Self-leveling type II polymer cement waterproof mortar

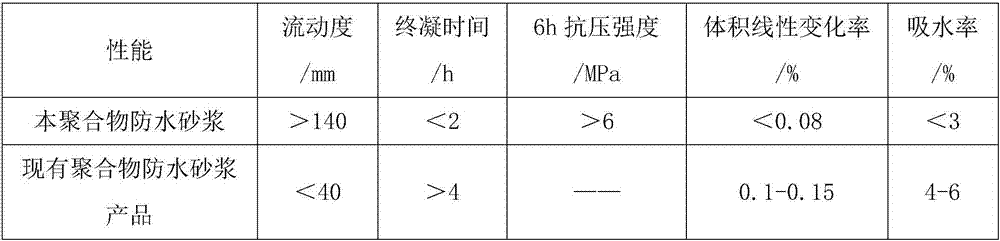

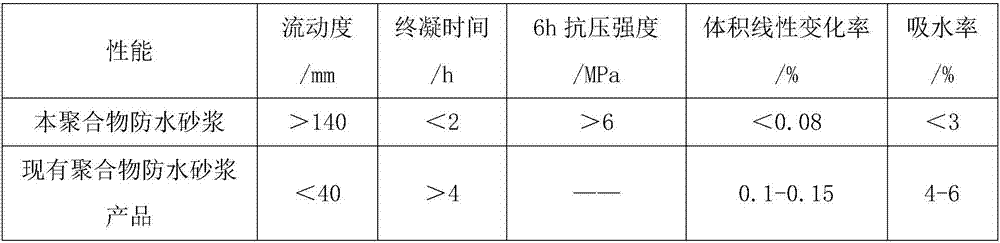

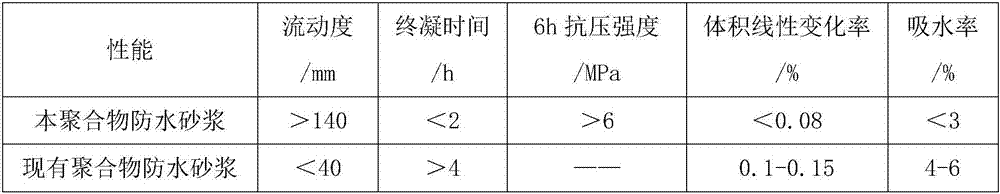

A waterproof mortar and polymer technology, applied in the field of waterproof mortar, can solve the problems of poor impermeability and durability, and achieve the effects of improving the speed of setting and hardening, high construction efficiency, and shortening the final setting time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A self-leveling type II polymer cement waterproof mortar, the formula is as follows: 85 parts of ordinary portland cement, 15 parts of composite hardening accelerator, 12 parts of fly ash, 0.8 parts of polycarboxylate superplasticizer powder, organic silicon hydrophobic 0.6 parts of agent, 0.3 parts of hydroxypropyl methylcellulose ether, 2 parts of VAE redispersible latex powder, 0.3 parts of defoamer, 90 parts of fine quartz sand, and 45 parts of water.

[0040] Among them, the composition of the composite hardening accelerator: 5 parts of quicklime, 4 parts of sodium sulfate, and 6 parts of aluminate cement.

[0041] Preparation method: Mix quicklime, sodium sulfate, and aluminate cement evenly to obtain a composite hardening accelerator;

[0042] Portland cement, composite hardening accelerator, fly ash, polycarboxylate superplasticizer powder, silicone water repellent, hydroxypropyl methylcellulose ether, VAE redispersible latex powder, defoamer, Mix fine quartz s...

Embodiment 2

[0047] A self-leveling type II polymer cement waterproof mortar, the formula is as follows: 80 parts of ordinary Portland cement, 15 parts of composite hardening accelerator, 10 parts of fly ash, 0.5 parts of polycarboxylate superplasticizer powder, organic silicon hydrophobic 0.4 parts of agent, 0.2 parts of hydroxypropyl methylcellulose ether, 1 part of VAE redispersible latex powder, 0.2 parts of defoamer, 80 parts of fine quartz sand, and 40 parts of water.

[0048] Among them, the composition of the composite hardening accelerator: 3 parts of quicklime, 2 parts of sodium sulfate, and 5 parts of aluminate cement.

[0049] Preparation method: Mix quicklime, sodium sulfate, and aluminate cement evenly to obtain a composite hardening accelerator;

[0050]Portland cement, composite hardening accelerator, fly ash, polycarboxylate superplasticizer powder, silicone water repellent, hydroxypropyl methylcellulose ether, VAE redispersible latex powder, defoamer, Mix fine quartz san...

Embodiment 3

[0053] A self-leveling type II polymer cement waterproof mortar, the formula is as follows: 85 parts of ordinary Portland cement, 20 parts of composite hardening accelerator, 15 parts of fly ash, 1 part of polycarboxylate superplasticizer powder, organic silicon hydrophobic 0.8 parts of agent, 0.4 parts of hydroxypropyl methylcellulose ether, 3 parts of VAE redispersible latex powder, 0.4 parts of defoamer, 100 parts of fine quartz sand, and 50 parts of water.

[0054] Among them, the composition of the composite hardening accelerator: 6 parts of quicklime, 5 parts of sodium sulfate, and 10 parts of aluminate cement.

[0055] Preparation method: Mix quicklime, sodium sulfate, and aluminate cement evenly to obtain a composite hardening accelerator;

[0056] Portland cement, composite hardening accelerator, fly ash, polycarboxylate superplasticizer powder, silicone water repellent, hydroxypropyl methylcellulose ether, VAE redispersible latex powder, defoamer, Mix fine quartz sa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com