Production technology for producing porous fine denier colored terylene pre-oriented filament by utilizing recycled polyester bottle flakes

A technology of polyester bottle flakes and colored polyester, applied in the melting of filament raw materials, filament forming treatment, filament/thread forming, etc., can solve problems that have not yet been discovered, and achieve enhanced drying effect, full texture, and good hand feeling Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

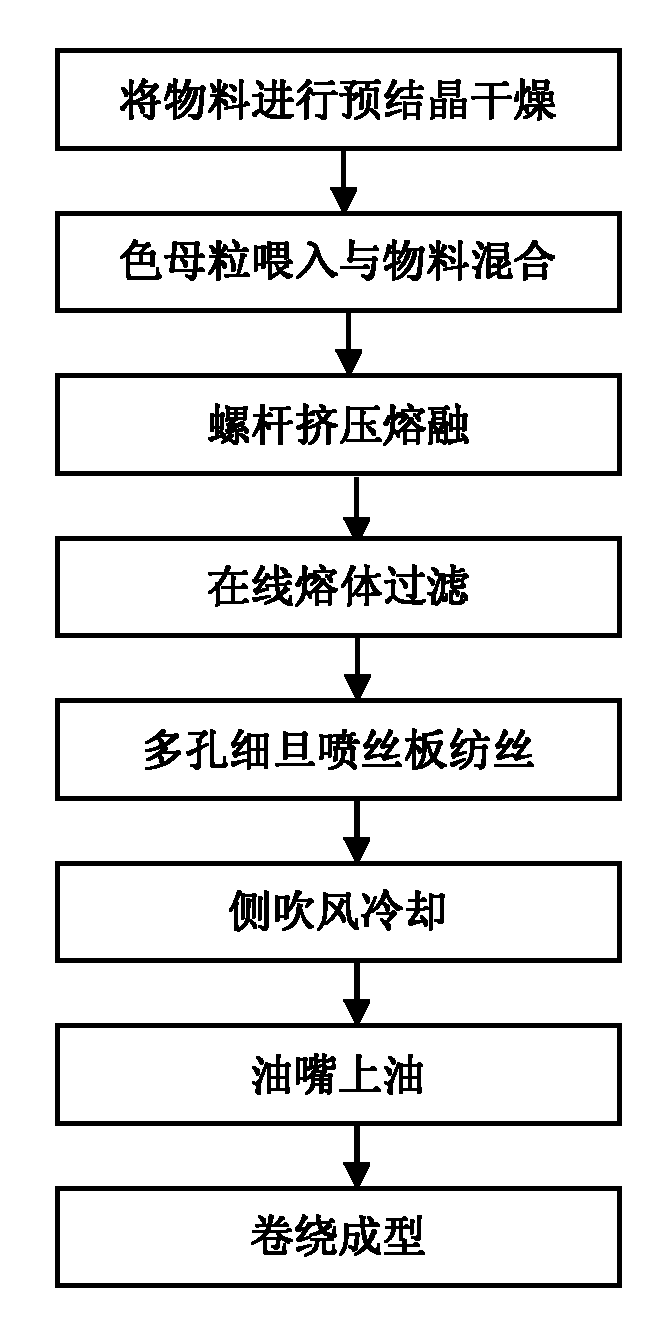

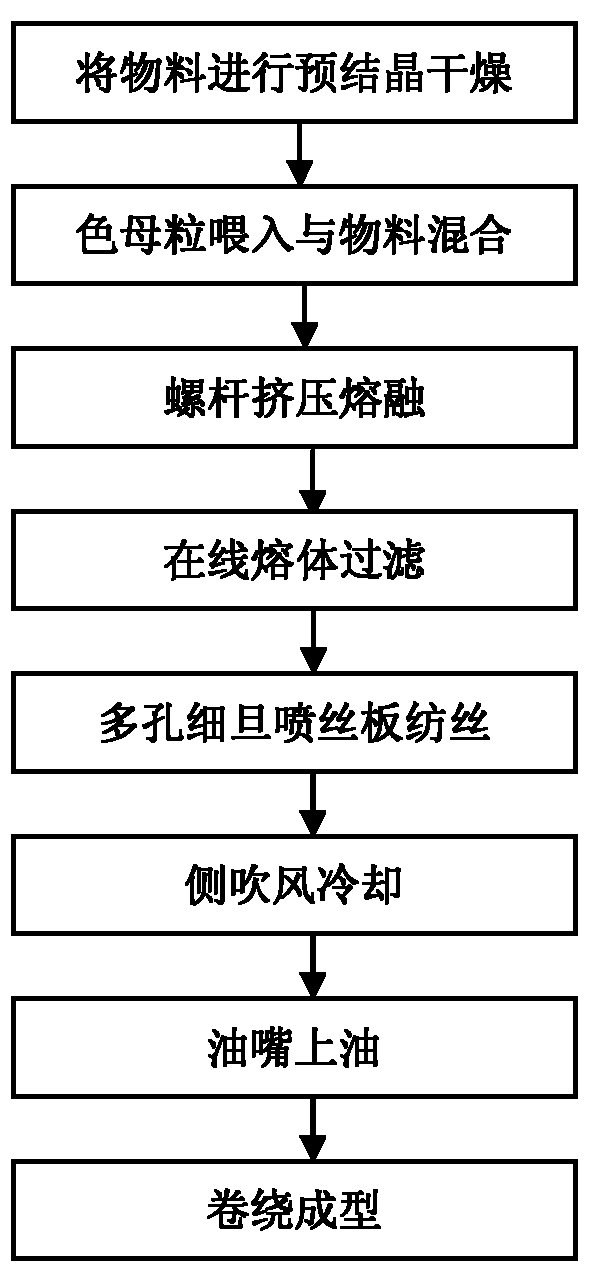

Method used

Image

Examples

Embodiment 1

[0033]This embodiment is the production process of producing 125dtex / 96f porous fine-denier colored polyester pre-oriented yarn, and its production process is as follows: the recycled polyester bottle flakes (moisture content at 40ppm) and color masterbatch with an intrinsic viscosity of 0.7 are used, and It is fed into a screw extruder with a diameter of Φ58mm and a length-to-diameter ratio (L / D) of 48. The recycled polyester bottle flakes and color masterbatch are melted in the screw extruder and filtered through a continuous filter. The precision is 25μm, the melt pressure before filtration is 12Mpa, the melt pressure after filtration is controlled at 10Mpa, and the melt temperature is 290°C. After being metered by a gear pump, it enters the spinning box for spinning, and the melt passes through a nozzle with Φ80mm and 96 holes. After spraying out from the circular spinneret hole on the wire plate, it is cooled by side blowing, oiled by the oil nozzle, and wound at high spee...

Embodiment 2

[0039] This embodiment is the production process of the 170dtex / 144f fine denier porous colored polyester pre-oriented yarn variety, and its production process is as follows: using recycled polyester bottle flakes (with a moisture content of 50 ppm) and polyester color masterbatches with an intrinsic viscosity of 0.80, And feed them together into a screw extruder with a diameter of Φ58mm and a screw length-to-diameter ratio (L / D) of 48. The recycled polyester bottle flakes and masterbatch are melted in the screw extruder and passed through a continuous filter. Filtration, the filtration accuracy is 25μm, the melt pressure before filtration is 12Mpa, the melt pressure after filtration is controlled at 10Mpa, and the melt temperature is 292°C. After metering by a gear pump, it enters the spinning box for spinning, and the melt passes through Φ100mm144 After the circular hole on the spinneret of the hole is sprayed out, it is cooled by side blowing, oiled by the oil nozzle, and wo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Breaking strength | aaaaa | aaaaa |

| Breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com