Internet of Things intelligent distribution box for tunnel engineering

A technology of tunnel engineering and distribution box, which is applied in the substation/distribution device casing, electrical components, panel/switch station circuit devices, etc. It can increase the heat dissipation effect, reduce the workload and improve the safety effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

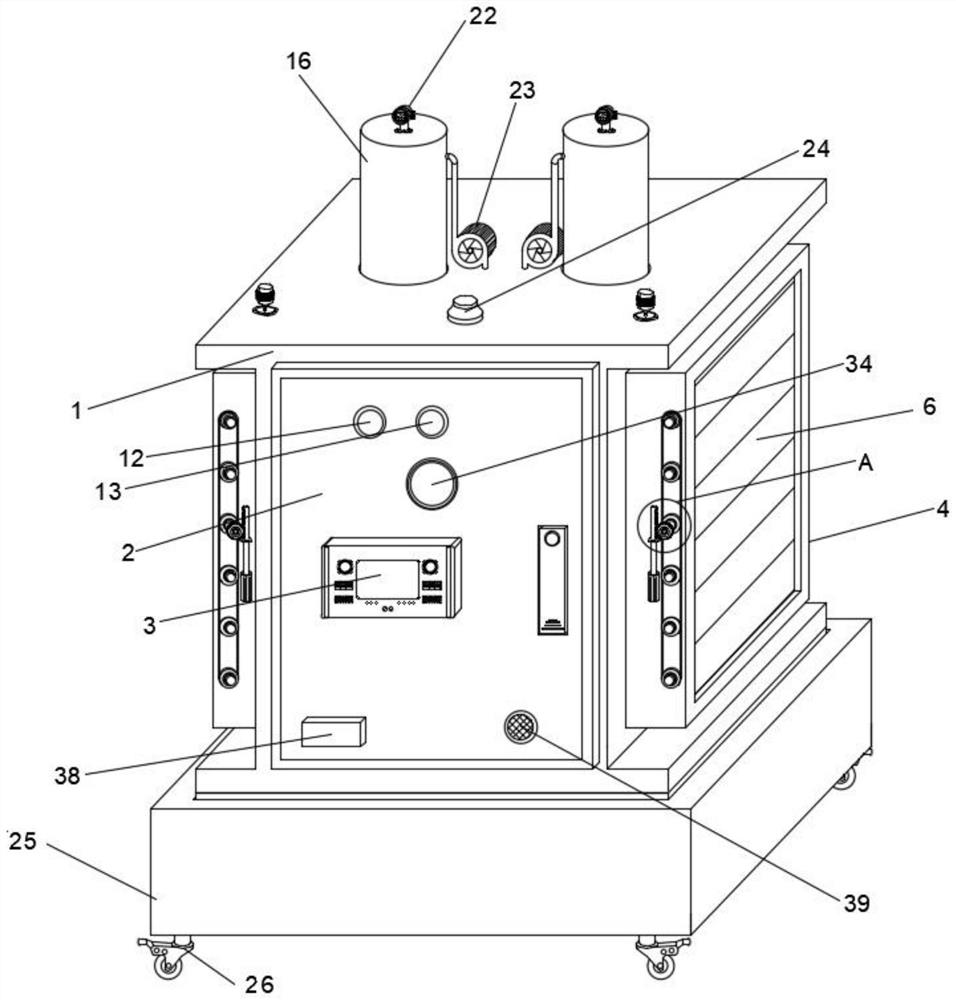

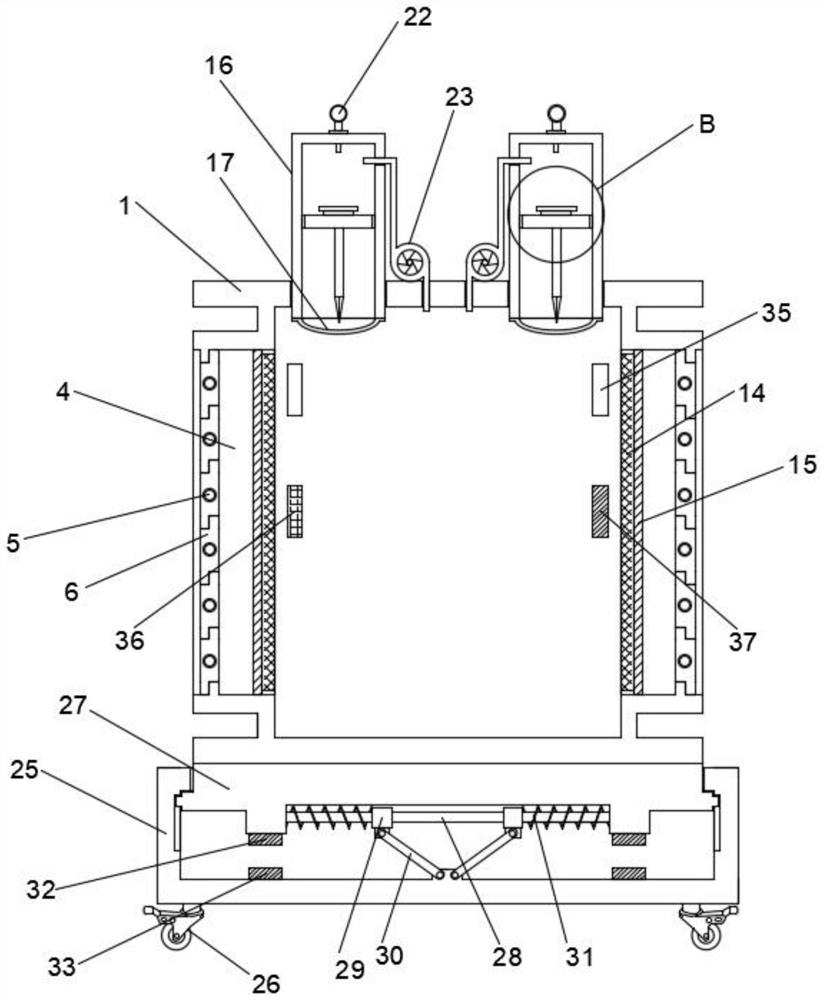

[0028] Example one, by Figure 1-4 Given, an IoT smart distribution box for tunnel engineering includes a box body 1, a box door 2 and a programming controller 3, the box door 2 is hinged on the front side of the box body 1, and the programming controller 3 is fixedly installed on the box door 2 On the front side, the left and right sides of the box body 1 are provided with ventilation windows 4. The ventilation window 4 is provided with a ventilation and heat dissipation mechanism. The top of the box body 1 is provided with a fire extinguishing mechanism. The bottom of the box body 1 is installed with a base 25. Locking universal wheels 26 are installed at the four corners of the electric meter, and a shock absorbing mechanism is arranged inside the base 25. The box 1 is provided with a remote monitoring module for remotely monitoring various parameters of its internal electric meter. A positioning module for assisting maintenance personnel to discover and troubleshoot abnorm...

Embodiment 2

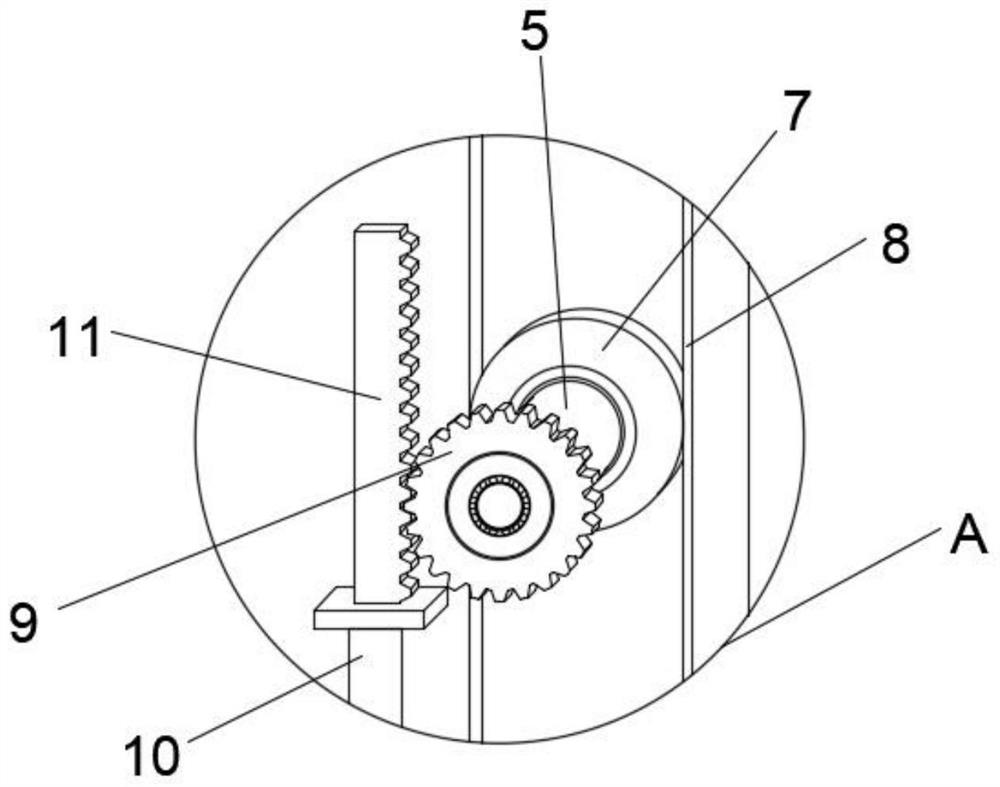

[0029] Embodiment 2, on the basis of Embodiment 1, the ventilation and heat dissipation mechanism includes a rotating shaft 5, a windshield 6, a synchronous wheel 7, a synchronous belt 8, a gear 9, an electric push rod 10, a rack 11, a temperature sensor 12 and a humidity Sensor 13, a plurality of rotating shafts 5 are rotatably installed inside the ventilation window 4, each rotating shaft 5 is fixedly installed with a windshield 6, the single windshields 6 are fitted with each other, and one end of each rotating shaft 5 penetrates through. The front side wall of the ventilation window 4 extends to the outside and is fixedly installed with a synchronous wheel 7. The synchronous wheel 7 is provided with a synchronous belt 8, and the transmission between the plurality of synchronous wheels 7 is realized by the synchronous belt 8, and one end of the rotating shaft 5 is fixedly installed There is a gear 9, an electric push rod 10 is fixedly installed on the front side wall of the ...

Embodiment 3

[0030] Embodiment 3, on the basis of Embodiment 1, the fire extinguishing mechanism includes a gas storage tank 16, a sealing membrane 17, a piston plate 18, a membrane rupture nail 19, an electromagnet 20, a silicon steel sheet 21, an air pressure sensor 22, an air pump 23 and smoke. For the sensor 24, two gas storage tanks 16 are fixedly installed on the top of the box body 1. The lower end of the gas storage tank 16 penetrates the top wall of the box body 1 and extends to the inside of the box body 1. The bottom surface of the gas storage tank 16 is fixedly installed with a sealing film 17. A piston plate 18 is slidably connected to the inside of the gas storage tank 16. The inside of the gas storage tank 16 is divided into two sealed cavities by the piston plate 18. The cavity at the lower part of the piston plate 18 is filled with inert gas, and the bottom of the piston plate 18 is fixed. The membrane breaking nail 19 is installed, the top of the piston plate 18 is fixedly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com