Production method of filament for capron 6 one-step full stretching superfine denier socks

A production method and full-drawing technology, applied in the melting of filament raw materials, filament/thread forming, melt spinning, etc., can solve the problems of unsuitability, low fiber uniformity, linear density unevenness, and breaking strength. Problems such as high elongation unevenness, to achieve the effect of tear resistance, obvious skinny feeling and stable size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

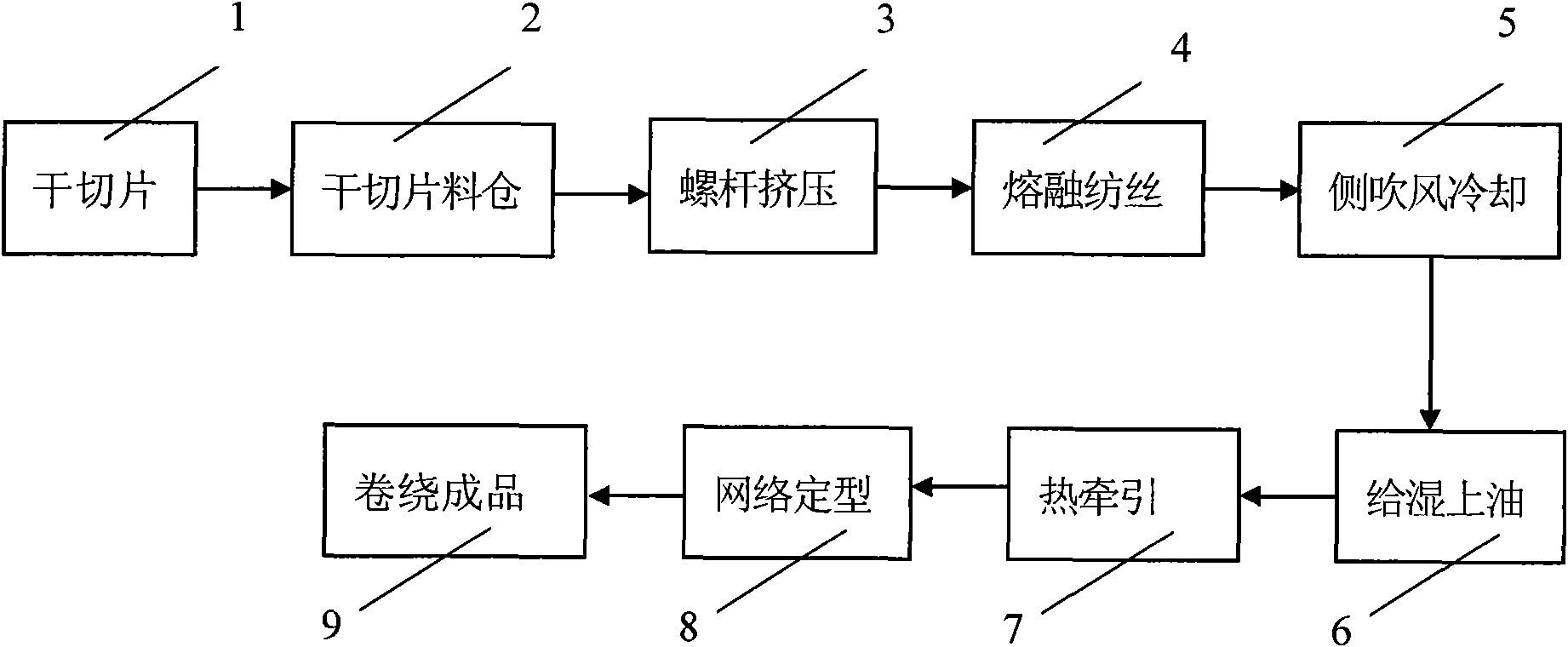

[0017] see figure 1 . The process flow of the present invention is: Nylon 6 dry slice 1→slice bin 2→screw extruder 3→melt spinning 4→side blowing cooling 5→wet oiling 6→heat traction 7→network shaping 8→winding Finished product9.

[0018] A kind of production method of nylon 6 (one-step method) full-drawn superfine denier socks filament of the present invention, comprises the following steps: (1) melting: the nylon 6 semi-dull slice raw material is imported into "screw rod" through "dry slice feed bin" (2) Spinning: Input the above-mentioned spinning melt into the "spinning box", after metering, press it into the assembly, extrude Form "spun fibers"; (3) cooling: cool the above-mentioned "spun fibers" through side blowing, oil nozzles, and tunnels; (4) forming: pre-interlace the above-mentioned cooled tow, heat them with R1 rolls and R2 rolls Stretching (heat setting), entanglement, traction treatment, winding forming, forming a finished silk cake. The production method is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com