A kind of magnesium oxysulfide cement

A technology of magnesium oxysulfide cement and magnesium sulfate, which is applied in the field of building materials to achieve the effects of no shrinkage of strength, high early strength, and increased coagulation and hardening speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

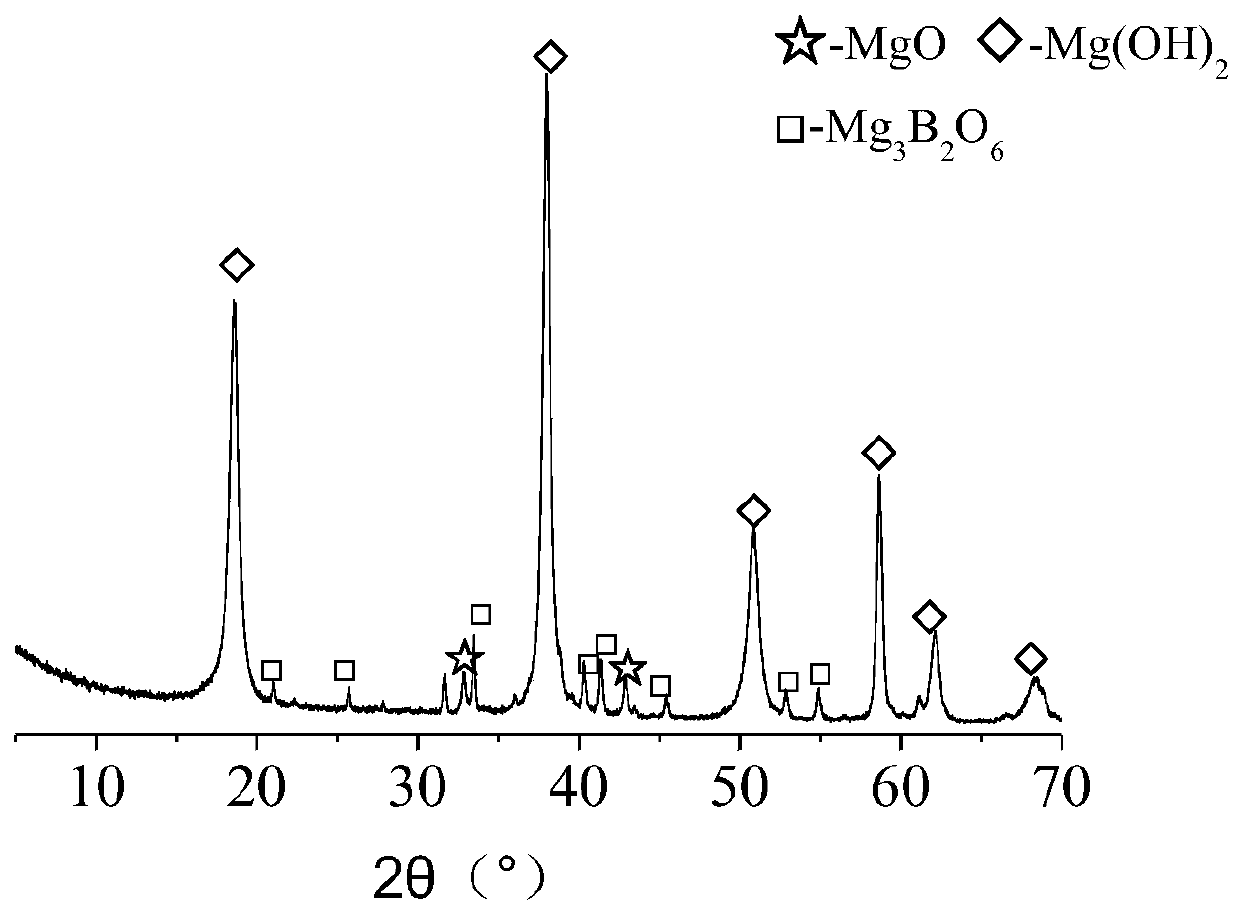

[0027] The lithium and magnesium slag extracted from the salt lake comes from CITIC Guoan Group Corporation, the chemical composition of which is shown in Table 1, and the XRD test is as follows: figure 1 as shown, figure 1 The analysis shows that the slag of lithium and magnesium extracted from salt lake is mainly magnesium hydroxide and magnesium borate, and there is also a small amount of magnesium oxide.

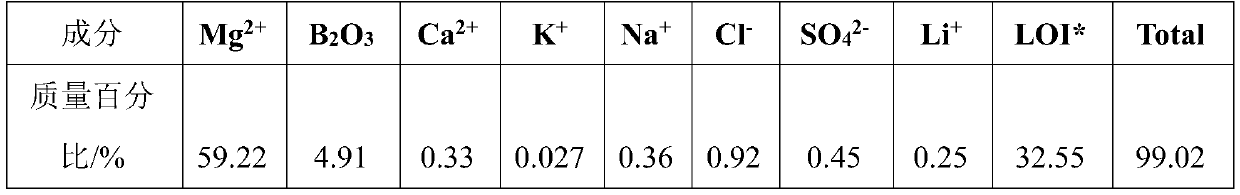

[0028] Table 1: Chemical composition of lithium and magnesium slag extracted from salt lake

[0029]

[0030] LOI*: is the weight loss of lithium and magnesium slag extracted from salt lake at 1000℃.

[0031] Preparation of magnesium oxysulfide cement:

[0032] Activated magnesium oxide powder was obtained by calcining the lithium-magnesium slag extracted from the salt lake at 600° C. for 3 hours.

[0033] Mix 100 parts of light-burned magnesite powder, 1 part of phosphorus pentoxide, and 90 parts of magnesium sulfate with a mass percentage of 25%, harden for 3 day...

Embodiment 2

[0036] The extraction of lithium and magnesium slag from the salt lake is the same as in Example 1.

[0037] Preparation of magnesium oxysulfide cement:

[0038] Activated magnesium oxide powder was obtained by calcining the lithium-magnesium slag extracted from the salt lake at 400°C for 6 hours.

[0039] Mix 50 parts of light-burned magnesite powder, 1 part of phosphorus pentoxide and 140 parts of magnesium sulfate with a mass percentage of 25%, harden for 2 days, crush and grind, and dry at 40°C for 24 hours to obtain a basic magnesium sulfate precursor .

[0040] 50 parts of active magnesium oxide powder, 50 parts of magnesium sulfate heptahydrate, 1 part of phosphorus pentoxide, and 10 parts of basic magnesium sulfate precursor were mixed and ground through a 100-mesh sieve to obtain rapid hardening magnesium oxysulfide cement.

Embodiment 3

[0042] The extraction of lithium and magnesium slag from the salt lake is the same as in Example 1.

[0043] Preparation of magnesium oxysulfide cement:

[0044] Activated magnesium oxide powder was obtained by calcining the lithium-magnesium slag extracted from the salt lake at 900° C. for 1 hour.

[0045] Mix 100 parts of light-burned magnesite powder, 0.5 parts of phosphorus pentoxide and 70 parts of magnesium sulfate with a mass percentage of 25%, harden for 2 days, crush and grind, and dry at 40°C for 24 hours to obtain a basic magnesium sulfate precursor .

[0046] 100 parts of activated magnesium oxide powder, 50 parts of magnesium sulfate heptahydrate, 2 parts of sodium formate, and 5 parts of basic magnesium sulfate precursor were mixed and ground through a 100-mesh sieve to obtain rapid hardening magnesium oxysulfate cement.

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com