Method for preparing dull fiber with wool-like effect

A matte fiber and wool-like technology, applied in stretch spinning, spinneret assembly, single-component polyester rayon, etc., can solve the problem of lack of hand feeling in the finished product, and achieve excellent fluffy performance and soft hand feeling , the effect of excellent nap performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

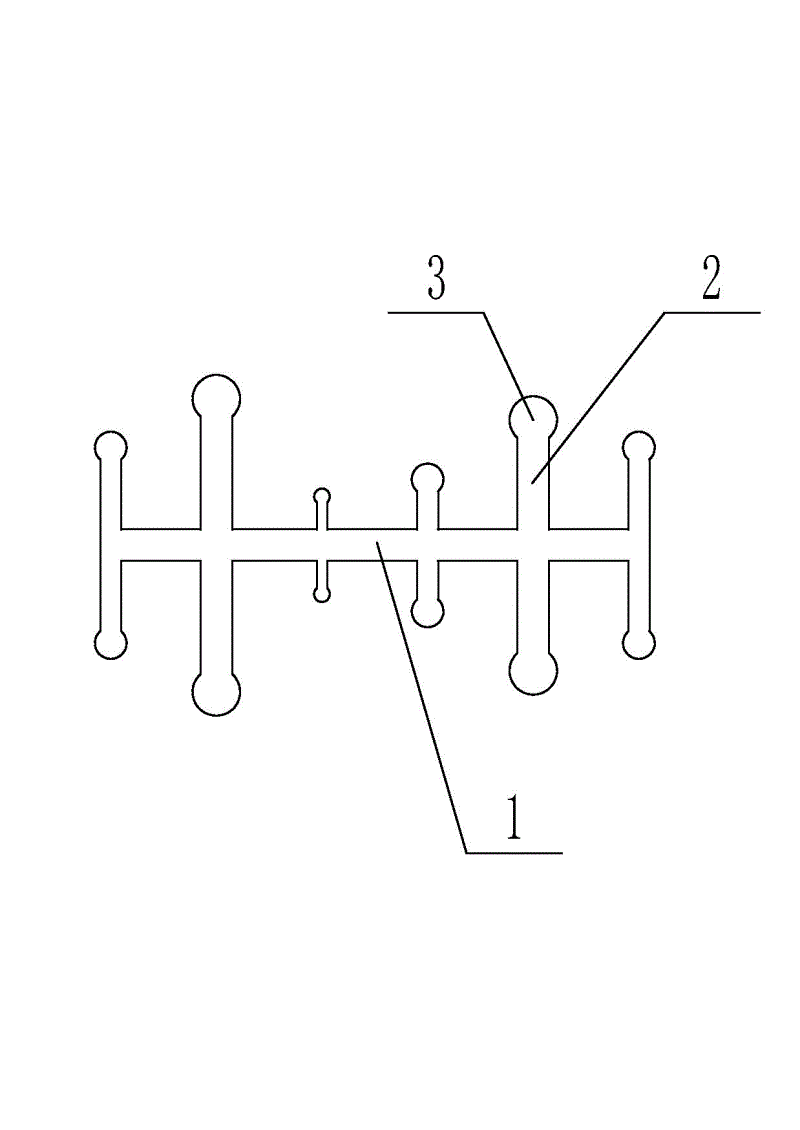

[0014] A method for preparing a matte fiber with wool-like effect, using polyester chips with an intrinsic viscosity of 0.680 and a titanium dioxide content of 2.5% as a raw material, and spinning with a hot-roller high-speed drafting spinning machine. Drying, drafting, setting temperature and drafting ratio, in order to achieve normal spinning to obtain a matt fiber product with a wool-like effect, the monofilament fineness of the matt fiber product with a wool-like effect is 1dpf~20dpf , the total fineness is 30dtex~150dtex, and the f number is 12~108. Wherein the spinning winding speed is 3800 m / min, and the shape of the spinneret hole of the spinneret produced by it is as follows: figure 1 As shown, it includes a horizontally arranged slotted hole 1 and six vertically arranged vertical holes 2 arranged horizontally along the slotted hole 1 and connected with the slotted hole 1. The two ends of the vertical hole 2 are respectively A round hole 3 is provided, and the diamet...

Embodiment 2

[0016] A method for preparing a matte fiber with wool-like effect, using polyester chips with an intrinsic viscosity of 0.680 and a titanium dioxide content of 3% as a raw material, and spinning with a hot roller high-speed draft spinning machine, and selecting appropriate Drying, drafting, setting temperature and drafting ratio, in order to achieve normal spinning to obtain a matt fiber product with a wool-like effect, the monofilament fineness of the matt fiber product with a wool-like effect is 1dpf~20dpf , the total fineness is 30dtex~150dtex, and the f number is 12~108. Wherein the spinning winding speed is 5200 m / min, and the shape of the spinneret hole of the spinneret produced by it is as follows: figure 1 As shown, it includes a horizontally arranged slotted hole 1 and six vertically arranged vertical holes 2 arranged horizontally along the slotted hole 1 and connected with the slotted hole 1. The two ends of the vertical hole 2 are respectively A round hole 3 is pro...

Embodiment 3

[0018] A method for preparing a matte fiber with wool-like effect, using polyester chips with an intrinsic viscosity of 0.680 and a titanium dioxide content of 2.8% as a raw material, and spinning with a hot roller high-speed drafting spinning machine, and selecting appropriate Drying, drafting, setting temperature and drafting ratio, in order to achieve normal spinning to obtain a matt fiber product with a wool-like effect, the monofilament fineness of the matt fiber product with a wool-like effect is 1dpf~20dpf , the total fineness is 30dtex~150dtex, and the f number is 12~108. Wherein the spinning winding speed is 4500 m / min, and the shape of the spinneret hole of the spinneret produced by it is as follows: figure 1 As shown, it includes a horizontally arranged slotted hole 1 and six vertically arranged vertical holes 2 arranged horizontally along the slotted hole 1 and connected with the slotted hole 1. The two ends of the vertical hole 2 are respectively A circular hole ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com