Crack-resistant early strength concrete and preparation method thereof

A technology of concrete and cellulose, applied in the field of building materials, can solve the problems of restricting the popularization and use of early-strength concrete, adverse effects on the later strength of concrete, and large shrinkage of concrete, so as to promote uniform dispersion and compatibility, and improve the later compression resistance. Strength and crack resistance, the effect of high early strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

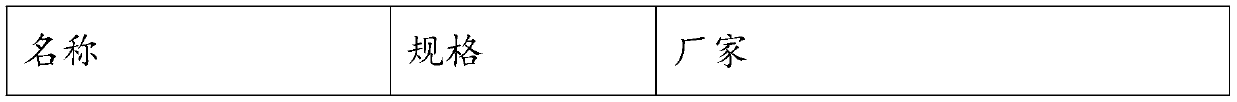

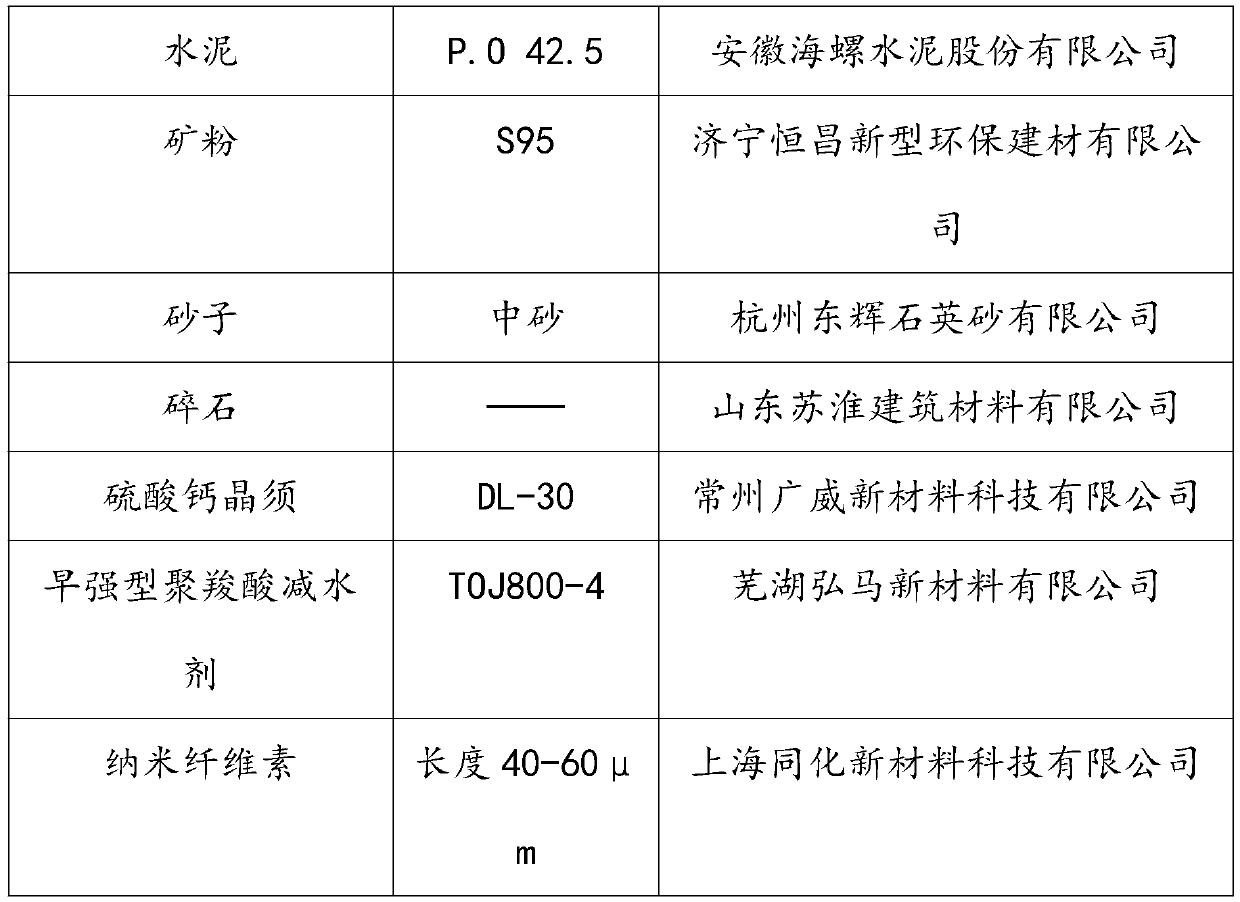

[0031] A crack-resistant early-strength concrete made of the following raw materials in parts by weight:

[0032] 460 parts of cement, 60 parts of mineral powder, 512 parts of sand, 1252 parts of gravel, 5 parts of cellulose-silica composite nanomaterials, 2 parts of calcium sulfate whiskers with an average length of 50 μm, early-strength polycarboxylate water-reducing 4.1 parts of agent, 175 parts of water.

[0033] Among them, the apparent density of sand is 2580kg / m 3 , the apparent density of gravel is 2600kg / m 3 .

[0034] The cellulose-silicon dioxide composite nanomaterial is made of the following raw materials in parts by weight: 4 parts of nanocellulose, 30 parts of tetraethyl orthosilicate, 30 parts of absolute ethanol, 80 parts of water, and an appropriate amount of ammonia water. The preparation method is as follows:

[0035] (1) adding nanocellulose into water, ultrasonically dispersing at 500W power for 10min, and then homogenizing under high pressure at 50MPa...

Embodiment 2

[0042] A crack-resistant early-strength concrete made of the following raw materials in parts by weight:

[0043] 469 parts of cement, 62 parts of mineral powder, 518 parts of sand, 1264 parts of gravel, 7 parts of cellulose-silica composite nanomaterials, 3 parts of calcium sulfate whiskers with an average length of 100 μm, early-strength polycarboxylate water-reducing 4.6 parts of agent, 178 parts of water.

[0044] Among them, the apparent density of sand is 2585kg / m 3 , the apparent density of gravel is 2680kg / m 3 .

[0045] The cellulose-silicon dioxide composite nanomaterial is made of the following raw materials in parts by weight: 4.5 parts of nanocellulose, 35 parts of tetraethyl orthosilicate, 35 parts of absolute ethanol, 90 parts of water, and an appropriate amount of ammonia water. The preparation method is as follows:

[0046] (1) Add nanocellulose to water and ultrasonically disperse for 6 minutes at a power of 800W, and then homogenize under high pressure fo...

Embodiment 3

[0053] A crack-resistant early-strength concrete made of the following raw materials in parts by weight:

[0054] 475 parts of cement, 65 parts of mineral powder, 527 parts of sand, 1288 parts of gravel, 10 parts of cellulose-silica composite nanomaterials, 5 parts of calcium sulfate whiskers with an average length of 200 μm, early-strength polycarboxylate water-reducing 4.9 parts of agent, 180 parts of water.

[0055] Among them, the apparent density of sand is 2590kg / m 3 , the apparent density of gravel is 2700kg / m 3 .

[0056] The cellulose-silicon dioxide composite nanomaterial is made of the following raw materials in parts by weight: 5 parts of nanocellulose, 40 parts of ethyl orthosilicate, 40 parts of absolute ethanol, 100 parts of water, and an appropriate amount of ammonia water. The preparation method is as follows:

[0057] (1) Add nanocellulose to water and ultrasonically disperse for 5 minutes under a power of 1000W, and then homogenize under high pressure for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com