Basic magnesium sulfate cement-based lightweight porous material and preparation method thereof

A porous material, magnesium sulfate technology, applied in the field of building materials, can solve the problems of low strength of light materials, unstable hydration products, poor durability, etc., and achieve the effect of high durability, fast speed and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

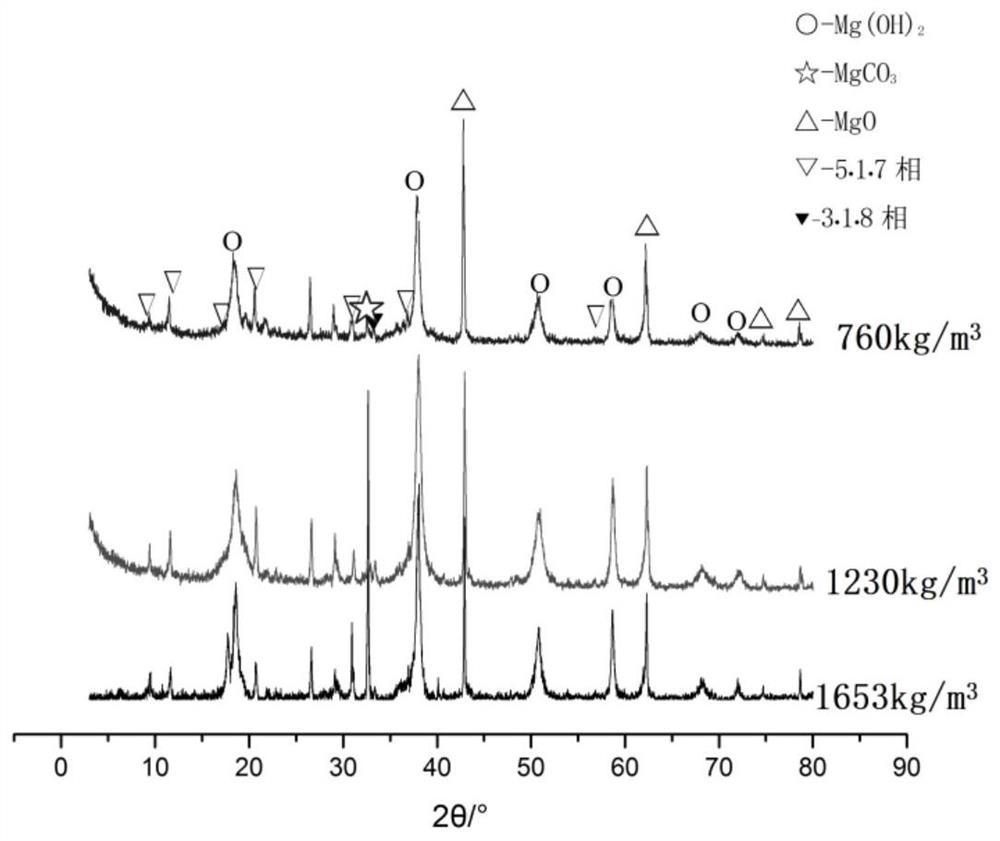

[0023] A basic magnesium sulfate cement-based lightweight porous material, the cement-based lightweight porous material is mainly obtained by mixing magnesium oxysulfate cement slurry with a modifier, adding bentonite as a pore-forming agent, mixing and stirring, and coagulating and hardening. of porous materials.

[0024] The preparation steps of the basic magnesium sulfate cement-based lightweight porous material in the present embodiment are as follows:

[0025] S1. Lightly burn MgO or lightly burn dolomite with MgSO 4 , and water are mixed and stirred evenly to obtain magnesium oxysulfide cement slurry;

[0026] S2, adding a modifier into the magnesium oxysulfate cement slurry to modify the magnesium oxysulfate cement slurry to obtain a basic magnesium sulfate cement slurry;

[0027] S3, adding a pore-forming agent into the basic magnesium sulfate cement slurry, stirring uniformly, then forming, and demoulding and curing to obtain a basic magnesium sulfate cement-based l...

Embodiment 2

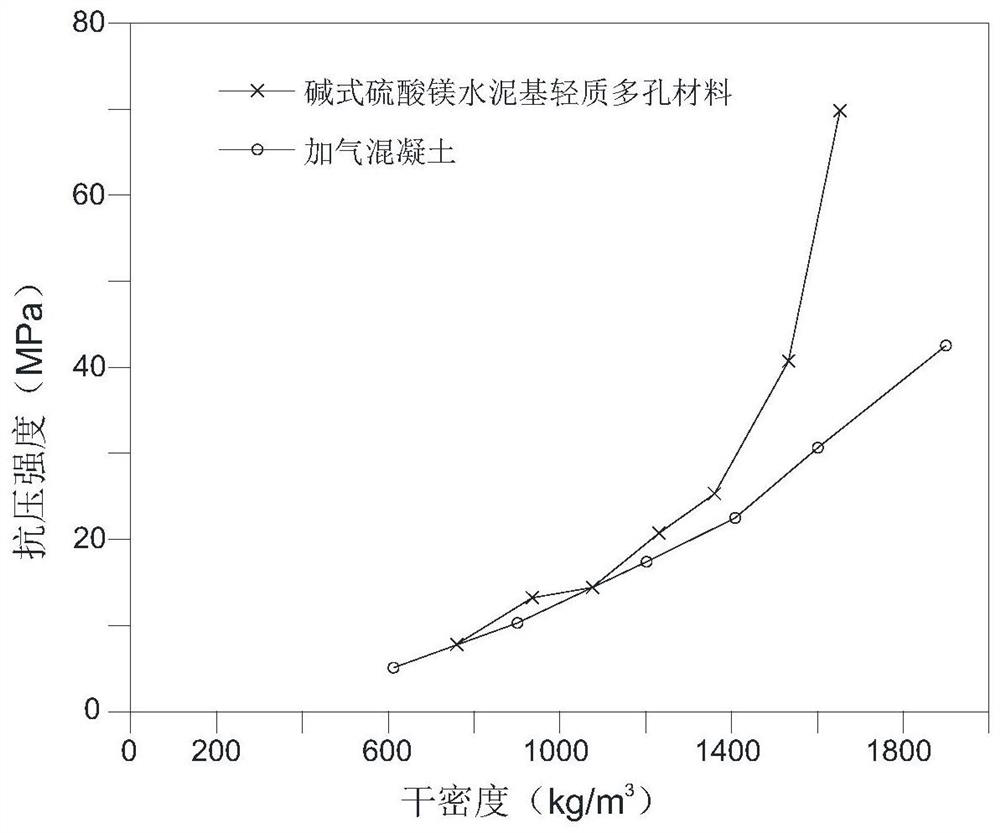

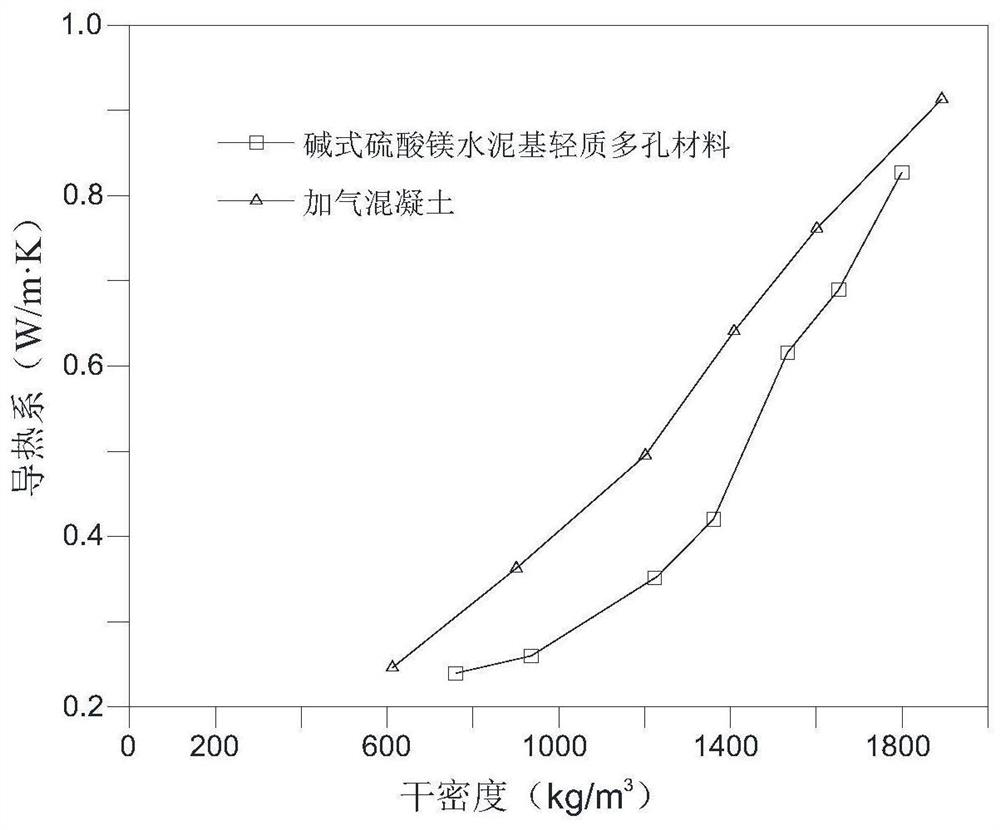

[0031] In this example, the benchmark mixing ratio of magnesium oxysulfate cement is: molar ratio MgO:MgSO 4 :H 2 O=20:1:18, 0.08% citric acid and 0.08% EDTA were selected as admixtures for compound blending. On the basis of the reference mixing ratio, bentonite is used as a pore-forming agent, and is prepared into a pore-forming agent slurry according to the ratio of pore-forming agent: water (mass ratio) of 1:5, and after standing for 24 hours, according to the pore-forming agent slurry The basic magnesium sulfate cement-based lightweight porous materials with different dry densities are prepared in different proportions of the basic magnesium sulfate cement slurry volume. ×160mm standard mold forming. Curing after demoulding, the curing conditions are temperature 15-25 DEG C, humidity 50-70%, to obtain basic magnesium sulfate cement-based light porous material.

[0032] In this example, the pore-forming agent slurry accounts for 0-60% of the basic magnesium sulfate cemen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com