Method for preparing dull fiber with wool-like effect

A matte fiber and wool-like technology, applied in the direction of stretch spinning, spinneret assembly, single-component polyester artificial filament, etc., can solve the problem of lack of hand feeling in the finished product, and achieve excellent fluffy performance and excellent nap The effect of performance and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

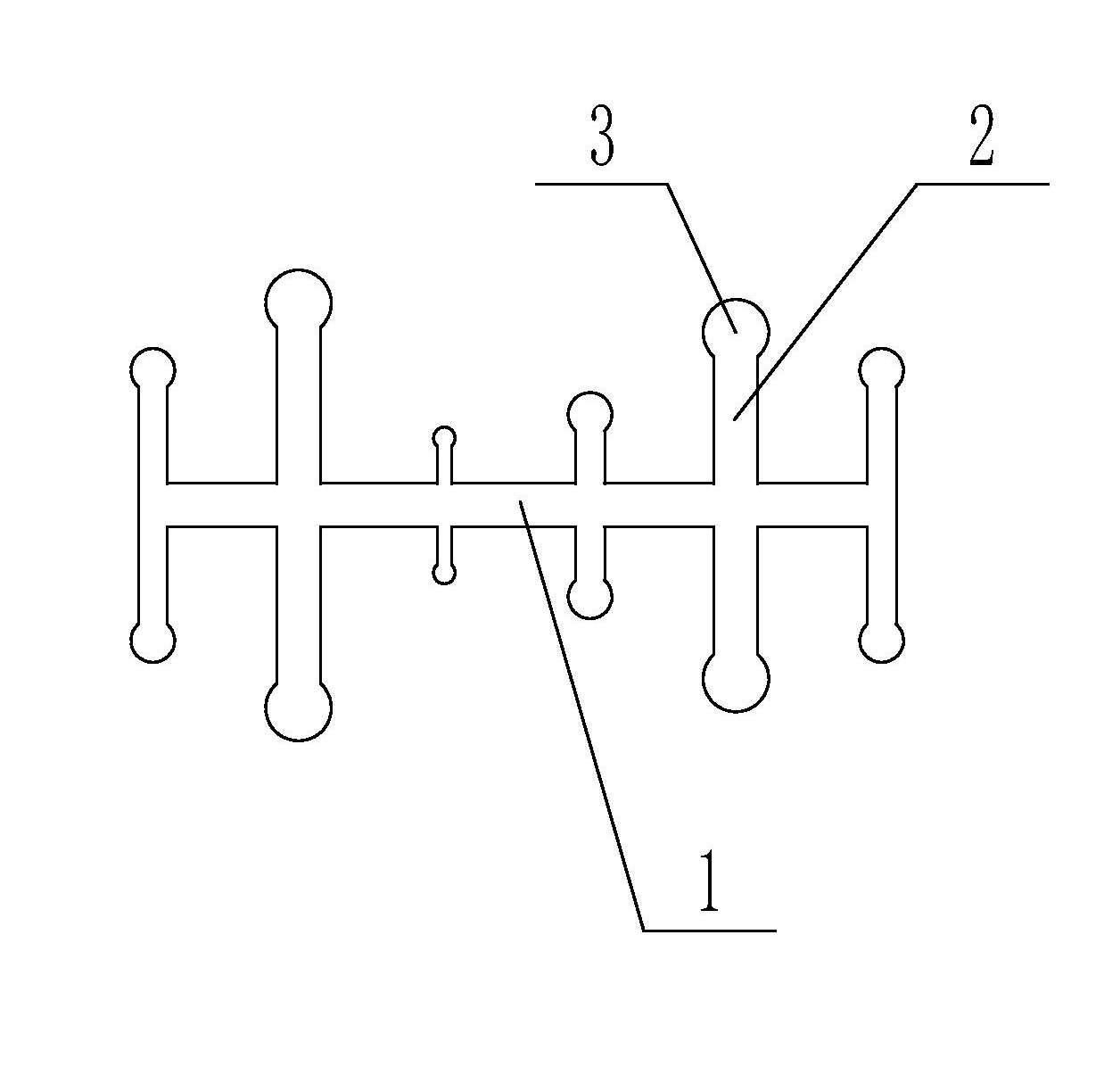

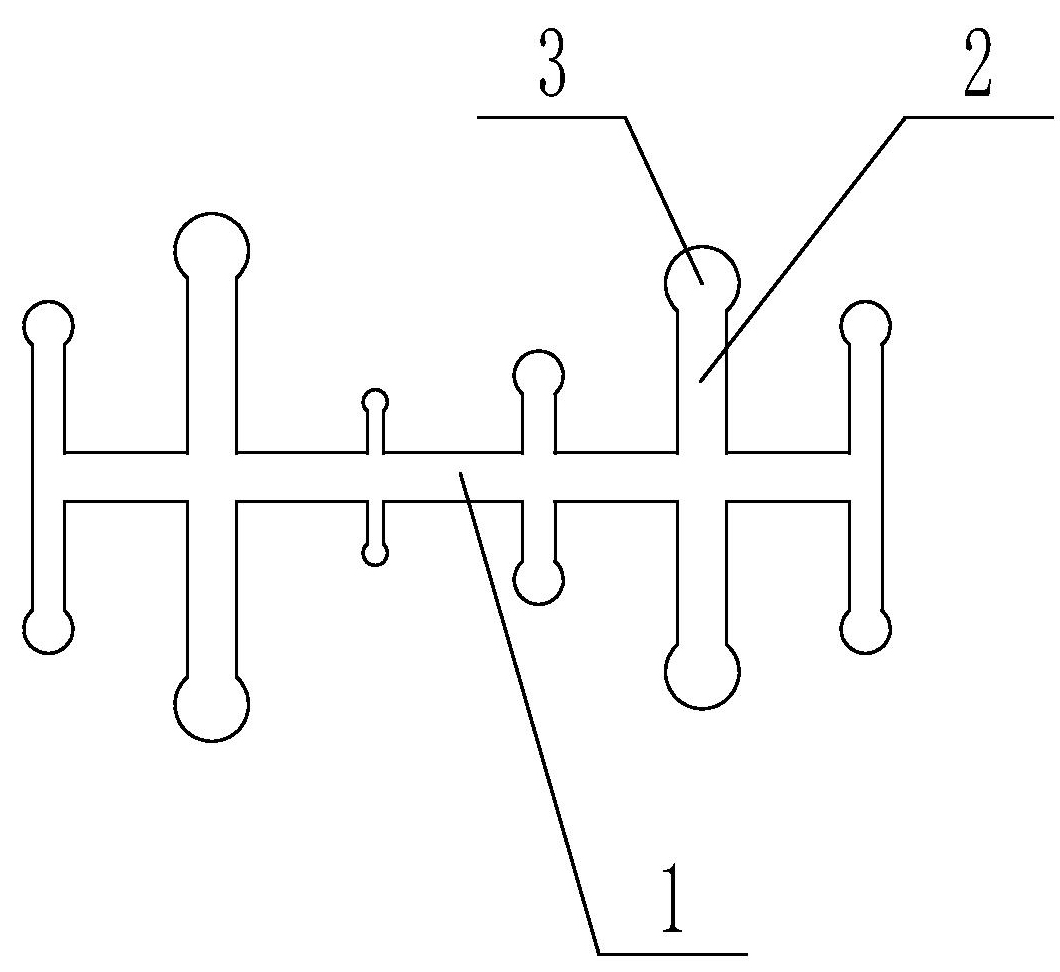

[0014] A method for preparing a matte fiber with wool-like effect, using polyester chips with an intrinsic viscosity of 0.680 and a titanium dioxide content of 2.5% as a raw material, and spinning with a hot-roller high-speed drafting spinning machine. Drying, drafting, setting temperature and drafting ratio, in order to achieve normal spinning to obtain a matt fiber product with a wool-like effect, the monofilament fineness of the matt fiber product with a wool-like effect is 1dpf~20dpf , the total fineness is 30dtex~150dtex, and the f number is 12~108. Wherein the spinning winding speed is 3800 m / min, and the shape of the spinneret hole of the spinneret produced by it is as follows: figure 1 As shown, it includes a horizontally arranged slotted hole 1 and six vertically arranged vertical holes 2 arranged horizontally along the slotted hole 1 and connected with the slotted hole 1. The two ends of the vertical hole 2 are respectively A round hole 3 is provided, and the diamet...

Embodiment 2

[0016] A method for preparing a matte fiber with wool-like effect, using polyester chips with an intrinsic viscosity of 0.680 and a titanium dioxide content of 3% as a raw material, and spinning with a hot roller high-speed draft spinning machine, and selecting appropriate Drying, drafting, setting temperature and drafting ratio, in order to achieve normal spinning to obtain a matt fiber product with a wool-like effect, the monofilament fineness of the matt fiber product with a wool-like effect is 1dpf~20dpf , the total fineness is 30dtex~150dtex, and the f number is 12~108. Wherein the spinning winding speed is 5200 m / min, and the shape of the spinneret hole of the spinneret produced by it is as follows: figure 1 As shown, it includes a horizontally arranged slotted hole 1 and six vertically arranged vertical holes 2 arranged horizontally along the slotted hole 1 and connected with the slotted hole 1. The two ends of the vertical hole 2 are respectively A round hole 3 is pro...

Embodiment 3

[0018] A method for preparing a matte fiber with wool-like effect, using polyester chips with an intrinsic viscosity of 0.680 and a titanium dioxide content of 2.8% as a raw material, and spinning with a hot roller high-speed draft spinning machine, and selecting appropriate Drying, drafting, setting temperature and drafting ratio, in order to achieve normal spinning to obtain a matt fiber product with a wool-like effect, the monofilament fineness of the matt fiber product with a wool-like effect is 1dpf~20dpf , the total fineness is 30dtex~150dtex, and the f number is 12~108. Wherein the spinning winding speed is 4500 m / min, and the shape of the spinneret hole of the spinneret produced by it is as follows: figure 1 As shown, it includes a horizontally arranged slotted hole 1 and six vertically arranged vertical holes 2 arranged horizontally along the slotted hole 1 and connected with the slotted hole 1. The two ends of the vertical hole 2 are respectively A circular hole 3 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com