Method for fixing biological molecules on polymer microporous membrane surface

A biomolecules and surface immobilization technology, applied in semi-permeable membrane separation, chemical instruments and methods, membrane technology, etc., can solve the problems of shortened membrane service life, large membrane mass transfer driving force, poor wettability, etc., and achieve equipment Simple, widely applicable, and low-cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

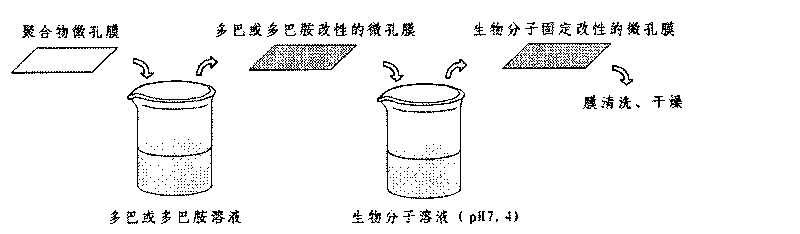

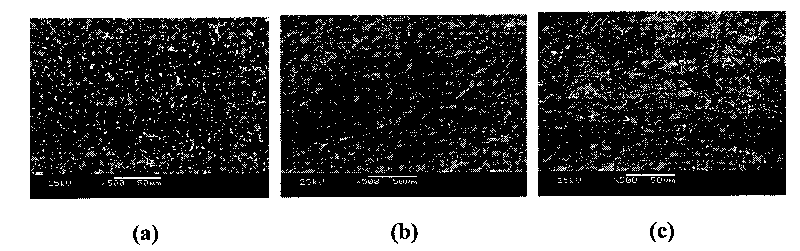

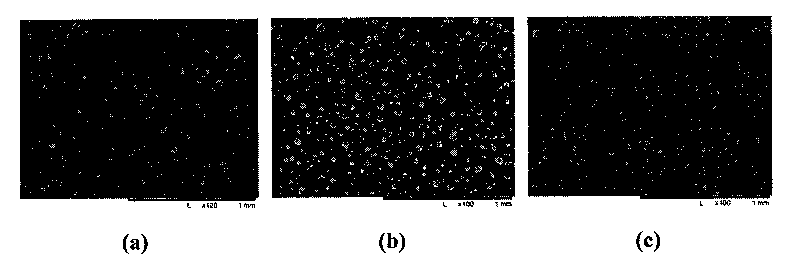

[0052] Dissolve dopa in tris-hydrochloric acid (Tris-HCl) buffer solution to form a dopa solution with a pH value of 7.5 and a concentration of 0.2 g / L; dissolve heparin in 0.01 mol / L phosphoric acid In the buffer solution, prepare heparin solution, the pH value of the solution is 7.4, and the solution concentration is 0.25-2.0 g / L; cut, wash and dry PE flat microporous membrane (prepared by stretching method, average pore size 0.5 micron) 5× 5cm 2 , soaked in 95% ethanol for 1 hour, took it out and placed it in the dopa solution and oscillated for 100 hours, the oscillation frequency was 60 times / min, and the reaction temperature was 10°C to obtain a dopa composite modified PE flat microporous membrane; Soak the dopa composite modified PE flat microporous membrane in the above heparin solution to react for a set time, take out the membrane and place it in deionized water for vibration cleaning, and then vacuum dry. The cleaning vibration frequency is 60 times / min, and the cle...

Embodiment 2

[0057] Dissolve dopamine in tris-hydrochloric acid (Tris-HCl) buffer solution to prepare a dopamine solution with a pH value of 7.5 and a concentration of 0.2 g / L; dissolve heparin in 0.01 mol / L phosphate buffer 20 PP hollow fiber microporous membranes with a length of 10 cm (prepared by stretching method, average pore size of 0.15 microns), washed Clean drying, soaking in 95% ethanol for 1 hour, placing in the above-mentioned dopamine solution, oscillating for 0.5 hours, the oscillation frequency is 80 times / min, and the reaction temperature is 60°C, to obtain a dopamine composite modified PP hollow fiber membrane; Soak the dopamine composite modified PP hollow fiber membrane in the aforementioned heparin solution to react for a set time, take out the membrane and place it in deionized water for oscillation cleaning, the cleaning oscillation frequency is 80 times / min, the cleaning time is 96 hours, and the cleaning temperature is 30°C , and then vacuum-dried at a drying tempe...

Embodiment 3

[0063] Dopa is dissolved in tris-hydrochloric acid (Tris-HCl) buffer solution to prepare a pH value of 10.0 and a concentration of 2.0 grams per liter of dopa solution; BSA is dissolved in 0.01 mol / liter of phosphoric acid In the buffer solution, it is made into BSA solution, the pH value of the solution is 7.4, and the solution concentration is 0.25-2.0 g / L; cut 10 PVDF hollow fiber microporous membranes with a length of 10 cm (prepared by dry-wet spinning method, average pore diameter 0.1 micron), fully washed with deionized water and dried, soaked in industrial ethanol for 1 hour, then placed in the aforementioned dopa solution, oscillating for 24 hours, the oscillating frequency was 70 times / min, and the reaction temperature was 60°C. Obtain the dopa composite modified PVDF hollow fiber membrane; soak the dopa composite modified PVDF hollow fiber membrane in the above-mentioned BSA solution to react until the set time, take out the membrane and place it in deionized water f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com