Super-hydrophobic nano-composite coating and preparation method thereof

A nano-composite, super-hydrophobic technology, applied in coatings and other directions, can solve the problems of reduced material transparency, difficulty in widespread application, increased reflection and absorption, and achieve low production costs, low prices, and high transparency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

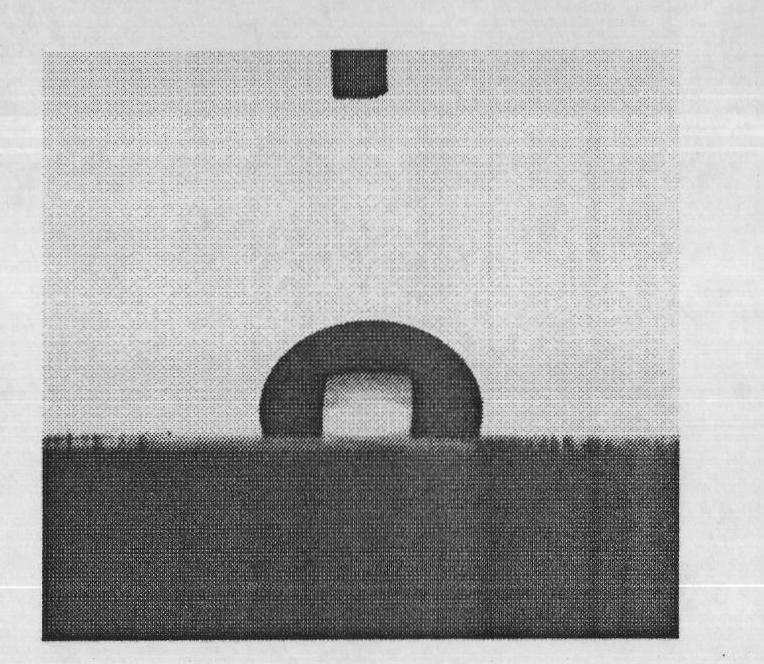

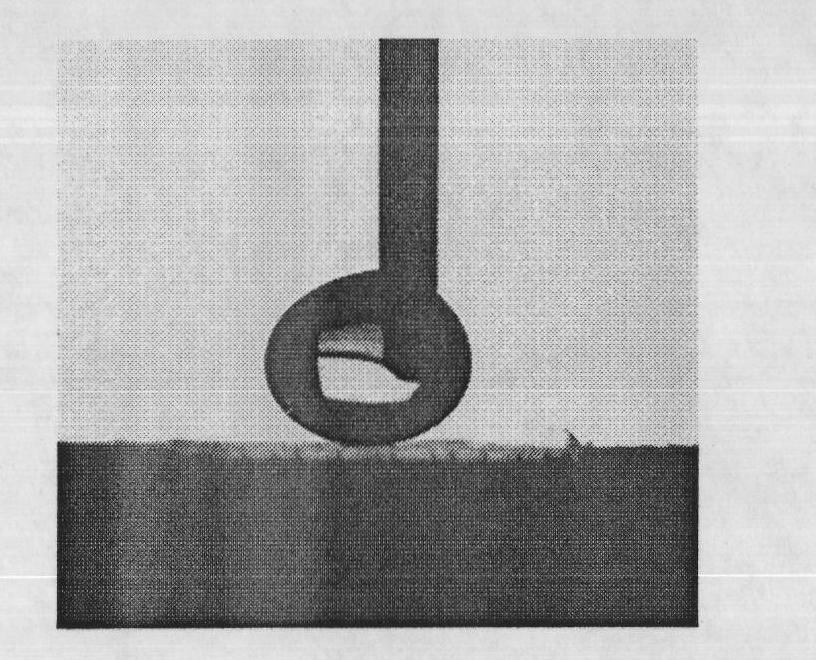

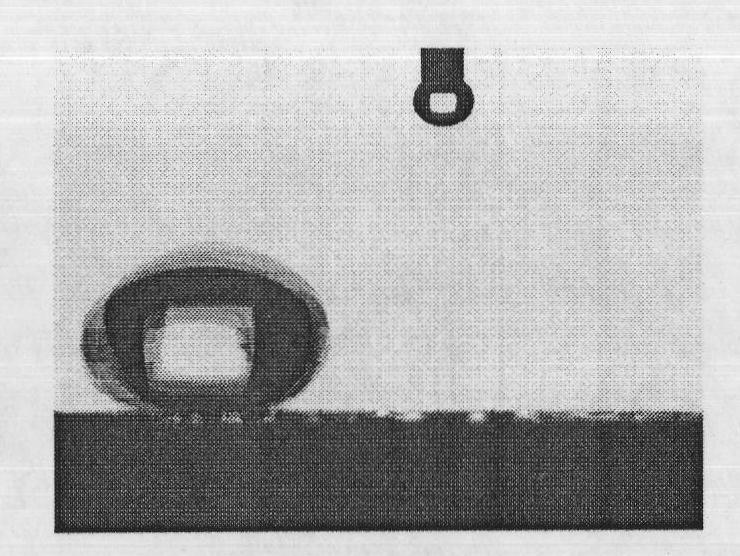

Image

Examples

Embodiment 1

[0032] First, 2.63 g of hydrophobically modified silicon dioxide with a particle size of 10-30 nm and 1.06 g of polydimethylsiloxane were added to 496.31 g of toluene, and then mechanically stirred and dispersed for 30 minutes at room temperature to obtain a transparent superhydrophobic coating.

[0033] The contact angle of the transparent super-hydrophobic coating is 152-154°; the rolling angle is 7-9°; and the light transmittance is 88-94%.

Embodiment 2

[0035] First, 3.97 g of hydrophobically modified silicon dioxide with a particle size of 10-30 nm and 1.56 g of polystyrene were added to 494.47 g of toluene, and then ultrasonically oscillated and dispersed for 30 min at room temperature to obtain a transparent superhydrophobic coating.

[0036] The contact angle of the transparent super-hydrophobic paint is 153-157°; the rolling angle is 3-5°; and the light transmittance is 88-94%.

Embodiment 3

[0038] First, 4.925 g of hydrophobically modified silicon dioxide and 2.465 g of fluorinated polyurethane were added to 492.61 g of xylene, and then dispersed by ball milling at room temperature for 50 minutes to obtain a transparent superhydrophobic coating.

[0039] The contact angle of the transparent super-hydrophobic coating is 153-155°; the rolling angle is 1-3°; and the light transmittance is 88-94%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com