A seed crystal for improving early strength of concrete and its application

An early strength and concrete technology, applied in the field of building materials, can solve the problems of insufficient concrete strength, concrete cracking, steel bar corrosion, etc., and achieve the effect of accelerating the setting and hardening speed, reducing processing costs, and improving early strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

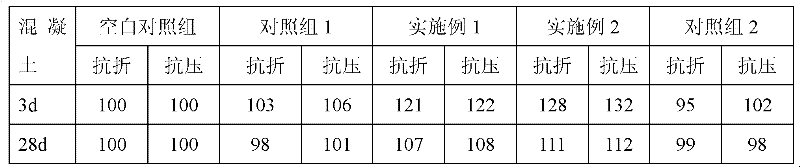

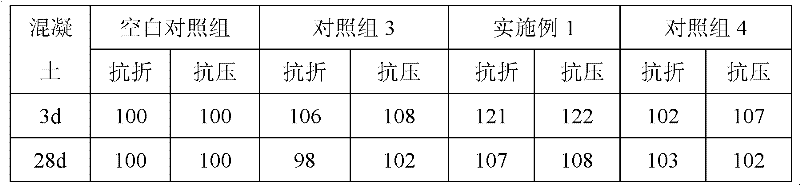

Examples

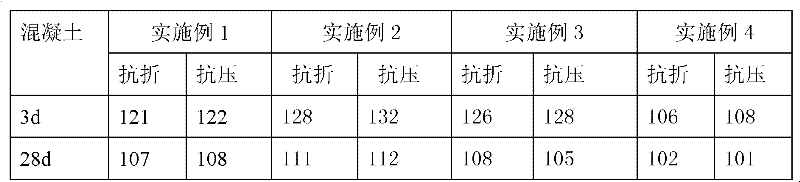

Embodiment 1

[0012] The present invention is a kind of crystal seed used to improve the early strength of concrete, which is made of cement stone through grinding, and the specific surface area of the cement seed crystal after crushing and grinding is 8000m 2 / kg. Wherein, the cement stone for preparing the seed crystal is obtained by adding 3% sodium chloride into ordinary Portland cement and curing for a certain age, and the curing time is 35 days.

[0013] The application of the seed crystal for improving the early strength of concrete in the present invention, the specific surface area obtained by grinding the cement stone is 8000m 2 The seed crystal / kg is added in the concrete, and the dosage of seed crystal is 1% of concrete quality, wherein the mix ratio of concrete is: cement: fine aggregate: water=1: 2.5: 0.5.

Embodiment 2

[0015] The present invention is a kind of crystal seed used to improve the early strength of concrete, which is made of cement stone through grinding, and the specific surface area of the cement seed crystal after crushing and grinding is 10000m 2 / kg. Wherein, the cement stone for preparing the seed crystal is obtained by adding calcium chloride with a mass percentage of 3% in ordinary Portland cement and curing for a certain age, and the curing time is 50 days.

[0016] The application of a seed crystal for improving the early strength of concrete in the present invention, the specific surface area obtained by grinding the cement stone is 10000m 2 The seed crystal / kg is added in the concrete, and the dosage of seed crystal is 3% of concrete quality, and wherein the mixing ratio of concrete is: cement: fine aggregate: water=1: 2.5: 0.5.

Embodiment 3

[0018] The present invention is a kind of crystal seed used to improve the early strength of concrete, which is made of cement stone through grinding, and the specific surface area of the cement seed crystal after crushing and grinding is 15000m 2 / kg. Wherein, the cement stone for preparing the seed crystal is obtained by adding sodium sulfate with a mass percentage of 3% to ordinary portland cement and curing for a certain age, and the curing time is 35 days.

[0019] The application of a seed crystal for improving the early strength of concrete in the present invention, the specific surface area obtained by grinding the cement stone is 15000m2 2 The seed crystal / kg is added in the concrete, and the dosage of seed crystal is 1% of concrete quality, wherein the mix ratio of concrete is: cement: fine aggregate: water=1: 2.5: 0.5.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com