A kind of magnesium oxysulfide cement and preparation method thereof

A technology of magnesium oxysulfide cement and magnesium sulfate, which is applied in the field of building materials to achieve the effects of improving production efficiency, increasing the speed of setting and hardening, and setting fast

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

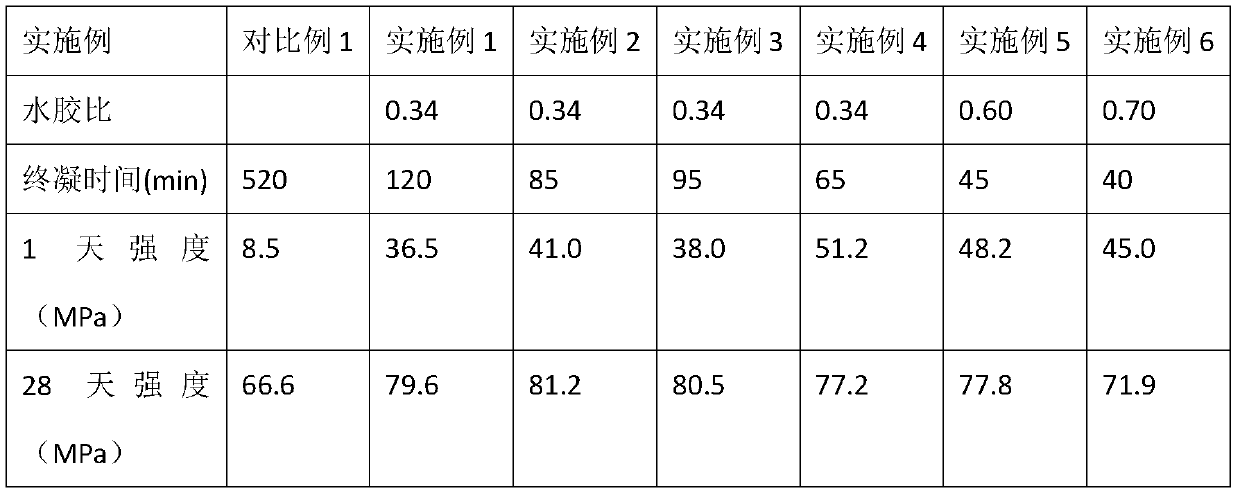

Examples

Embodiment 1

[0023] The magnesium oxide content of light magnesia is 95.5%.

[0024] Mix 100 parts by mass of light magnesium oxide, 1 part by mass of formic acid and 240 parts by mass of magnesium sulfate with a mass percentage of 25%, harden for 7 days, grind and dry at 80°C for 12 hours to obtain basic magnesium sulfate Precursor.

[0025] 100 mass parts of light-burned magnesium oxide powder, 50 mass parts of magnesium sulfate heptahydrate, 1 mass part of phosphorus pentoxide, and 1 mass part of the basic magnesium sulfate precursor are mixed and ground through a 100-mesh sieve to obtain rapid hardening sulfur Magnesia cement.

Embodiment 2

[0027] The magnesium oxide content of light magnesia is 95.5%.

[0028] Mix 100 parts by mass of light magnesium oxide, 1 part by mass of formic acid and 240 parts by mass of magnesium sulfate with a mass percentage of 25%, harden for 1 day, grind and dry at 60°C for 24 hours to obtain basic sulfur oxide Magnesium cement precursor.

[0029] 100 parts by mass of light-burned magnesium oxide powder, 100 parts by mass of magnesium sulfate heptahydrate, 2 parts by mass of sodium formate, and 0.5 parts by mass of basic magnesium sulfate precursor were mixed and ground through a 100-mesh sieve to obtain rapid hardening magnesium oxysulfide cement.

Embodiment 3

[0031] The magnesium oxide content of light magnesia is 95.5%.

[0032] Mix 50 parts by mass of light magnesium oxide, 0.1 part by mass of formic acid and 240 parts by mass of magnesium sulfate with a mass percentage of 25%, harden for 3 days, grind and dry at 70°C for 16 hours to obtain basic sulfur oxide Magnesium cement precursor.

[0033] 50 parts by mass of light-burned magnesium oxide powder, 50 parts by mass of magnesium sulfate heptahydrate, 1 part by mass of sodium formate, and 1 part by mass of basic magnesium sulfate precursor were mixed and ground through a 100-mesh sieve to obtain rapid hardening magnesium oxysulfide cement.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com