Transformer core grounding current monitoring device

A transformer core and grounding current technology, applied in the direction of measuring devices, measuring current/voltage, instruments, etc., can solve the problem that regular inspections cannot guarantee the multi-point grounding fault of the iron core, and it is difficult to measure the accuracy and accuracy of the clamp ammeter And other problems, to achieve the effect of good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

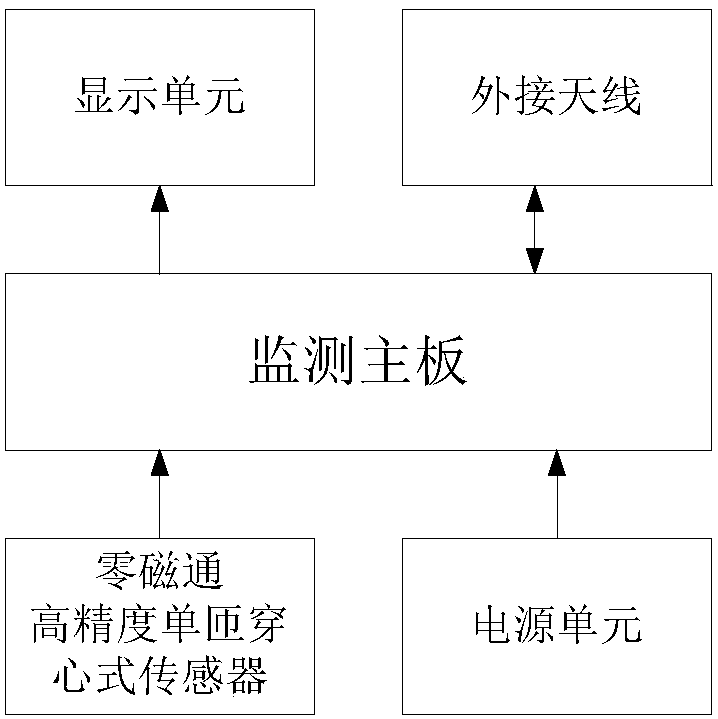

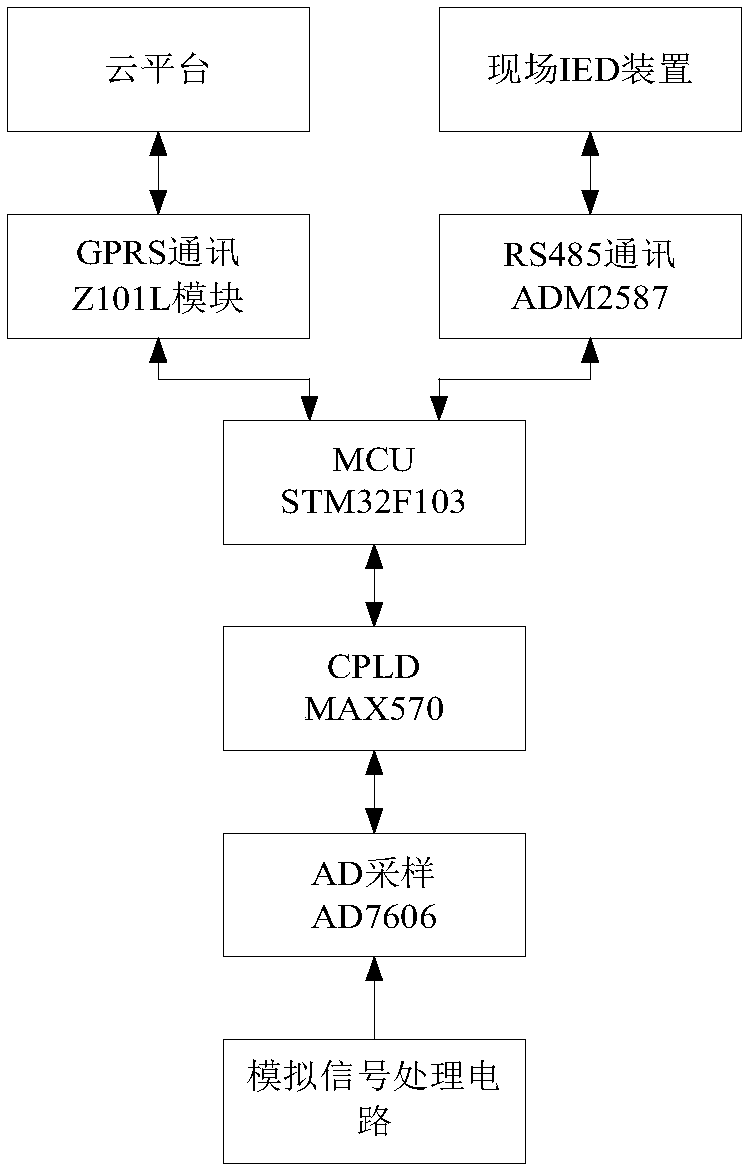

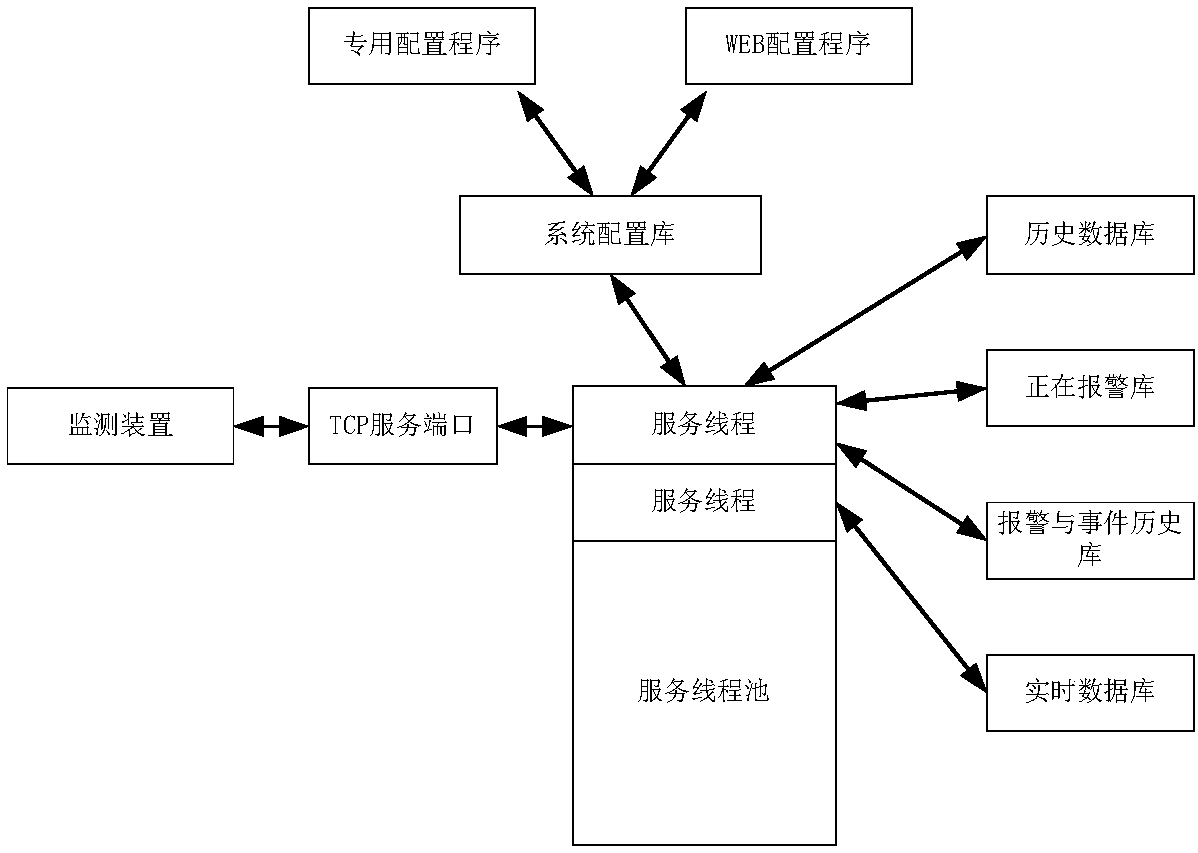

[0015] figure 1 , 2 As shown in , a transformer core grounding current monitoring device based on a cloud platform is composed of a zero-flux high-precision single-turn core-through current sensor, a monitoring board, a display unit, a power supply unit, and an external GPRS communication antenna. High-precision single-turn core-through current sensor, monitoring main board, display unit and power supply unit are installed in the device box, and the external GPRS communication antenna is led out from the device box. The power output terminal of the power supply unit is connected to the power input terminal of the monitoring board. The ground wire of the transformer core passes through the zero-flux high-precision single-turn core-through current sensor, and the zero-flux high-precision single-turn core-through current sensor is connected to the primary ground. The current is converted into a secondary current, the output terminal of the zero-flux high-precision single-turn co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com