Dry-method spinning technique for preparing super high molecular weight polyethylene fibre

A technology of ultra-high molecular weight and polyethylene fiber, which is applied in the direction of single-component polyolefin artificial filament, dry spinning method, fiber treatment, etc., and can solve the problems of high production cost and high sealing efficiency requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

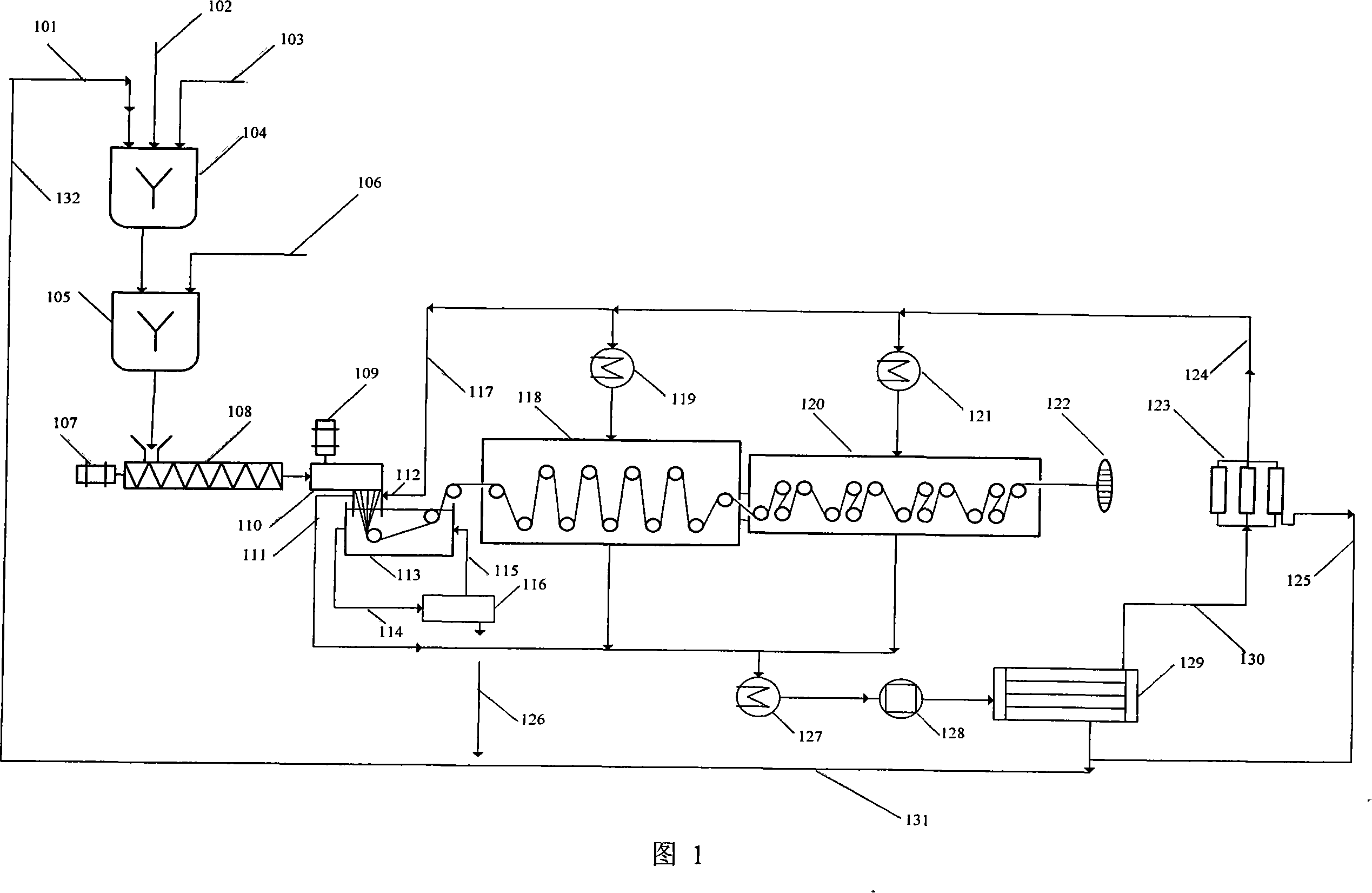

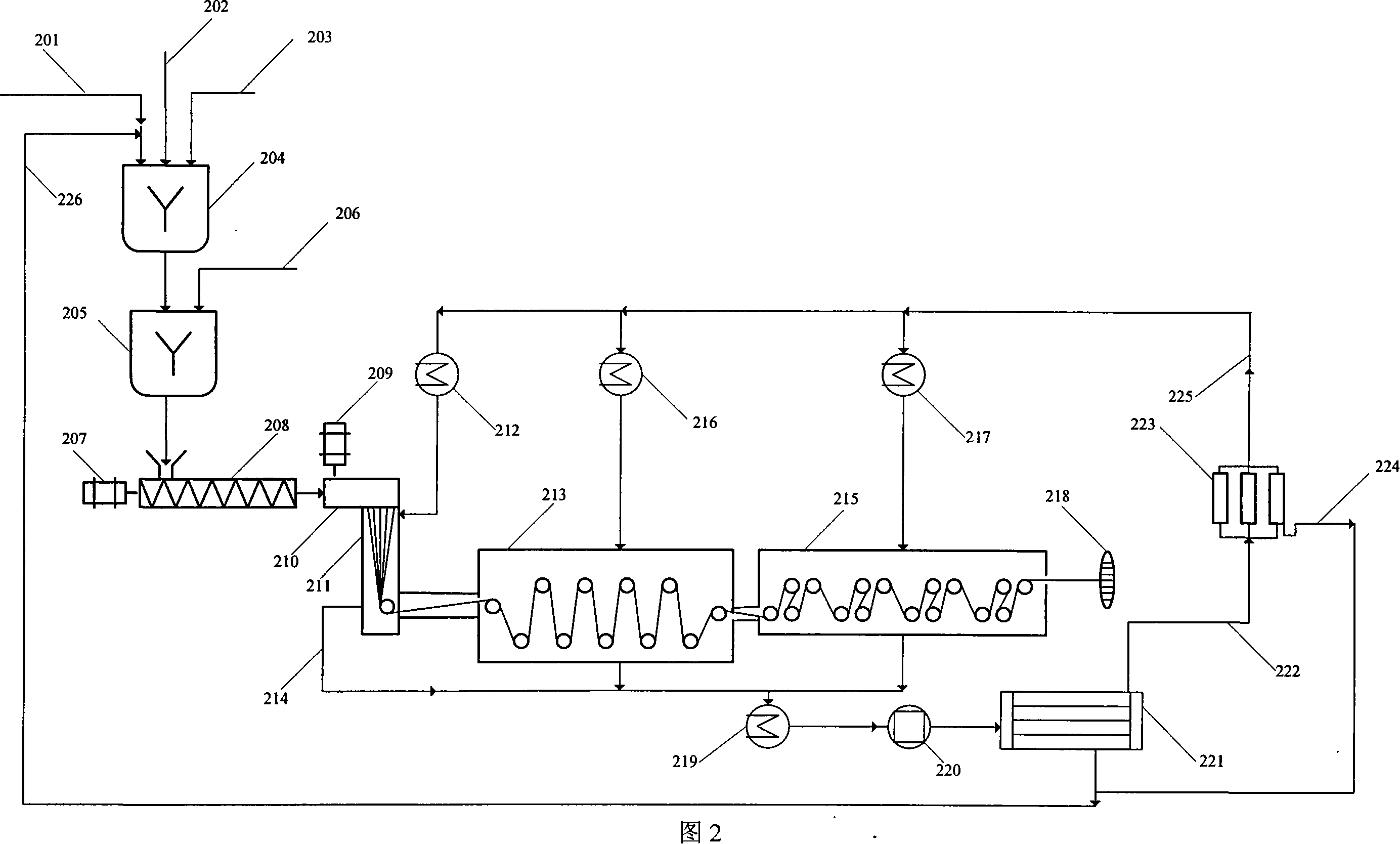

Embodiment 1

[0045] Add polyethylene powder with a relative molecular weight of 5 million, antioxidants, flow promoters and other additives, and m-xylene into the stirring tank A. The weight of the polyethylene material accounts for 4% of the total feed, and the Irganox B225 antioxidant accounts for 0.8% of the total feed. The temperature of the stirred tank was kept at 120° C., and the stirring time of the stirred tank was 10 hours. Then the material enters the stirred tank B, and the polyethylene powder is continuously added to make it account for 7% of the total material amount. The temperature of the stirred tank is maintained at 120° C. and stirred for 5 hours. Then the material in the stirring tank B enters the twin-screw extruder, and the temperature of the twin-screw extruder is 120°C. It is extruded through the metering pump, spinning box, and spinneret, and enters the spinning tunnel. The length of the spinning tunnel was 10 cm, 8 cm of which were immersed below the surface of ...

Embodiment 2

[0052] The polyethylene powder with a relative molecular weight of 5 million and antioxidant IrganoxB215, CABOT company's CAB-O-SIL M-5P flow promoter and other additives, and 34% o-xylene, 33% m-xylene, 33% p-xylene The composed solvent is added to the stirring tank A. The weight of polyethylene accounts for 1% of the total feed, the antioxidant accounts for 0.5% of the total feed, and the flow promoter accounts for 0.1% of the total feed. The temperature of the stirred tank was kept at 90° C., and the stirring time of the stirred tank was 10 hours. Then the material enters the stirring tank B, and the polyethylene powder is continuously added, so that the polyethylene material accounts for 4.5% of the total material amount, and the temperature of the stirring tank is maintained at 90° C., and stirred for 8 hours. Then the material in the stirred tank B enters the twin-screw extruder, and the temperature of the twin-screw extruder is 125°C. It is extruded through the meteri...

Embodiment 3

[0059] Add polyethylene powder with a relative molecular weight of 5 million, additives such as Ultranox 877A antioxidant, and o-xylene into the stirring tank A. The weight of the polyethylene material accounts for 1.5% of the total feed, and the antioxidant accounts for 0.5% of the total feed. The temperature of the stirred tank was maintained at 130° C., and the stirring time of the stirred tank was 10 hours. Then the material enters the stirred tank B, and the polyethylene powder is continuously added to make it account for 4% of the total material amount. The temperature of the stirred tank is maintained at 120° C. and stirred for 5 hours. Then the material in the stirred tank B enters the twin-screw extruder, and the temperature of the twin-screw extruder is 125°C. It is extruded through the metering pump, spinning box, and spinneret, and enters the spinning tunnel. The length of the spinning tunnel was 30 cm. Nitrogen gas is passed into the spinning shaft, and the tem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Strength | aaaaa | aaaaa |

| Modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com