Magnesium oxychloride cement-based material, sand-preventing and sand-fixing plate and preparation methods of magnesium oxychloride cement-based material and sand-preventing and sand-fixing plate

A technology of magnesium oxychloride cement and base materials, which is applied in manufacturing tools, additive processing, infrastructure engineering, etc., and can solve the problems of short life, high cost, and secondary pollution of sand prevention and sand fixation materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

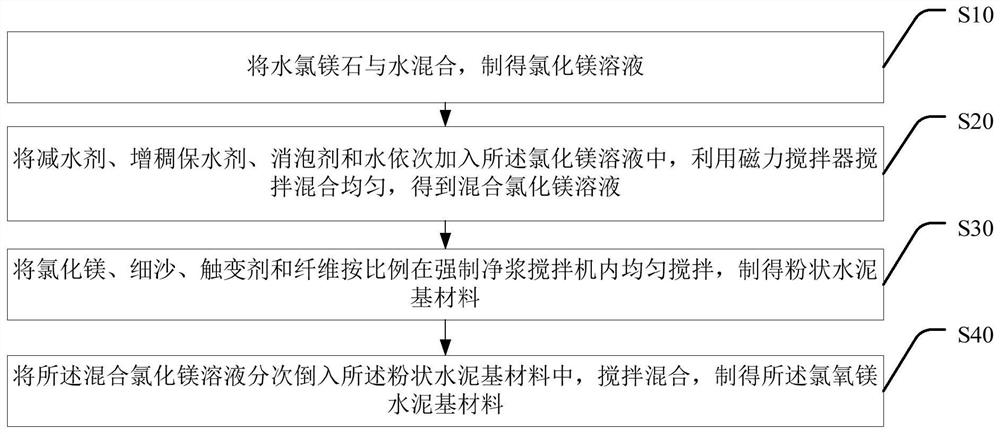

[0036] In some embodiments, such as figure 1 Shown, also provide a kind of preparation method of magnesium oxychloride cement-based material, it comprises steps:

[0037] S10, mixing bischofite with water to obtain a magnesium chloride solution;

[0038] S20, adding water reducing agent, thickening water retaining agent, defoamer and water into the magnesium chloride solution in sequence, stirring and mixing evenly with a magnetic stirrer to obtain a mixed magnesium chloride solution;

[0039] S30, uniformly stirring the magnesium chloride, fine sand, thixotropic agent and fiber in a forced slurry mixer in proportion to prepare a powdery cement-based material;

[0040] S40. Pour the mixed magnesium chloride solution into the powdered cement-based material in stages, and stir and mix to prepare the magnesium oxychloride cement-based material.

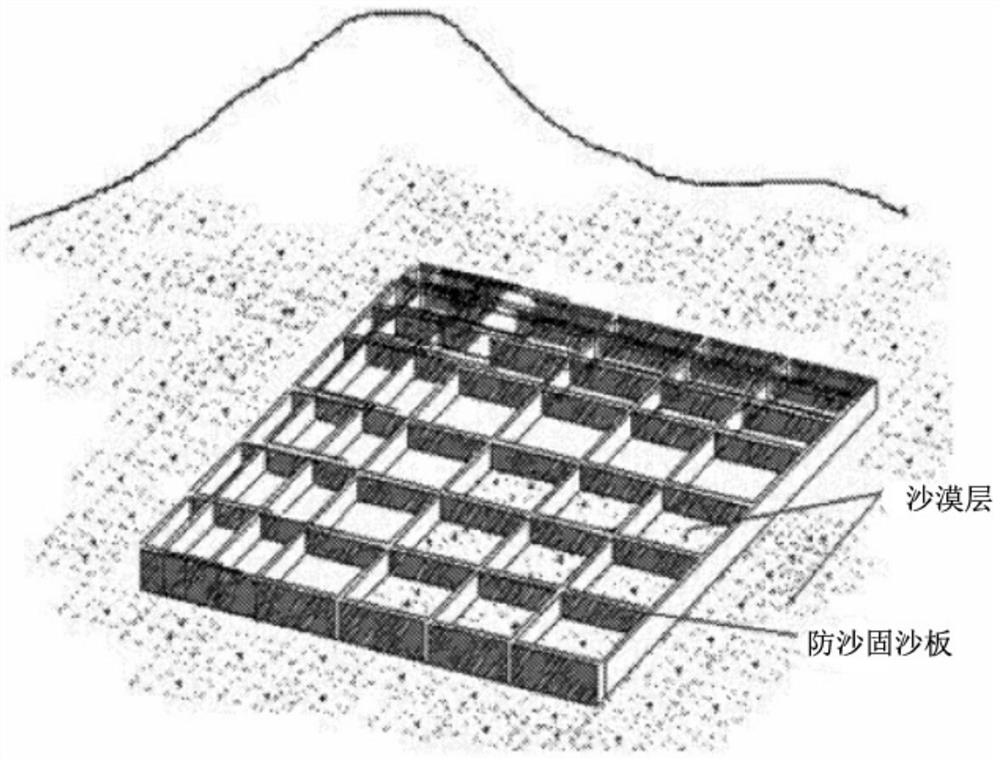

[0041] Based on the above-mentioned magnesium oxychloride cement-based material, the present invention also provides a sand-proof and...

Embodiment 1

[0047] Prepare the following materials in parts by weight: 8 parts in magnesium chloride, 80 parts in fine sand, bischofite (MgCl 2 ·6H 2 O) 8 parts, 0.5 parts of water-reducing agent, 0.2 parts of thickening and water-retaining agent, 1.0 part of thixotropic agent, 0.3 parts of defoamer, 1.0 part of fiber, and 25 parts of water.

[0048] bischofite (MgCl 2 ·6H 2 O) be made into magnesium chloride solution with water;

[0049] Add water reducer (polycarboxylate high-efficiency water reducer), thickening water retaining agent (hydroxypropyl methyl cellulose ether) and defoamer (high carbon alcohol) into the prepared magnesium chloride solution in sequence, and stir with a magnetic stirrer Mixed evenly for 2min to obtain a mixed magnesium chloride solution for standby use;

[0050] Magnesium chloride, fine sand, thixotropic agent (nano-clay) and fiber are uniformly stirred in a forced slurry mixer for 3 minutes in proportion to obtain powdery magnesium oxychloride cement-bas...

Embodiment 2

[0056] Prepare the following materials in parts by weight: 38 parts of magnesium chloride, 38 parts of fine sand, bischofite (MgCl 2 ·6H 2 O) 19 parts, water reducing agent 1.1 parts, thickening and water retention agent 0.2 parts, thixotropic agent 1.5 parts, defoamer 0.2 parts, fiber 2.0 parts and water 35 parts.

[0057] bischofite (MgCl 2 ·6H 2 O) be made into magnesium chloride solution with water;

[0058] Add water reducer (polycarboxylate high-efficiency water reducer), thickening water retaining agent (hydroxypropyl methyl cellulose ether) and defoamer (high carbon alcohol) into the prepared magnesium chloride solution in sequence, and stir with a magnetic stirrer Mixed evenly for 2min to obtain a mixed magnesium chloride solution for standby use;

[0059] Magnesium chloride, fine sand, thixotropic agent (nano-clay) and fiber are uniformly stirred in a forced slurry mixer for 3 minutes in proportion to obtain powdery magnesium oxychloride cement-based material;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com