Medium-density high-aluminum silicon carbide castable and preparation method thereof

A high-alumina silicon carbide and castable technology, which is applied in the field of refractory materials, can solve the problems of easy cracking of materials and local overheating, and achieve the effects of reducing porosity, reducing dosage, and low thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

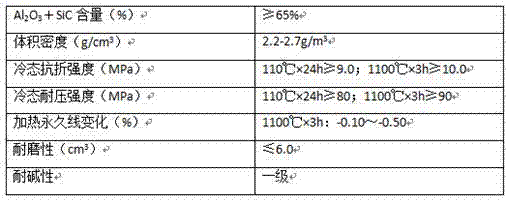

Image

Examples

Embodiment 1

[0022] A medium-density high-alumina silicon carbide castable, the components of which include by weight: 10 parts of lightweight mullite aggregates with a particle size of 3-8mm, and 12 parts of lightweight alumina aggregates with a particle size of 3-5mm , 13 parts of iron hook waste, 13 parts of silicon molybdenum waste aggregate, 5 parts of silicon carbide powder with a particle size of less than 0.088 mm, 5 parts of silicon micropowder with a particle size of less than 1 μm, and Al with a particle size of less than 1.2 μm 2 o 3 3 parts of fine powder, 4 parts of calcium aluminate cement, 0.02 part of sodium tripolyphosphate, 0.01 part of melamine formaldehyde tree, and 1.5 parts of alloy steel fiber with a diameter of less than 0.3 mm and a length of 20-25 mm.

[0023] Prepare the castable according to the following steps: mix the raw materials of the castable above, add 4% water and stir evenly, pour the stirred material into the mold, vibrate and form, bake after curin...

Embodiment 2

[0025] A medium-density high-alumina silicon carbide castable, the components of which include by weight: 15 parts of lightweight mullite aggregates with a particle size of 3-8mm, and 14 parts of lightweight alumina aggregates with a particle size of 3-5mm , 13 parts of iron hook waste, 14 parts of silicon molybdenum waste aggregate, 6 parts of silicon carbide powder with a particle size of less than 0.088 mm, 6 parts of silicon micropowder with a particle size of less than 1 μm, and Al with a particle size of less than 1.2 μm 2 o 3 3 parts of fine powder, 5 parts of calcium aluminate cement, 0.18 parts of sodium tripolyphosphate, 0.09 parts of melamine formaldehyde tree, and 1.8 parts of alloy steel fibers with a diameter of less than 0.3 mm and a length of 20-25 mm.

[0026] Prepare the castable according to the following steps: mix the raw materials of the castable above, add 4% water and stir evenly, pour the stirred material into the mold, vibrate and form, bake after cu...

Embodiment 3

[0028] A medium-density high-alumina silicon carbide castable, the components of which include by weight: 18 parts of lightweight mullite aggregates with a particle size of 3-8mm, and 14 parts of lightweight alumina aggregates with a particle size of 3-5mm , 13 parts of iron hook waste, 14 parts of silicon molybdenum waste aggregate, 8 parts of silicon carbide powder with a particle size of less than 0.088 mm, 7 parts of silicon micropowder with a particle size of less than 1 μm, and Al with a particle size of less than 1.2 μm 2 o 3 4 parts of micro powder, 5 parts of dolomite cement, 0.2 part of sodium tripolyphosphate, 0.1 part of melamine formaldehyde tree, and 2.0 parts of alloy steel fiber with a diameter of less than 0.3mm and a length of 20-25mm.

[0029] Prepare the castable according to the following steps: mix the raw materials of the castable above, add 5% water and stir evenly, inject the stirred material into the mold, vibrate and form, bake after curing for 64 h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com