Hub type brake braking torque true value detection sensor and braking torque true value detection method

A hub brake and detection sensor technology, applied in the field of sensors, can solve the problem that the braking torque of the hub brake cannot be detected in real time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

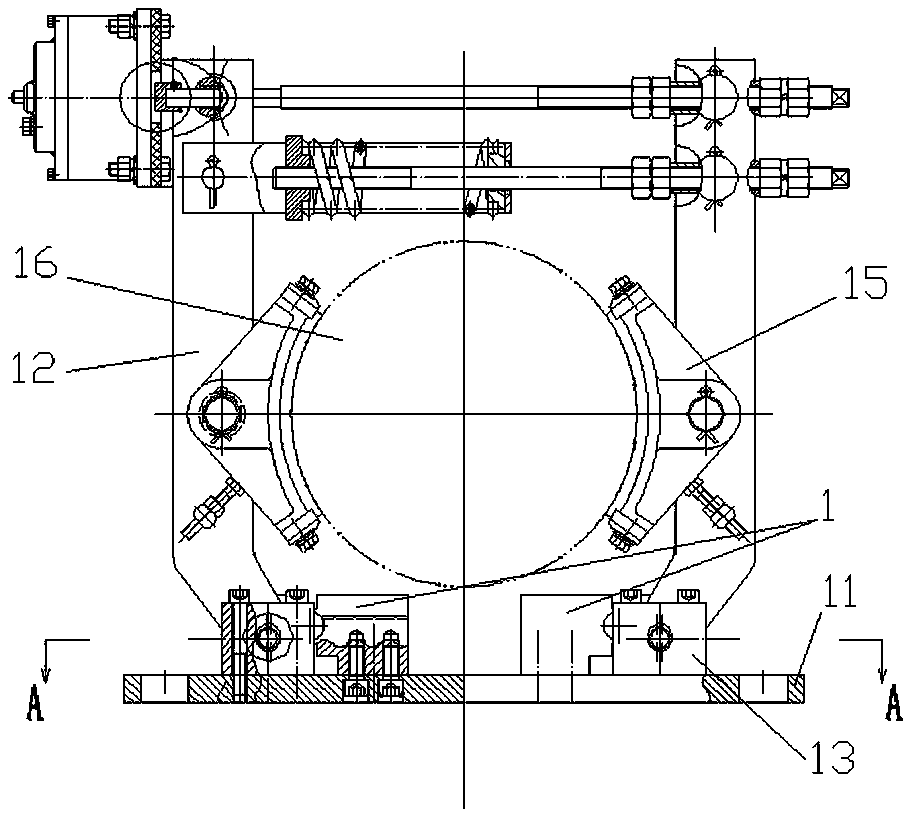

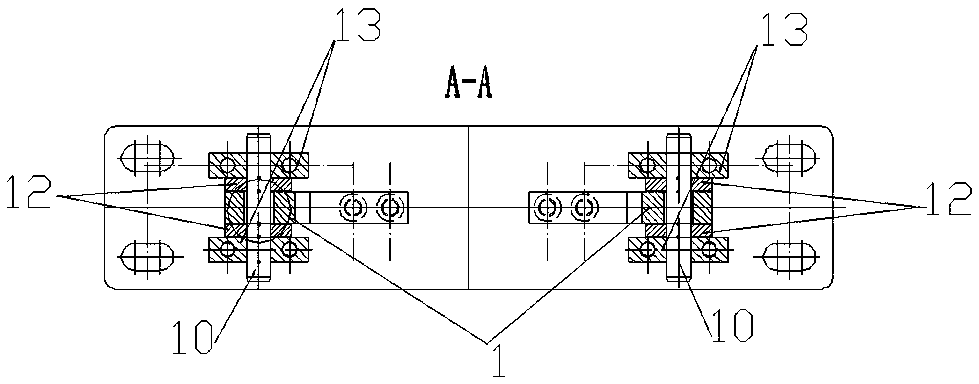

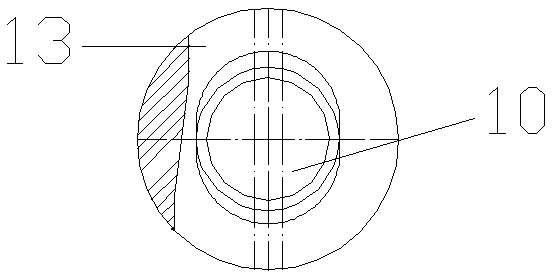

Embodiment 1

[0039] Such as Figure 6 , Figure 7 As shown, the base plate 1 is a knife handle-shaped plate, the part with the lower convex edge 3 on the base plate 1 is the fixed connection part, and the part suspended at the bottom is the suspended extension part. An oblong transverse through hole 4 (or oval or elongated hole type) is opened at the lower part of the suspended extension part to pass through the hinge shaft 10 of the brake arm. The tension and pressure sensors 2 are respectively attached on the substrate and the lower edge of the suspended extension ( Figure 6 ), preferably close to the root of the knife handle, to detect the tension and compression force on the substrate when the brake is applied. The tension and pressure sensors 2 can also be respectively attached to the substrate surface of the suspended extension ( Figure 7 ).

Embodiment 2

[0041] Such as Figure 8 — Figure 11 As shown, the shape of the substrate 1 is similar to that of Embodiment 1. On the suspended extension of the substrate 1, there are vertical upper and lower through grooves 5 near the plate body of the fixed connection portion. Grooving on both sides of the board can also be done symmetrically on both sides of the board. The tension and pressure sensors 2 are respectively attached to the upper and lower edges of the plate body at the notch of the upper and lower through grooves ( Figure 8 , Figure 9 ) to detect the tension and compression force on the substrate 1 when the brake is applied. The tension and pressure sensor 2 can also be respectively attached to the upper and lower ends of the groove bottom surface of the upper and lower through grooves 5 ( Figure 10 , Figure 11 ).

Embodiment 3

[0043] Such as Figure 12 , Figure 13 As shown, the shape of the substrate 1 is similar to that of Embodiment 1, and an upper flat groove 7 and a lower flat groove 9 are opened on the plate body of the suspended extension part of the substrate close to the fixed connection part, and the upper flat groove 7 and the lower flat groove 9 face away from each other up and down. The tension and pressure sensors 2 are respectively attached to the groove bottom surface of the upper flat groove 7 and the groove bottom surface of the lower flat groove 9 ( Figure 12 ) to detect the tension and compression force on the substrate 1 when the brake is applied. The tension-compression sensor 2 can also be respectively attached on the base plate body near the port of the upper flat groove and the port of the lower flat groove, and the tension-compression sensor 2 is on a vertical line with the upper flat groove and the lower flat groove ( Figure 13 ).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com