Dynamic self-assembled process for preparing low-pressure high-throughput charged nanofiltration membrane

A self-assembly, low-pressure and high-pressure technology, applied in the field of nanofiltration membranes, can solve problems such as unsuitability for industrial production, increased operating pressure, and long assembly time, and achieve the effects of simple method, low operating pressure, and controllable membrane structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The ultrafiltration membrane used in this example is an alkali-modified polyacrylonitrile (PAN) ultrafiltration membrane with a molecular weight cut-off of 50,000.

[0025] Dynamic self-assembly was performed in a stainless steel vessel with a diameter of 9 cm and a porous support layer at the bottom. The membrane surface of the ultrafiltration membrane is facing up, the edge is fixed, placed in the container, and self-assembled according to the following steps:

[0026] 1) Dissolve polyallyl ammonium chloride (Mw=60,000) in deionized water to make a solution with a concentration of 0.2%, then add NaCl to the polyallyl ammonium chloride solution, and the concentration of NaCl solution is 0.5% M, then add concentrated hydrochloric acid dropwise to adjust the pH value of the solution to 2.5; dissolve sodium polystyrene sulfonate (Mw=70,000) with deionized water to make a 0.4% aqueous solution, and then dissolve it in the sodium polystyrene sulfonate solution Add CaCl 2 ...

Embodiment 2

[0033] The ultrafiltration membrane used in this example is a PES-SPES blend ultrafiltration membrane with a molecular weight cut off of 30,000.

[0034] Dynamic self-assembly was performed in a stainless steel vessel with a diameter of 9 cm and a porous support layer at the bottom. The membrane surface of the PES-SPES blend ultrafiltration membrane is facing upwards, the edge is fixed, placed in the container, and self-assembled according to the following steps:

[0035] 1) Dissolve polyallyl ammonium chloride (Mw=60,000) with deionized water to make a solution with a concentration of 0.2%, then add NaCl, the concentration of the NaCl solution is 0.5M, then add concentrated hydrochloric acid dropwise to adjust the concentration of the solution The pH value is 2.3; dissolve sodium polystyrene sulfonate (Mw=70,000) in deionized water to make a 0.4% aqueous solution, and then add CaCl 2 , so that CaCl 2 The concentration of the solution is 0.5M, and the pH value of the solutio...

Embodiment 3

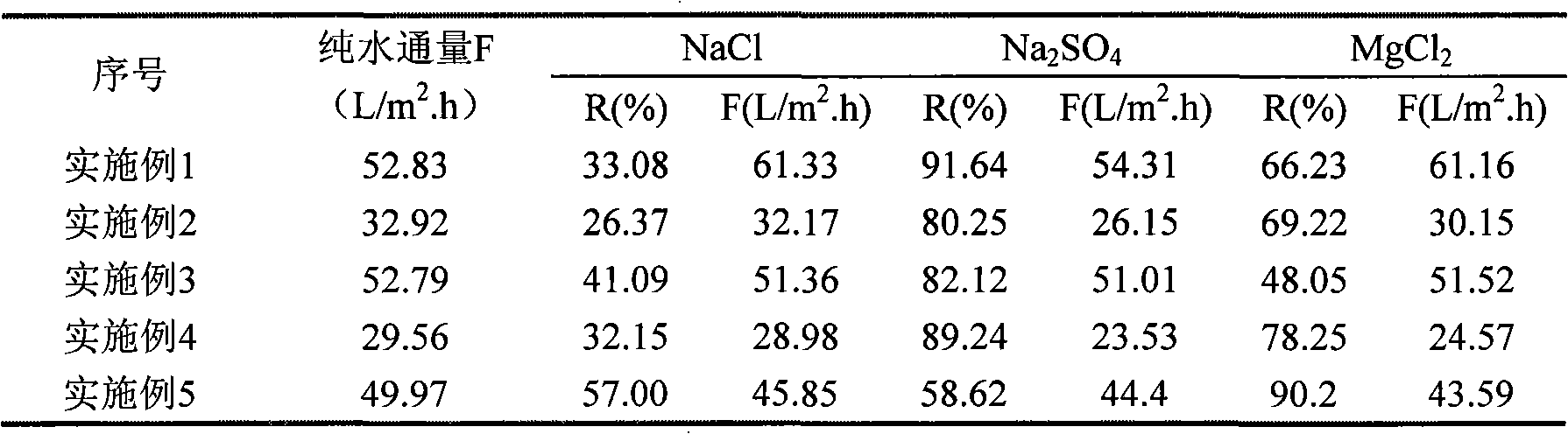

[0042] According to the conditions of Example 1, the alkali-modified polyacrylonitrile (PAN) ultrafiltration membrane was used as the base membrane, and the molecular weight cut-off was 50,000. The concentration of the sodium polystyrene sulfonate-maleic acid (salt) copolymer solution was 3.22%. The membrane is sensitive to NaCl, Na 2 SO 4 , MgCl 2 The separation performance is shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com