Production line and preparation method of bristles for brushes

A production line and filament brushing technology, which is applied in the complete sets of equipment for producing artificial threads, drawing spinning, melting of filament raw materials, etc., to achieve the effects of large filtration area, lower production costs, and energy savings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

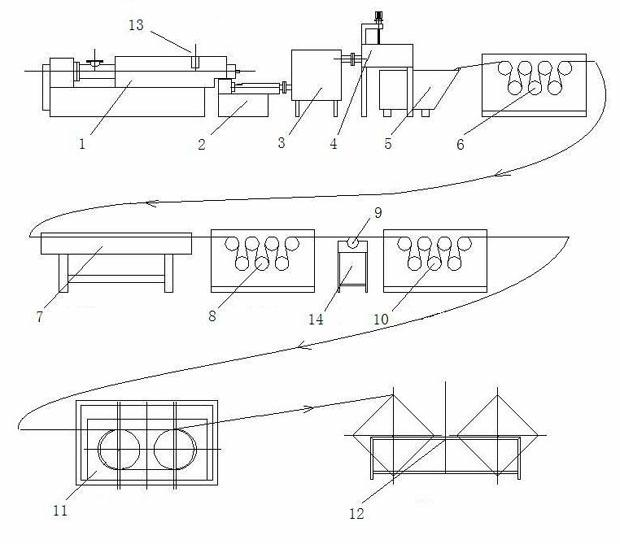

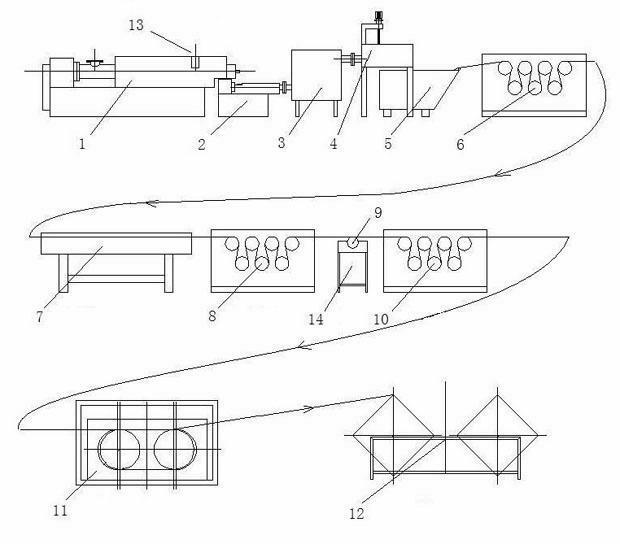

[0030] Such as figure 1 As shown, the discharge port of the upper screw extruder 1 in the wire brushing production line is located above the feed port of the lower screw extruder 2, and the discharge port of the lower screw extruder 2 communicates with the feed port of the filter device 3, The discharge port of the filter device 3 is connected with the feed port of the metering pump. In this embodiment, the discharge port of the metering pump is connected with two die heads through a three-way pipe (for illustration purpose).

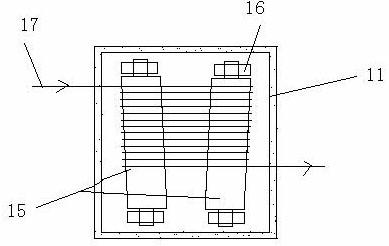

[0031] still as figure 1 As shown, a cold water tank 5 is provided below the die head 4 of the metering pump, and a first drafting device 6, a hot water tank 7, a second drafting device 8, an oil tanker 9, and a third drafting device are arranged in sequence behind the cold water tank 5. Drafting device 10, heat setting box 11, winding device 12.

[0032] still as figure 1 As shown, the barrel of the upper screw extruder 1 is divided into three chamb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com