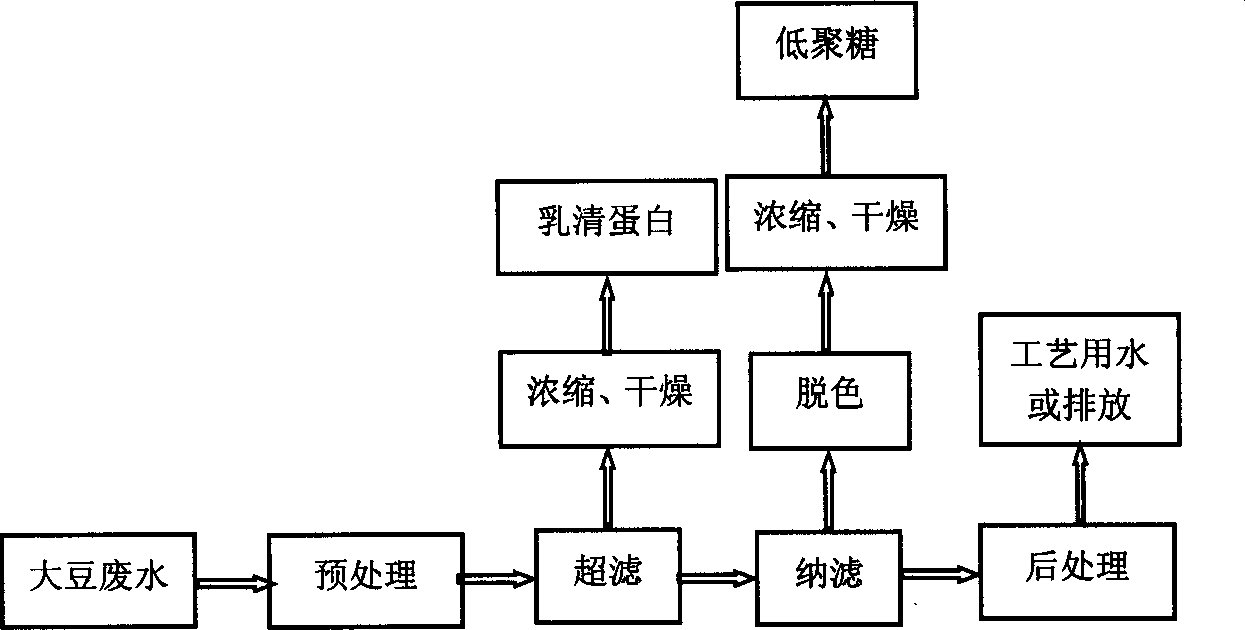

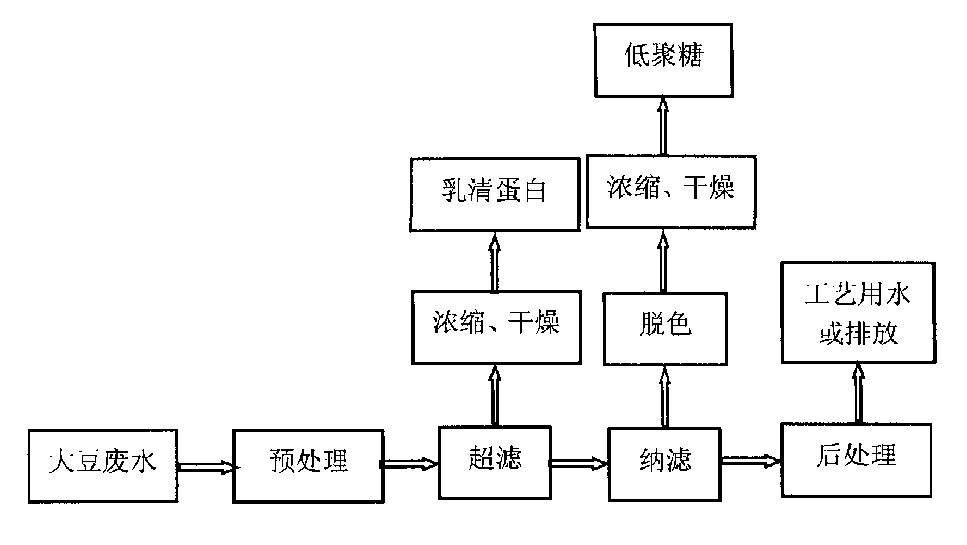

Membrane separation process of treating soybean processing waste water

A technology for processing wastewater and membrane separation, which is applied in the direction of osmosis/dialysis water/sewage treatment, ultrafiltration, etc. It can solve problems such as poor quality, polluted equipment operation, and low concentration, and achieve low equipment investment and operating costs and improved product quality. , the effect of mitigating the impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Step 1): Pretreatment: collect the soybean processing wastewater into the wastewater tank, and enter the pretreatment device through the wastewater booster pump. Preliminary treatment of soybean processing wastewater: add an appropriate amount of sodium hydroxide to the soybean processing wastewater to make the pH of the soybean processing wastewater 8; then add flocculant CaCl 2 To remove the fat in the soybean processing wastewater, the added CaCl 2 According to the amount of Ca in soybean processing wastewater 2+ After the addition, the content is determined to be about 200 mg / l; then the soybean processing wastewater is centrifuged to remove the flocculation sediment; the clarified soybean processing wastewater is pre-filtered and micro-filtered to remove particles above 5 μm and 0.2 μm respectively and bacteria, etc.; finally, adjust the temperature of the aforementioned treated soybean processing wastewater to keep it at about 45°C;

[0017] Step 2): Ultrafiltra...

Embodiment 2

[0021] Step 1)~step 3) of the present embodiment are identical with embodiment 1:

[0022] Step 4): post-treatment: carry out aerobic biological treatment on the nanofiltration membrane permeate liquid obtained in step 3 according to the prior art, and the treated water meets the relevant national sewage discharge standards, and is discharged according to regulations.

Embodiment 3

[0024] Step 1): Pretreatment: collect the soybean processing wastewater into the wastewater tank, and enter the pretreatment device through the wastewater booster pump. Preliminary treatment of soybean processing wastewater: add an appropriate amount of sodium hydroxide to the soybean processing wastewater to make the pH of the soybean processing wastewater 7; then add flocculant CaCl 2 To remove the fat in the soybean processing wastewater, the added CaCl 2 According to the amount of Ca in soybean processing wastewater 2+ After the addition, the content is determined to be about 300 mg / l; then the soybean processing wastewater is centrifuged to remove the flocculation sediment; the clarified soybean processing wastewater is pre-filtered and micro-filtered to remove particles above 5 μm and 0.2 μm respectively and bacteria, etc.; finally, adjust the temperature of the soybean processing wastewater after the aforementioned treatment to keep it at 40°C;

[0025] Step 2): Ultra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com