Railway power equipment history management system and method based on fault location function

A fault location, power equipment technology, applied in data processing applications, geographic information databases, database design/maintenance, etc., can solve problems such as large number of required, power outage running production, operation, difficult to accurately locate, etc., to reduce labor strength, eliminate power accidents, and reduce the effect of manual intervention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in detail below in combination with specific embodiments.

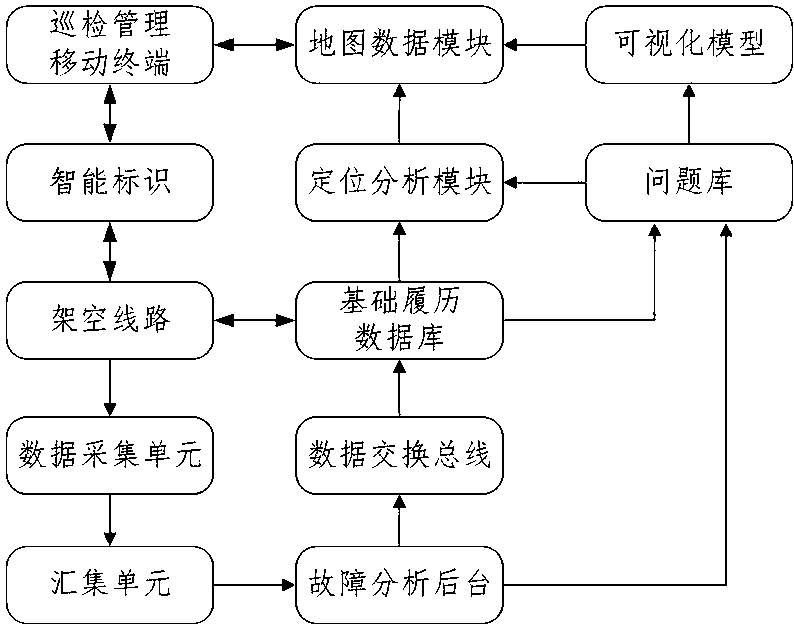

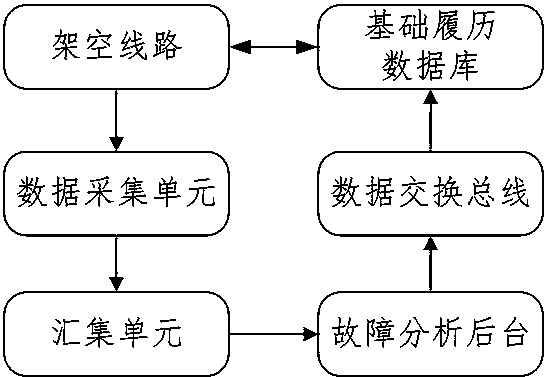

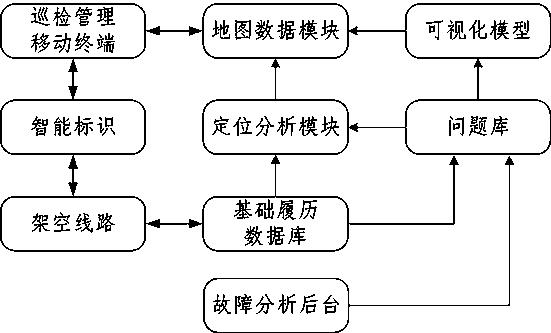

[0033] The history management system of railway power equipment based on the fault location function involved in the present invention includes an overhead line, a data acquisition unit, a collection unit, a fault analysis background, a data exchange bus, a basic history database, a question bank, a visualization model, a map data module, a tour Inspection and management of mobile terminals and smart signs;

[0034] The overhead line is connected to the data acquisition unit, and the data collected by the data acquisition unit is transmitted to the fault analysis background through the collection unit, and the fault analysis background is connected to the basic history database through the data exchange bus, and the data in the basic history database corresponds to the overhead line data;

[0035] The basic history database and the fault analysis background collect proble...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com