing images and processing the images, a server used for collecting all detection data and processing background data and a vehicle-mounted signal system used for detecting vehicle speed and transmitting the data to the information processing equipment. A non-contact detection device is provided creatively, the needed detection information is directly obtained through an information collecting module installed on a vehicle roof, and it is unnecessary to transform a pantograph; the system has the advantages of being automatic, intelligent, easy to operate, convenient and flexible to install and adjust, monitors and traces the using status, a cable stagger value and hard spot arcing in the online operation process of the pantograph in real time, analyzes the pantograph catenary operation state, and gives an alarm when the catenary stagger value of the pantograph is overlarge, and hard spot arcing occurs on the pantograph.

Owner:TIANJIN BEIHAI COMM TECH

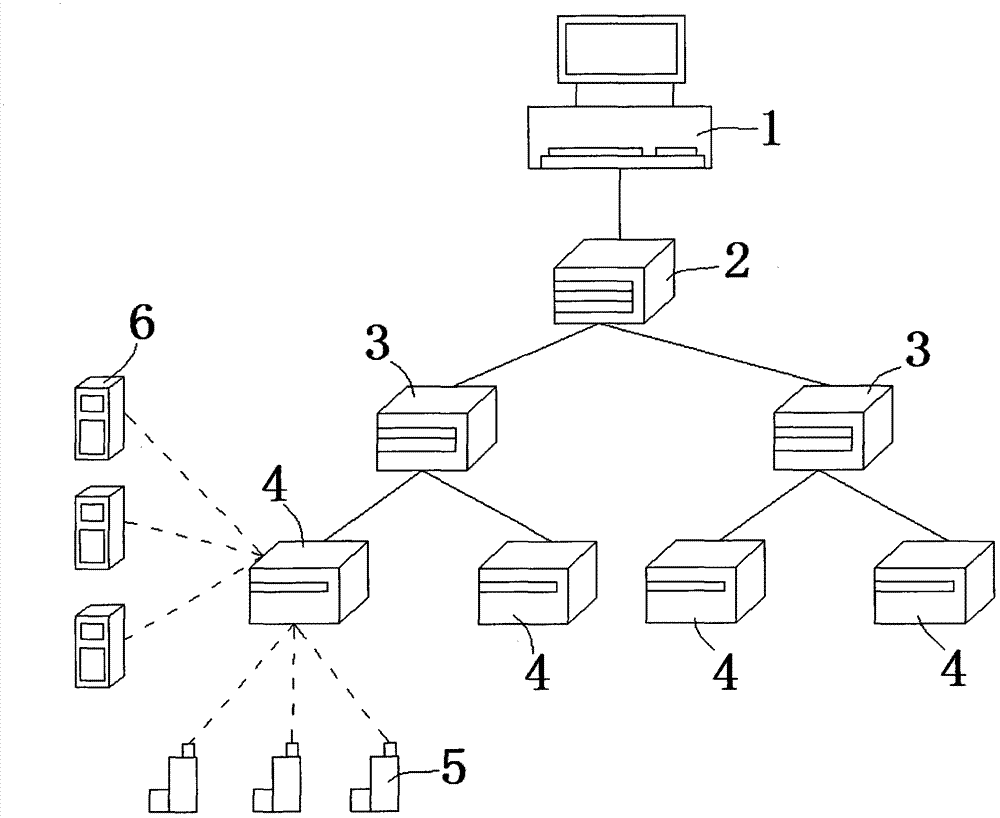

Power equipment and transmission line malfunction comprehensive online monitoring system

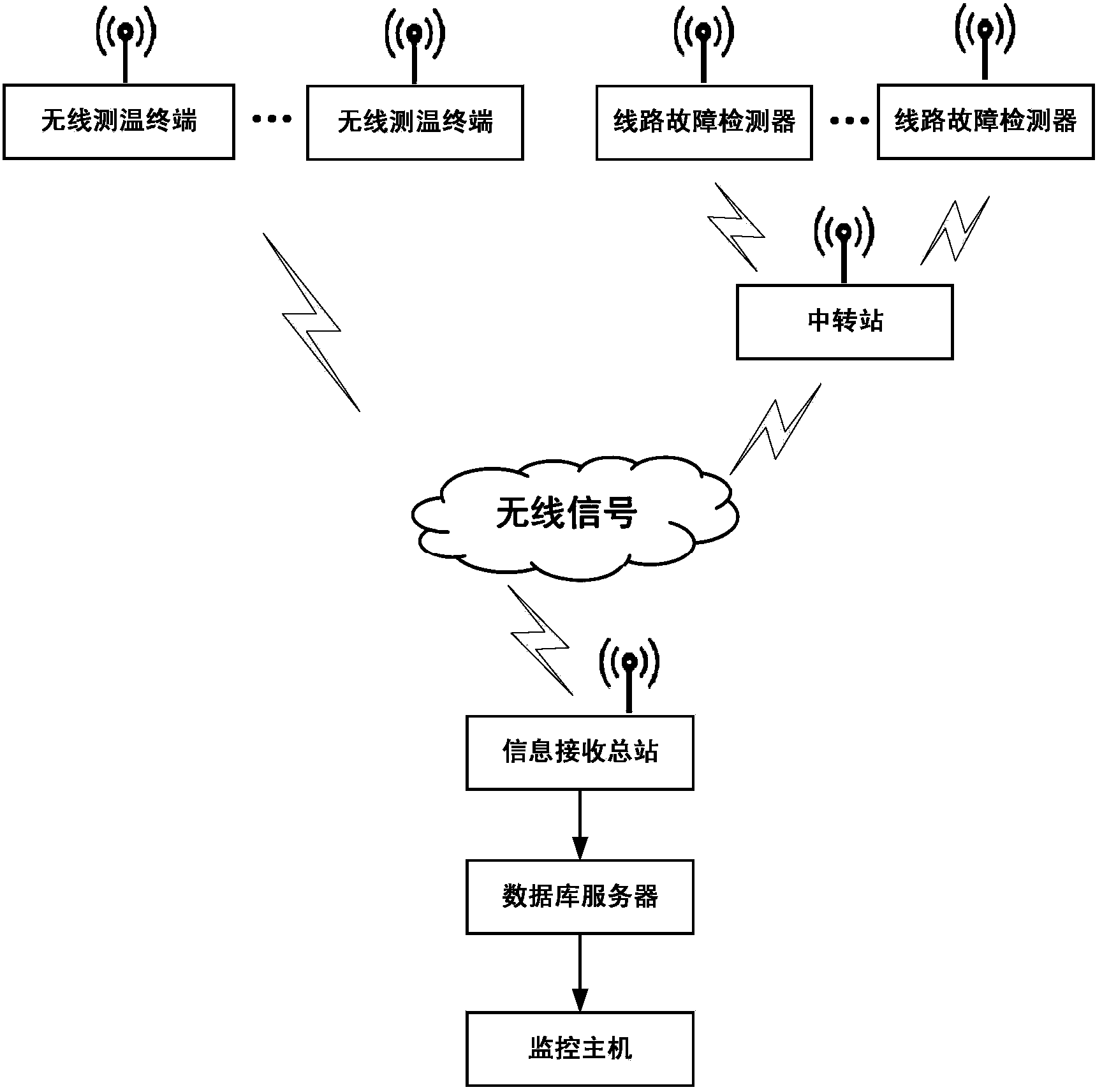

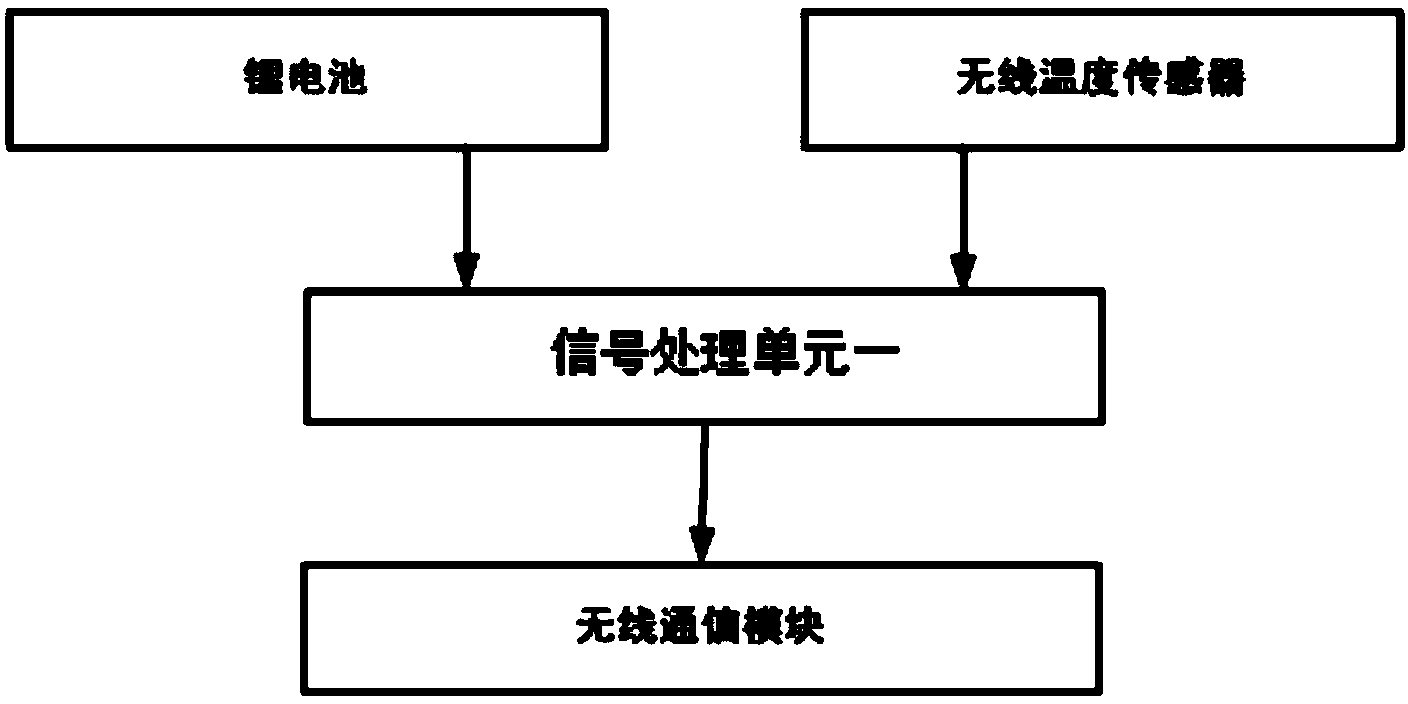

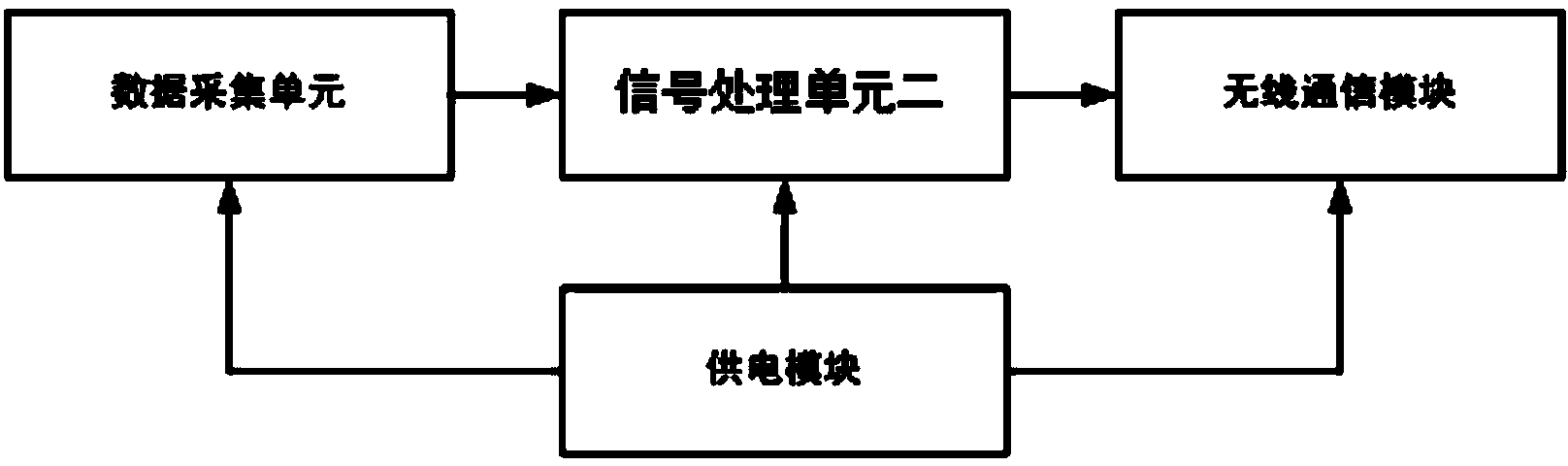

InactiveCN104316839AImprove signal anti-interference abilityTo achieve temperature compensationFault locationInformation technology support systemDatabase serverMonitoring system

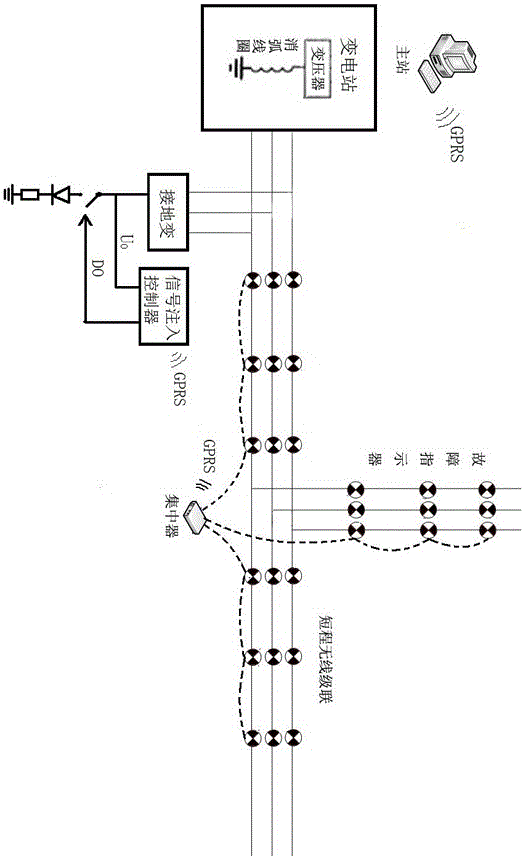

The invention discloses a power equipment and transmission line malfunction comprehensive online monitoring system which comprises a wireless temperature measuring terminal, a line malfunction detector, a transfer station, an information receiving main station, a database server and a monitoring host. The wireless temperature measuring terminal is wirelessly connected with the information receiving main station through a built-in wireless communication module, the line malfunction detector is wirelessly connected with the information receiving main station through a built-in wireless communication module and the transfer station, and the information receiving main station is connected with the database server which is connected with the monitoring host. The system can monitor and upload power equipment temperature rise standard exceeding and transmission line ground fault information in real time, quickly locate line fault sections and fault branches, shorten fault clearing time and improve safety and reliability of power equipment and transmission lines.

Owner:ANSHAN POWER SUPPLY COMPANY OF STATE GRID LIAONING ELECTRIC POWER COMPANY +1

Method for detecting post insulator cracks based on vibration acoustics

ActiveCN102095802AReduce investmentReduce the impactAnalysing solids using sonic/ultrasonic/infrasonic wavesElectric power transmissionVibration based

The invention provides a method for detecting post insulator cracks based on vibration acoustics, which belongs to the field of electric transmission and in particular relates to a method for detecting post insulator cracks based on vibration acoustics. The method comprises the following steps of: (1) exciting post insulators to be detected one by one with acoustic waves in a frequency spectrum range of 1000-10000Hz and detecting the forced vibration inherent frequency of the insulators; and (2) inputting the detection results of the continuous forced vibration acoustic wave frequency spectrum of the detected post insulators into post insulator internal crack judgment functions previously established to judge the internal cracks of the post insulators. The method can carry out site live line monitoring on the post insulators. During detection, as long as continuous acoustic wave collection is carried out on the post insulators once, the internal cracks of the post insulators can be detected respectively through various judgment functions previously established.

Owner:HEILONGJIANG ELECTRIC POWER RES INST +1

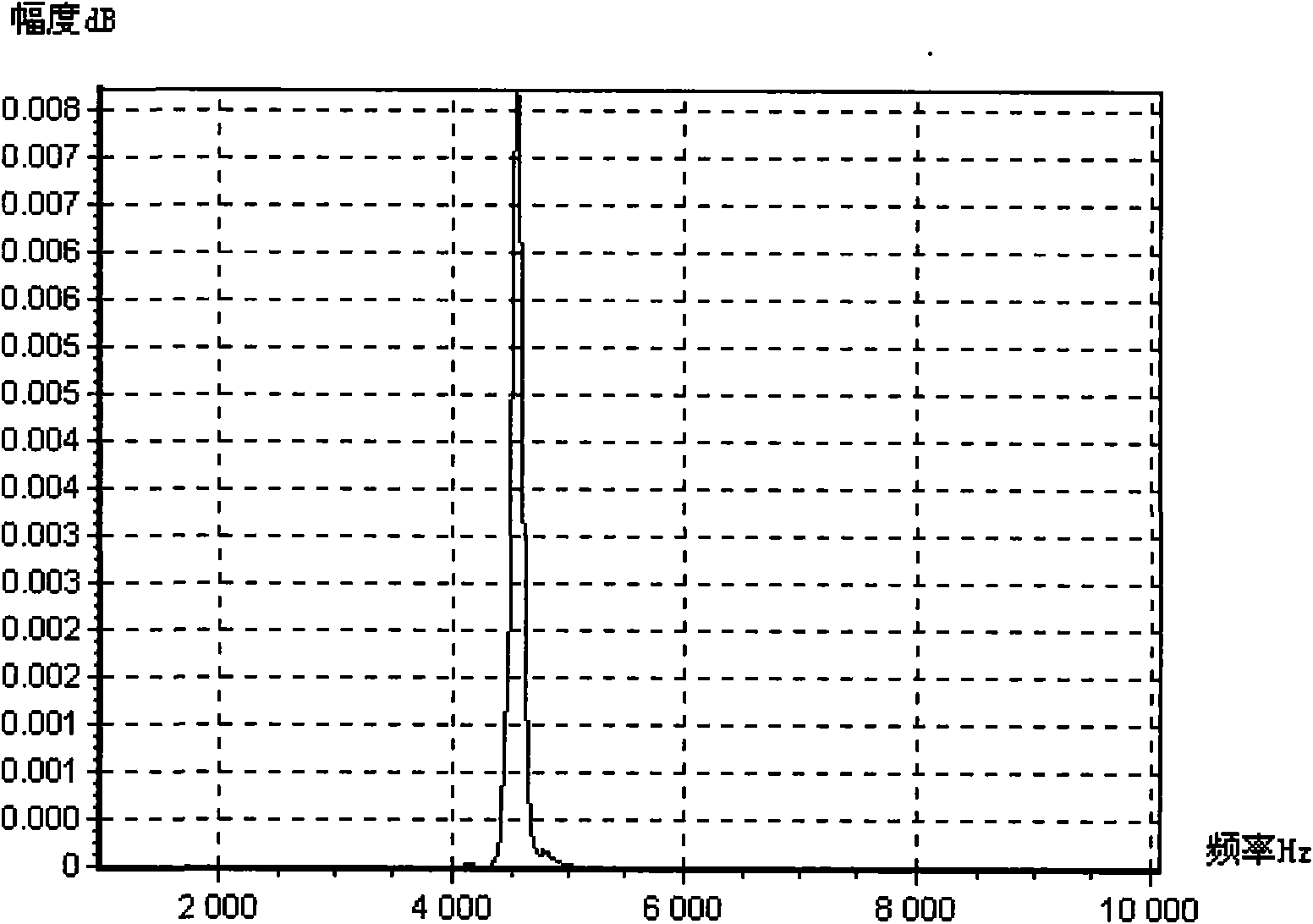

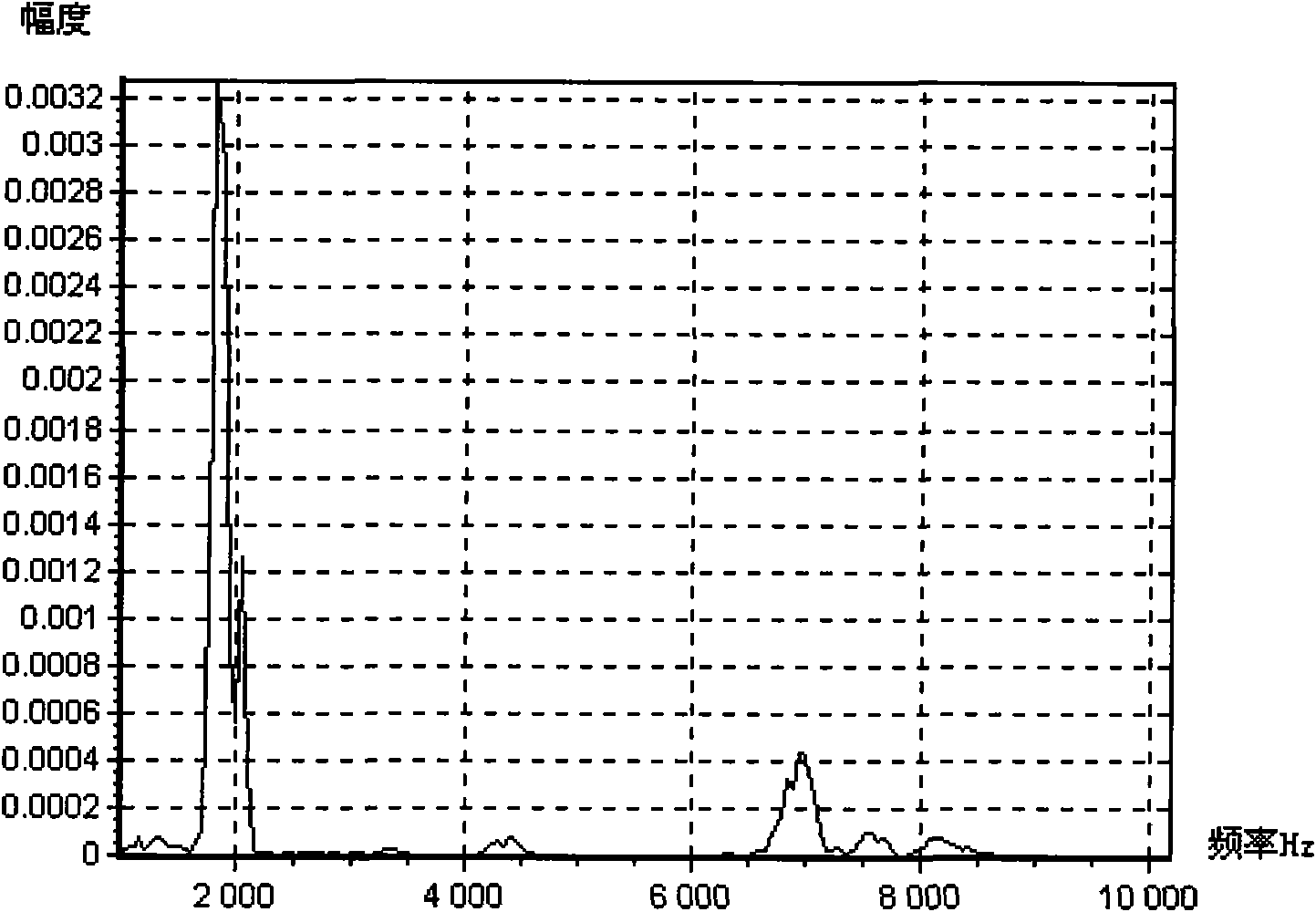

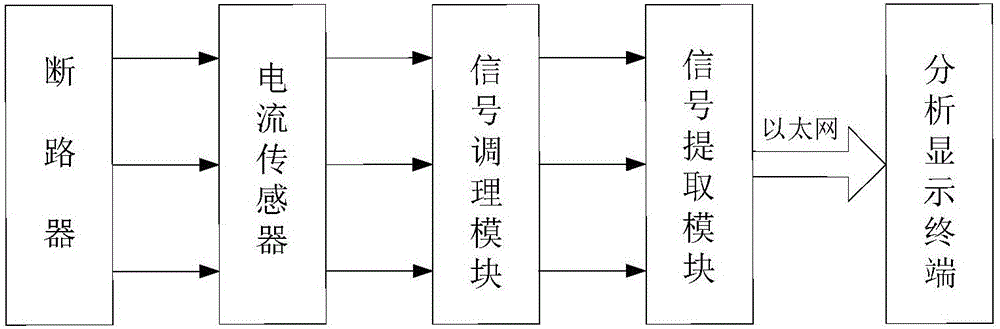

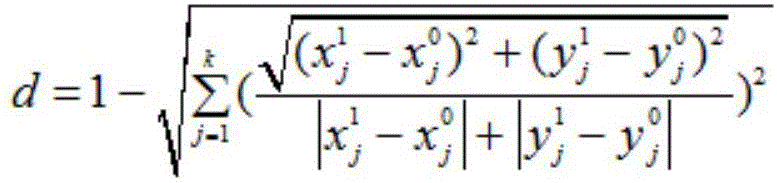

Monitoring system and monitoring method for circuit breaker state based on divide-shut brake coil current

ActiveCN106443433ATimely detection of hidden troublesImprove reliabilityCircuit interrupters testingSignal conditioningElectric power system

The invention discloses a monitoring system and monitoring method for circuit breaker state. The circuit breaker state monitoring system and monitoring method based on the divide-shut brake coil current are characterized in that the system comprises a current sensor, a signal conditioning module, a signal extracting module and a signal analyzing displaying terminal; a current signal of the circuit breaker divide-shut brake coil is detected by utilizing the current sensor, with respect to obtained circuit signals of a normal working condition circuit breaker and a monitored circuit breaker, circuit vector set similarity is calculated, and a monitoring result is thus judged. According to the monitoring system and monitoring method for the circuit breaker state, by conducting identification on a mechanical state of the circuit breaker, a potential failure can be found in time when the circuit breaker switches and closes, and reliability and safety of operation of the circuit breaker and an electric power system can be improved.

Owner:STATE GRID CORP OF CHINA +1

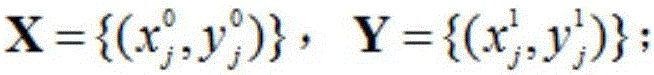

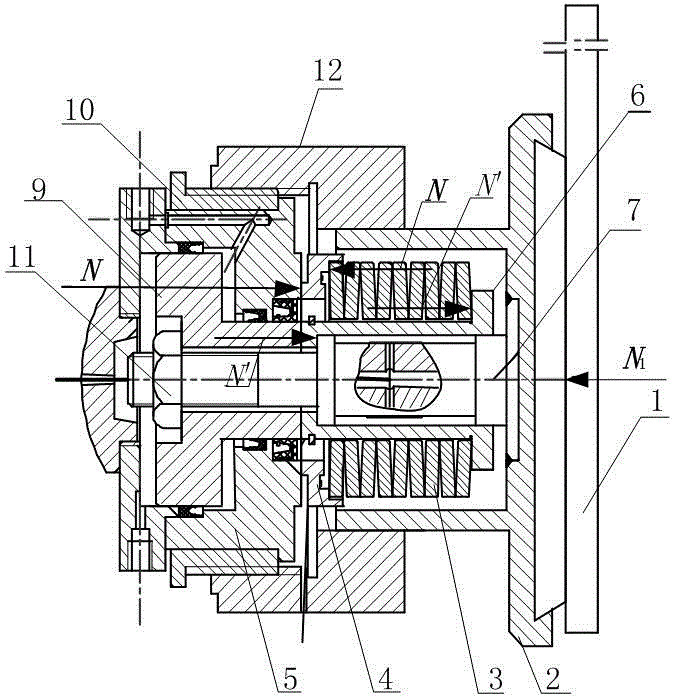

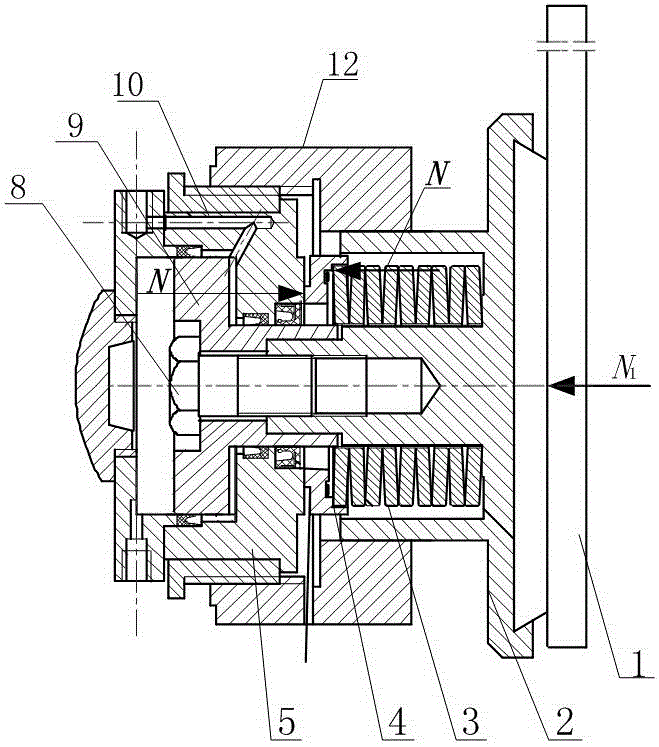

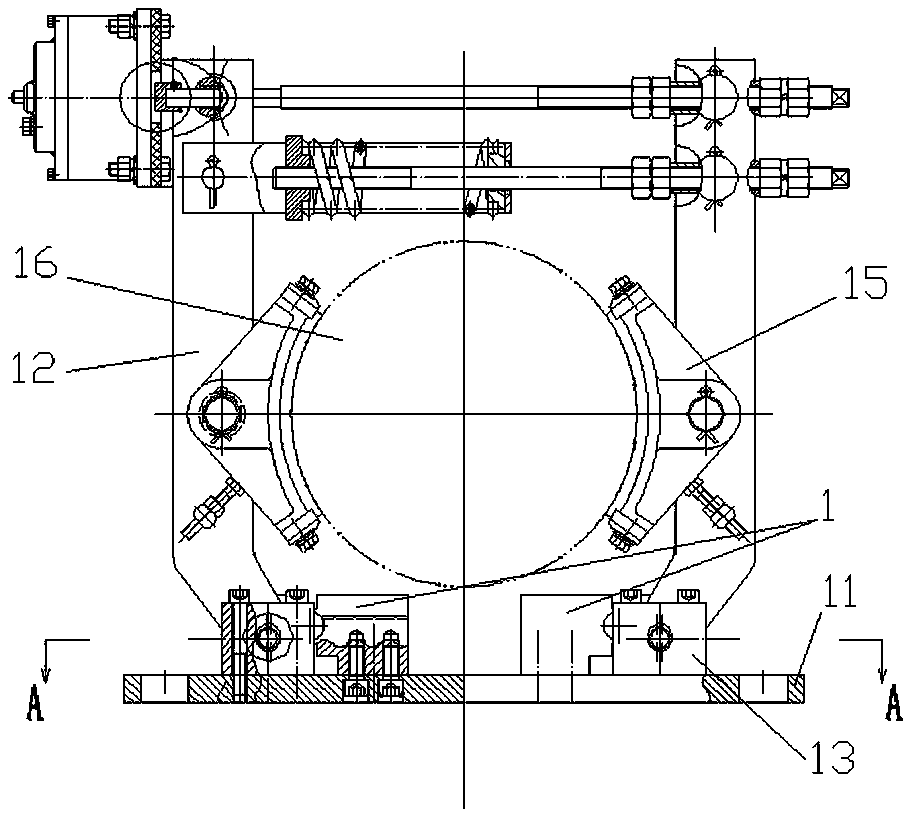

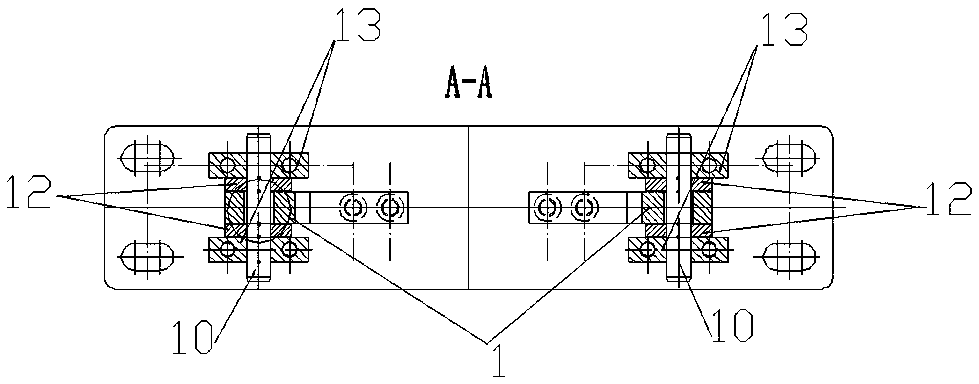

Disc brake capable of diagnosing braking fault and monitoring braking force

ActiveCN105909702AReliable braking force monitoring dataTimely detection of hidden troublesBrake typesSpring forceBrake shoe

The invention discloses a disc brake capable of diagnosing a braking fault and monitoring braking force. The disc brake is characterized in that a disc spring force sensor and a braking force sensor are arranged; the disc spring force sensor is used for monitoring disc spring force generated by deformation of a disc spring set; and the braking force sensor is used for monitoring braking force applied to a brake disc by a brake shoe component. The working principle of the disc brake is as follows: under a braking state, the disc spring force is totally applied to the brake shoe; and according to experiments, friction force is very small and ignorable compared with the disc spring force, so that the braking force is equal to the disc spring force. Under the braking state, values monitored by the two sensors are compared; if the two values are equal, the value is taken as the monitored braking force; if the values are not equal, the braking fault of the disc brake is diagnosed. By adopting the disc brake capable of diagnosing the braking fault and monitoring the braking force, the braking fault can be diagnosed; the braking force monitoring precision is high; braking is reliable; and the disc brake has wide practicability.

Owner:XUZHOU DAHENG MEASUREMENT & CONTROL TECH +2

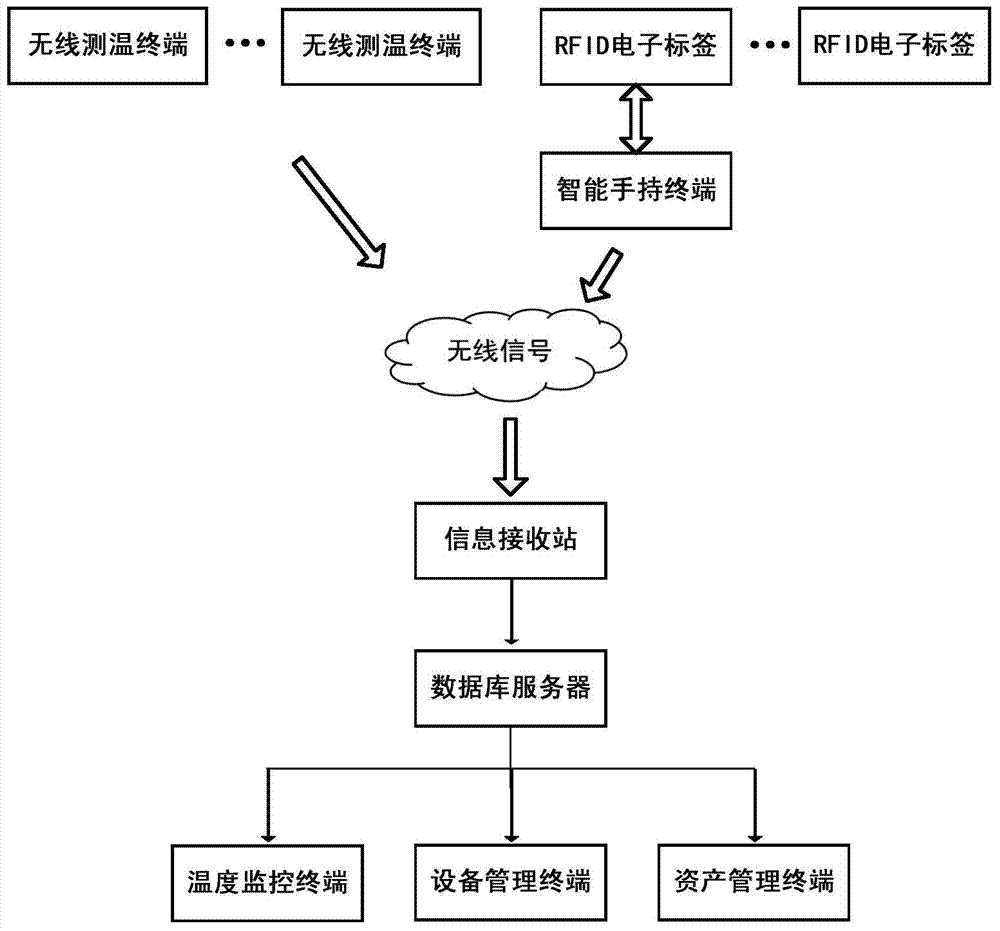

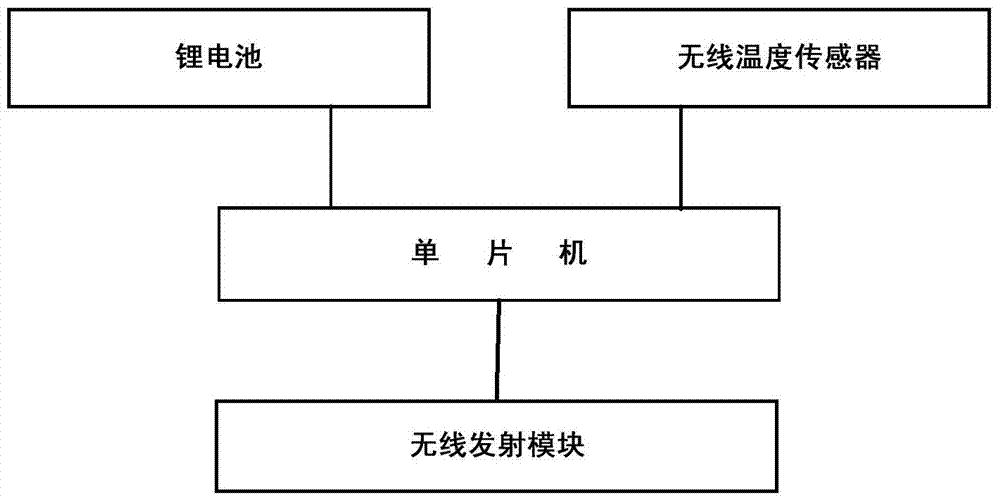

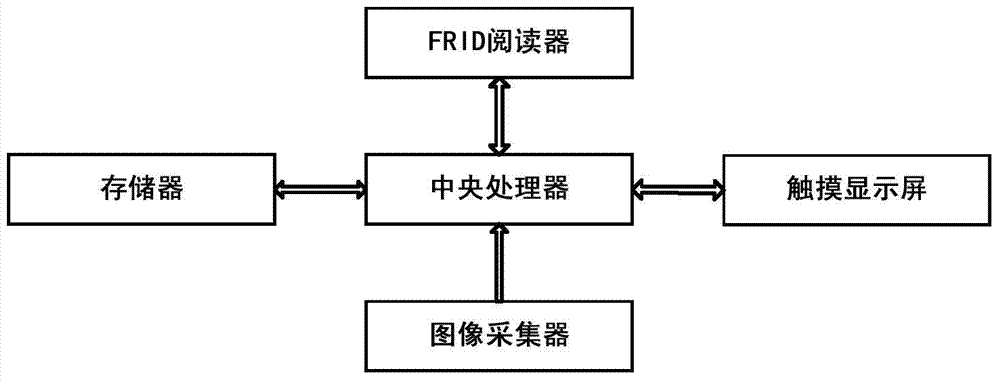

Intelligent inspection management system for power equipment

InactiveCN104331943AAvoid burning accidentsTimely detection of excessive temperature riseChecking time patrolsData processing applicationsHand heldPower equipment

The invention discloses an intelligent inspection management system for power equipment. The intelligent inspection management system comprises a wireless temperature measurement terminal, an intelligent hand-held terminal, an information receiving station, a database server, a temperature monitoring terminal, an equipment management terminal and an asset management terminal, wherein the wireless temperature measurement terminal and the intelligent hand-held terminal are in wireless connection with the information receiving station through a built-in GPRS communication module respectively; the information receiving station is connected with the database server; and the temperature monitoring terminal, the equipment management terminal and the asset management terminal are respectively connected with the database server. According to the system, on one hand, the abnormal condition of the power equipment in operation can be timely found out, and can be processed within the shortest period of time; the inspection quality and the work efficiency of a patrol officer are ensured; the reliability of the power equipment is improved; and the potential safety hazards are eliminated; and on the other hand, the management level of the full life circle of enterprise equipment asset can be improved.

Owner:CHAOYANG POWER SUPPLY COMPANY OF STATE GRID LIAONING ELECTRIC POWER SUPPLY +2

Mine fully-mechanized coal mining face wireless network transmitting system

InactiveCN104506799AImprove safety prevention capabilitiesImprove predictive abilityClosed circuit television systemsWireless dataWireless camera

The invention relates to a mine fully-mechanized coal mining face wireless network transmitting system, which comprise wireless cameras for acquiring images and carrying out wireless data interaction on the images, mining wireless base stations for carrying out wireless data interaction with the plurality of wireless cameras, and converting wireless signals and wired signals, a mining core switch for carrying out wired data interaction with the plurality of mining wireless base stations, and a control center for carrying out wired data interaction with the mining core switch and displaying the images. The mine fully-mechanized coal mining face wireless transmitting system realizes safety production monitoring anytime and anywhere, and with an automatic pushing mechanism for automatic alarm information, related personnel can discover accident potentials and treat in time, the accident prediction and prognosis capability is improved, a working face is unattended, the accident occurrence rate and the casualty rate are reduced, the operation quality and the reliability of a coal mine safety production system are improved, and the production efficiency is improved.

Owner:BEIJING TANGBAI COMM TECH

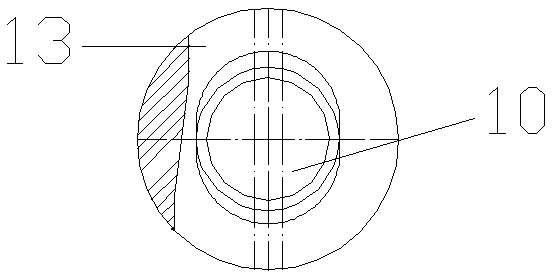

Hub type brake braking torque true value detection sensor and braking torque true value detection method

PendingCN108373089ARealize real-time detectionTimely detection of hidden troublesBrake typesElevatorsBrake torqueControl theory

The invention relates to a hub type brake braking torque true value detection sensor and a braking torque true value detection method. The hub type brake braking torque true value detection sensor comprises a base plate used for being fixed to a brake base and a tension and compression sensor attached to the base plate; the base plate is divided into a suspending extending part of which the bottomside is suspended and a fixed connecting part fixedly connected with the brake base, the suspending extending part of the base plate is provided with a transverse through hole, and the transverse through hole is used for a braking arm hinging shaft of a hub type brake to penetrate through to convert perpendicular acting force generated when a braking arm brakes into tension and compression actingforce to the base plate through the braking arm hinging shaft; the tension and compression sensor is attached to the suspending extending part at the portion, between the transverse through hole andthe fixed connecting part, on the base plate to be used for detecting the tension and compression acting force exerted on the base plate, and then through the geometric size of a braking drum installed on hoisting equipment of the hub type brake, the braking torque true value of the hub type sensor is obtained through calculation.

Owner:SHIJIAZHUANG WULON BRAKE

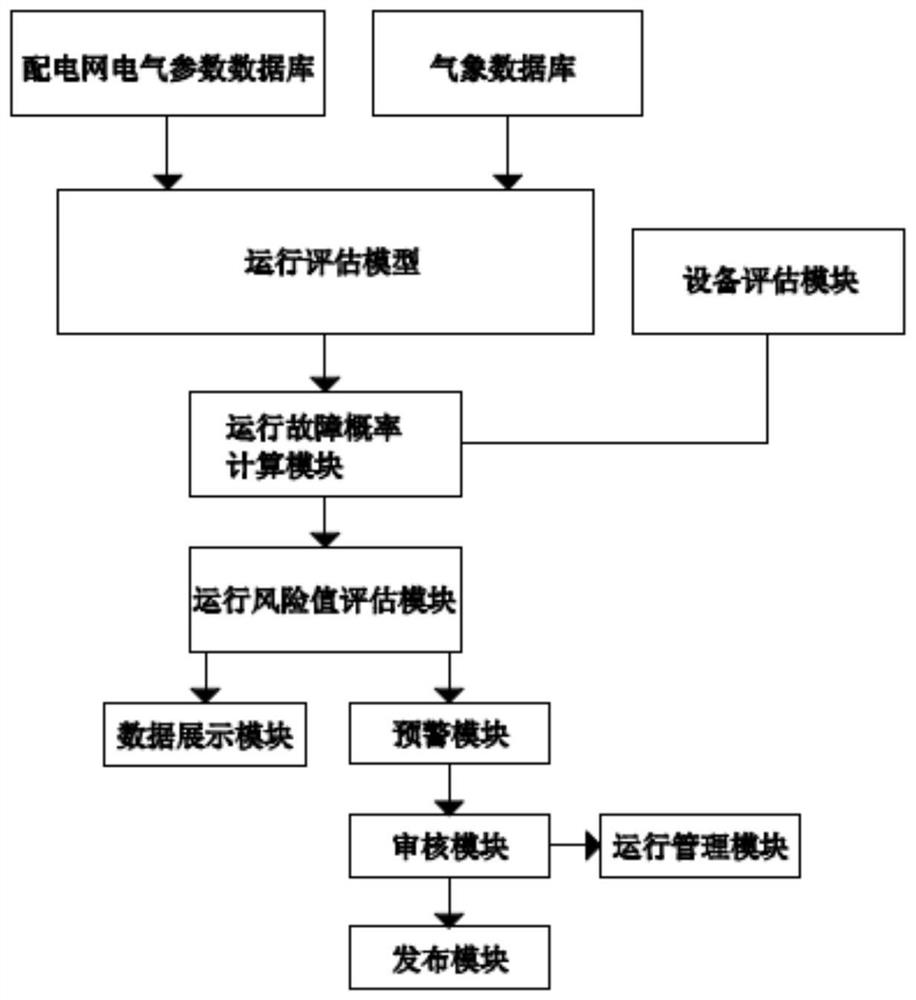

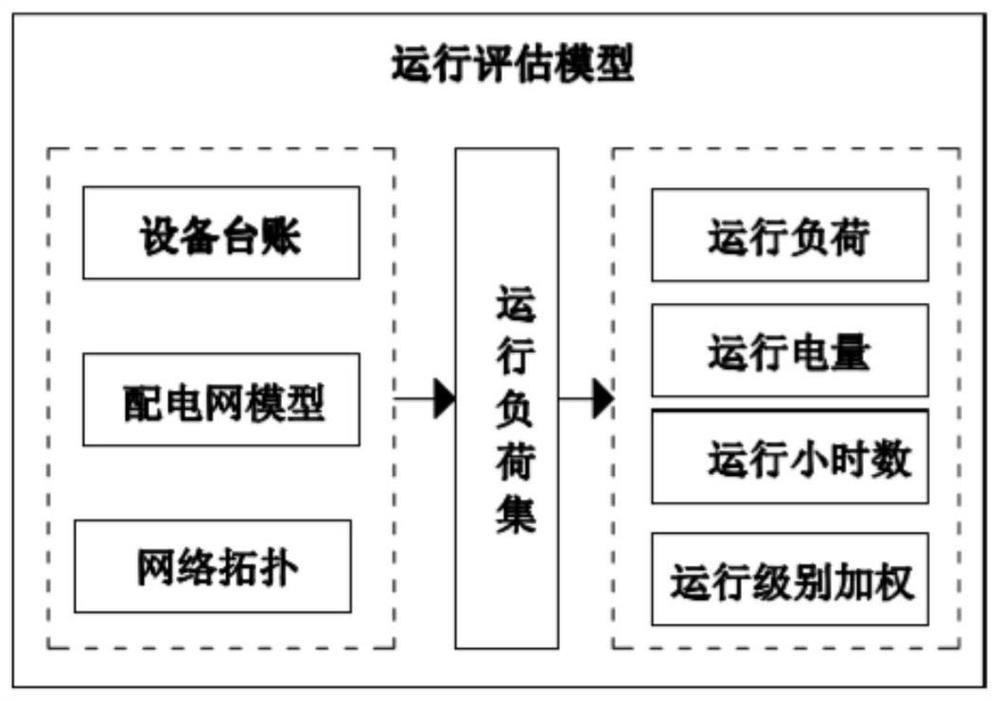

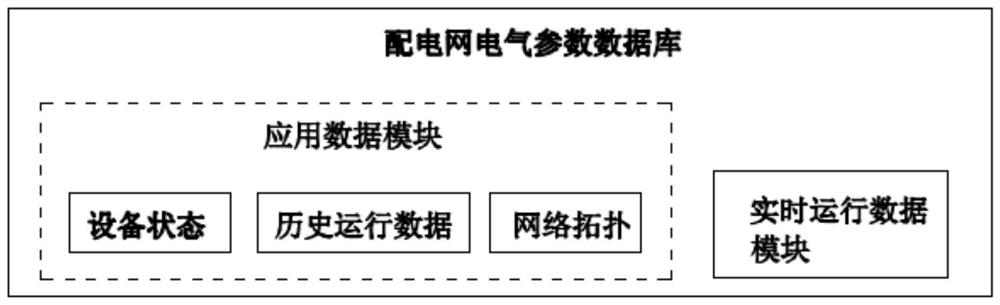

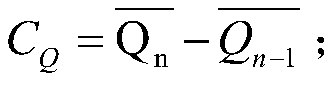

Distribution network production safety risk early warning system

PendingCN111798029ATimely detection of hidden troublesImprove reliabilityForecastingResourcesData displayEarly warning system

The invention discloses a distribution network production safety risk early warning system, which comprises a distribution network electrical parameter database, a meteorological database and an operation evaluation model, and is characterized in that the operation evaluation model is connected with the distribution network electrical parameter database and the meteorological database. The systemfurther comprises an equipment evaluation module and an operation fault probability calculation module. The operation fault probability calculation module is connected with the operation evaluation module and the equipment evaluation module. The system further comprises an operation risk value evaluation module, a data display module and an early warning module, the operation risk value evaluationmodule is connected with the operation fault probability calculation module, and the data display module and the early warning module are both connected with the operation risk value evaluation module. The system further comprises an early warning module, an auditing module, a publishing module and an operation management module. According to the invention, real-time calculation and online earlywarning of the fault risk value of the power distribution network are realized, equipment maintenance can be carried out in time through fault early warning, and the pertinence of equipment maintenance is improved.

Owner:GUANGZHOU POWER SUPPLY BUREAU GUANGDONG POWER GRID CO LTD

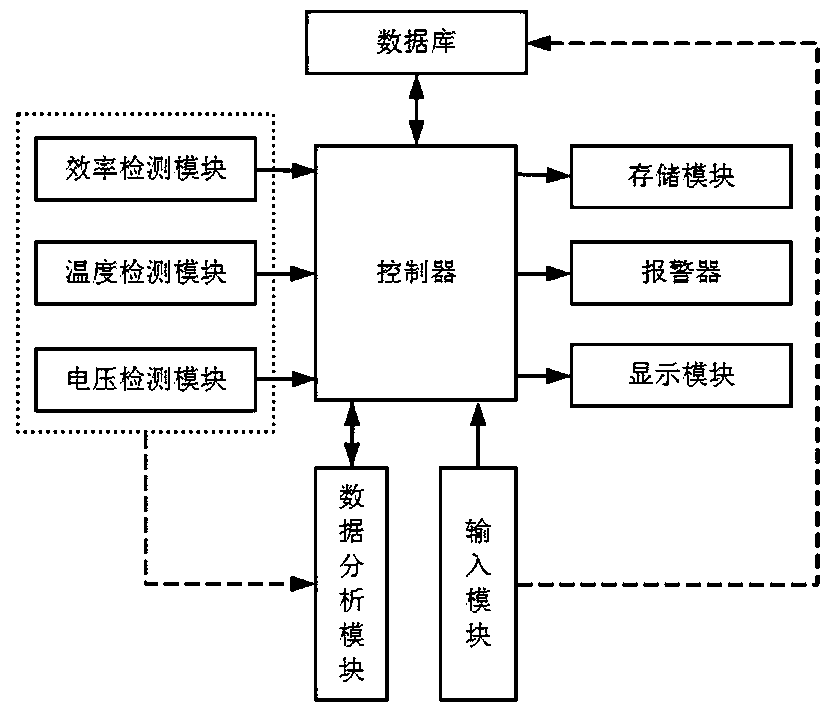

Operation state detection system of mechanical equipment electrical system

ActiveCN110487327ATimely detection of hidden troublesTimely discover and deal with hidden troublesMeasurement devicesComputer moduleMechanical equipment

The invention relates to the technical field of electrical system detection, and discloses an operation state detection system of a mechanical equipment electrical system. The operation state detection system comprises an efficiency detection module, a temperature detection module, a voltage detection module, a controller, a storage module, a data analysis module and an input module; the efficiency detection module is used for collecting the production efficiency of mechanical equipment; the temperature detection module is used for collecting temperature information Ti of a specified positionand sending the temperature information Ti to the controller; the voltage detection module is used for collecting operation voltage information Vi of the electrical system and sending the operation voltage information Vi to the controller; the input module is used for calculating a coefficient and an alarm threshold; the data analysis module is used for analyzing the operation state of the mechanical equipment electrical system according to the collected production efficiency, temperature information and voltage information; and the controller is used for outputting an alarm signal accordingto an analysis result of the data analysis module. The hidden fault danger of the mechanical equipment electrical system can be found and handled in time, and the production and machining efficiency is guaranteed.

Owner:CHINA RAILWAY 12TH BUREAU GRP +1

Cable local discharging on-line monitoring method and device

InactiveCN109001601AGuaranteed uptimeAccurate Partial Discharge Early WarningTesting dielectric strengthElectric power transmissionEngineering

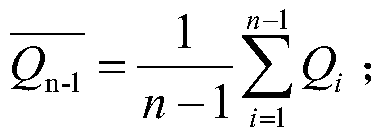

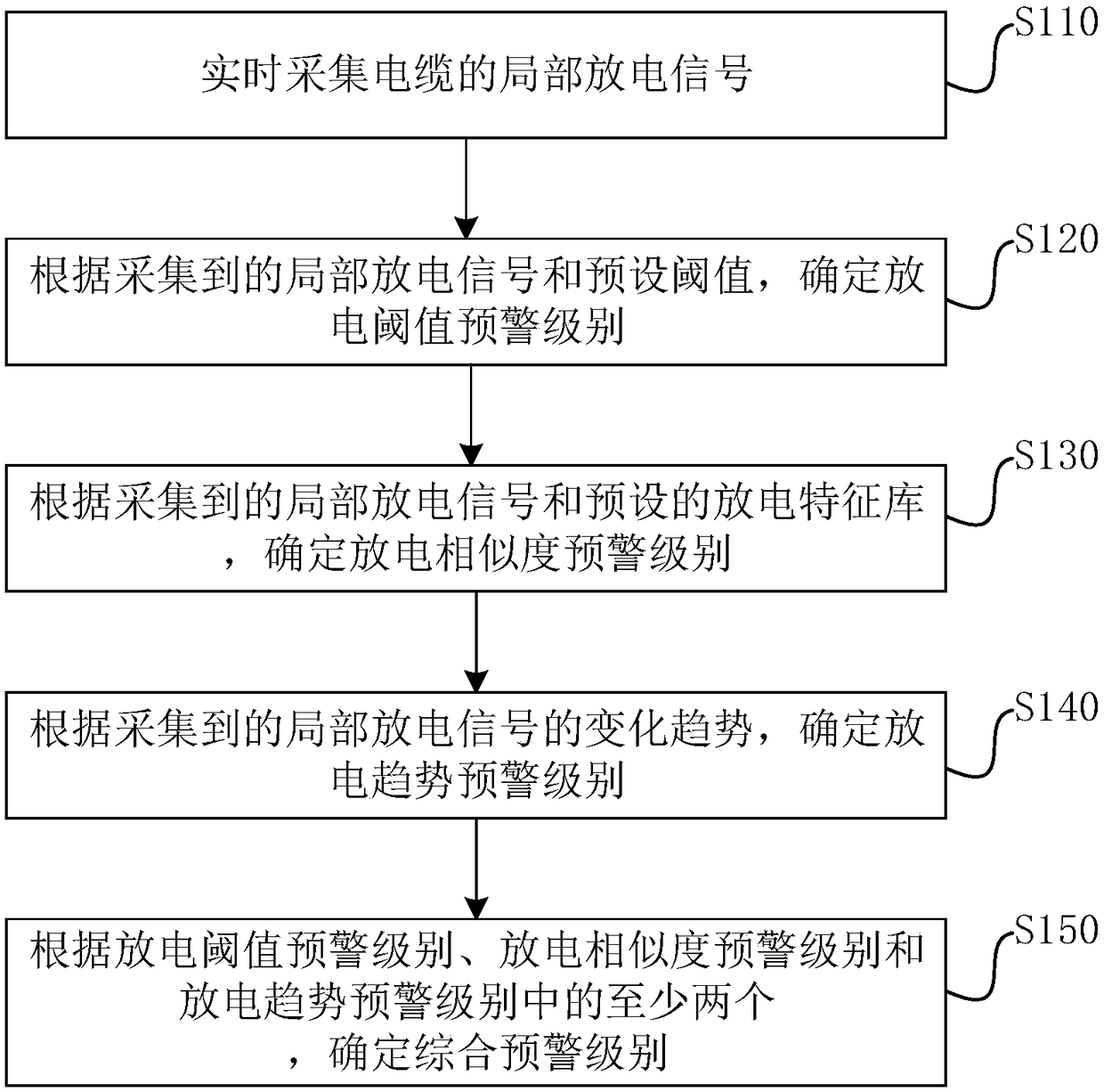

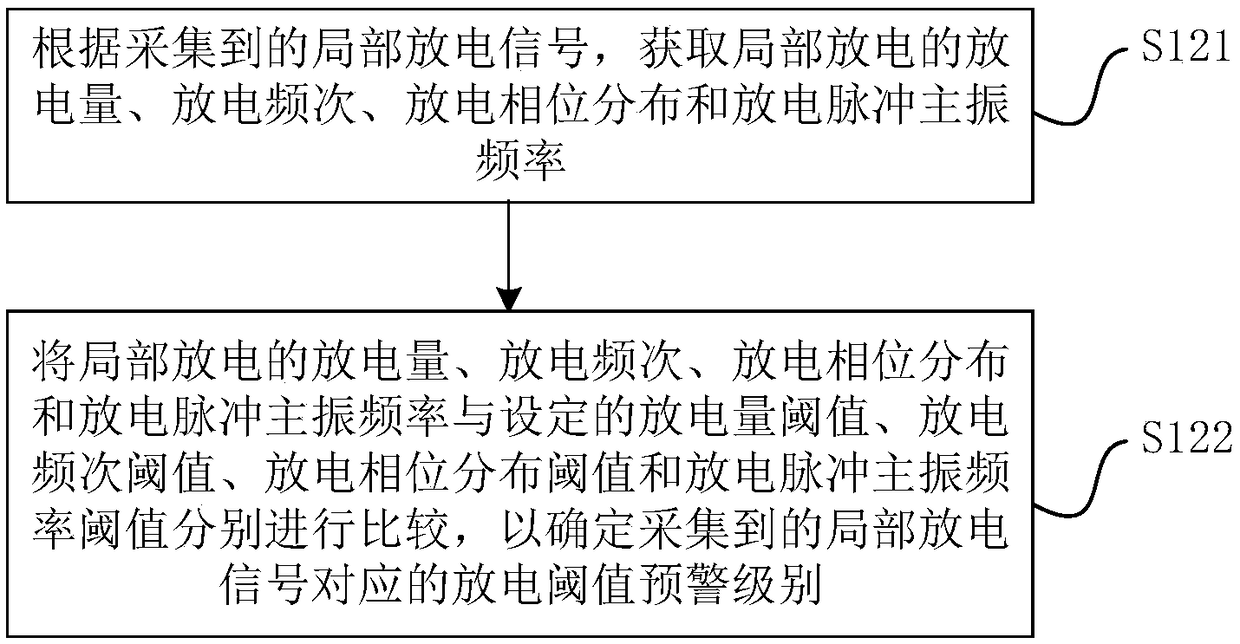

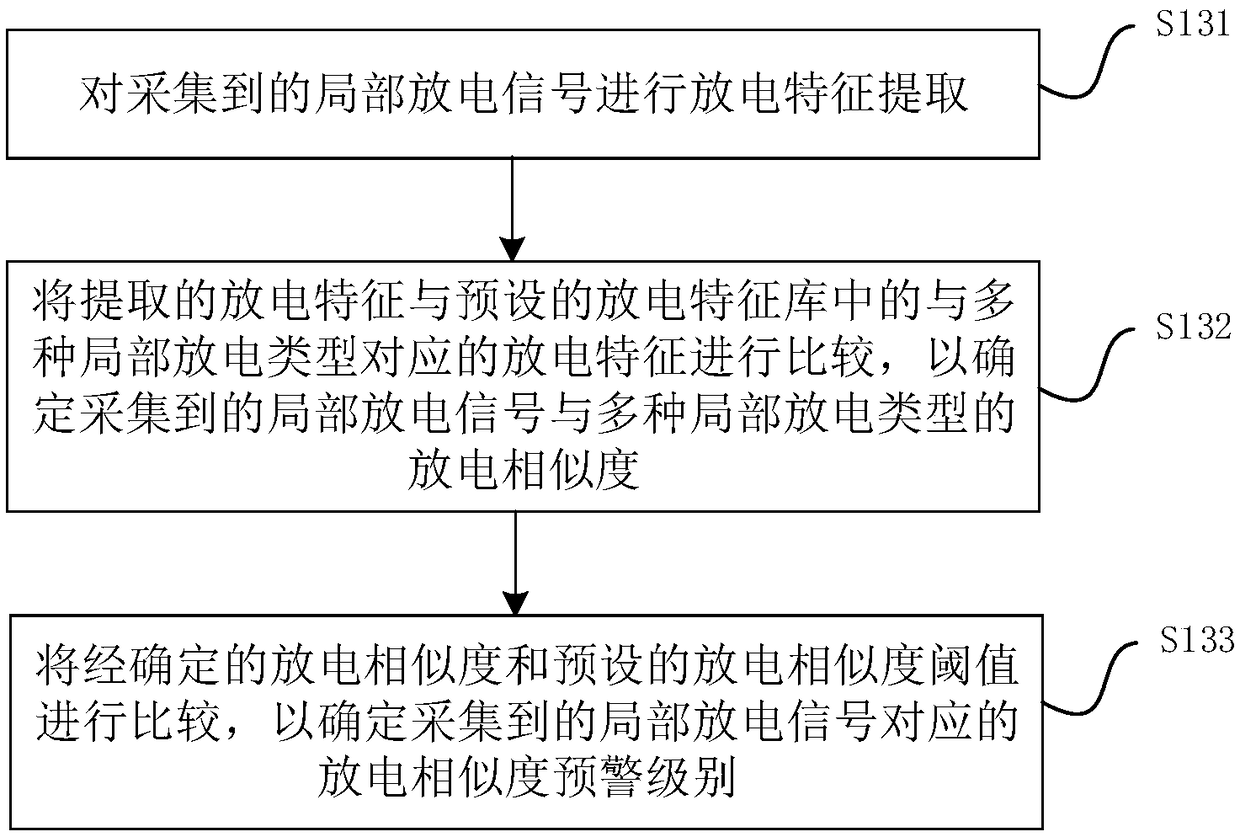

The invention relates to a cable local discharging on-line monitoring method and device. The cable local discharging on-line monitoring method provided by the invention comprises the steps of: acquiring a local discharging signal of the cable in real time; determining a discharging threshold early-warning level according to the acquired local discharging signal and a preset threshold; determininga discharging similarity early-warning level according to the acquired local discharging signal and a preset discharging characteristic library; determining a discharging trend early-warning level according to the change trend of the acquired local discharging signal; and determining an integral early-warning level according to at least two of the determined discharging threshold early-warning level, the discharging similarity early-warning level and the discharging trend early-warning level. With the method provided by the application, local discharging early-warning can be more accurately performed, potential risk of a fault can be timely found out, and reliable running of a power transmission line is guaranteed. The invention also provides the cable local discharging on-line monitoringdevice and a computer readable storage medium.

Owner:SUZHOU GUANGGE EQUIP

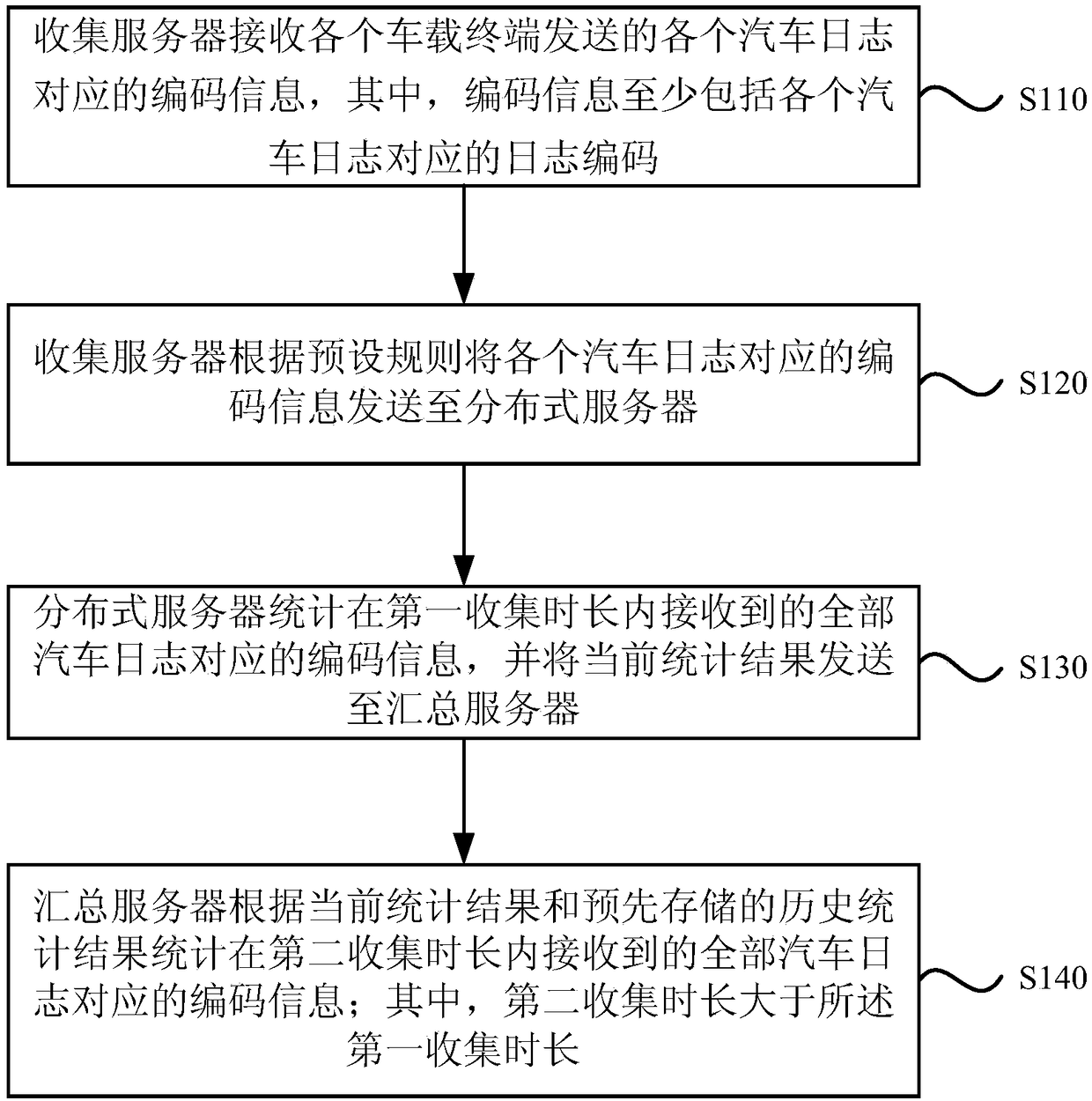

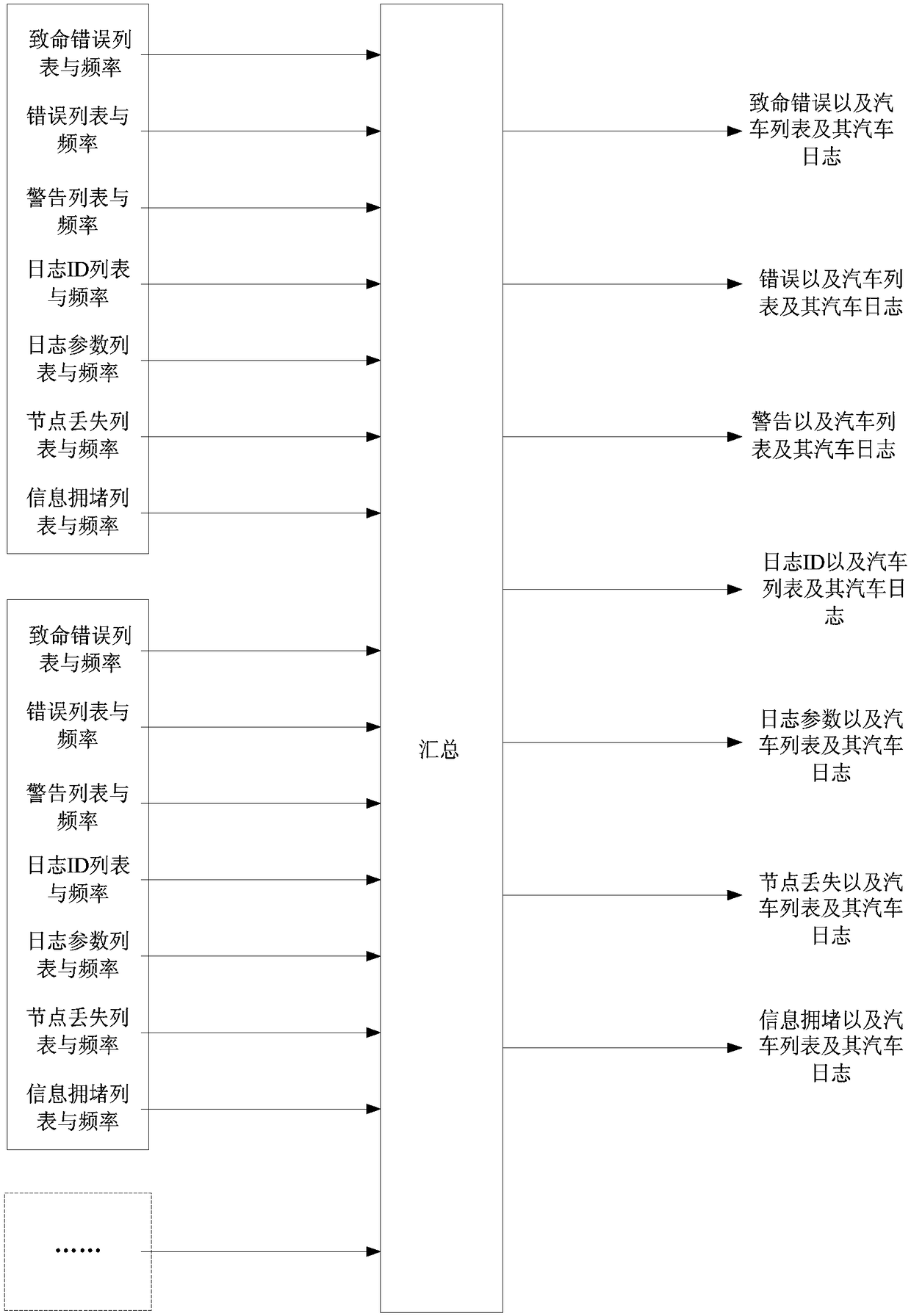

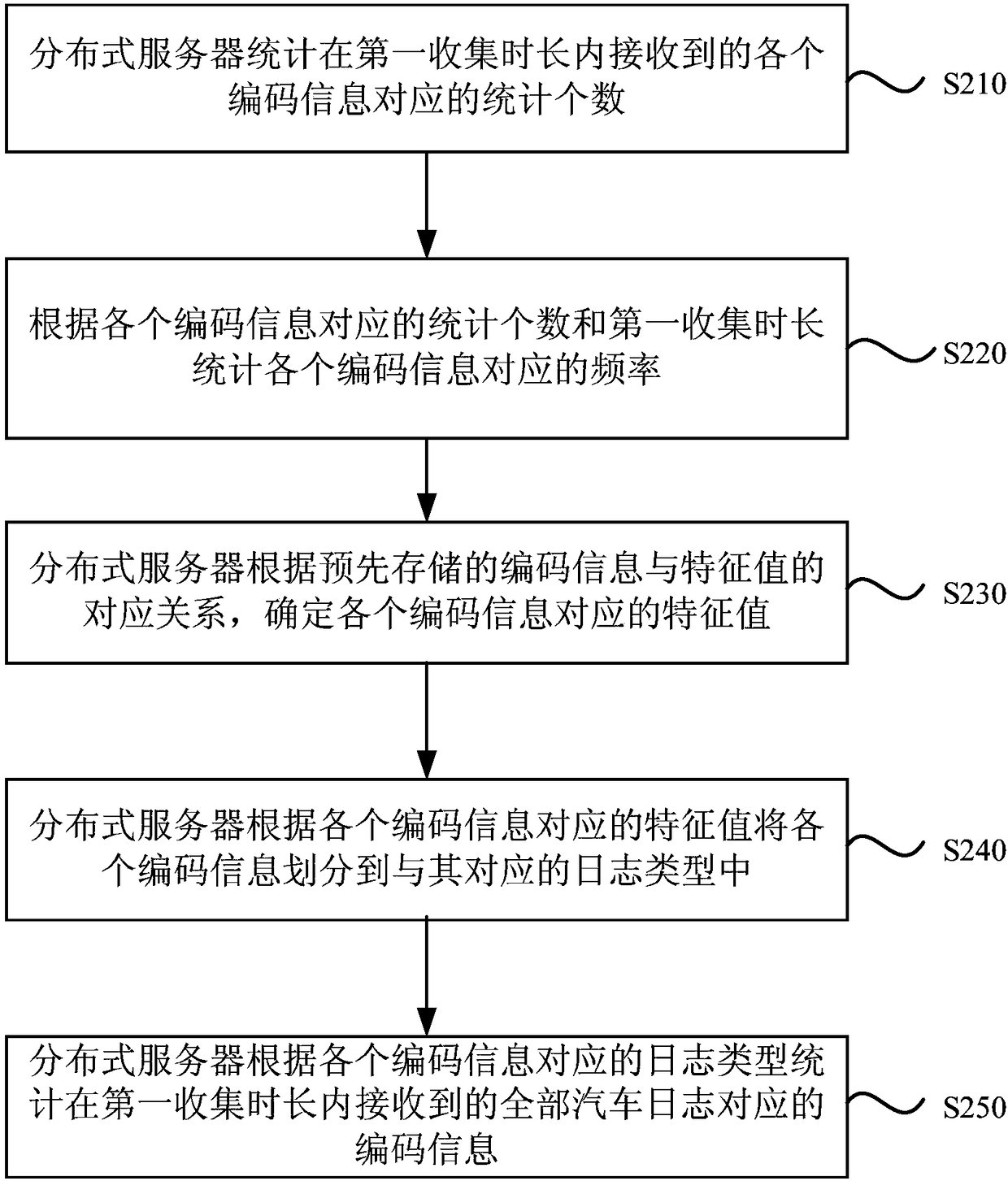

Log statistic method, collection server, distributed server and summarizing server

ActiveCN108228379AReal-time statistical analysisTimely detection of hidden troublesNon-redundant fault processingStatistical analysisDistributed servers

The invention discloses a log statistic method, a collection server, a distributed server and a summarizing server. The method comprises the steps that the collection server receives encoding information corresponding to automobile logs sent by vehicle-mounted terminals, and the collection server sends the encoding information corresponding to the automobile logs to the distributed server according to preset rules; the distributed server performs statistics on the encoding information corresponding to all the received automobile logs within a first period of collection time, and sends the current statistic result to the collection server; the collection server performs statistics on the encoding information corresponding to all the received automobile logs within a second period of collection time according to the current statistic result and the prestored historical statistic result. According to the technical scheme, statistical analysis can be performed on the automobile logs in real time, and therefore undefined potential failures of parts of the automobile can be found in time.

Owner:YUANFENG TECH CO LTD

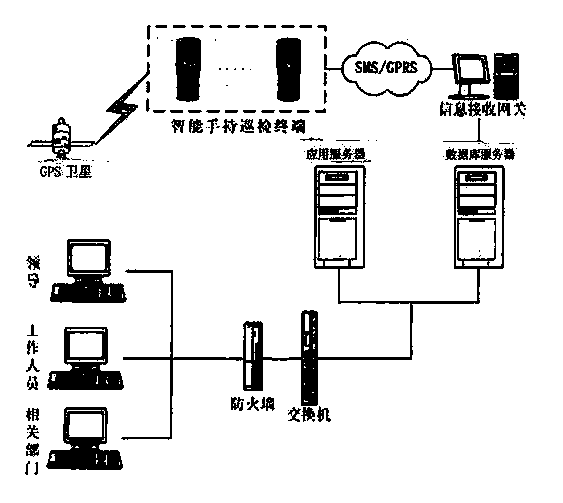

Handheld equipment terminal inspection system for transformer substation

InactiveCN103632407AReal-timeTimely detection of hidden troublesChecking time patrolsTransformerElectric equipment

The invention provides a handheld equipment terminal inspection system for a transformer substation, belonging to the field of electrical technologies and equipment. According to the technical scheme, the system is composed of a handheld equipment terminal inspection device, an information receiving gateway, an application server, a database server, a switchboard, a firewall and a monitoring terminal, wherein the handheld equipment terminal inspection device is used for transmitting information to the information receiving gateway by storage management services (SMS) and general packet radio services (GPRS); the information receiving gateway is supported by the application server and the database server, is intercommunicated with the monitoring terminal by the switchboard and is separated and protected by the firewall. The handheld equipment terminal inspection system for the transformer substation has the beneficial effects that inspection data is transmitted to an inspection management department in real time to find out fault hidden dangers of electric equipment in time and scientifically manage and arrange inspection work of inspection personnel; the invention provides a scientific and effective method for inspection; the instantaneity and the scientization of the inspection are realized; the maintenance management level and the working efficiency are improved; the handheld equipment terminal inspection system has an advanced technology, is efficient to operate and is reliable to use.

Owner:STATE GRID HENAN ELECTRIC POWER COMPANY ANYANG POWER SUPPLY

Power transmission line inspection arrival rate online monitoring system and method based on electronic tag

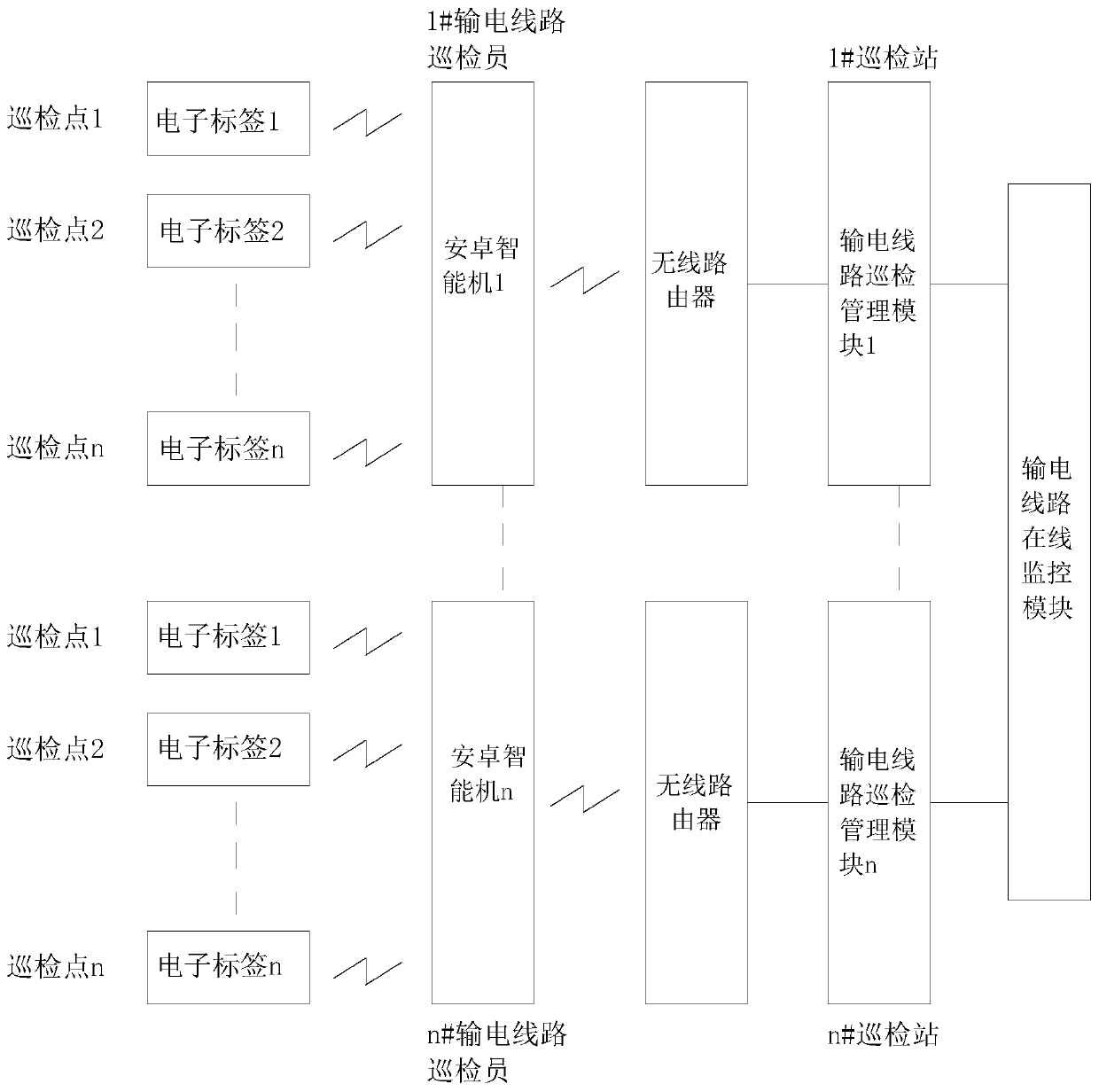

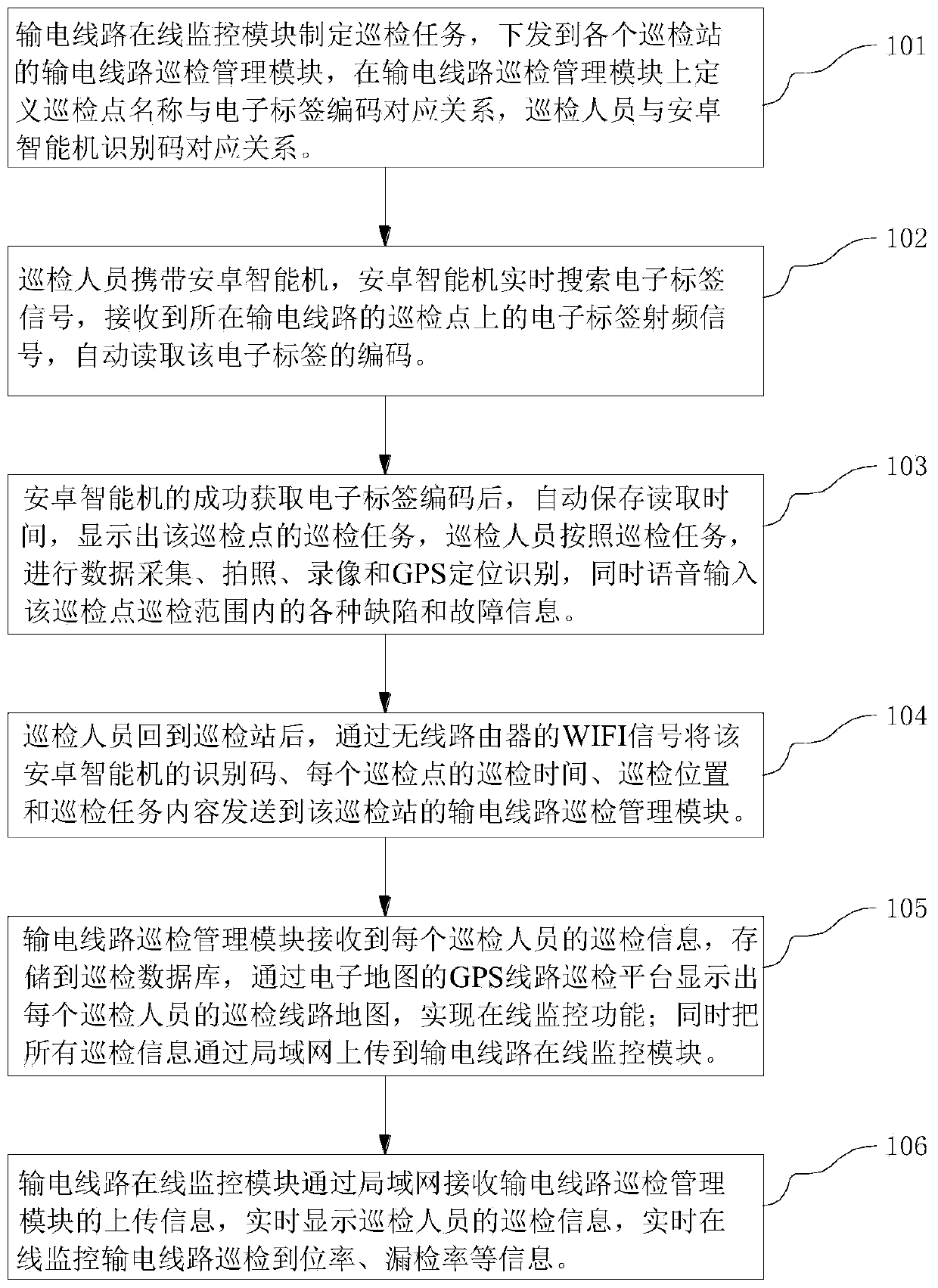

PendingCN110992512ATimely detection of hidden troublesEnsure safetyRegistering/indicating working of machinesCo-operative working arrangementsWireless routerElectronic tagging

The invention relates to a power transmission line inspection arrival rate online monitoring system and method based on an electronic tag. The system comprises an electronic tag, an Android intelligent machine, a wireless router, a power transmission line inspection management module and a power transmission line online monitoring module. An inspector arrives at an inspection point to automatically read the electronic tag; data acquisition, photographing, video recording and GPS positioning are carried out; meanwhile, defect and fault information is input through voice; all inspection information is uploaded to the power transmission line on-line monitoring module through the power transmission line inspection management module. Information such as the inspection arrival rate and the omission ratio of the power transmission line is monitored online in real time; the inspection arrival rate is effectively improved. The fault hidden trouble of the power transmission line is found in time, the inspection condition of each power transmission line is displayed in an electronic map mode, the inspection condition of each inspection point is found in time, whether each inspector reaches the corresponding inspection point or not and whether the inspection task is completed or not are monitored online in real time, the inspection arrival rate is effectively monitored, and the operation safety of the power transmission line is guaranteed.

Owner:CHAOYANG POWER SUPPLY COMPANY OF STATE GRID LIAONING ELECTRIC POWER SUPPLY +1

Transformer substation equipment online monitoring method and device

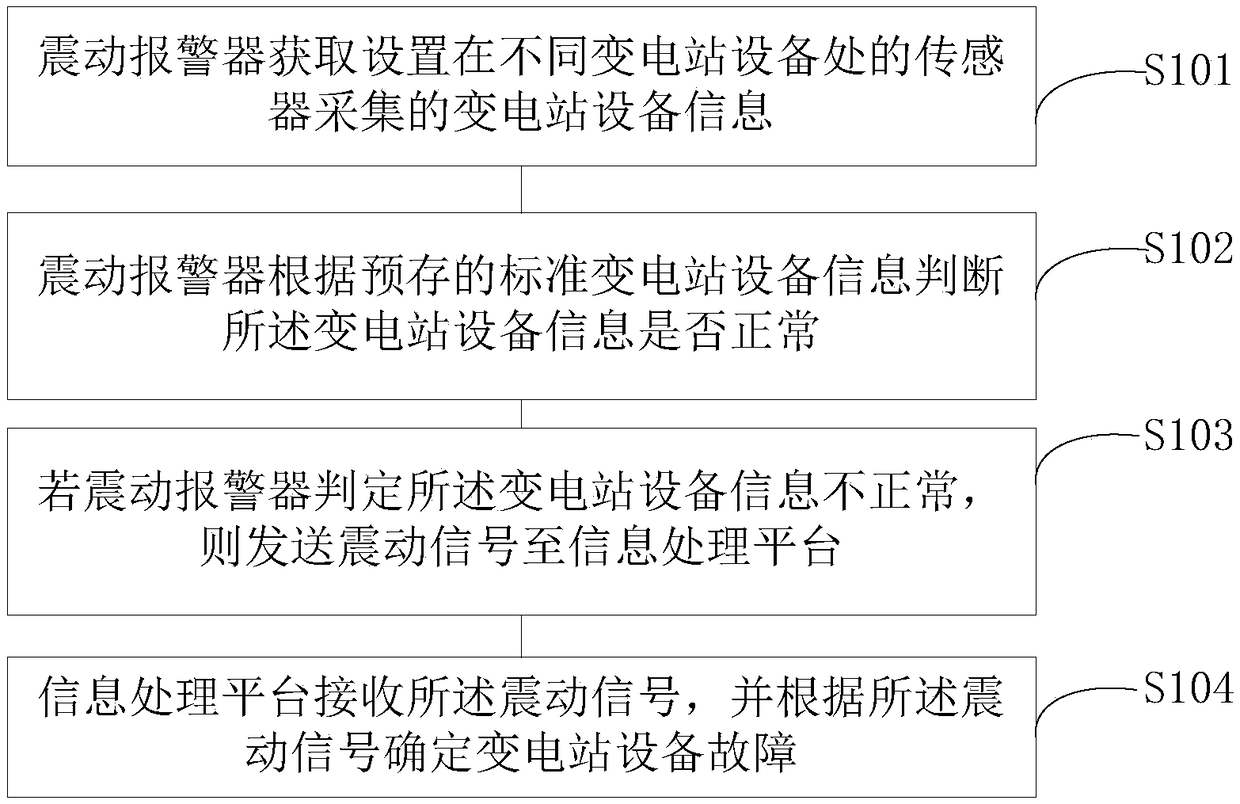

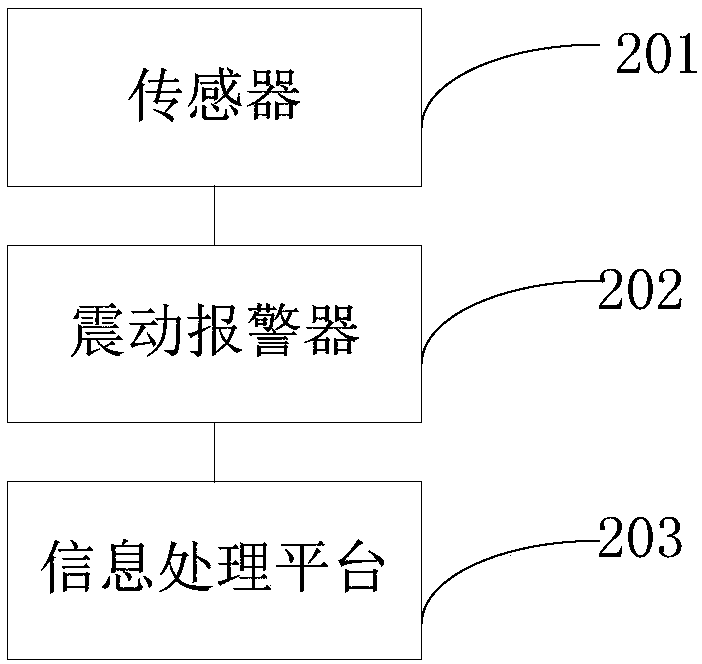

ActiveCN108333449ASafe and stable operationTimely detection of hidden troublesElectrical testingPlatform integrity maintainanceInformation processingTransformer

The invention belongs to the technical field of transformer substation monitoring, and particularly relates to a transformer substation equipment online monitoring method and a transformer substationequipment online monitoring device. The transformer substation equipment online monitoring method comprises the steps of acquiring transformer substation equipment information collected by sensors arranged at different substation equipment by means of a vibration alarm; judging whether the transformer substation equipment information is normal or not according to pre-stored standard transformer substation equipment information by means of the vibration alarm; if the vibration alarm judges that the transformer substation equipment information is not normal, sending a vibration signal to an information processing platform; receiving the vibration signal by the information processing platform, and determining the fault of the transformer substation equipment according to the vibration signal.By the adoption of the scheme, the state of the transformer substation equipment can be monitored through various different sensors. As a result, various fault hidden dangers caused by the long-timeand high-load operation of the transformer substation equipment can be found in time. The safe and stable operation of the transformer substation equipment is guaranteed.

Owner:STATE GRID CORP OF CHINA +1

Railway power equipment history management system and method based on fault location function

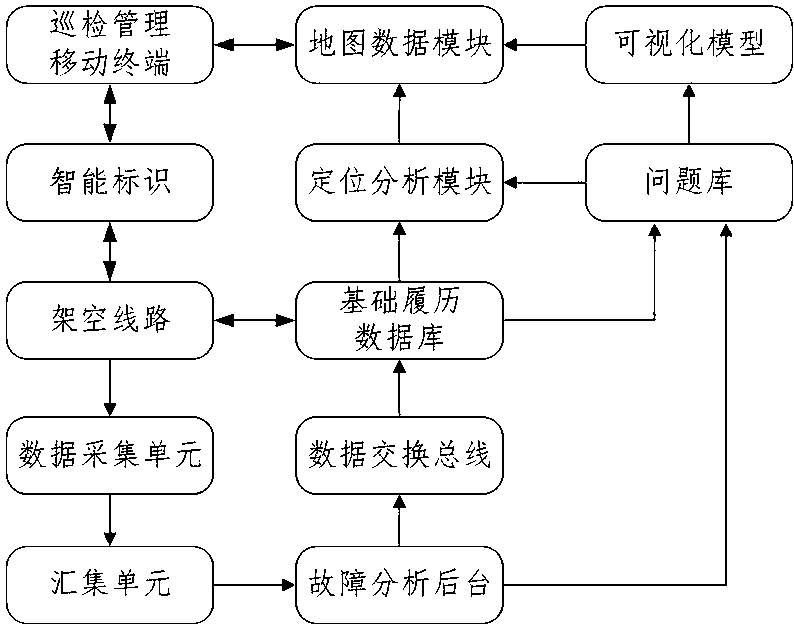

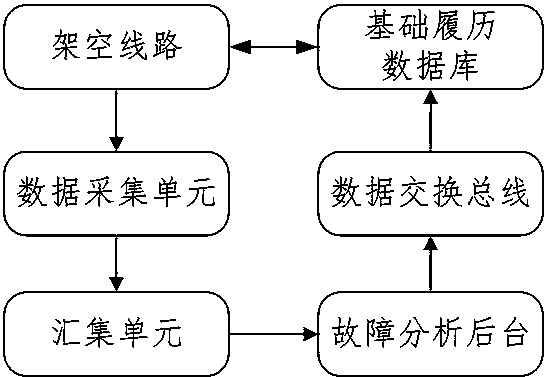

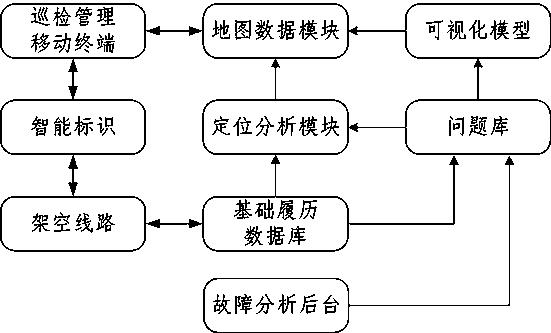

InactiveCN109408492APrecise positioningGuaranteed accuracyData processing applicationsVisual data miningData streamElectric power equipment

The invention relates to a railway electric power equipment history management system based on fault location function and a method thereof. The system monitors an overhead line on-line through a dataacquisition unit, analyzes a real-time fault, returns to a foundation history database for storage through a data exchange bus, and corresponds to the actual data of the field overhead line one by one. Combined with the fault data to form the problem library, combined with the overhead line visual model, pushed to the patrol management mobile terminal, the terminal to the overhead line intelligent identification data association; the overhead line collects the fault information through the data acquisition unit, transmits the fault analysis background analysis by the aggregation unit, and then imports the results into the basic resume database. Combined with the data results of the positioning analysis module, the map positioning and navigation guidance are carried out through the map data module, and the site fault point is uniquely confirmed. The implementation of the invention can improve the accuracy of the intelligent judgment, reduce the manual patrol workload, and realize the ring-type data flow and fault comprehensive analysis and positioning of the overhead line facilities with the whole life cycle closed.

Owner:中铁一院(陕西)工程建设有限公司 +2

Multidirectional distance dynamic monitoring and early warning method based on edge calculation

InactiveCN112291303ATimely detection of hidden troublesGuaranteed safe operationCircuit arrangementsTransmissionDynamic monitoringSafe operation

The invention relates to a multidirectional distance dynamic monitoring and early warning method based on edge calculation. The method comprises the following steps: a dynamic monitoring sensor sendsacquired initial information of a power transmission line to edge calculation equipment; the edge calculation equipment stores the initial information collected by the dynamic monitoring sensor as initial information; the dynamic monitoring sensor dynamically collects power transmission line information in real time according to a set monitoring period; the edge calculation equipment compares andjudges the real-time dynamic information with stored initial information, and transmits the real-time dynamic information to an alarm system when deviation is greater than a set threshold value; and if the data which cannot be judged exists, the data is uploaded to a cloud server. According to the invention, on-line dynamic monitoring of the power transmission line is realized, fault hidden troubles of the power transmission line can be discovered and processed in time, safe operation of the power transmission line is effectively guaranteed, power supply accidents are prevented, and safe powersupply is guaranteed.

Owner:CHANGCHUN INST OF TECH

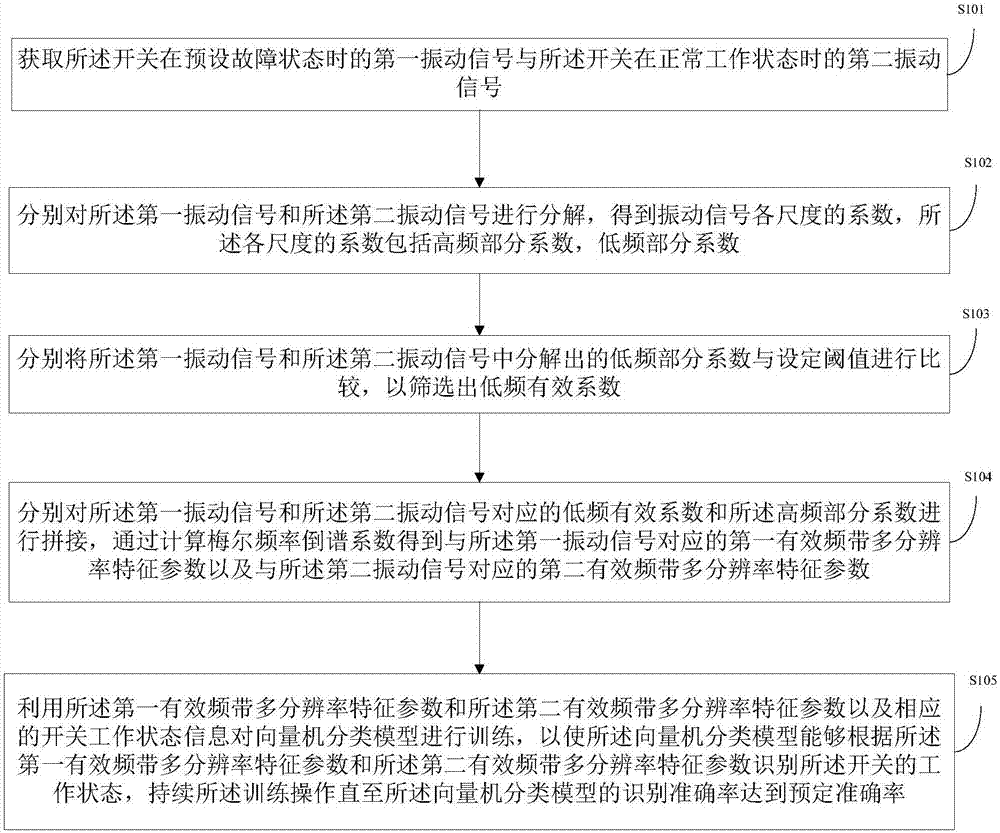

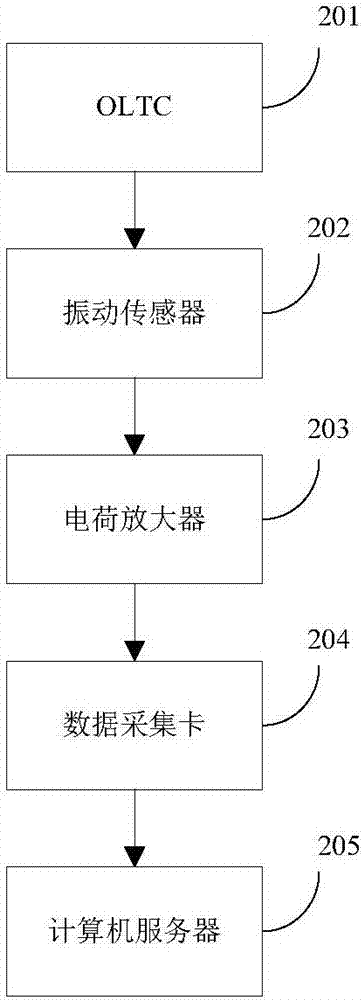

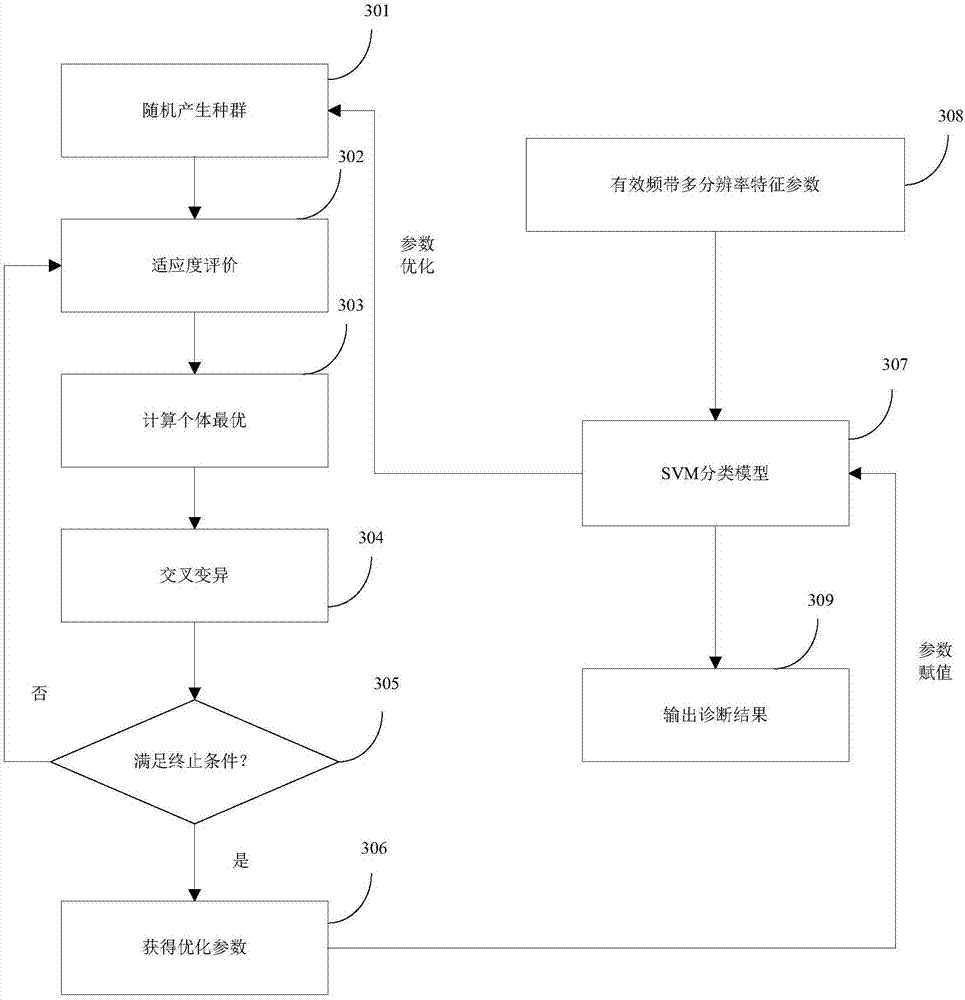

On-load tap-changer diagnosis method and device

InactiveCN107271024AHigh time-frequency resolutionFully reflect the signal characteristicsVibration measurement in solidsDiagnosis methodsTap changer

The invention provides an on-load tap-changer diagnosis method and device. The method comprises steps that a vibration signal of a switch is acquired; the vibration signal is decomposed to acquire a coefficient of each scale of the vibration signal, and the coefficients comprise high frequency coefficients and low frequency coefficients; the low frequency coefficients are compared with a set threshold to acquire low frequency effective coefficients through screening; the low frequency effective coefficients and the high frequency coefficients are spliced, and an effective frequency band multi-resolution characteristic parameter is acquired through calculating a Mel-frequency cepstral coefficient; whether the switch is in fault is determined according to the effective frequency band multi-resolution characteristic parameter. The method is advantaged in that online monitoring and state evaluation are realized, and the specific hidden trouble can be more accurately discovered.

Owner:STATE GRID SHANDONG ELECTRIC POWER +1

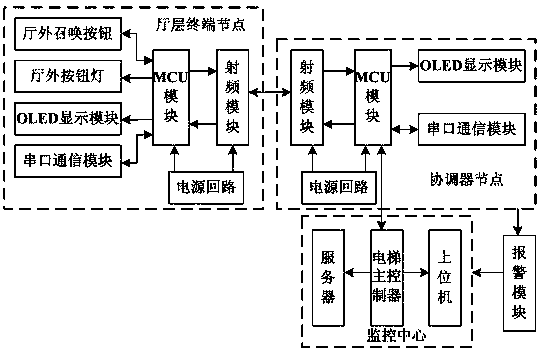

Elevator wireless hall calling communication system

InactiveCN108203027ASolve complexitySolve maintenanceElevatorsCommunications systemWireless transmission

The invention relates to an elevator wireless hall calling communication system. The elevator wireless hall calling communication system is composed of a hall floor terminal node, a coordinator node,an alarming module and a monitoring center. The hall floor terminal node comprises a hall outside calling button, a hall outside press button light, an OLED display module, a serial port communicationmodule, an MCU module, a radio frequency module and a power source loop. The coordinator node comprises the radio frequency module, the MCU module, the OLED display module, the serial port communication module and the power source loop. The monitoring center comprises an elevator master controller, an upper computer and a server. The hall floor terminal node and the coordinator node communicate through 433 MHZ wireless transmission data. The coordinator node and the elevator master controller communicate through an RS485 connector. The elevator wireless hall calling communication system takesan Si4663 radio frequency chip and an M0516 chip as the core, and the problems that a traditional elevator hall calling communication system is complex in line layout, and inconvenient to debug and maintain are solved.

Owner:天津市军联科技有限公司

Multi-source data fusion high-voltage cable line fault on-line positioning device and method based on traveling wave principle

ActiveCN112083263ATimely detection of hidden troublesGuaranteed uptimeFault location by conductor typesInformation technology support systemMulti source dataElectric cables

The invention relates to a multi-source data fusion high-voltage cable line fault on-line positioning device and method based on a traveling wave principle. The positioning device comprises a data collection device, a data background, a server and an equipment front end. According to the improved cable fault accurate identification and positioning method, signals are deeply researched and analyzed, characteristic semaphore is further extracted by using various signal analysis methods, and through theoretical analysis and simulation, fault judgment can be further improved, and a current cable detection method is improved. Operation and maintenance personnel are assisted to discover cable fault hidden troubles in time, normal operation of the cable is ensured, electric power accidents are reduced, and an effective solution is provided for intelligent detection of a power grid cable line.

Owner:STATE GRID HEBEI ELECTRIC POWER RES INST +2

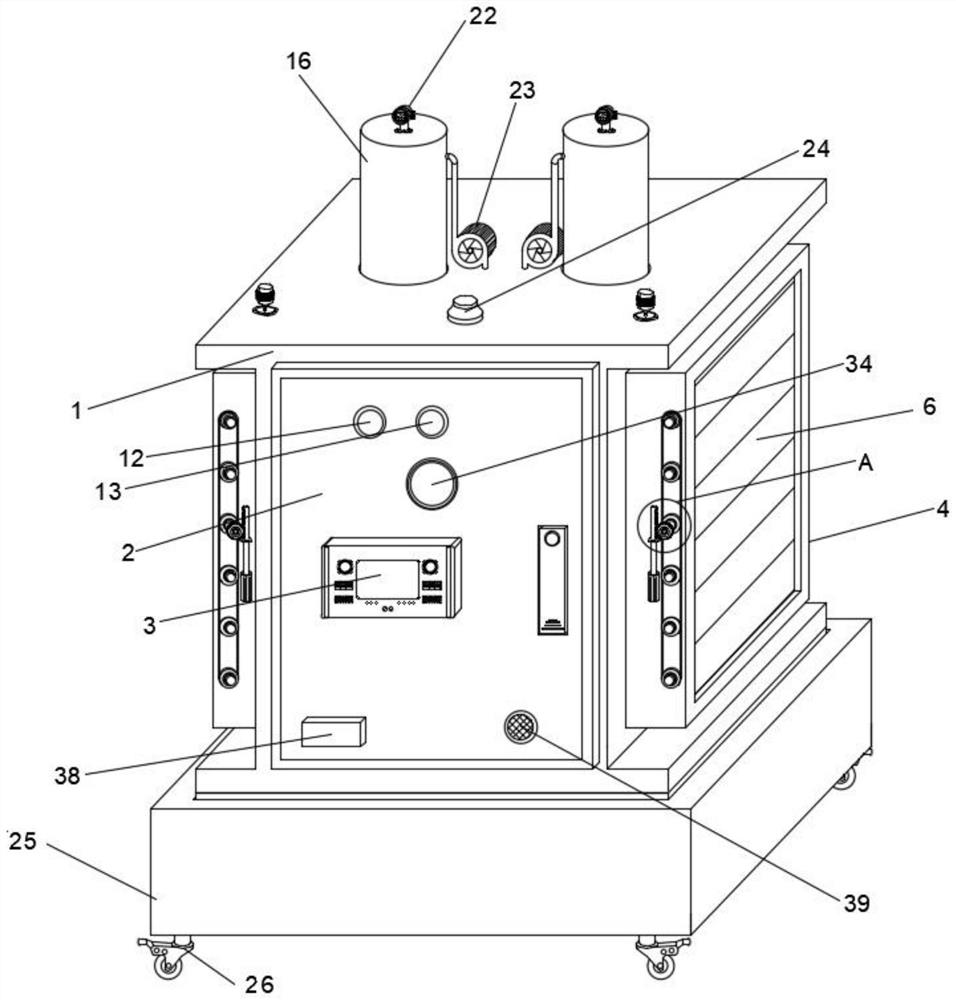

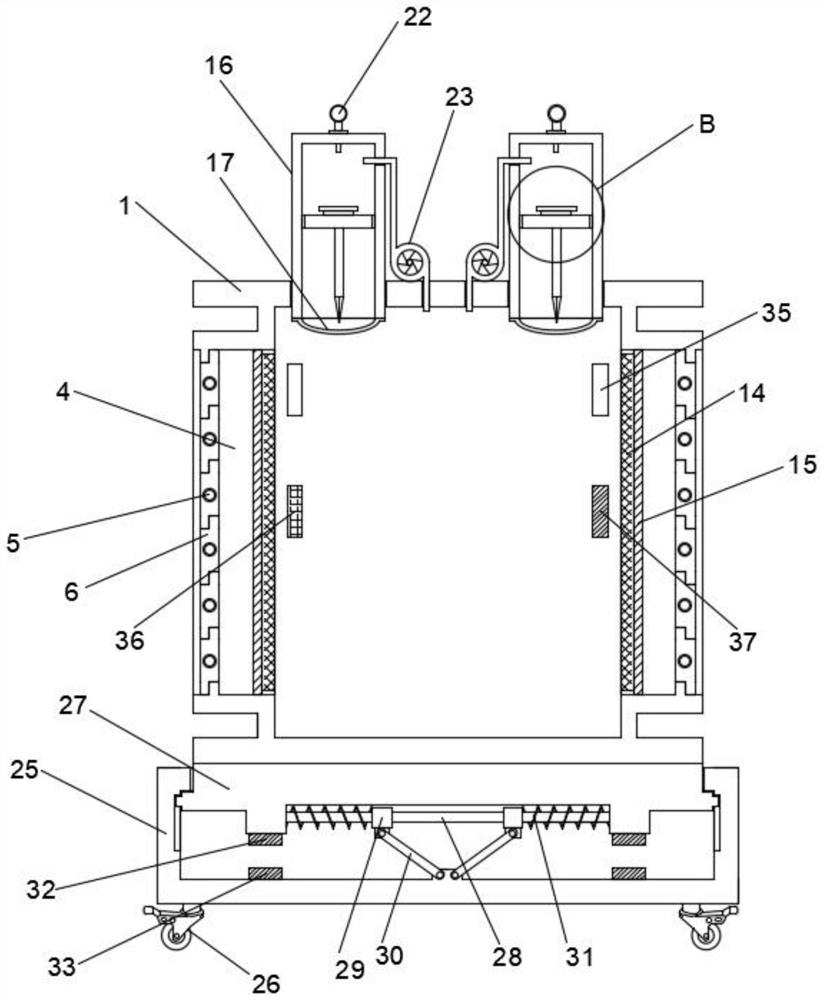

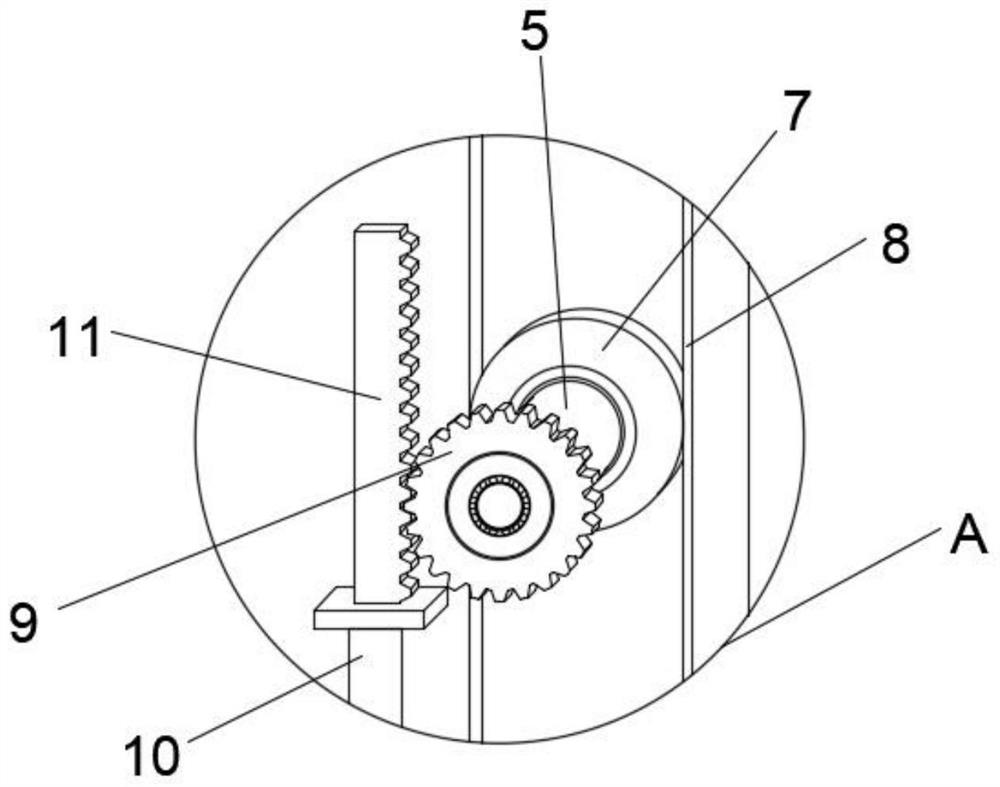

Internet of Things intelligent distribution box for tunnel engineering

PendingCN114744513AImprove heat dissipationImprove cooling effectMining devicesBoards/switchyards circuit arrangementsRemote monitoring and controlTunnel engineering

The invention discloses an Internet of Things intelligent distribution box for tunnel engineering, which comprises a box body, a box door and a programming controller, the box door is hinged to the front side of the box body, the programming controller is fixedly mounted on the front side of the box door, ventilation windows are formed in the left side and the right side of the box body, and ventilation and heat dissipation mechanisms are arranged in the ventilation windows. A fire extinguishing mechanism is arranged at the top of the box body, a base is installed at the bottom of the box body, locking universal wheels are installed at the four corners of the bottom of the base, and a damping mechanism is arranged in the base. The heat dissipation effect of the distribution box is enhanced, electrical elements in the distribution box are prevented from working in a high-temperature state, the service life of the electrical elements in the distribution box is prolonged, the distribution box has a fire extinguishing function, economic losses caused by combustion are reduced, the distribution box has remote monitoring and fixed-point troubleshooting functions, the technical level of equipment maintenance is improved, and the service life of the distribution box is prolonged. And the safety and the reliability of electricity utilization are ensured.

Owner:CHINA RAILWAY LIUYUAN GRP CO LTD

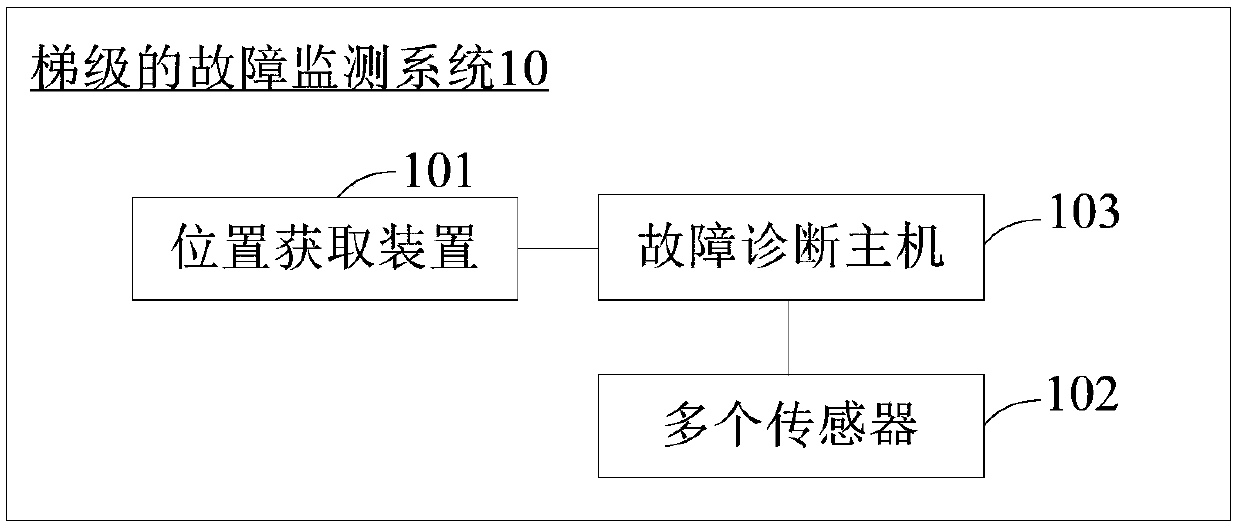

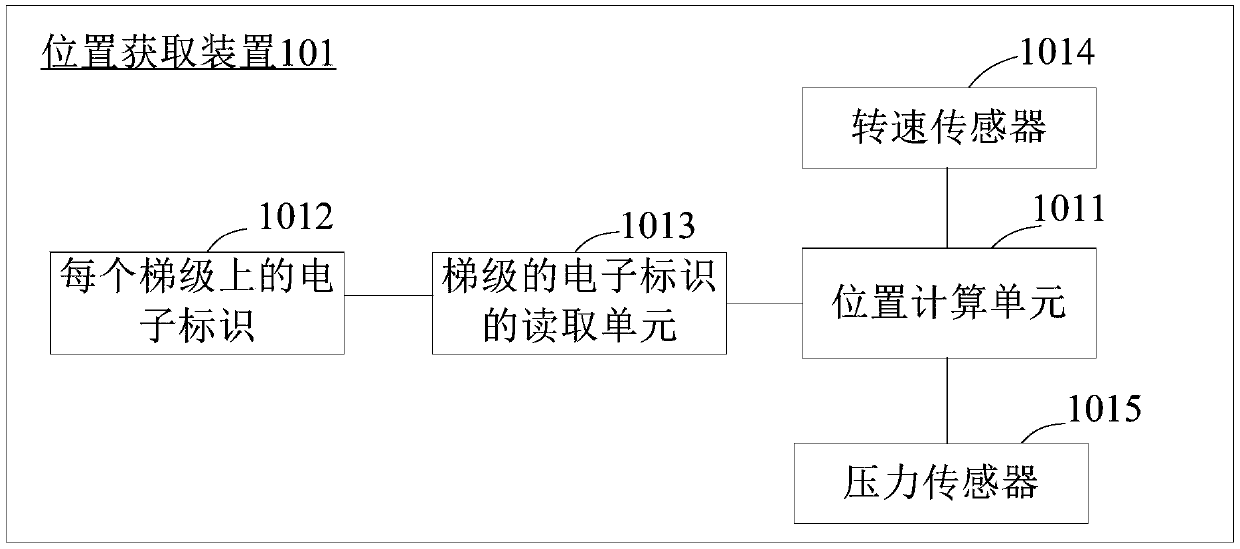

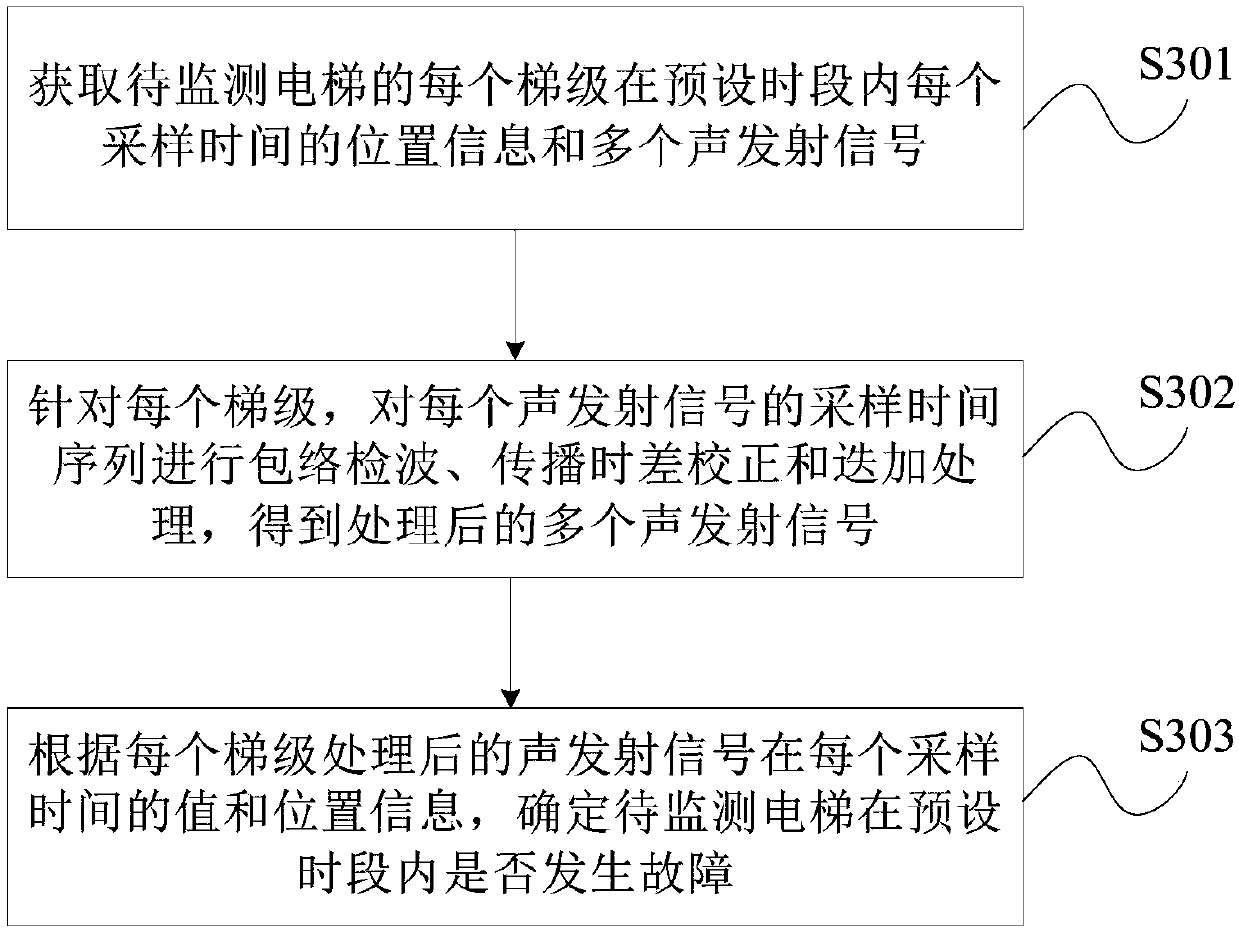

Cascaded fault monitoring method, device and system

ActiveCN111071906AImprove user experienceTimely detection of hidden troublesEscalatorsAcoustic emissionTime difference

The embodiment of the invention provides a cascaded fault monitoring method, device and system. The cascaded fault monitoring method comprises the following steps: obtaining the position information of each sampling time of each cascade of a to-be-monitored elevator within the preset time interval and a plurality of acoustic emission signals; for each cascade, carrying out envelope detection, spreading time difference correction and superposition treatment on the sampling time sequence of each acoustic emission signal to obtain a plurality of processed acoustic emission signals; and accordingto the value and position information of the processed acoustic emission signal of each cascade within each sampling time, determining whether the to-be-monitored elevator has fault within the presettime interval. The cascaded fault monitoring method can timely find hidden danger of the cascaded fault to improve the user's experience.

Owner:北京昊鹏智能技术有限公司

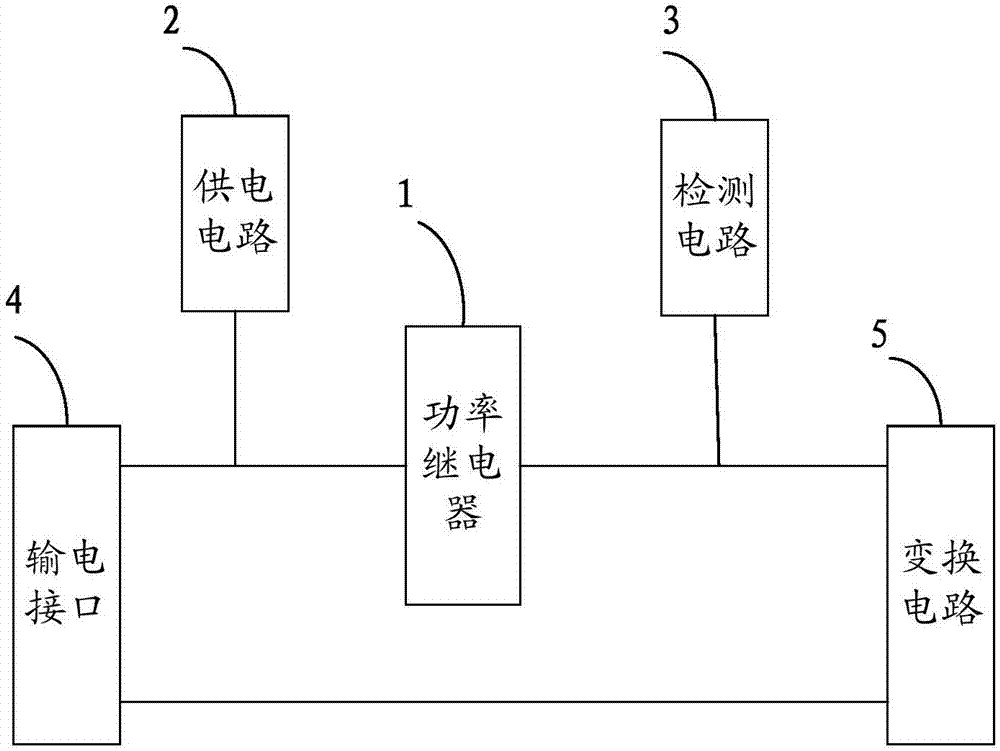

Detection circuit for power relay of vehicle-mounted charger, vehicle-mounted charger, and vehicle

InactiveCN107300670AEffective detection of good and badTimely detection of hidden troublesBatteries circuit arrangementsCharging stationsElectricityEngineering

The invention discloses a detection circuit for a power relay of a vehicle-mounted charger, the vehicle-mounted charger, and a vehicle. The detection circuit comprises the power relay; a power supply circuit and a detection circuit, which are connected with the power relay; and a detection controller which is connected with the detection circuit. The detection controller determines that the power relay works normally when the detection controller detects a high level during the connection of the power supply circuit, the power relay and the detection circuit and detects a low level during the disconnection of the power supply circuit, the power relay and the detection circuit. The detection circuit can effectively detect the quality of the power relay, and prevents the damage of the power relay from causing the damages to the whole unit.

Owner:BEIJING ELECTRIC VEHICLE

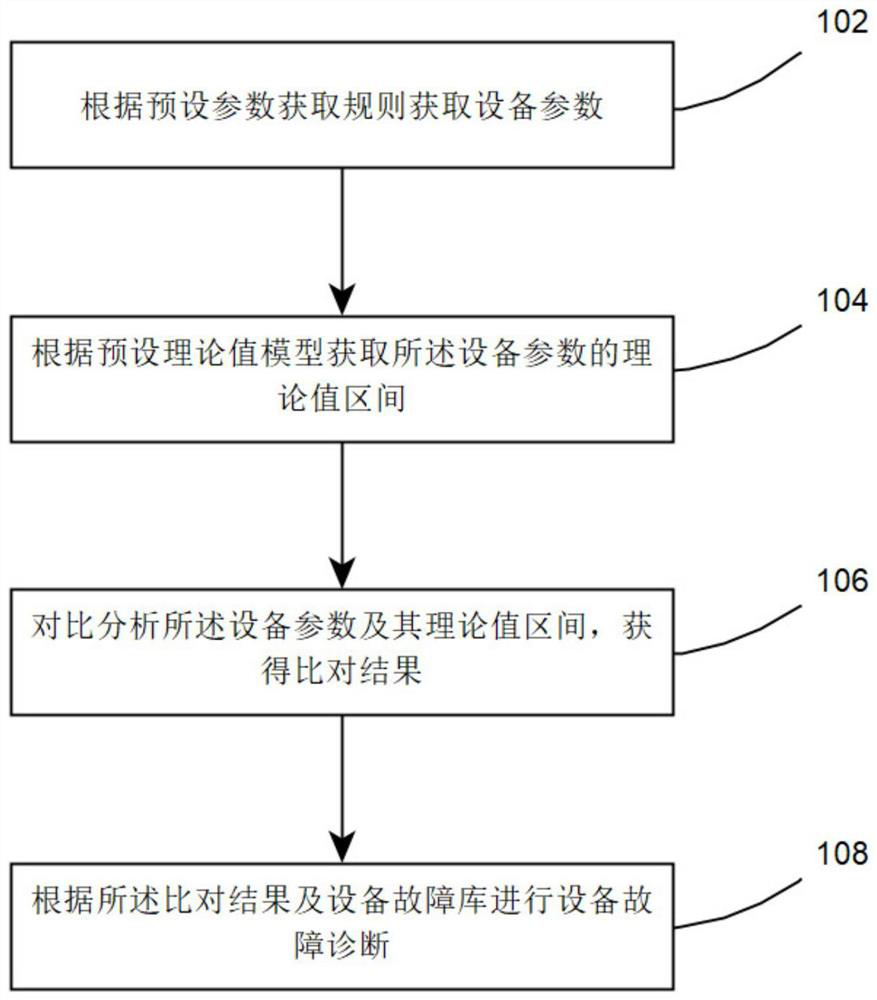

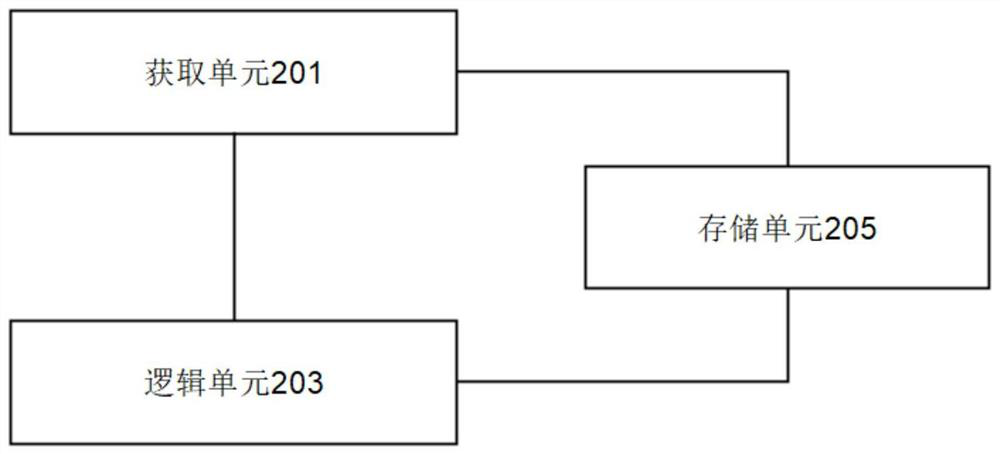

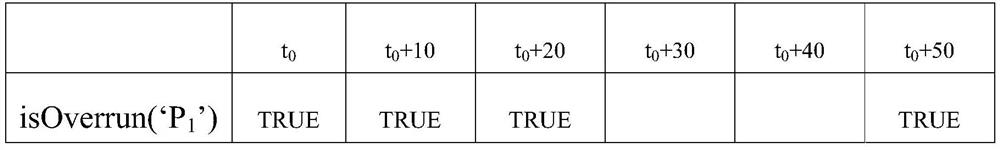

Equipment fault diagnosis method and device

ActiveCN112650200ARealize intelligent diagnosisImprove fault diagnosis efficiencyProgramme controlElectric testing/monitoringReliability engineeringComputer engineering

The invention discloses an equipment fault diagnosis method and device. The equipment fault diagnosis method comprises the steps of: obtaining equipment parameters according to a preset parameter obtaining rule; obtaining a theoretical value interval of the equipment parameters according to a preset theoretical value model; comparing and analyzing the equipment parameters and the theoretical value interval thereof to obtain a comparison result; and performing equipment fault diagnosis according to the comparison result and an equipment fault library. By the adoption of the method, intelligent diagnosis of equipment faults is achieved, and the equipment fault diagnosis efficiency is effectively improved.

Owner:中能融安(北京)科技有限公司

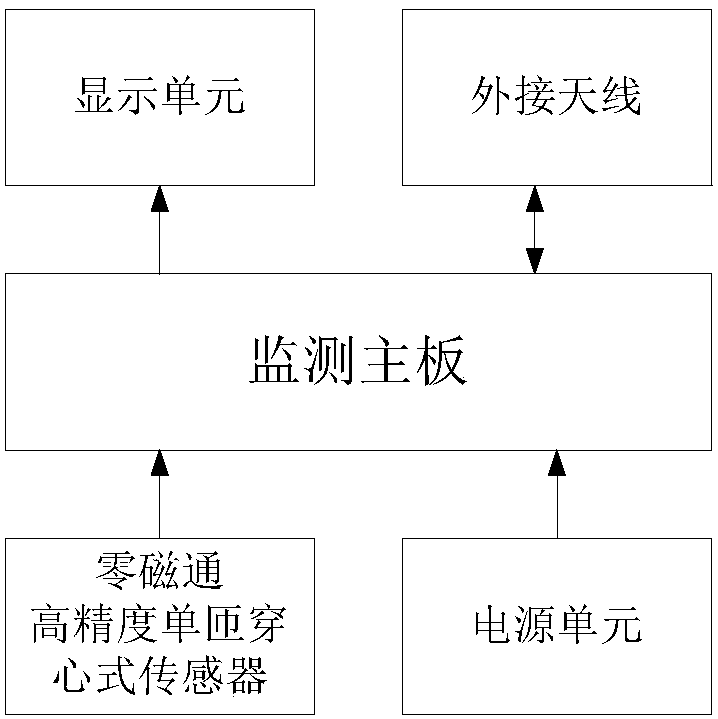

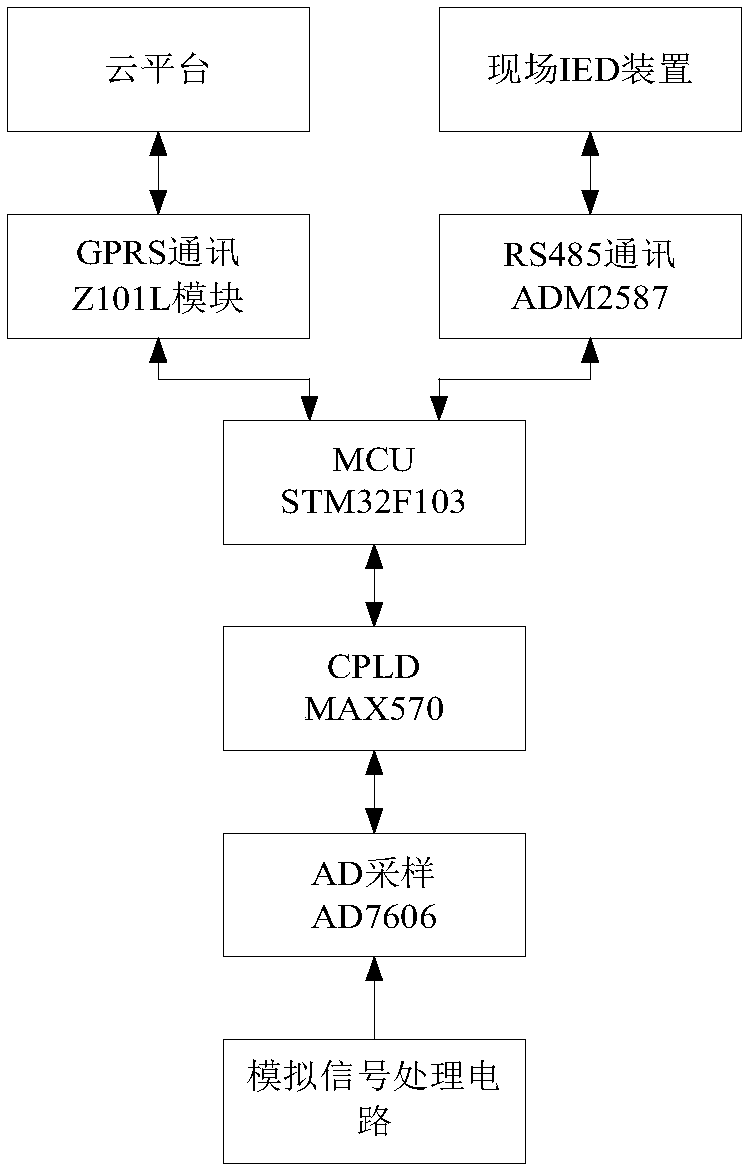

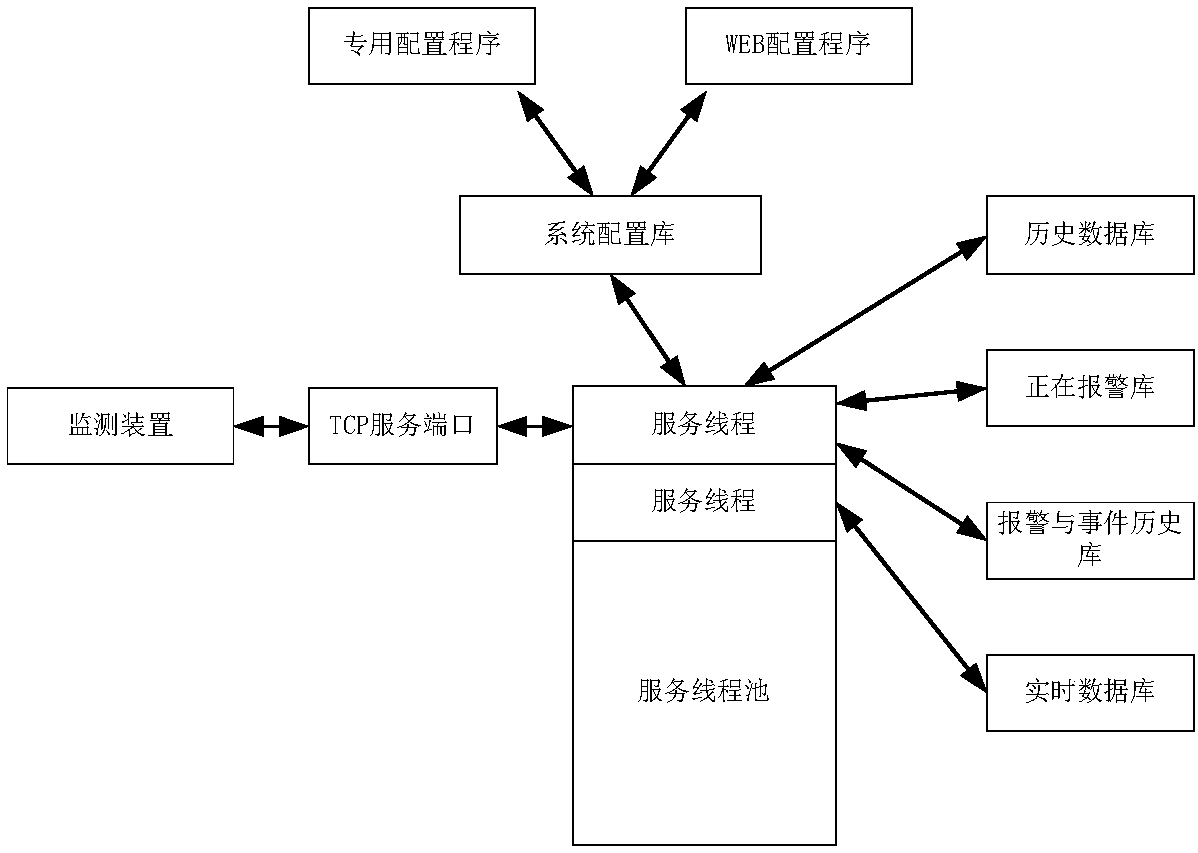

Transformer core grounding current monitoring device

PendingCN108241087AReduce or replace inspection workTimely detection of hidden troublesTransmissionMeasurement using digital techniquesCommunication unitTransformer

A transformer core grounding current monitoring device belongs to the field of on-line monitoring technology of transformers. The transformer core grounding current monitoring device comprises a zero-flux high-precision single-turn cross-core current sensor, a monitoring main board, a display unit, a power supply unit and a communication unit, the zero-flux high-precision single-turn cross-core current sensor, the display unit, the power supply unit and the communication unit are connected to the monitoring main board respectively, and the monitoring main board is used to receive a sensing signal of the zero-flux high-precision single-turn cross-core sensor and display the sensing signal locally and send the sensing signal to a remote server through the communication unit. The transformercore grounding current monitoring device can monitor the transformer core grounding current in real time, the monitoring data is sent to the cloud platform server in real time, and the cloud platformserver processes the monitoring data in real time.

Owner:CHINA RAILWAY ERYUAN ENG GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com